Steel plate concrete column and construction method

A technology of steel plate concrete and construction method, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of the steel plate and concrete not working together, the segregation effect of the steel plate and the concrete column, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

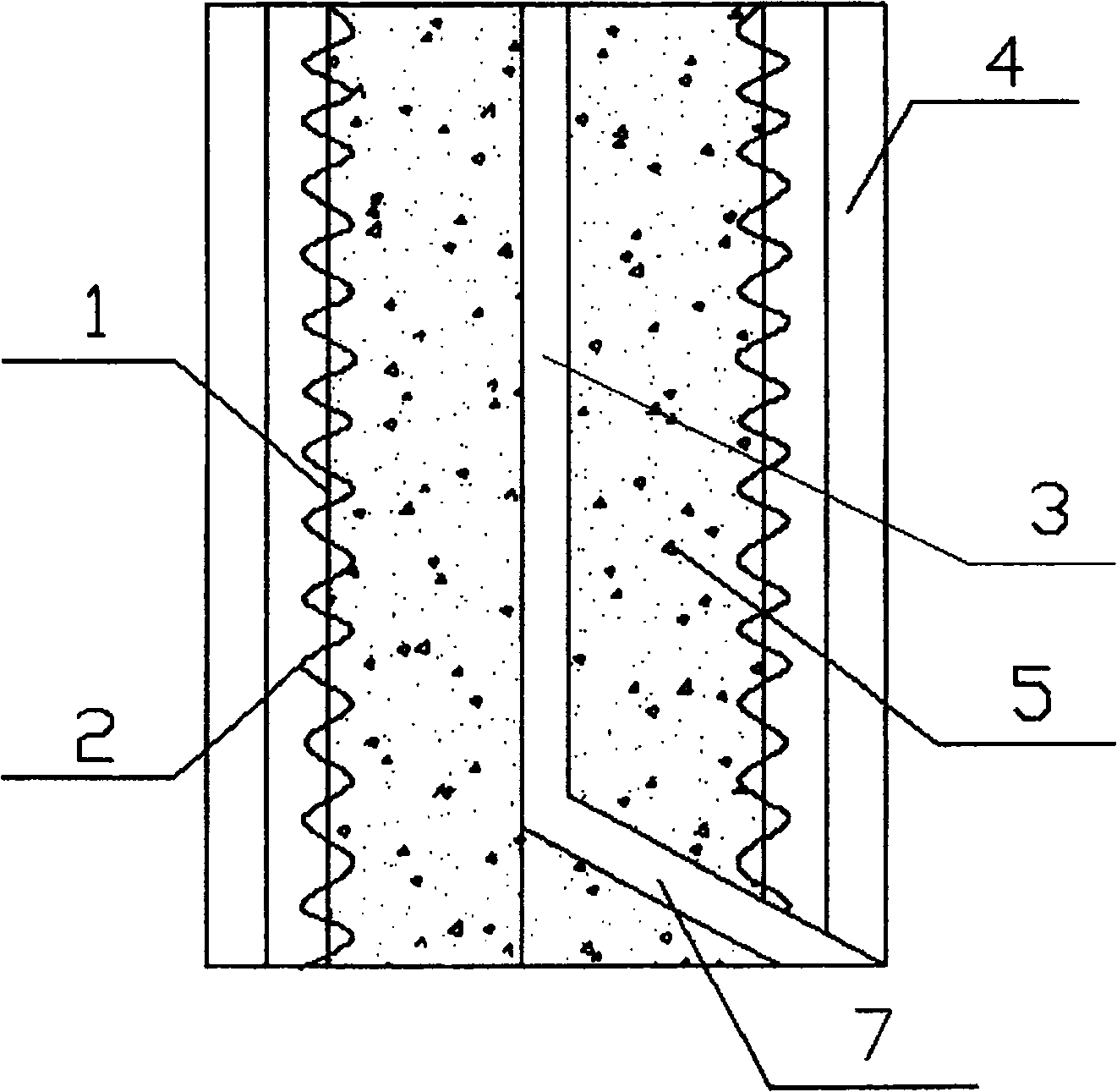

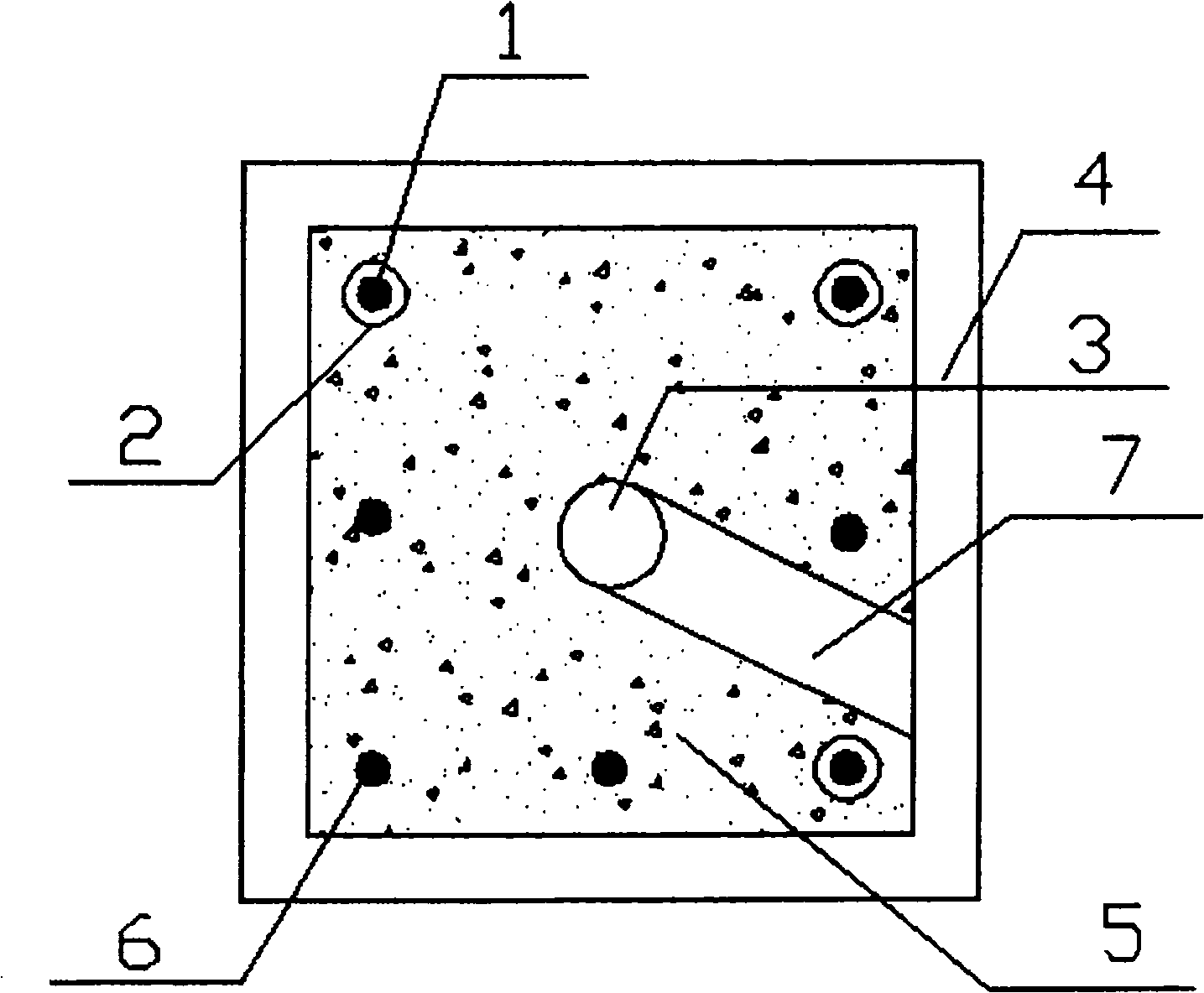

[0020] The present invention heats the steel plate concrete in the process of pouring concrete. Since the linear expansion coefficient of the steel plate 4 is greater than the linear expansion coefficient of the concrete 5, the expansion of the steel plate 4 is larger than that of the concrete 5. When the concrete 5 is hardened, the shrinkage of the steel plate 4 is greater than that of the concrete 5, which is equivalent to The concrete 5 exerts prestress on the steel pipe 4, so that the concrete 5 is kept in a three-dimensional compression state at the initial loading stage. By forming different potential distributions in the concrete 5 during the pouring of the concrete 5, the free water in the concrete 5 is discharged, so as to avoid the problem of segregation of the steel plate 4 and the concrete column due to hydration.

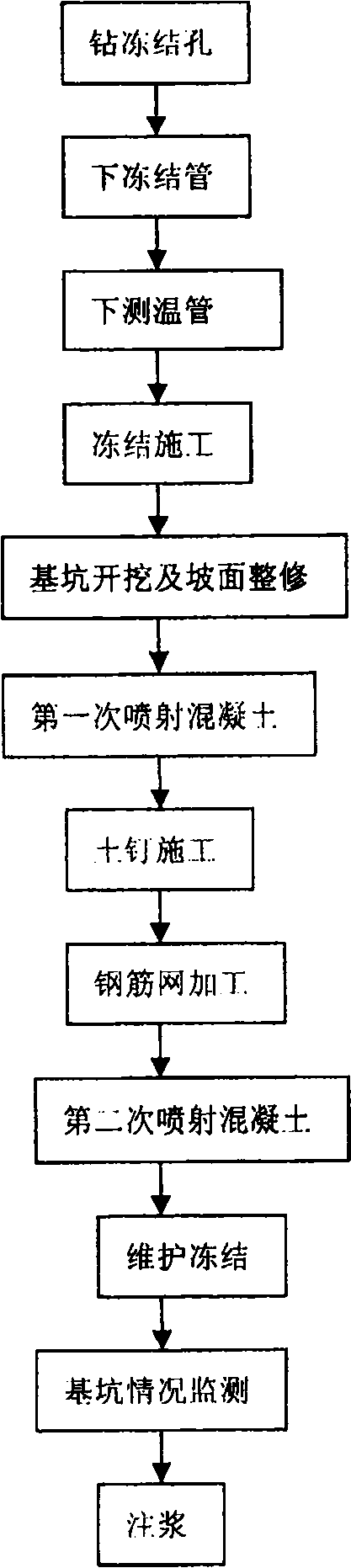

[0021] Construction steps of the present invention include:

[0022] (1) Binding steel bars

[0023] (2) Wrap the plastic-coated aluminum-core wire 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com