Biomass formaldehyde-free adhesive for artificial board and preparation method thereof

A technology of aldehyde adhesive and biomass, which is applied in the field of biomass aldehyde-free adhesive for wood-based panels and its preparation, can solve the problems of easy moisture absorption and mildew, deviation of water resistance, low initial bonding strength, etc., and achieve easy application Glue, zero formaldehyde content, high-efficiency bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

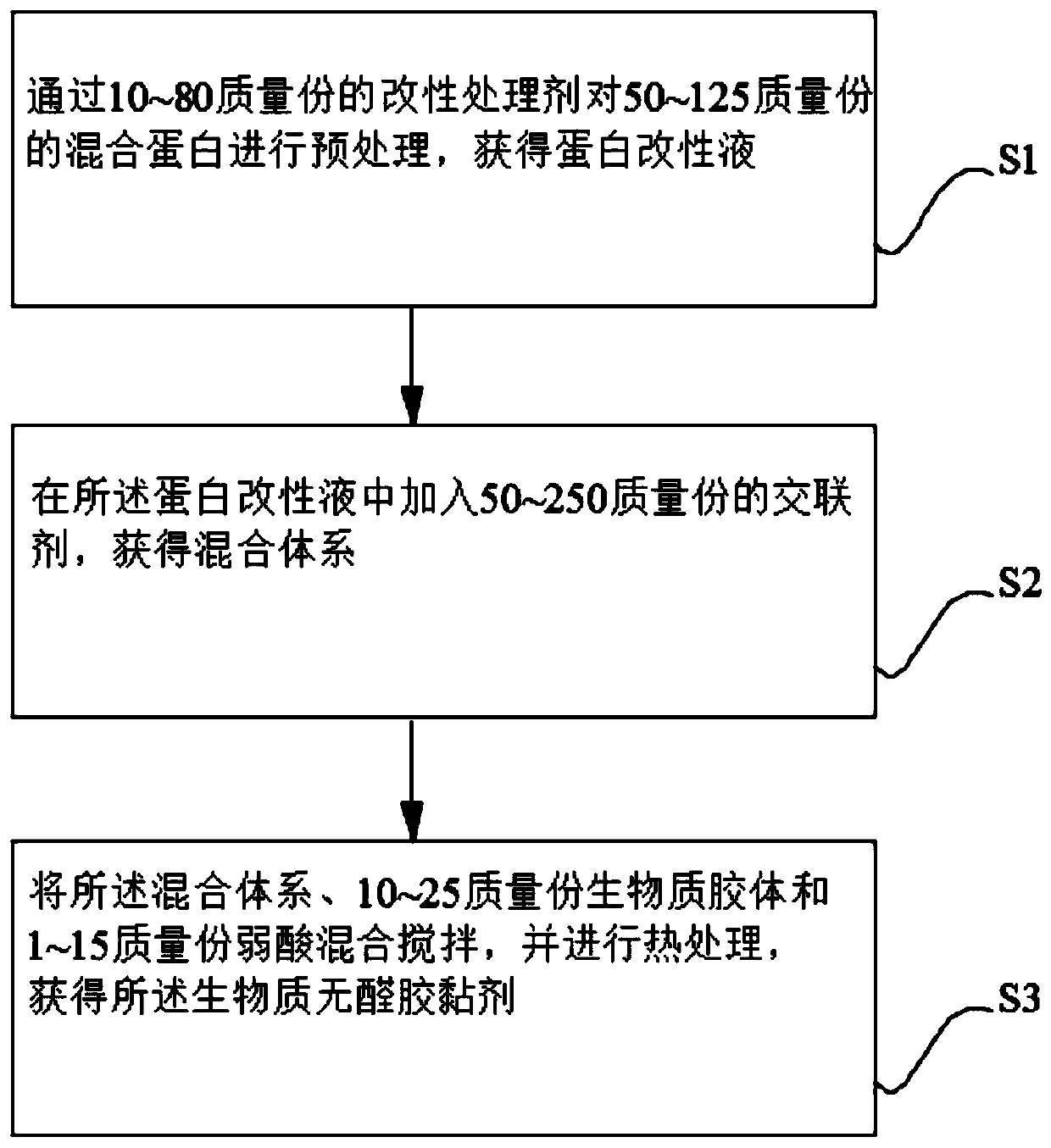

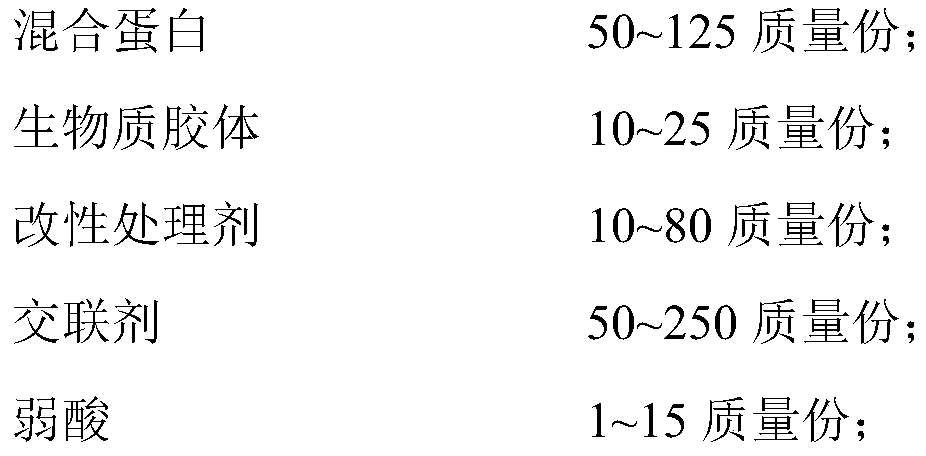

[0029] Such as figure 1 Shown is a schematic flow diagram of the method according to an embodiment of the present invention. A method for preparing a biomass aldehyde-free adhesive is provided, which at least includes the following steps:

[0030] S1. Pre-treating 50-125 parts by mass of the mixed protein with 10-80 parts by mass of a modification treatment agent to expose the functional groups on the protein molecular chain of the mixed protein to obtain a protein modification solution;

[0031] S2. Add 50-250 parts by mass of a cross-linking agent to the protein modification solution, and the cross-linking agent reacts with the functional group to form a three-dimensional cross-linked network structure to obtain a mixed system;

[0032] S3. Mix and stir the mixing system, 10-25 parts by mass of biomass colloid and 1-15 parts by mass of weak acid, and heat treatment to obtain the biomass aldehyde-free adhesive.

[0033] Specifically, in step S1, the process of pretreatment includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com