Environment-friendly high-speed cigarette holder glue for cigarettes and preparation method thereof

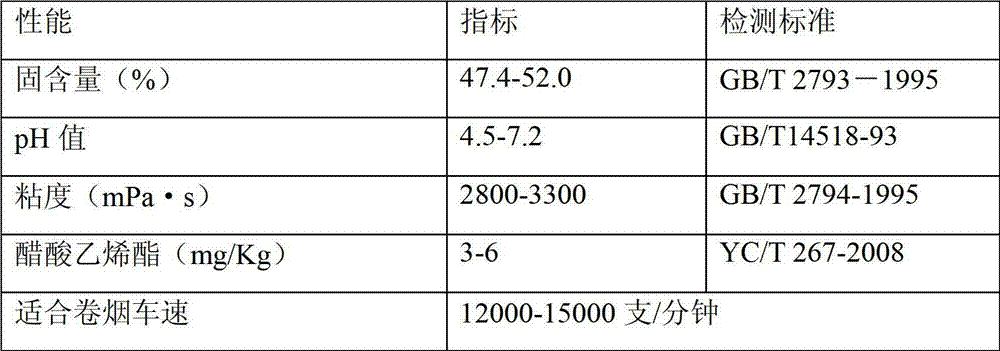

An environmentally friendly, nozzle-adhesive technology, used in adhesives, adhesive types, graft polymer adhesives, etc., to achieve the effect of improving water resistance, good initial viscosity, and low residual content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

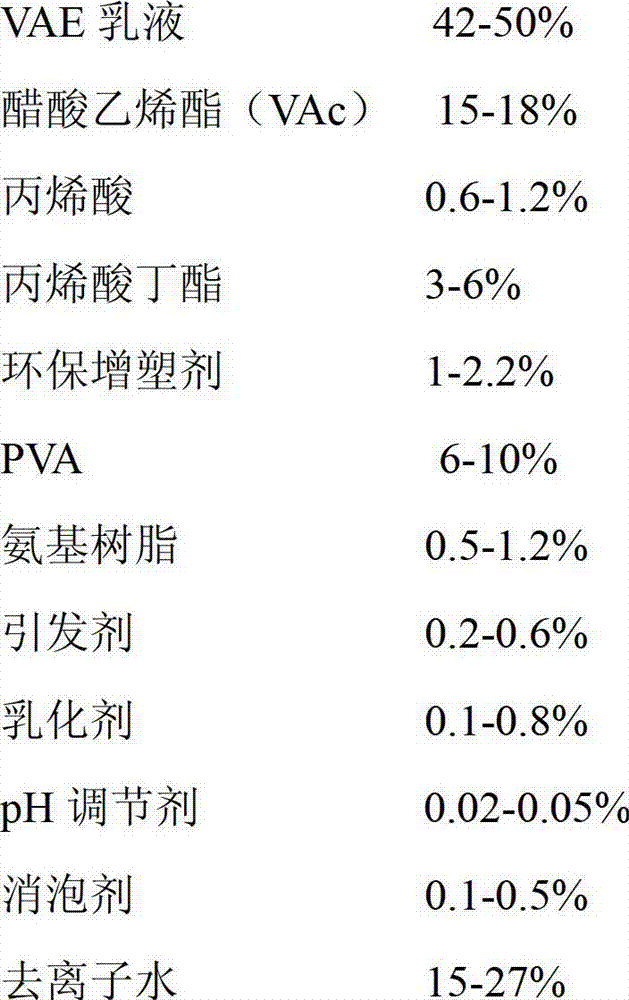

Method used

Image

Examples

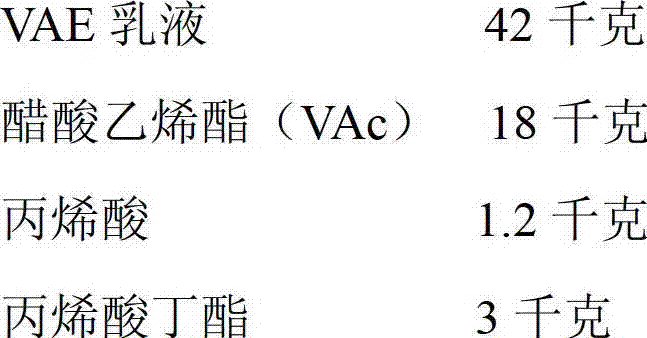

Embodiment 1

[0024]

[0025]

[0026] Get 42 kg of VAE emulsion into a sealed container, turn on the mixer, set the stirring speed to 100 rpm, add 18 kg of VAc, 3 kg of butyl acrylate, 1.2 kg of acrylic acid and 12 kg of deionized water, stirring continuously to mix well. Turn on the heating device, heat up to 70°C, add 0.2 kg of initiator, adjust the stirring speed to 200 rpm, and continue to heat up to 85°C, and add the remaining initiator within 1 hour. Heat up to 95°C again, add 6 kg of PVA and 1.2 kg of amino resin, and keep stirring for 1 hour. Cool down to 48°C, add 2.2 kg of environmentally friendly plasticizer, 0.7 kg of emulsifier, 0.05 kg of pH regulator, 0.35 kg of defoamer and the remaining deionized water in order, continue to stir for about 0.8-1.5 hours, and let it stand for cooling. Filter the discharge.

Embodiment 2

[0028]

[0029] Take 50 kg of VAE emulsion and add it to a sealed container, turn on the mixer, set the stirring speed to 120 rpm, add 15 kg of VAc, 6 kg of butyl acrylate, 0.8 kg of acrylic acid and 6 kg of deionized water, stirring continuously to mix well. Turn on the heating device, heat up to 75°C, add 0.12 kg of initiator (about one-third of the total initiator dose), adjust the stirring speed to 250 rpm, and continue to heat up to 90°C within 1 hour The remaining initiator was added to completion. Heat up to 95°C again, add 6 kg of PVA and 0.6 kg of amino resin, and keep stirring for 1.2 hours. Cool down to 55°C, add 1 kg of environmentally friendly plasticizer, 0.8 kg of emulsifier, 0.02 kg of pH regulator, 0.41 kg of defoamer and the remaining deionized water in order, continue to stir for about 1.5 hours, let stand to cool, and filter out material.

Embodiment 3

[0031]

[0032] Take 46 kg of VAE emulsion and add it to a sealed container, turn on the mixer, set the stirring speed to 110 rpm, add 18 kg of VAc, 4 kg of butyl acrylate, 0.6 kg of acrylic acid and 10 kg of After deionized water, keep stirring to mix well. Turn on the heating device, heat up to 73°C, add 0.1 kg of initiator, adjust the stirring speed to 240 rpm, and continue to heat up to 89°C, and add the remaining initiator within 1 hour. Heat up to 95°C again, add 7 kg of PVA and 0.5 kg of amino resin, and keep stirring for 1 hour. Cool down to 50°C, add 2 kg of environmentally friendly plasticizer, 0.3 kg of emulsifier, 0.03 kg of pH regulator, 0.5 kg of defoamer and the remaining deionized water in order, continue to stir for about 1 hour, let stand to cool, and filter out material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com