Adhesive resin for aluminum ceiling

A technology for bonding resins and ceilings, applied in the direction of synthetic resin layered products, adhesives, adhesive types, etc., can solve the problem of unstable bonding strength and service life of aluminum ceilings, reduction of bonding strength and bonding durability, etc. problems, to achieve the effect of enhancing the overall compatibility, reducing crystal points, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the adhesive resin for aluminum ceilings, the method comprising: mixing the raw materials evenly according to the formula ratio, and then granulating them through a reaction-type twin-screw extruder, and the main engine speed is 300 -500rpm, the length-to-diameter ratio of the twin-screw extruder L:D≥44:1, and the extrusion processing temperature range is 130-220°C.

[0044] The present invention also provides an aluminum ceiling adhesive film structure, the adhesive film structure includes an adhesive resin layer and a PE layer colored with white mica, and the adhesive resin is the above adhesive resin. Described adhesive film structure in the specific embodiment of the present invention is to adopt three-layer structure, by weight ratio, bonding resin (30%) is the first layer, and the PE layer (35%) of white mica coloring is the second layer and white The third layer is the PE layer (35%) colored with mica. In...

Embodiment 1-4

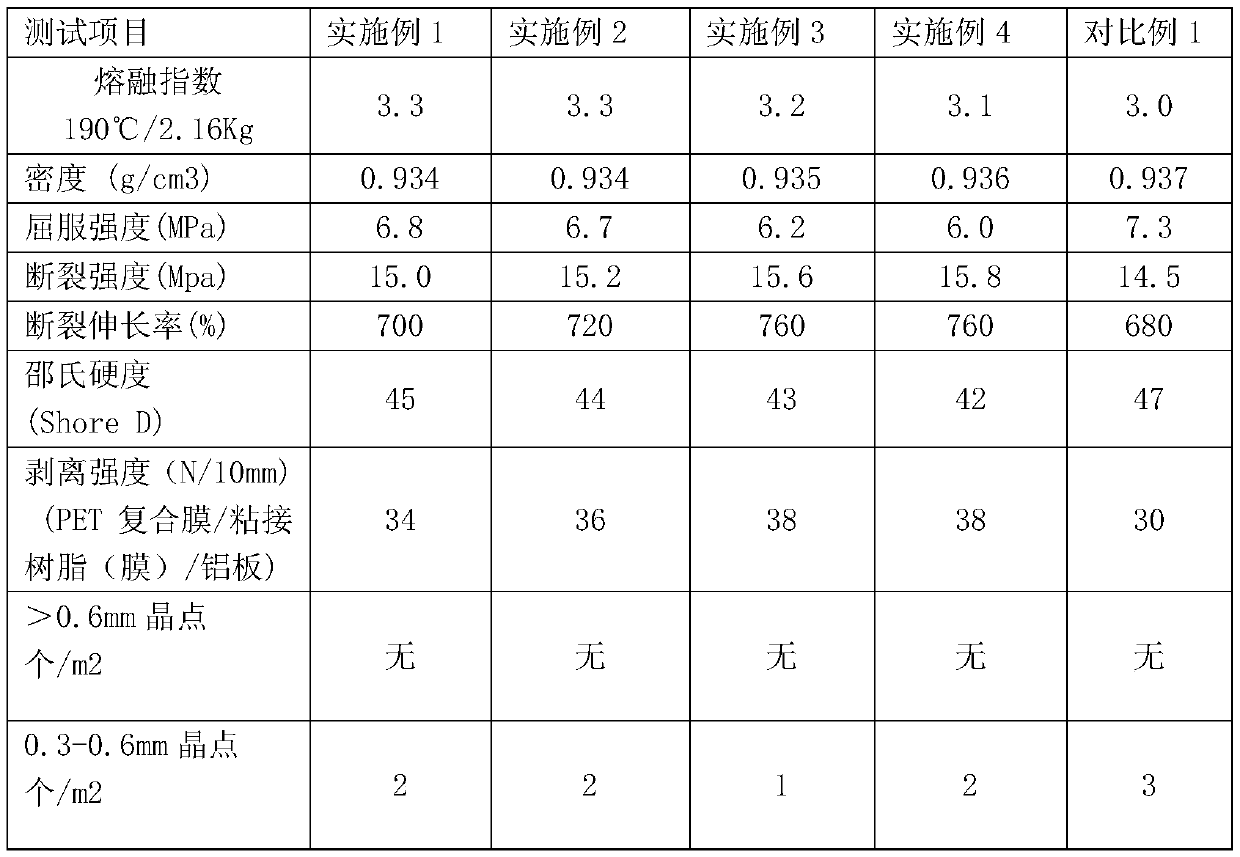

[0047] Embodiment 1-4, comparative example 1

[0048] Preparation of polyethylene graft masterbatch:

[0049] The polyethylene grafting masterbatch of embodiment 1-4 and comparative example 1, by following formula ratio (weight percent), MLLDPE: LDPE: HomopolyPP: two-2,5-hexane original: maleic acid dry=95 : 2: 3: 0.025: 1. After mixing evenly, it is prepared by extruding and granulating through a reactive twin-screw extruder through a plasticizing and blending process. The main engine speed is 300-400rpm, and the length-diameter ratio of the extruder L: D≥44:1, the extrusion processing temperature range is 80-210°C, and the basic physical properties of the obtained masterbatch are as follows:

[0050] Melt index (190°C / 2.16Kg): 2.4; density (g / cm3): 0.915; yield strength (MPa): 6.7; breaking strength (Mpa): 30.2; elongation at break (%): 70%; Shore Hardness (Shore D): 45.

[0051] Preparation of Adhesive Resin for Aluminum Ceilings

[0052] The adhesive resins for aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com