Self-curing polyacrylate-epoxy resin adhesive as well as preparation method and application of self-curing polyacrylate-epoxy resin adhesive

A technology of polyacrylate and epoxy resin adhesives, which is applied in the direction of epoxy resin adhesives, adhesives, ester copolymer adhesives, etc., can solve the problems of high brittleness of epoxy resin adhesives and unsuitable pressure-sensitive adhesives, etc., and achieve Good bonding strength, simple preparation, good initial tack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

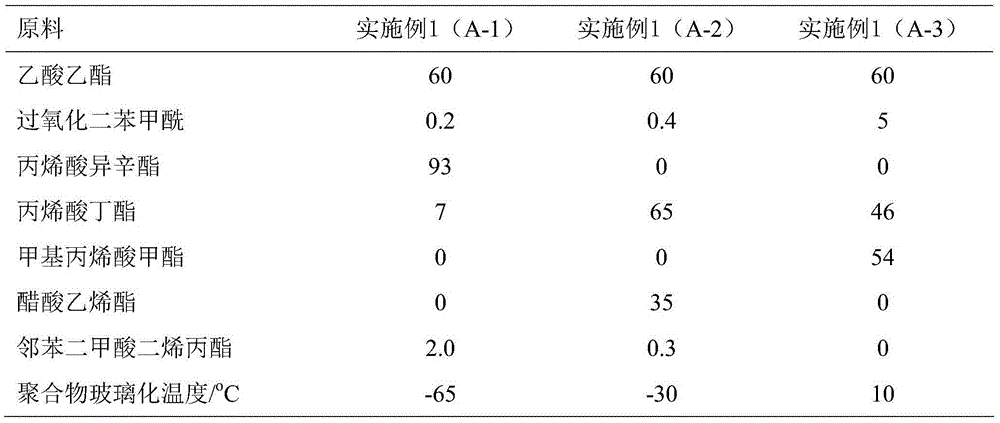

[0031] Examples 1-3 Preparation of polyacrylate polymer (A) with a glass transition temperature of -65°C to 10°C:

[0032] (1) According to the formula in Table 1, take isooctyl acrylate, butyl acrylate, methyl methacrylate, and vinyl acetate;

[0033] (2) Add the initiator and crosslinking agent to the liquid obtained in step (1), and mix well to obtain a mixed liquid;

[0034] (3) Drop the mixed liquid obtained in step (2) into the organic solvent ethyl acetate under a nitrogen atmosphere, and react at 70°C for 6 hours to obtain glass transition temperatures of -65°C, -30°C and 10°C, respectively. Polyacrylate polymer (A).

[0035] Table 1 (mass ratio)

[0036]

[0037] Experiments have shown that benzoyl tert-butyl peroxide, methyl ethyl ketone peroxide, azobisisobutyronitrile, azobisisoheptanonitrile or dimethyl azobisisobutyrate are substituted for the diphenyl peroxide in Example 1 Using acyl as an initiator can also prepare polyacrylate polymers (A) with a glass t...

Embodiment 4~6

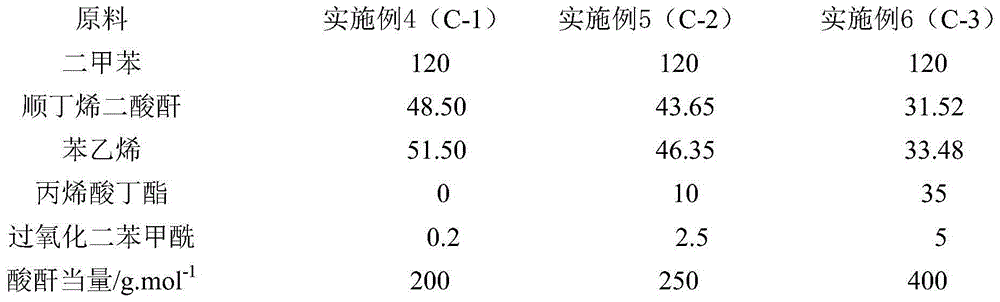

[0042] The preparation of embodiment 4~6 acid anhydride curing agent:

[0043] By copolymerizing maleic anhydride with styrene and other monomers, copolymers with different anhydride equivalents can be prepared, and the raw material ratio for preparing the anhydride curing agent is shown in Table 2.

[0044] (1) Dissolve maleic anhydride in xylene and pass N 2 And stir and heat up to 70°C;

[0045] (2) After blending styrene, butyl acrylate and dibenzoyl peroxide as the initiator, continuously drop into the liquid obtained in step (1), the dropwise addition is completed in 2 hours, keep warm for 6 hours, and pump the obtained white precipitate Filter and dry to obtain the acid anhydride curing agent;

[0046] The molar ratio of maleic anhydride and styrene is 1:1;

[0047] The quality of described butyl acrylate accounts for maleic anhydride, styrene and butyl acrylate total mass and is respectively 0,10%, 35%; The consumption of initiator is respectively maleic anhydride, ...

Embodiment 7~13

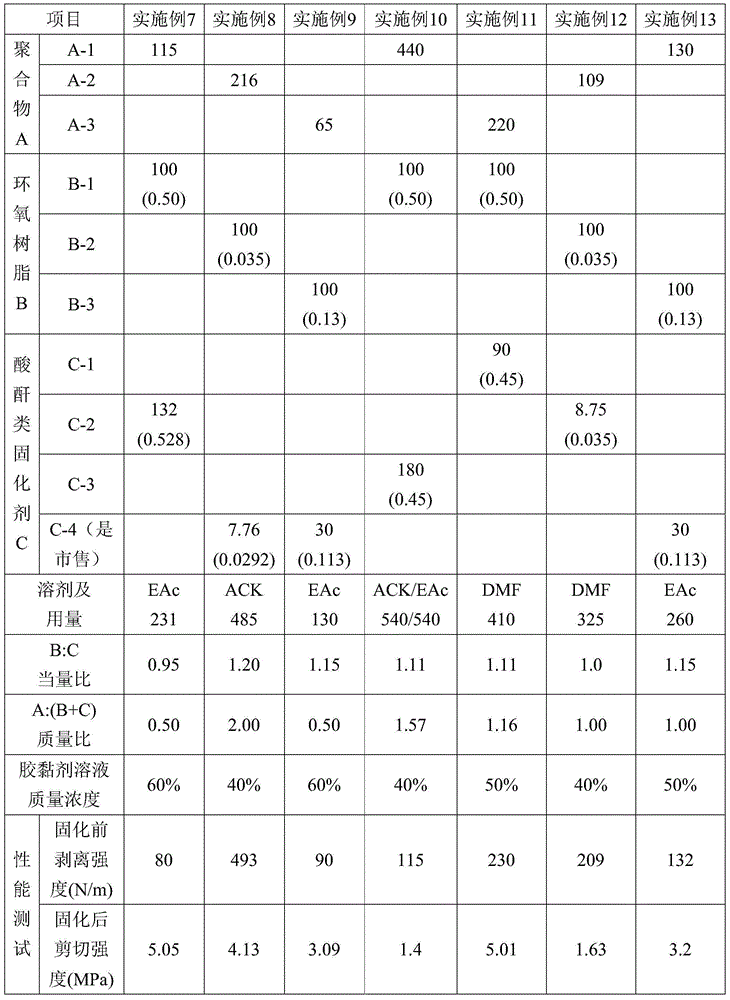

[0053] Embodiment 7-13 Preparation of a self-curing polyacrylate-epoxy resin adhesive

[0054] A kind of preparation method of self-curing polyacrylate-epoxy resin adhesive:

[0055] (1) Mix polymer A, epoxy resin B and acid anhydride curing agent C; Table 3 is the ratio of raw materials, the amount indicated in the table is the mass ratio, and the brackets correspond to epoxy resin and anhydride Curing agent equivalent ratio.

[0056] (2) Dissolving the mixture obtained in step (1) in a solvent to prepare an adhesive.

[0057] Test the peel strength of pressure sensitive tape to stainless steel plate. In addition, the self-curing polyacrylate-epoxy pressure-sensitive adhesive (adhesive) of the present invention was used to overlap stainless steel plates, and cured at 120°C for 4 hours to test the shear strength of the adhesive. The obtained data are listed in Table 3.

[0058] From the test results in Table 3, it can be seen that the self-curing polyacrylate-epoxy resin p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com