Combined type fender

A composite fender technology, applied in the field of composite fenders, can solve the problems of short service life, ugly, easy to be crushed, etc., and achieve the effects of short service life, long service life and slow response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

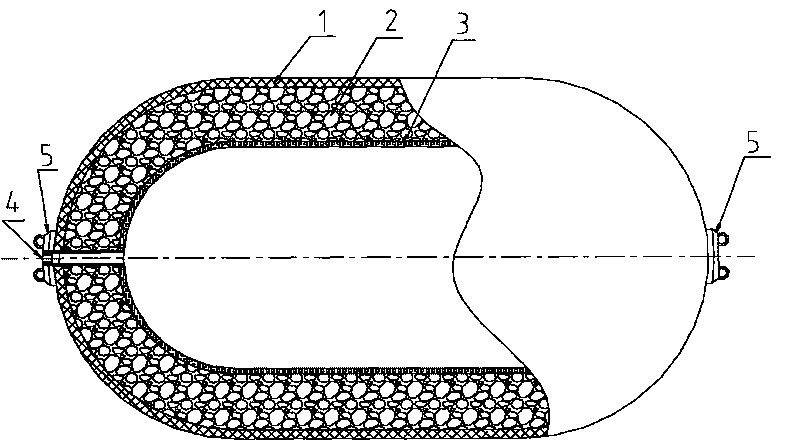

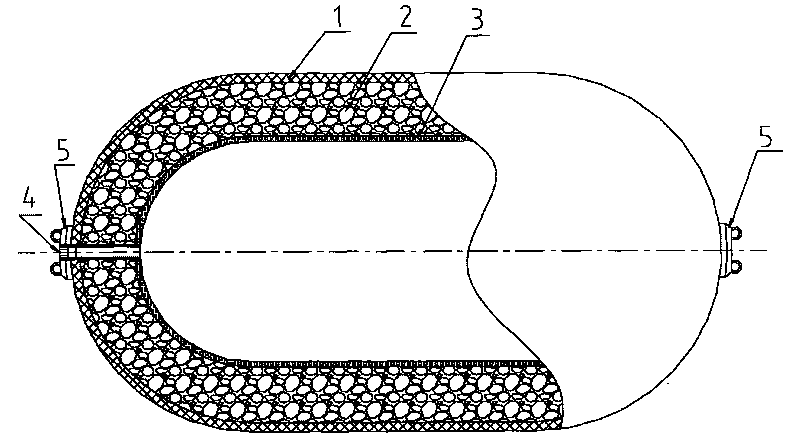

[0025] Embodiment 1, as shown in the figure, the composite fender used for the protection of docks, ships, ocean engineering, etc. is composed of an outer shell 1, a buffer protective layer 2, and an inner tank 3. There is an inflation nozzle 4 on the inner tank 3, and the fender The two ends of the side are provided with a mooring flange 5, and the mooring flange 5 is also provided with a mooring ring and the like. The overall length of the fenders is 3m. The diameter is 2m, and its aspect ratio is 1.5. Both ends of the airbag adopt hemispherical heads. The shell of the fender is made of rubber or plastic, and contains three layers of rubber-coated steel cord skeleton material. The surface of the shell is coated with a protective layer of light blue-gray PU with a thickness of 6mm; the buffer protective layer 2 of the fender adopts non-cross-linked obturator Structural rubber foam material with a thickness of 350mm and a density of 0.302g / cm 3 , hardness (Shore A type) 33°,...

Embodiment 2

[0026] Embodiment 2, as shown in the figure, the giant composite fender is composed of an outer shell 1, a buffer protection layer 2, and an inner tank 3, and the inner tank 3 has an inflation nozzle 4, and the two ends of the fender are provided with a cable flange 5. There are also mooring rings and the like on the mooring flange 5 . The total length of the fender is 5m, the diameter is 3m, and its length-to-diameter ratio is 1.67. Both ends of the airbag adopt oval heads. The shell of the fender is made of rubber or plastic, containing twelve layers of polyamide fiber cord fabric skeleton material, and the surface of the shell is coated with a protective layer of silver-gray neoprene rubber with a thickness of 4mm; Closed-cell rubber foam material with a thickness of 500mm and a density of 0.26g / cm 3 , hardness (Shore A type) 30°, tensile strength not less than 1.8MPa, tear strength not less than 1.5MPa, elasticity 40%, flexing and cracking 120,000 times; the liner 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com