Adhesive emulsion for environment-friendly textile gilding printing paste and preparation method thereof

A textile and environment-friendly technology, which is applied in the field of adhesive emulsion for bronzing printing paste of environmentally friendly textiles and its preparation. problems, to achieve the effect of excellent initial tack, high yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

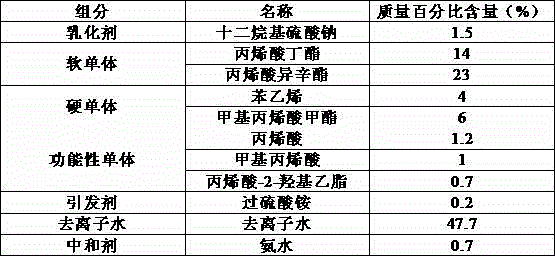

[0022] Weigh the raw materials according to the formula ratio in Table 1.

[0023] Table 1

[0024]

[0025] The preparation method of the present embodiment comprises the following steps:

[0026] A. Dissolve emulsifier sodium lauryl sulfate in 30.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0027] B, ammonium persulfate is dissolved and made into initiator solution with 10% deionized water for stand-by;

[0028] C. Add the remaining amount of deionized water to the reactor, take 5% of the pre-emulsion prepared in step A and add it to the reactor, raise the temperature to 78°C, add 20% of the initiator solution prepared in step B, and react After 20 minutes, heat up to 80°C; start adding the remaining pre-emulsion and the remaining amount of initiator solution dropwise, and complete the dropwise addition in 3.5 hours. After all the dropping is completed, raise the temperature to 85°C and heat-preserve for 2 ...

Embodiment 2

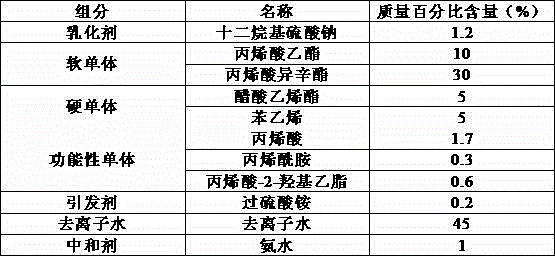

[0030] Weigh the raw materials according to the formula ratio in Table 2.

[0031] Table 2

[0032]

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] A. Dissolve emulsifier sodium lauryl sulfate in 30.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0035] B, ammonium persulfate is dissolved and made into initiator solution with 10% deionized water for stand-by;

[0036] C. Add the remaining amount of deionized water to the reactor, take 5% of the pre-emulsion prepared in step A and add it to the reactor, raise the temperature to 78°C, add 20% of the initiator solution prepared in step B, and react After 20 minutes, the temperature was raised to 80°C; the remaining pre-emulsion and the remaining amount of initiator solution were added dropwise, and the dropwise addition was completed in 4 hours. After the pH value is 7.0-8.0, filter the material with a 120-mesh gau...

Embodiment 3

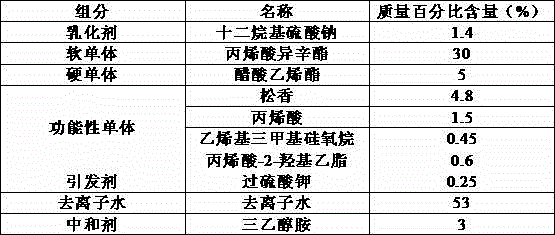

[0038] Weigh the raw materials according to the formula ratio in Table 3.

[0039] The preparation method of the present embodiment comprises the following steps:

[0040] A. Dissolve emulsifier sodium lauryl sulfate in 30.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0041] B, ammonium persulfate is dissolved and made into initiator solution with 10% deionized water for stand-by;

[0042] C. Add the remaining amount of deionized water to the reactor, take 5% of the pre-emulsion prepared in step A and add it to the reactor, raise the temperature to 78°C, add 20% of the initiator solution prepared in step B, and react After 20 minutes, heat up to 80°C; start adding the remaining pre-emulsion and the remaining amount of initiator solution dropwise, and the dropwise addition is completed in 3 hours. After all the dropping is completed, raise the temperature to 85°C and heat-preserve for 1.5 hours, cool down to below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com