Rat-proof optical cable, preparation method thereof, and outer sheath material of rat-proof optical cable

A technology of outer sheath and optical cable, which is applied in the field of optical fiber and optical cable, can solve the problems of difficult construction, high cost of armoring materials, and thick cable diameter, and achieve the effects of simple and convenient preparation method, improved production rate, and preventable tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

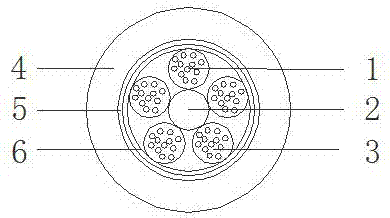

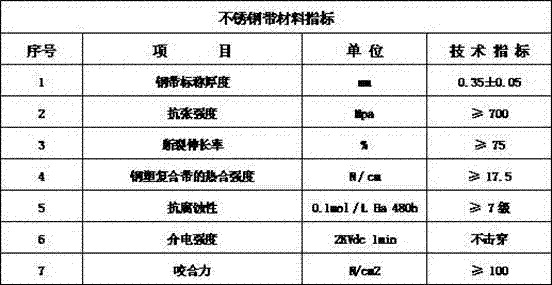

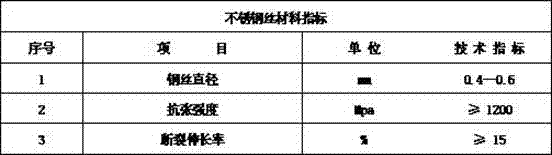

[0023] like figure 1 As shown, the present invention provides a rodent-proof optical cable, including a cable core, the cable core is twisted by a central reinforcement 2 and several bundle tubes 3 surrounding the reinforcement, and inside the bundle tube 3 Several optical fibers 1 are provided; a stainless steel band 6 is wrapped around the cable core, and an outer sheath 4 is extruded at the outermost layer of the cable core; It is a 2.5mm crimped stainless steel strip, and hot melt glue is injected into the overlapping part of the crimped steel strip, and then a plurality of stainless steel wires 5 with a diameter of 0.4mm are wrapped around the crimped stainless steel strip, which prevents rodents from using their teeth Pry off the strap joints.

[0024] As a further improvement, the material of the bundle tube 3 is polyurethane, which is more stable than PBT and easier to form, which is convenient for the bundle tube 3 to be made smaller. The outer diameter of the bundle...

Embodiment 2

[0029] The present invention also provides a preparation method of the anti-rat optical cable, comprising the following steps:

[0030] 1) The optical fiber is cured and colored by UV. The tension of the optical fiber is 65g±5g, the tension of the take-up is 75g±5g, and the production speed is 2400m / min. In order to ensure the quality of curing, two curing furnaces are used for curing. In the curing furnace The nitrogen injection method is adopted in the glass tube, the pressure flow valve is 0.4MPa, the pressure injection valve is 3 MPa, the ink coating pressure is 0.35MPa, and the ink mold is heated, and the working temperature needs to reach 65±5℃;

[0031] 2) Put the optical fiber into the polyurethane bundle tube through the oil needle, and pass through the hot water tank and the cold water tank for secondary cooling. The temperature of the hot water tank is 30~33°C, and the temperature of the cold water tank is 25~28°C. The take-up tension is 3~5N, and the production spe...

Embodiment 3

[0038] The present invention also provides an outer sheath material for an anti-rodent optical cable, comprising the following components in parts by mass: 25 parts of modified high molecular weight polyethylene, 3 parts of polyphenylene sulfone resin, 9 parts of thermoplastic polyurethane elastomer, 1 part of mixture of tetrapentaerythritol and triester of phosphite, 2 parts of carbon black masterbatch, 0.5 part of rheology modifier, 1 part of stearic acid, 0.5 part of zinc stearate, 3 parts of diatomaceous earth, β-type 1 part of hemihydrate gypsum, 2 parts of silicon dioxide, 1 part of asbestos fiber, 5 parts of goat pollen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com