Hot-melting pressure-sensitive adhesive for PVC (Polyvinyl Chloride) plastic floor tiles and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and floor tiles, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of high prices and inconvenient purchases, and achieve the goal of reducing production costs and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

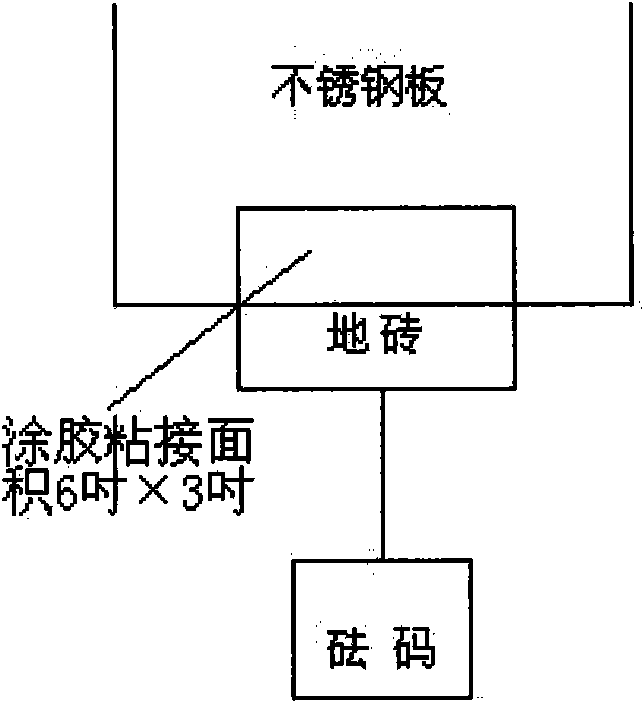

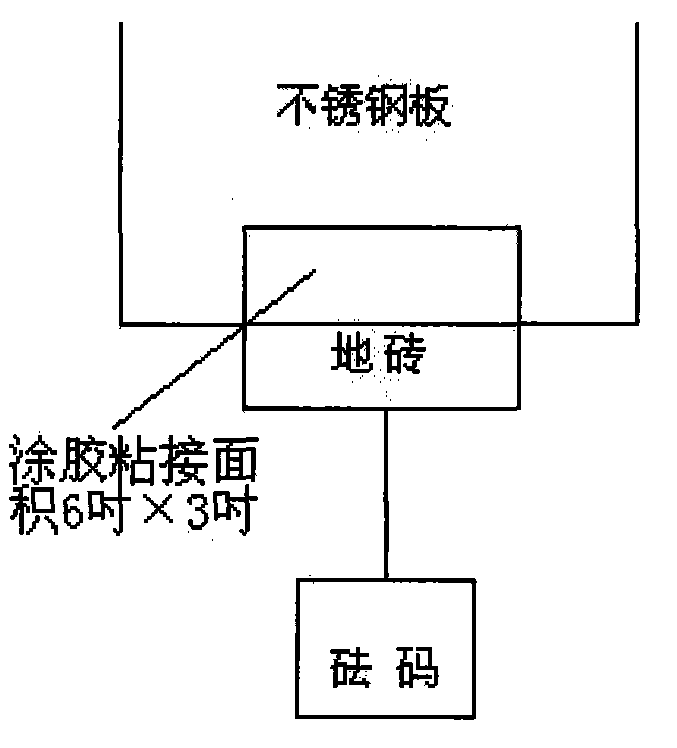

Image

Examples

Embodiment 1

[0037] Rubber softening oil KN4010: 10kg

[0038] Thermoplastic rubber: 9kg thermoplastic elastomer SBS7920kg thermoplastic elastomer SIS4211

[0039] Tackifier: 9kg of petroleum resin ESCOREZ5020

[0040] 30kg of petroleum resin ESCOREZ1000

[0041] 18kg of petroleum resin ESCOREZ5000;

[0042] Antioxidant 0.15kg Antioxidant 1010 and 0.15kg Antioxidant 168

[0043] The preparation method is as follows:

[0044] (1) Put 10kg of rubber softening oil KN4010 into the heat transfer oil reactor, heat it, and control the temperature at 160°C;

[0045] (2) After heating for 30 minutes, stir and add 0.15kg of antioxidant 1010 and 0.15kg of antioxidant 168, then drop into 9kg of petroleum resin ESCOREZ5020, after melting, drop into 30kg of petroleum resin ESCOREZ1000, 18kg of petroleum resin ESCOREZ5000;

[0046] (3) After all the petroleum resins are melted, add 9kg of thermoplastic elastomer SBS792; after stirring evenly, add 20kg of thermoplastic elastomer SIS4211.

[0047] (4...

Embodiment 2

[0051] Rubber softening oil KN4010: 14kg

[0052] Thermoplastic rubber: 5kg thermoplastic elastomer SBS79225kg thermoplastic elastomer SIS4211

[0053] Tackifier: 6kg of petroleum resin ESCOREZ5020

[0054] 21kg of petroleum resin ESCOREZ1000

[0055] 15kg of petroleum resin ESCOREZ5000;

[0056] Antioxidant 0.25kg Antioxidant 1010 and 0.25kg Antioxidant 168

[0057] Preparation:

[0058] (1) Put 14kg of rubber softening oil KN4010 into the heat transfer oil reactor, heat, and control the temperature at 180°C;

[0059] (2) After heating for 25 minutes, stir and add 0.25kg of antioxidant 1010 and 0.25kg of antioxidant 168, then drop into 6kg of petroleum resin ESCOREZ5020, after melting, drop into 21kg of petroleum resin ESCOREZ1000, 15kg of petroleum resin ESCOREZ5000;

[0060] (3) After all the petroleum resins are melted, put in 5kg of thermoplastic elastomer SBS792; after stirring evenly, put in 25kg of thermoplastic elastomer SIS4211.

[0061] (4) Seal the reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com