Latent single-component polyurethane hot melt adhesive, preparation method thereof and adhesive film

A polyurethane hot-melt adhesive, one-component technology, used in polyurea/polyurethane adhesives, heat-activated films/sheets, adhesives, etc., can solve the problems of limited application and harsh storage conditions, and improve heat resistance and oxidation resistance. Performance, low cost, avoid slow post-curing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

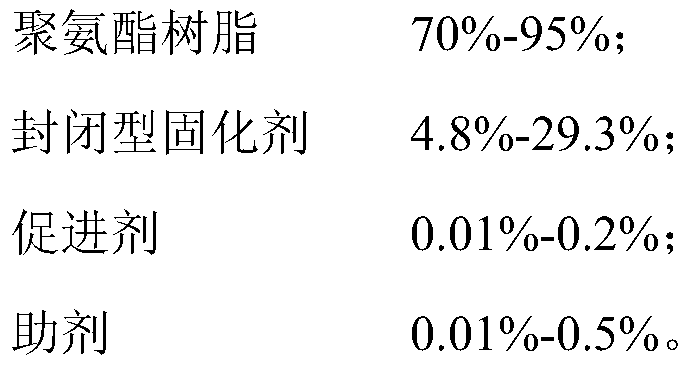

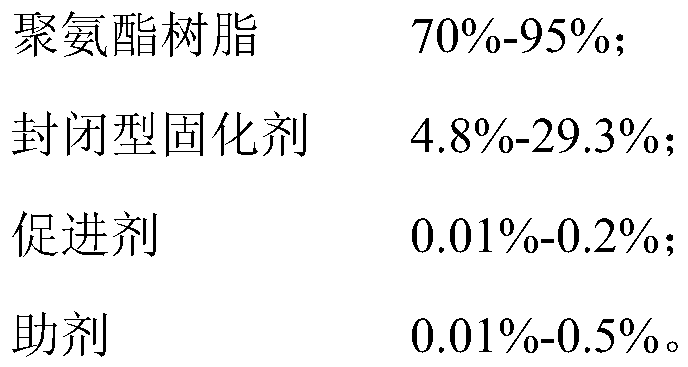

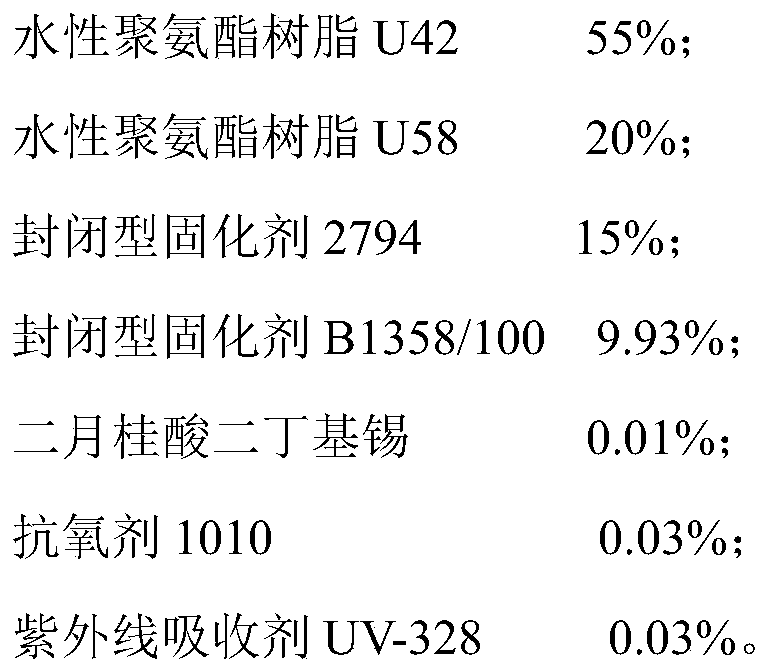

[0043]A latent one-component polyurethane hot-melt adhesive, comprising the following components by weight percentage:

[0044]

[0045] The preparation method of above-mentioned latent one-component polyurethane hot-melt adhesive comprises the following steps:

[0046] Water-based polyurethane resin U42, water-based polyurethane resin U58, closed curing agent 2794 (NCO group content is 11.5%, unblocking temperature 105 ° C), closed curing agent B1358 / 100 (NCO group content is 12.5%, unblocking temperature Temperature 130°C), dibutyltin dilaurate, antioxidant 1010, and ultraviolet absorber UV-328 were put into the reaction kettle, and mixed evenly at a low speed at a stirring speed of 100rpm to obtain a latent one-component polyurethane hot melt adhesive.

[0047] An adhesive film is obtained by curing the latent one-component polyurethane hot melt adhesive.

[0048] Specifically, a latent one-component polyurethane hot-melt adhesive was added into a coating machine, and c...

Embodiment 2

[0050] A latent one-component polyurethane hot-melt adhesive, comprising the following components by weight percentage:

[0051]

[0052] The preparation method of above-mentioned latent one-component polyurethane hot-melt adhesive comprises the following steps:

[0053] Put water-based polyurethane resin U2849, water-based polyurethane resin U58, closed curing agent B1358 / 100 (NCO group content is 12.5%, unblocking temperature 130 ℃), stannous octoate, antioxidant 1010, ultraviolet absorber UV-5411 into Into the reaction kettle, mix evenly at a low speed at a stirring speed of 50rpm, and obtain a latent one-component polyurethane hot melt adhesive.

[0054] An adhesive film is obtained by curing the latent one-component polyurethane hot melt adhesive.

[0055] Specifically, a latent one-component polyurethane hot-melt adhesive was added into a coating machine, and coated on glassine paper with a thickness of 0.1 mm by a scraper of a coating head to obtain an adhesive film...

Embodiment 3

[0057] A latent one-component polyurethane hot-melt adhesive, comprising the following components by weight percentage:

[0058]

[0059] The preparation method of above-mentioned latent one-component polyurethane hot-melt adhesive comprises the following steps:

[0060] Solvent-based polyurethane resin CX6049, solvent-based polyurethane resin 2550, blocked curing agent B1358 / 100 (NCO group content is 12.5%, unblocking temperature 130 ° C), triethylenediamine, antioxidant 168, ultraviolet absorber UV -9 was put into the reaction kettle, and mixed evenly at a low speed at a stirring speed of 100rpm to obtain a latent one-component polyurethane hot melt adhesive.

[0061] An adhesive film is obtained by curing the latent one-component polyurethane hot melt adhesive.

[0062] Specifically, a latent one-component polyurethane hot-melt adhesive was added into a coating machine, and coated on glassine paper with a thickness of 0.05 mm by a scraper of a coating head to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com