Compatible technology for thermal expansion displacement adjustment and control over hot water main pipeline

A main pipeline, thermal expansion technology, applied in the direction of expansion compensation devices, pipes, pipe components, etc. for pipelines, can solve the problems of high temperature resistance, low pressure resistance, poor anti-fatigue effect, easy aging, etc., to reduce friction. , good compatibility, reducing the effect of moving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

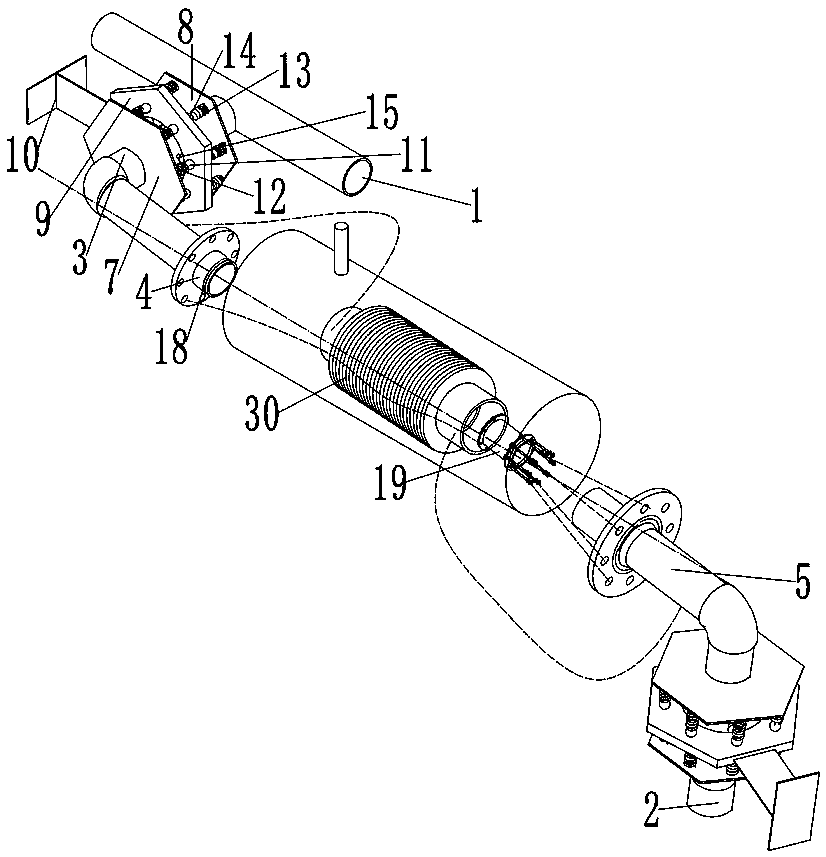

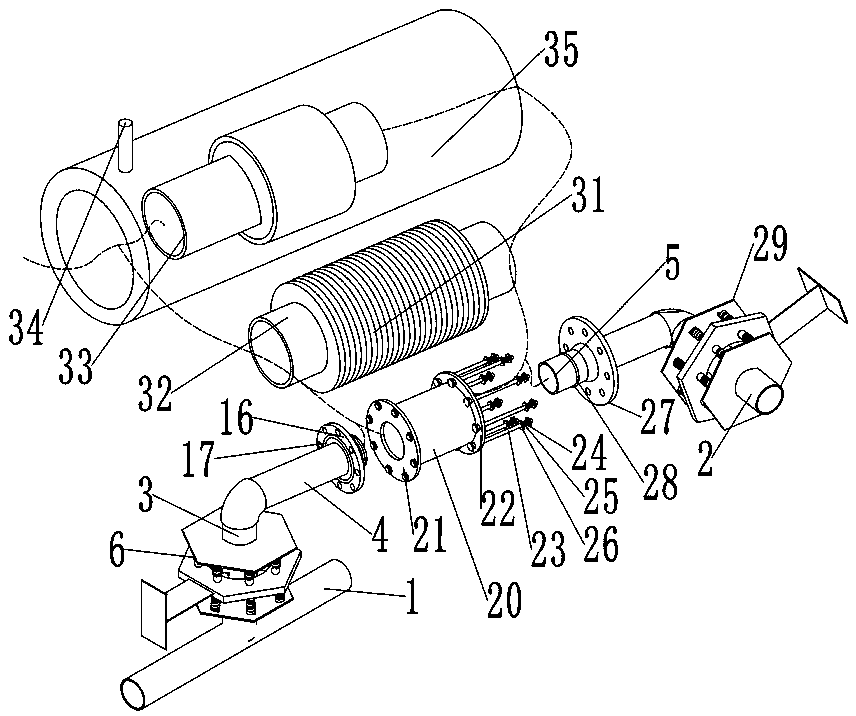

[0030] Such as Figure 1-2 As shown, the hot water main pipeline flexible branch system of this embodiment includes a main pipeline 1, a branch output pipeline 2 distributed on the main pipeline 1, and a branch input pipeline 3 connected to the branch output pipeline 2;

[0031]The branch output pipeline 2 includes the input first joint 4 that the input end is connected with the main pipeline 1, the input second joint 5 that the output end is connected with the branch input pipeline 3, and the input second joint 5 connected between the input first joint 4 outlet and the input second joint 5 inlet. Thermal expansion redundant devices between branches;

[0032] The branch thermal expansion redundant device includes an input connecting plate 16 arranged at the outlet of the input first joint 4, an input end face sealing ring 17 arranged on the back of the input connecting plate 16, and an input shaft arranged on the outer wall at the outlet end of the input first joint 4. To the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com