Colorful anti-ultraviolet polyethylene cable outer sheath material

An anti-ultraviolet, polyethylene technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as cable damage, cable exposure, cable gnawing, etc., to improve bearing capacity, reduce extrusion, and prevent gnawing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

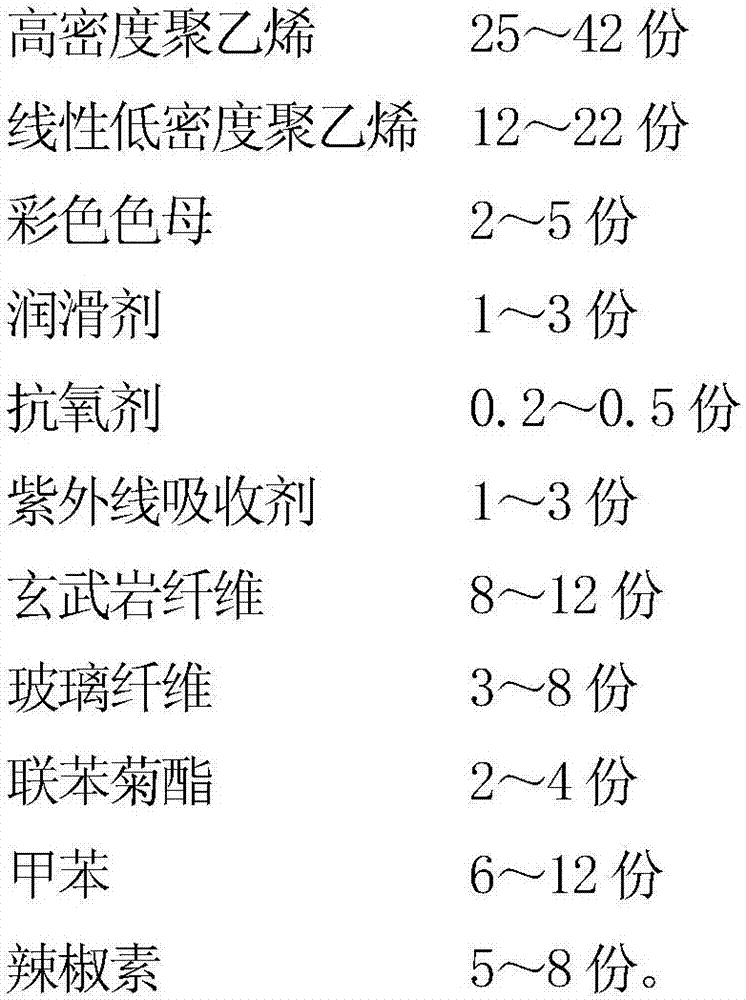

Method used

Image

Examples

Embodiment 1

[0018] Step 1, after fully mixing the toner with EVA resin, zinc stearate, and EBS (ethylene bis stearamide), use a co-rotating twin-screw extruder with a length-to-diameter ratio of 36:1 to Extrusion granulation and drying to make color masterbatch; described toner: EVA resin: zinc stearate: the weight ratio of EBS is 45: 50: 3.5: 1.5;

[0019] Step 2, chopping basalt fibers and glass fibers to obtain basalt fibers and glass fibers with a length below 0.5 mm;

[0020] Step 3, weigh 25 parts of high-density polyethylene HE6062, 22 parts of linear low-density polyethylene 7042, 5 parts of color masterbatch in step 1, 2 parts of lubricant, 0.2 part of antioxidant, 2 parts of ultraviolet absorber, 10 parts Basalt fiber from step 2, 6 parts glass fiber from step 2, 3 parts bifenthrin, 9 parts toluene and 6 parts capsaicin;

[0021] Step 4, mix high-density polyethylene HE6062 and linear low-density polyethylene 7042 and heat it while stirring evenly to 270°C, keep it warm for 2.5...

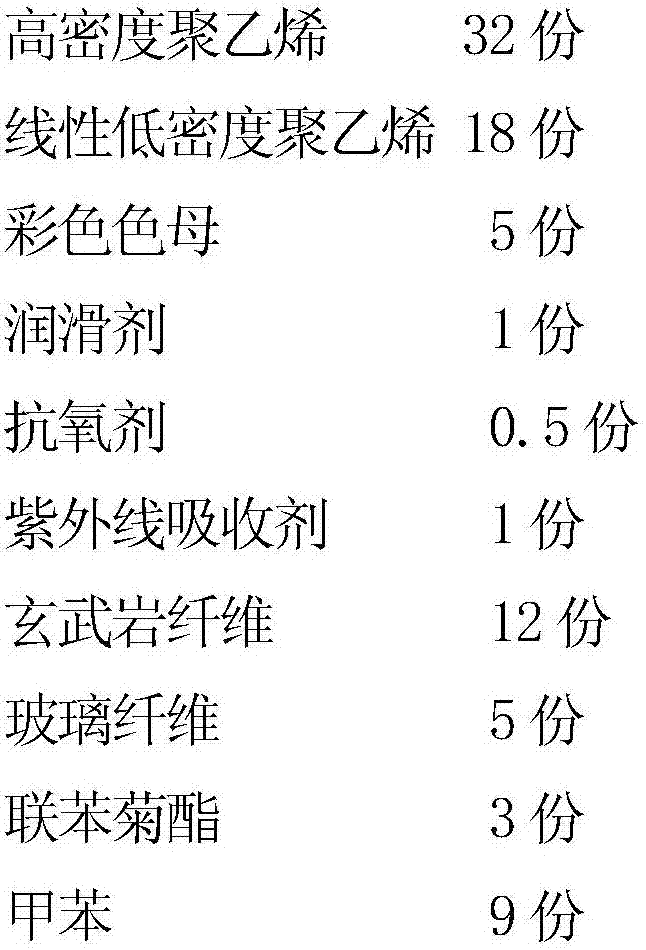

Embodiment 2

[0026] Step 1, after fully mixing the toner with EVA resin, zinc stearate, and EBS (ethylene bis stearamide), use a co-rotating twin-screw extruder with a length-to-diameter ratio of 36:1 to Extrusion granulation and drying to make color masterbatch; described toner: EVA resin: zinc stearate: the weight ratio of EBS is 45: 50: 3.5: 1.5;

[0027] Step 2, chopping basalt fibers and glass fibers to obtain basalt fibers and glass fibers with a length below 0.5mm;

[0028] Step 3, weigh 42 parts of high-density polyethylene HE6062, 22 parts of linear low-density polyethylene 7042, 2 parts of color masterbatch in step 1, 1 part of lubricant, 0.5 part of antioxidant, 1 part of ultraviolet absorber, 8 parts Basalt fiber from step 2, 8 parts glass fiber from step 2, 3 parts bifenthrin, 8 parts toluene, and 6 parts capsaicin;

[0029] Step 4, mix high-density polyethylene HE6062 and linear low-density polyethylene 7042 and heat it while stirring evenly to 270°C, keep it warm for 4 hour...

Embodiment 3

[0034] Step 1. After fully mixing the toner with EVA resin, zinc stearate, and EBS (ethylene bis stearamide), use a co-rotating twin-screw extruder with a length-to-diameter ratio of 36:1 to heat the powder at 175°C. Extrusion granulation and drying to make color masterbatch; described toner: EVA resin: zinc stearate: the weight ratio of EBS is 45: 50: 3.5: 1.5;

[0035] Step 2, chopping basalt fibers and glass fibers to obtain basalt fibers and glass fibers with a length below 0.5mm;

[0036] Step 3, weigh 38 parts of high-density polyethylene HE6062, 18 parts of linear low-density polyethylene 7042, 4 parts of color masterbatch in step 1, 2 parts of lubricant, 0.4 part of antioxidant, 2 parts of ultraviolet absorber, 9 parts Basalt fiber from step 2, 4 parts glass fiber from step 2, 3 parts bifenthrin, 10 parts toluene and 7 parts capsaicin;

[0037] Step 4, mix high-density polyethylene HE6062 and linear low-density polyethylene 7042 and heat it while stirring evenly to 27...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com