Online sizing spinning machine and sizing method of cellulose fiber yarn at room temperature

A technology of cellulose fiber and spinning frame, applied in spinning machine, continuous winding spinning machine, fiber treatment, etc., can solve the problems of improving yarn performance without water-based solution components, reducing yarn hairiness, etc., and achieving Avoid secondary hairiness, reduce yarn hairiness, reduce process and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the drawings and technical solutions.

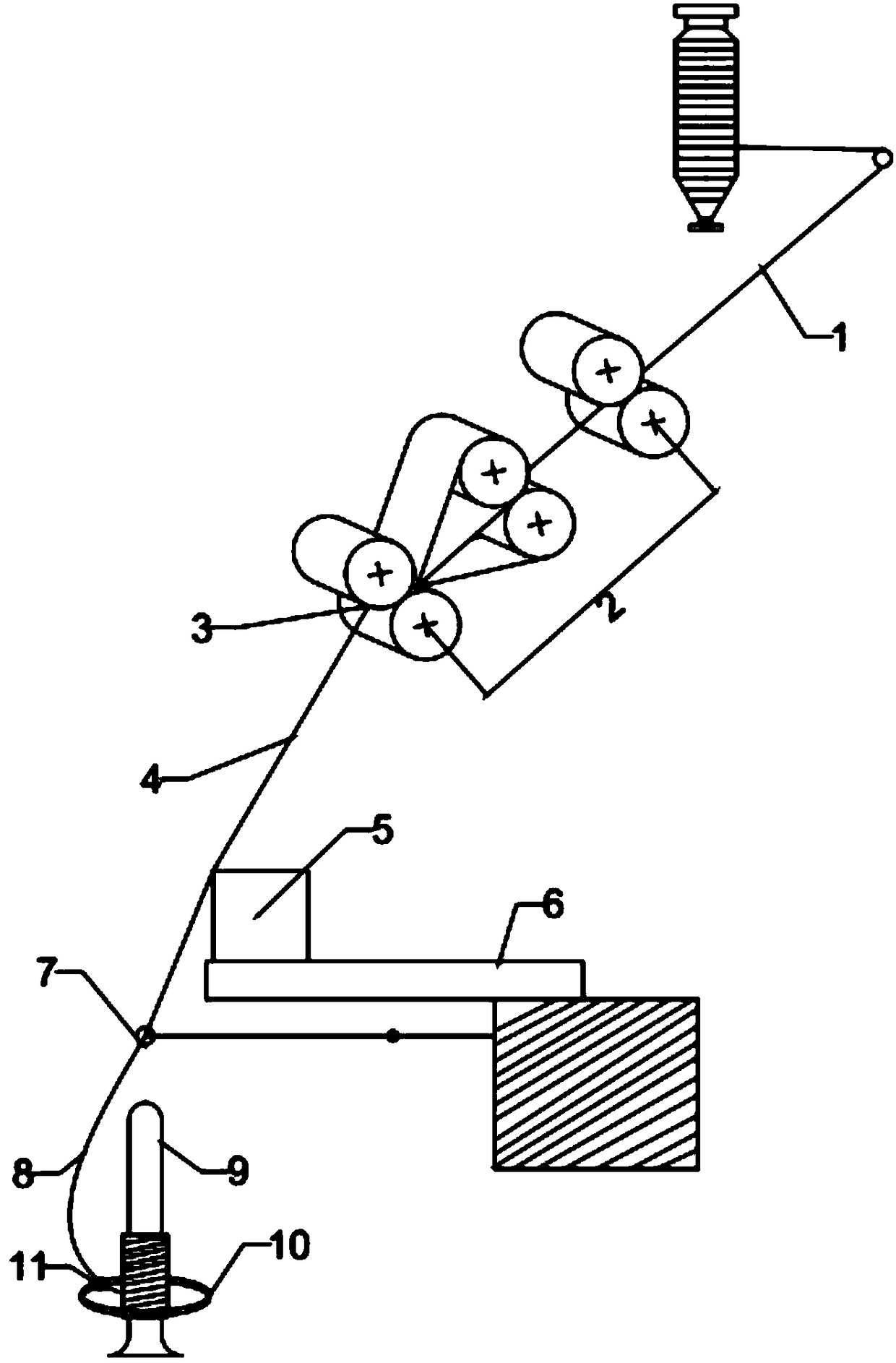

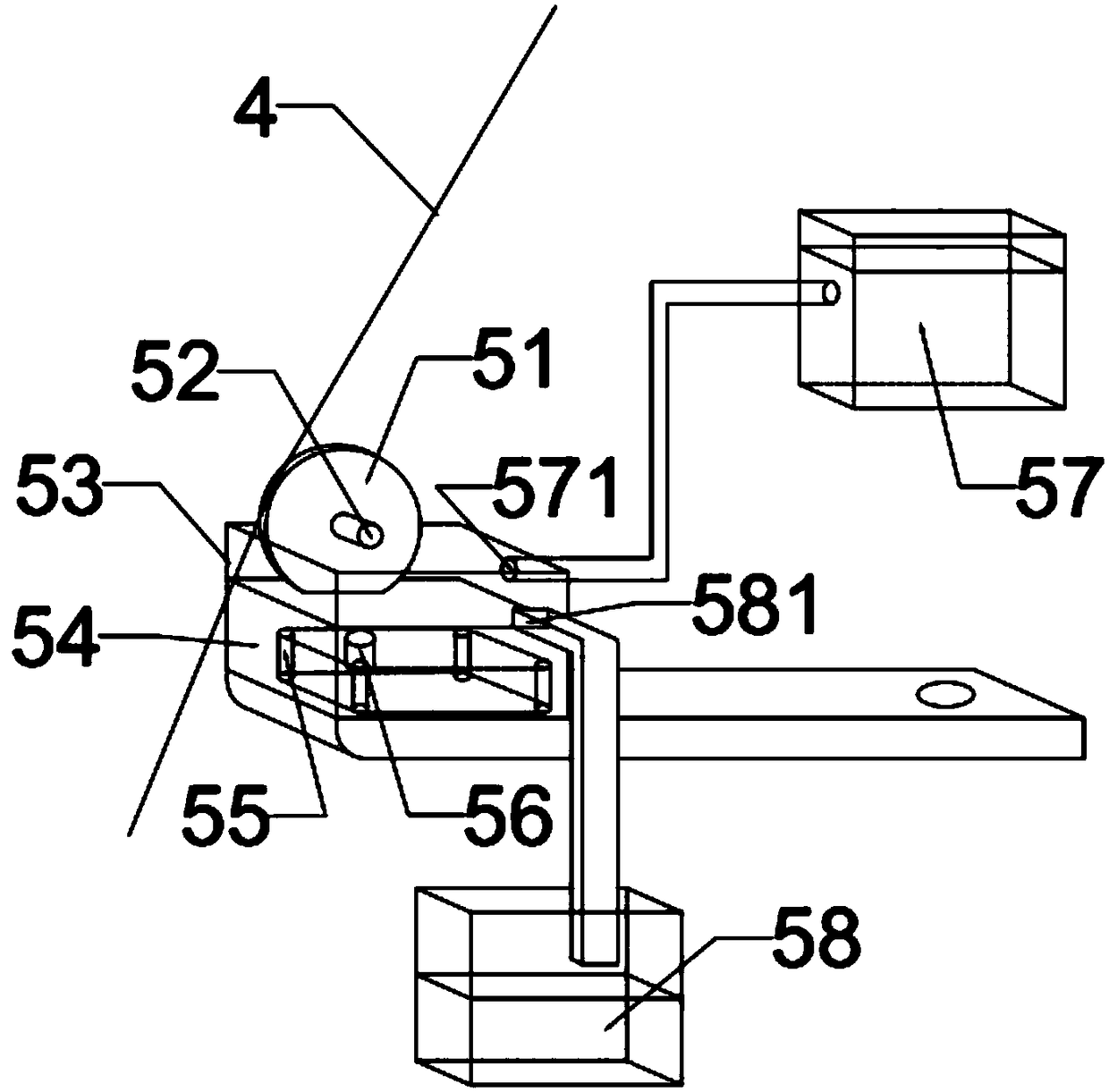

[0035] Such as figure 1 with figure 2 As shown, a normal temperature on-line sizing spinning machine for cellulose fiber spun yarns includes a ring spinning frame and a sizing device 5; the sizing device 5 is fixed on the ring spinning frame through a fixing plate 6, and the sizing device 5 is located on the ring spinning machine. Between the front roller nip 3 and the yarn guide 7 of the machine, the yarn twisting section 4 output from the front roller nip 3 is sizing through the sizing device 5.

[0036] The sizing device 5 includes a guide roller 51, a rotating shaft 52, a motor A, a slurry tank 53, a circulation device 55, a motor 56, an external slurry supply system 57, and a recovery system 58;

[0037] The motor A is connected to the guide roller 51 through a rotating shaft 52 to drive the guide roller 51 to rotate; the lower en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com