Waterproof and highly-elastic foamable pure acrylic emulsion, and foamed material prepared therefrom

A pure acrylic emulsion and foaming material technology, applied in the field of foaming materials, can solve the problems of poor water resistance of polyurethane, high production cost, harm to producers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

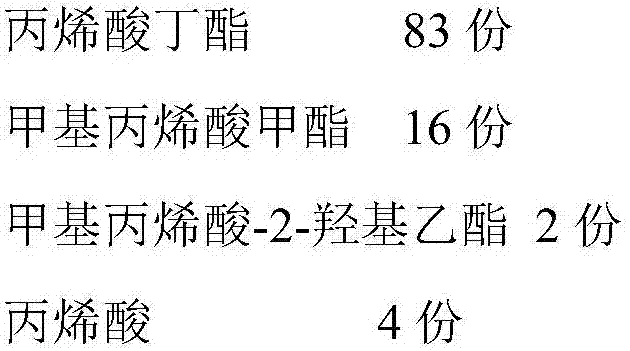

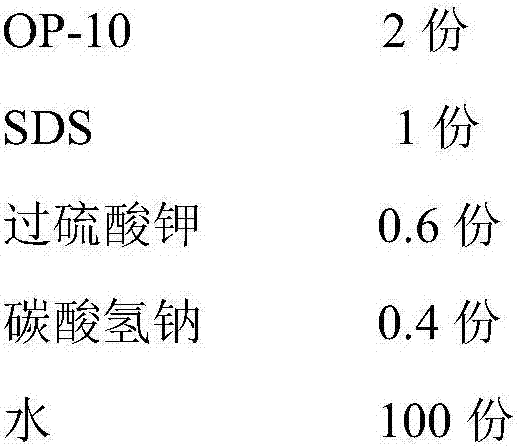

[0017] Pure acrylic emulsion is prepared using the following components in parts by mass:

[0018]

[0019]

[0020] Preparation Process:

[0021] (1) Mix the emulsifier according to the above ratio, add 90 parts of water, fully dissolve until transparent;

[0022] (2) Weigh the soft monomers, hard monomers, functional monomers and surface active monomers in proportion, mix them evenly, and gradually add them dropwise into the emulsifier aqueous solution under high-speed stirring, and stir them stably for about 30 minutes after adding them all.

[0023] (3) Take 1 / 3 of the emulsion to the reactor;

[0024] (4) The initiator is dissolved in 10 parts of water to form a stable solution, and 1 / 3 is added to the kettle;

[0025] (5) The stirring speed is 120-150rpm, and the temperature gradually rises to 75°C. If the temperature in the kettle rises and boils, the temperature should be lowered, and the remaining emulsion and initiator aqueous solution should be added simulta...

Embodiment 2

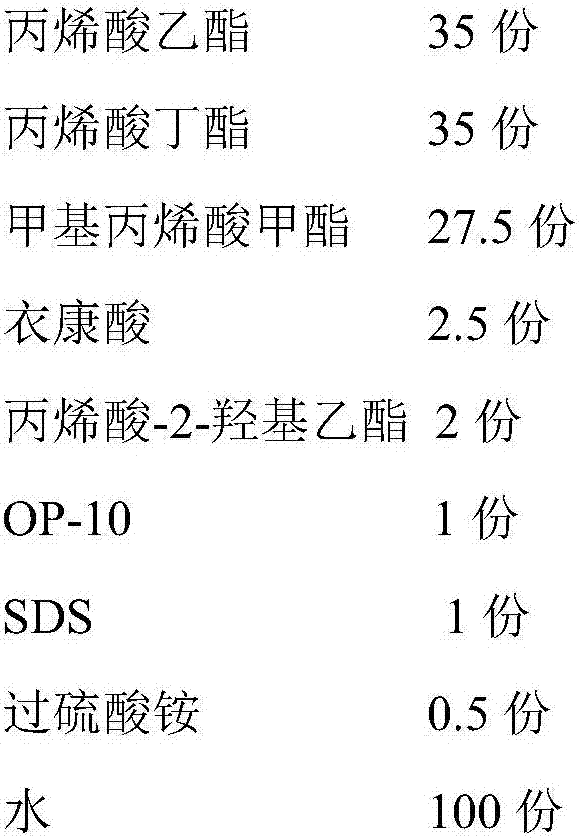

[0037] Pure acrylic emulsion is prepared using the following components in parts by mass:

[0038]

[0039] The preparation process is the same as in Example 1.

[0040] Test results of pure acrylic emulsion: solid content: 49.98%, viscosity: 500mPa.s, water absorption: 2.5%.

Embodiment 3

[0042] The foaming material is prepared using the following components in parts by mass, and the pure acrylic emulsion adopts the product prepared in Example 1:

[0043]

[0044] Preparation Process:

[0045] (1) 100 parts of emulsion, add a thickener, stir evenly to obtain a viscous emulsion;

[0046] (2) Take the thickening emulsion, add foaming agent, foam stabilizer, crosslinking agent, and stir;

[0047] (3) Inflate or stir at high speed to foam to obtain cream-like foam;

[0048] (4) Spread it on the non-woven fabric, and strictly control the glue amount of 250~300g / m 2 ;

[0049] (5) Heating temperature is about 125-150°C, blast drying, and complete dehydration to obtain the product.

[0050] Detection method:

[0051] Water resistance: Washing machine for more than 5 times without glue falling and powdering;

[0052] High elasticity: After being pressed with a finger (about 20N), it can rebound within 10 seconds and return to its original shape;

[0053] Init...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com