Battery diaphragm based on aramid fibre

A battery separator, aramid fiber technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems affecting the application of battery separators, a large number of solvents, difficult to control and other problems, and achieve thermal stability and automatic shutdown protection performance Good, good spatial stability and flatness, small interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

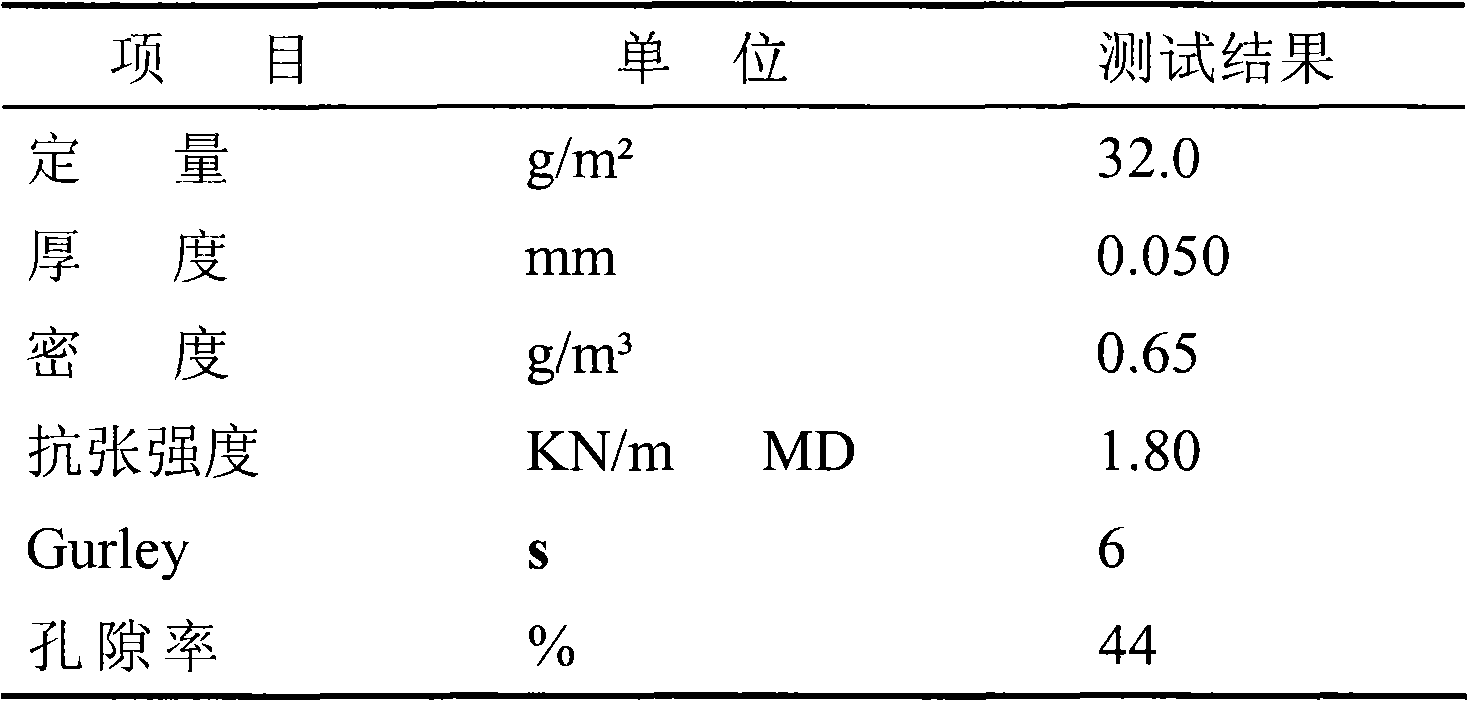

[0027] Prepare the battery separator of Example 1 according to the following ratio:

[0028] Aramid 1414 fiber (2-4mm) 75 parts by weight

[0029] Aramid 1414 precipitated fiber 25 parts by weight

[0030]After the aramid fiber 1414 fiber with the above content is 1% by weight, it is thawed by a hydraulic deflagging machine, and then further beaten by disc grinding, and the final pulping degree is 10-70° SR pulp A. The aramid 1414 precipitated fiber with the above content is decomposed in a hydraulic deflaker, and further beaten by disc grinding, and finally made into SR slurry B with a degree of percussion of 10-75°, and then adding water to slurry A and slurry B in the batching tank Mix well to form a slurry that can be added to the former headbox, adding the appropriate amount of polyethylene oxide to the stabilizer box. The head of the slurry on the net is adjusted by the stabilizer box, and the slurry is evenly distributed on the forming wire in the headbox, and the exc...

Embodiment 2

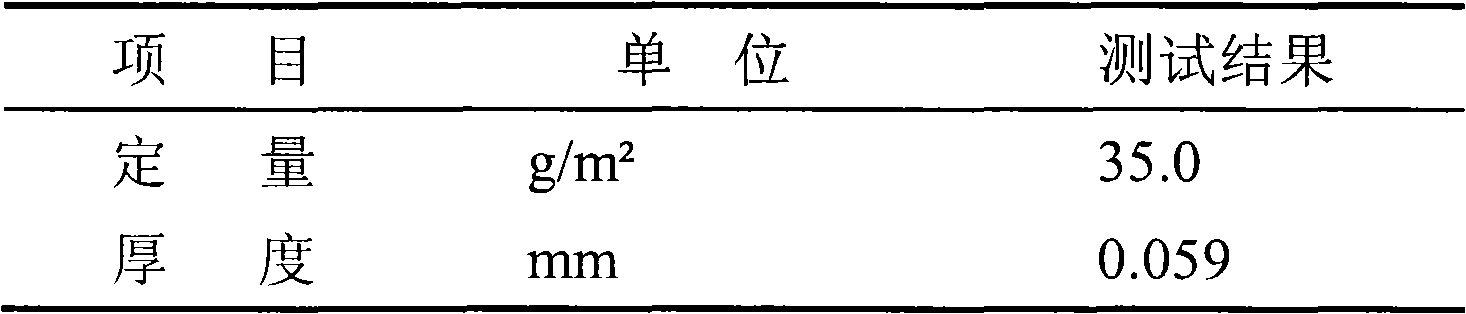

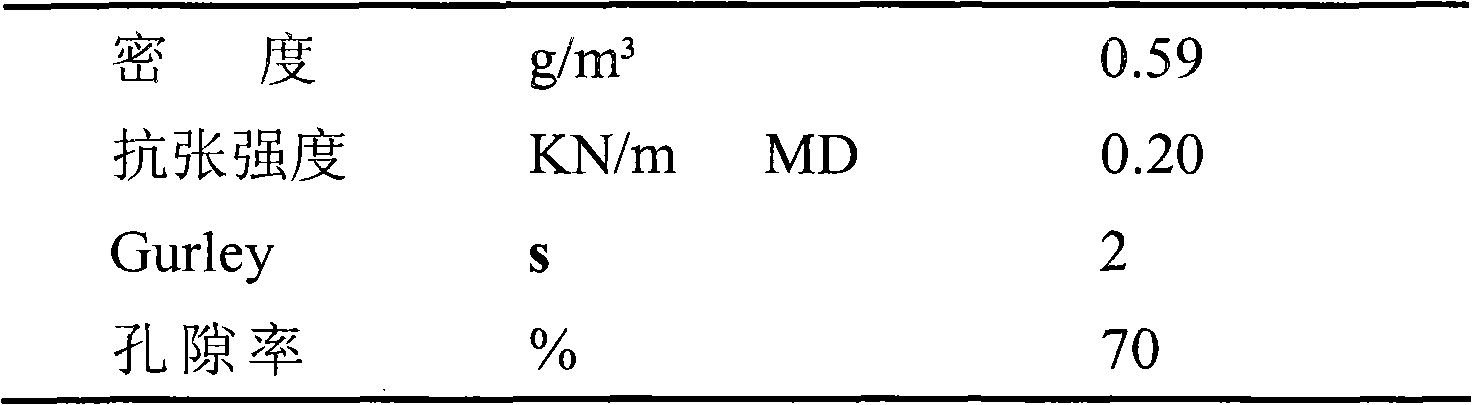

[0034] Prepare the battery separator of Example 2 according to the following parts by weight:

[0035] Aramid 1414 fiber (2-4mm) 97 parts by weight

[0036] Aramid 1414 precipitated fiber 3 parts by weight

[0037] The preparation method of the battery separator is the same as in Example 1, and the results obtained are shown in Table 2:

[0038] Table 2

[0039]

[0040]

Embodiment 3

[0042] The battery separator of Example 3 was prepared in the following parts by weight:

[0043] Aramid 1414 fiber (2-4mm) 65 parts by weight

[0044] Aramid 1414 precipitated fiber 35 parts by weight

[0045] The preparation method of the battery separator is the same as in Example 1, and the test results obtained are shown in Table 3:

[0046] table 3

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com