Patents

Literature

43results about How to "Anti-extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

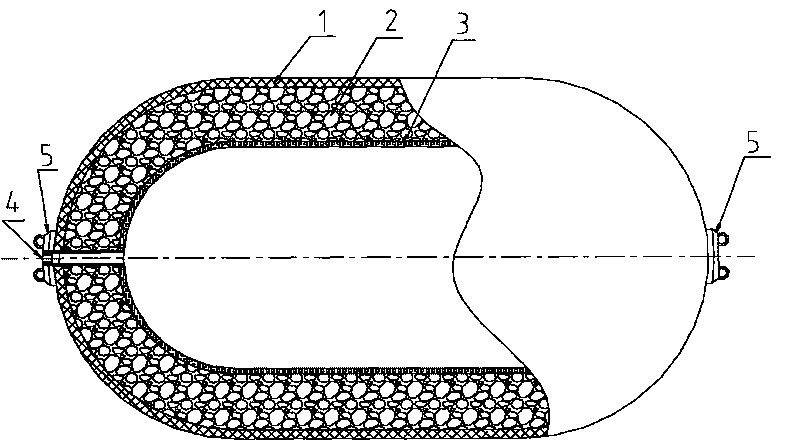

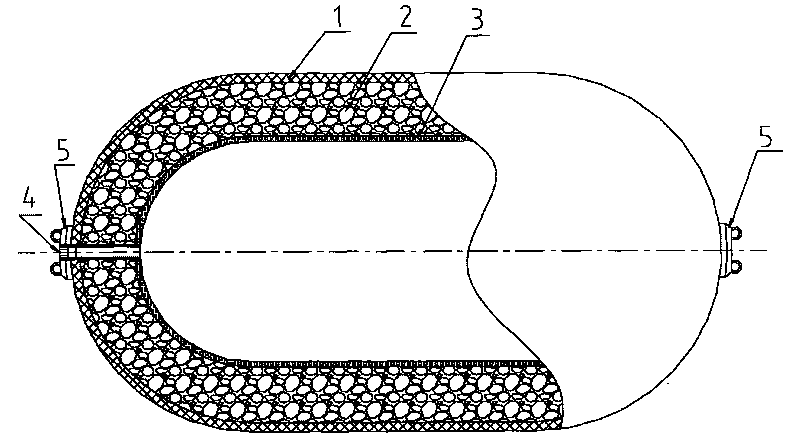

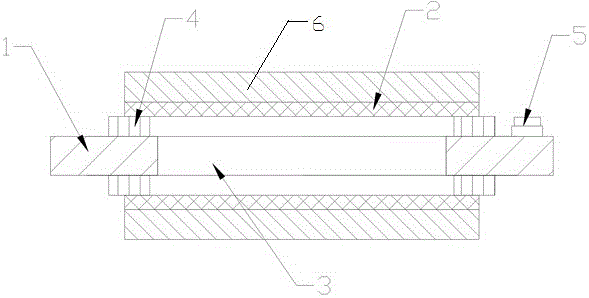

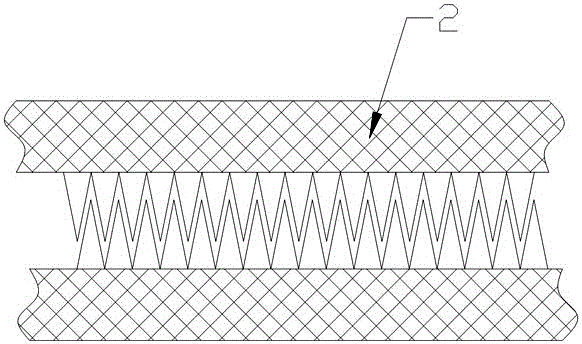

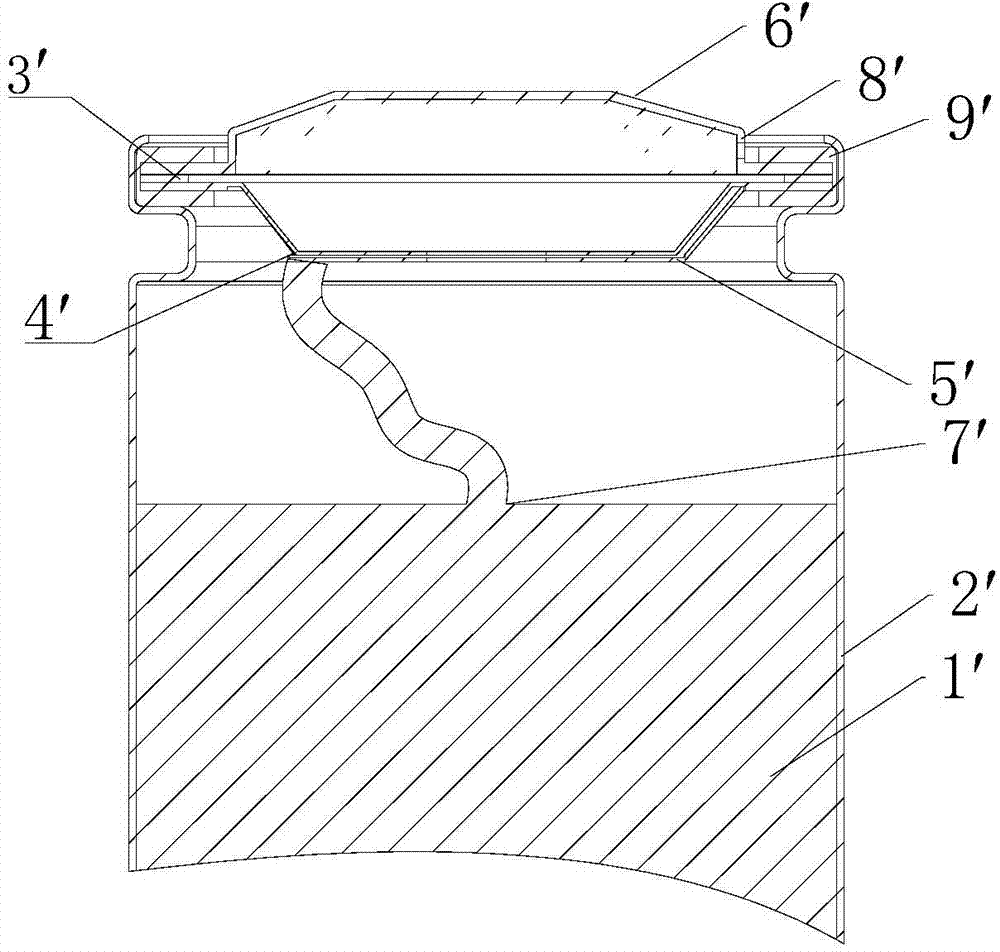

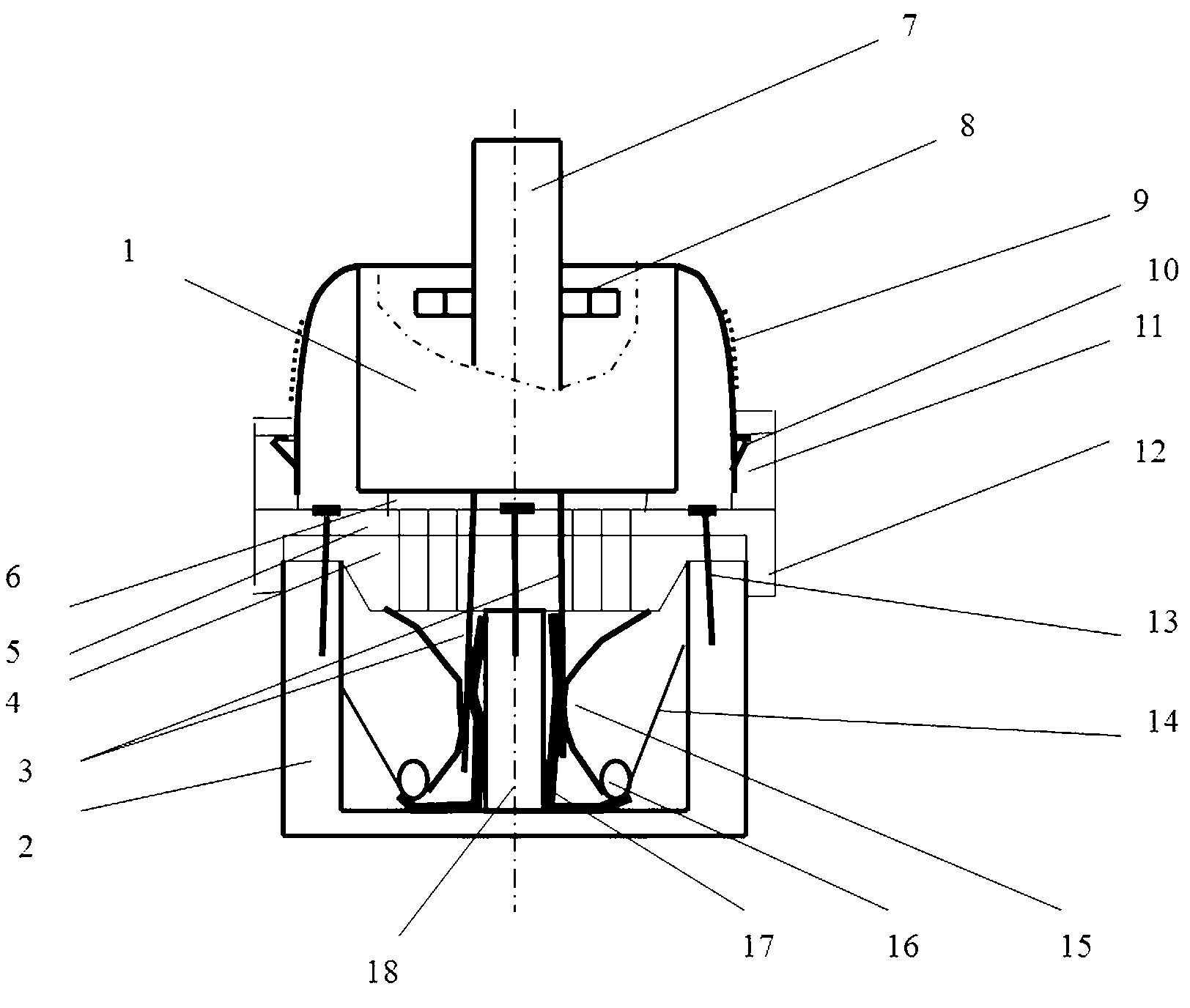

Combined type fender

InactiveCN101698424AAnti-agingExtended service lifeVessel cleaningClimate change adaptationEnergy absorptionEngineering

The invention relates to a combined type fender, which is a protective device to be used in docks, shipping and oceanographic engineering. The combined type fender is characterized by consisting of a shell, a buffering protective layer and a liner. The combined type fender integrates the advantages of various fenders, has the characteristics of toughness, extrusion resistance, fatigue resistance, ageing resistance and long service life of a fender taking rubber as a buffering medium, and avoids the disadvantages that the weight is large, the fender cannot float on a water surface, energy absorption is less and counter-force is large; the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force and pricking resistance which are possessed by a fender taking a foaming material as the buffering medium, and avoids the disadvantages of slow response speed and short service life; and in addition, the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force, quick response speed, capability to backpressure adjustment on the energy absorption and the counter-force and the like which are possessed by an air inflation type fender taking gas as the buffering medium, and avoids the defects that the combined type fender is easy for pricking, aging and air leakage, and needs to be maintained frequently.

Owner:钟爱民

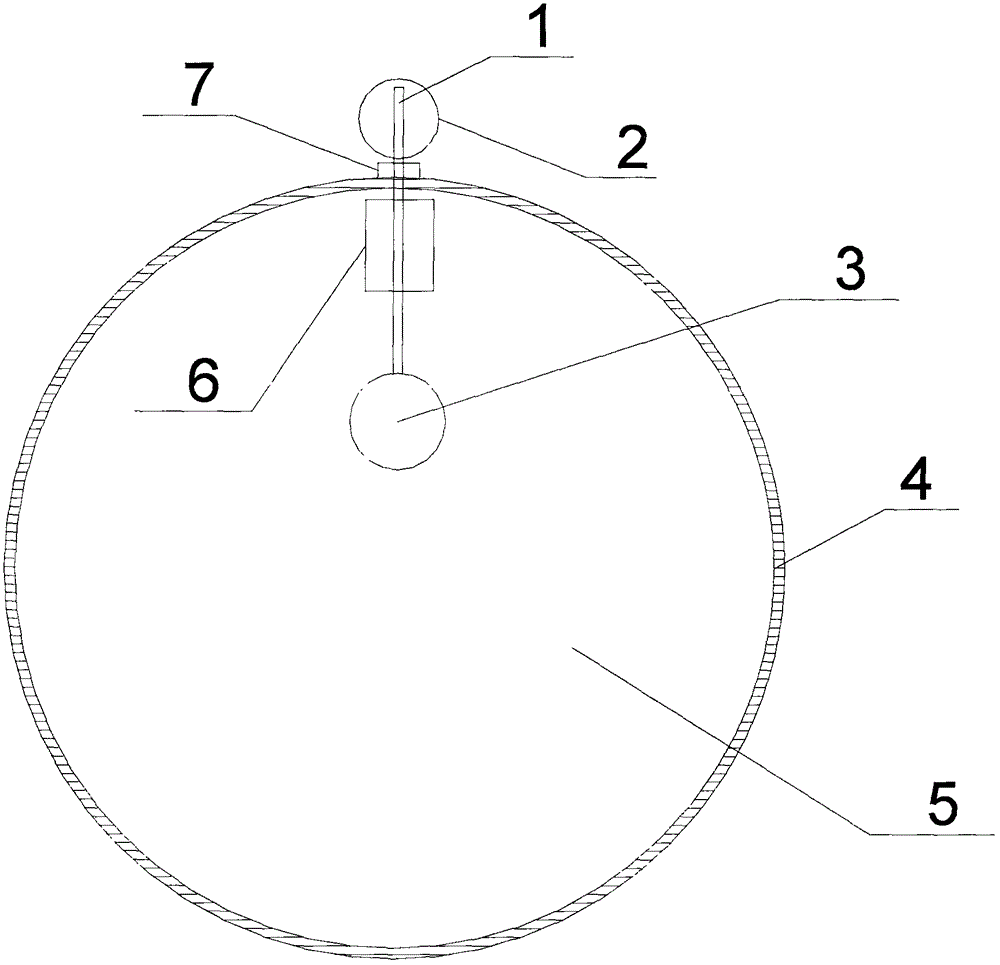

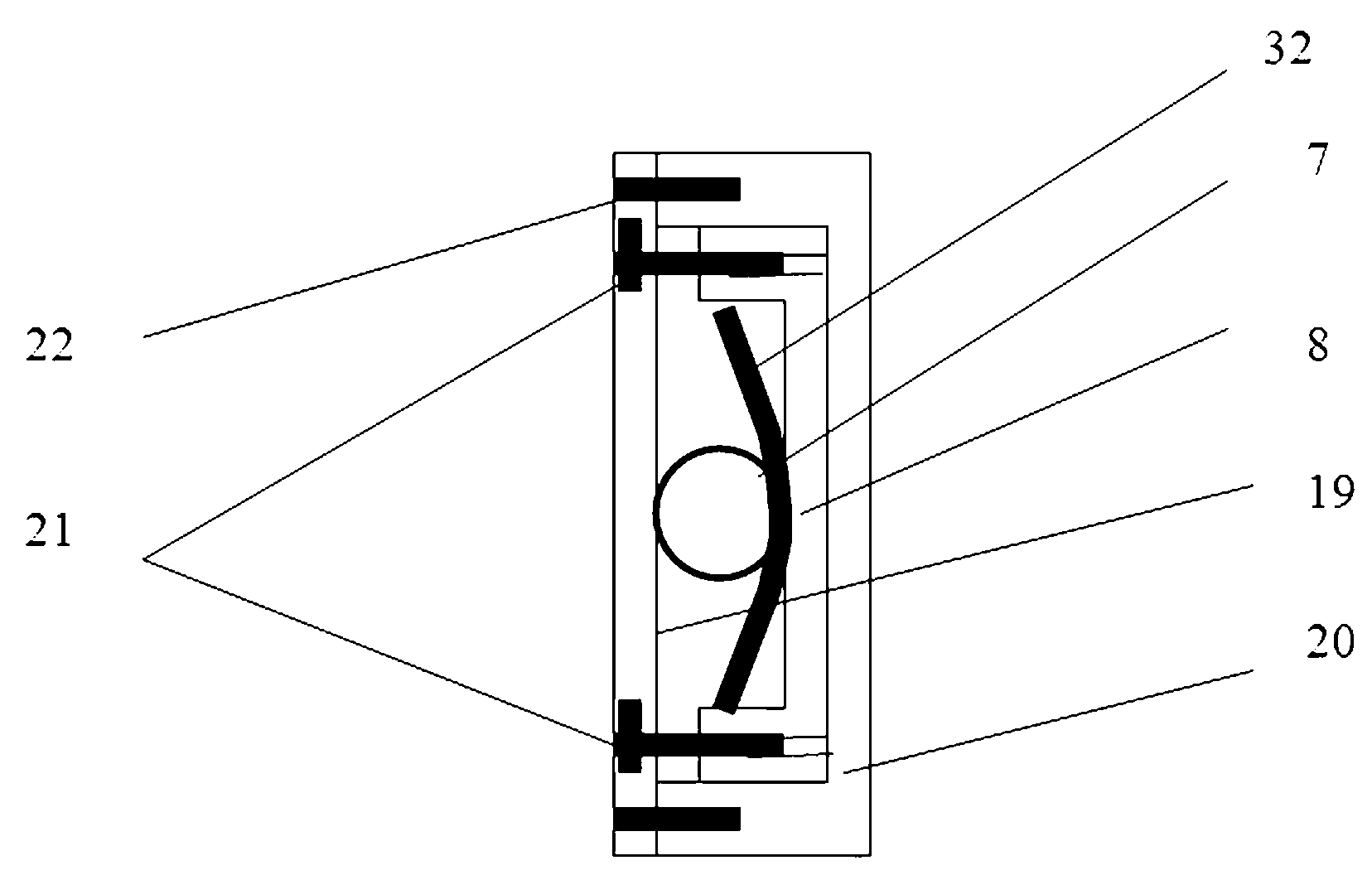

Fire-extinguishing bomb thrown through unmanned aerial vehicle

The invention discloses a fire-extinguishing bomb thrown through an unmanned aerial vehicle. The fire-extinguishing bomb comprises a shell, a fire-extinguishing agent, a hanging mechanism and a starting system; the starting system comprises a self-inflammation unit, a throwing delayer, an infrared detector and a starter, the fire-extinguishing agent is placed in the shell, and the starting system is installed on the shell; and the throwing delayer penetrates through the shell, the upper end of the throwing delayer is connected with the hanging mechanism which is a lifting ring, and the lower end of the throwing delayer is connected with the starter. The fire-extinguishing bomb thrown through the unmanned aerial vehicle is reasonable in design, simple in structure, good in exploding orientation of the fire-extinguishing bomb, little in detonating energy and capable of achieving umbrella type covering; and throwing can be conducted towards a fire scene by diversified means, fire fighting is more convenient to be conducted for a site, where people cannot easily enter, with a high mountain and a thick wood, and meanwhile safety of a rescue person is protected.

Owner:BEIJING SHENGTAI FIRE FIGHTING EQUIP

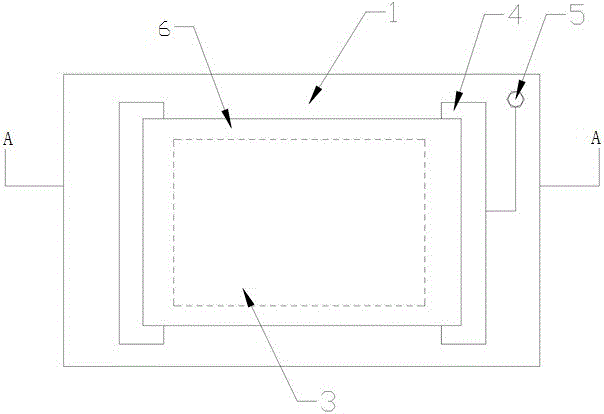

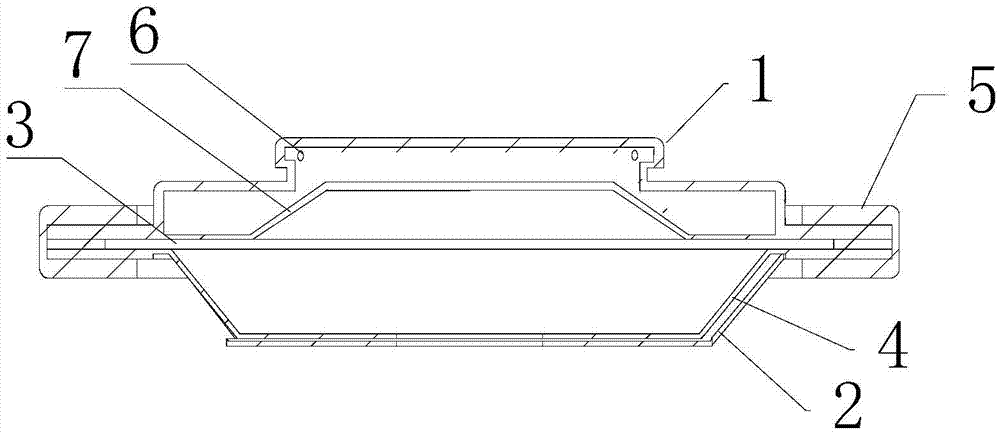

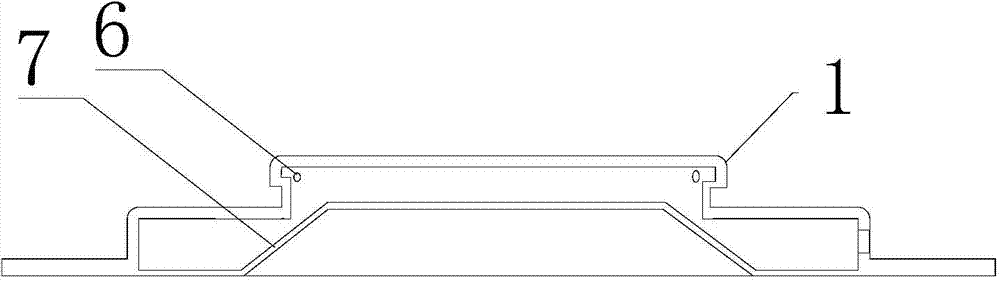

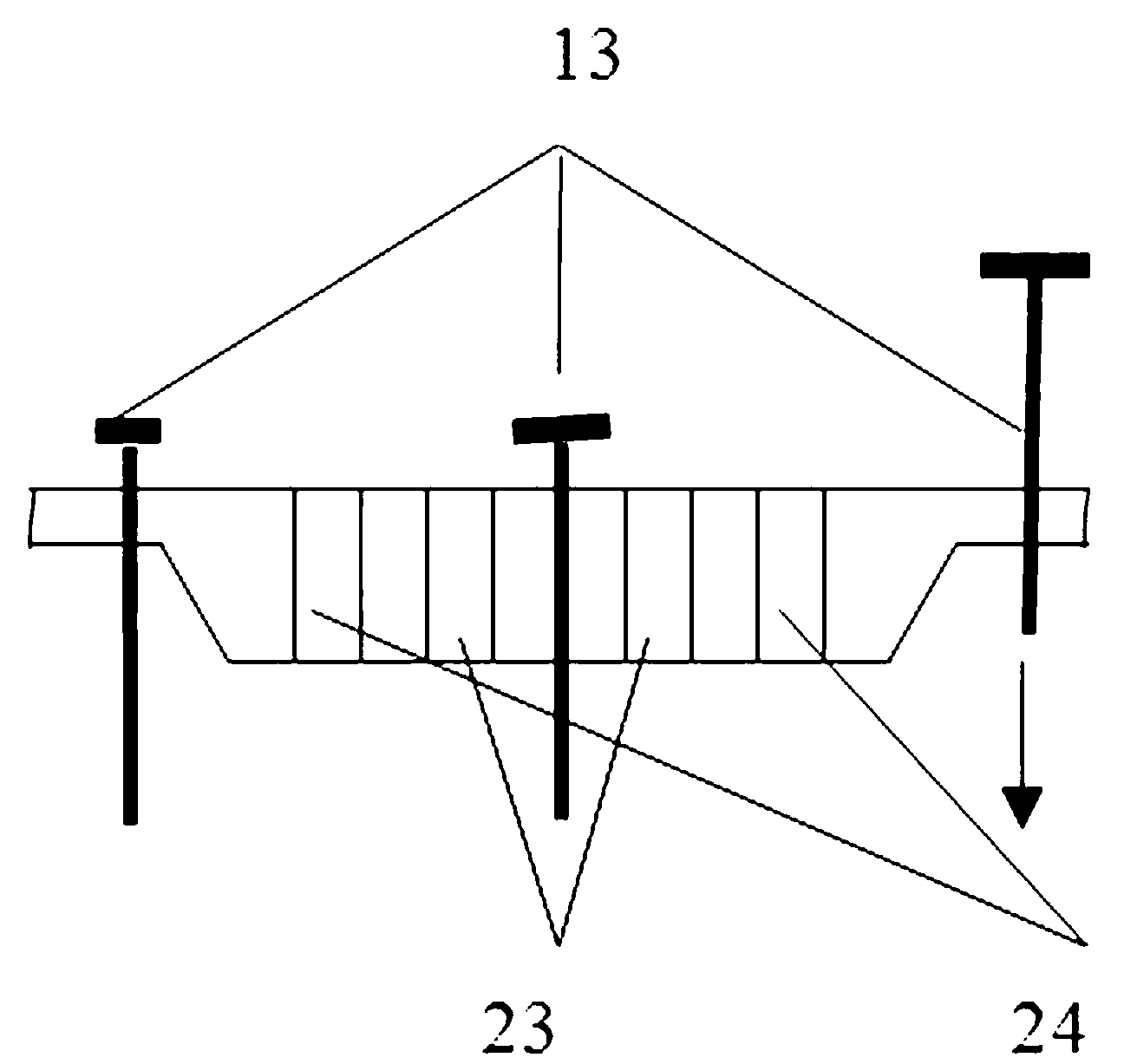

Graphene detection element for detecting fine deformation of equipment housing

ActiveCN106197253AWith micro deformation detectionRealize fine deformation detectionConductive layers on insulating-supportsElectrical/magnetic solid deformation measurementElectrical and Electronics engineering

The invention discloses a graphene detection element for detecting the fine deformation of an equipment housing, and the element comprises a circuit board which is provided with a hollow-out part. The two faces of the hollow-out part on the circuit board are provided with graphene conductive films in a pasting manner. The graphene conductive films are attached to an insulating elastic base layer, and the upper and lower graphene conductive films are arranged oppositely. A gluing electrode is disposed between the graphene conductive films and the circuit board. The element is pasted at a to-be-detected part of the equipment. When the housing bears a force and then deforms, the effective contact area of the upper and lower graphene conductive films changes, thereby enabling the conduction impedance of the upper and lower graphene conductive films to change. Through detecting the change of the impedance, the element calculates the size of an external force, and further solves the deformation quantity of the equipment housing.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Bionic double-layer dressing and preparation method thereof

ActiveCN109481737AGood tensile propertiesExcellent semi-permeable barrierPharmaceutical delivery mechanismTissue regenerationIntestinal submucosaSmall intestine

The invention provides bionic double-layer dressing, comprising acellular animal intestinal submucosa and a gel layer crosslinked to the same. The acellular animal intestinal submucosa and the gel layer jointly form the bionic double-layer dressing in double-layer structure. Preparation steps include preparing the acellular animal intestinal submucosa, preparing powder of the acellular animal intestinal submucosa, preparing a solution of the acellular animal intestinal submucosa, preparing the bionic double-layer dressing; the solution of the acellular animal intestinal submucosa is mixed witha crosslinking liquid, the mixture is added to the surface of the acellular animal intestinal submucosa, and freezing and crosslinking are performed to obtain the bionic double-layer dressing. The bionic double-layer dressing has excellent tension resistance, has semipermeable barrier, can prevent moisture evaporation and bacterial penetration, is good for healing of a wound, and enables wound healing speed to be evidently increased, with the wound healing speed evidently increased on third to seventh day after surgery.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

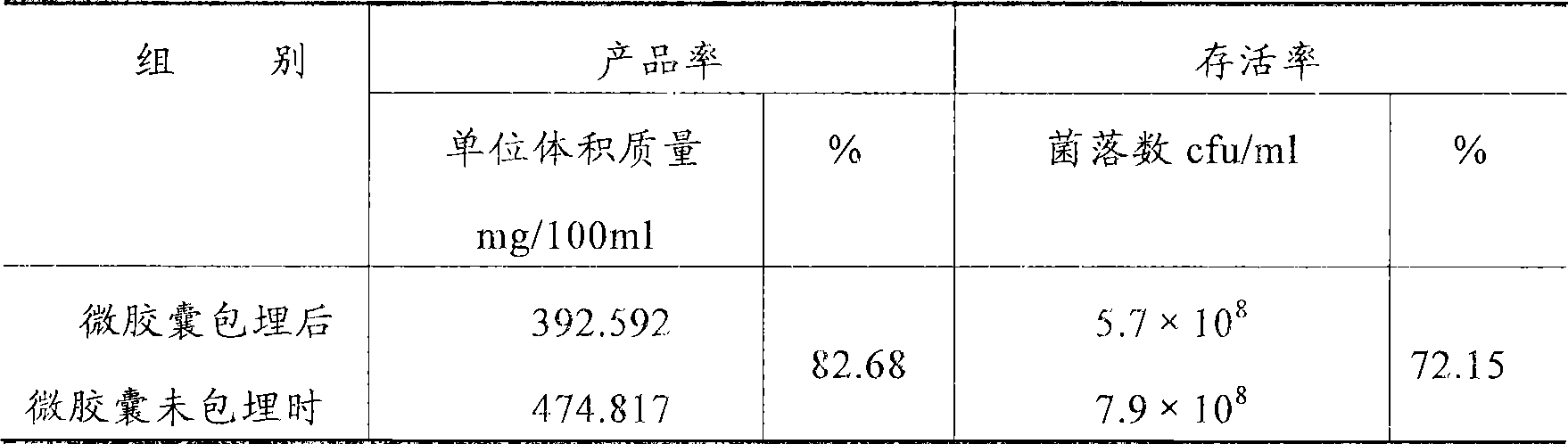

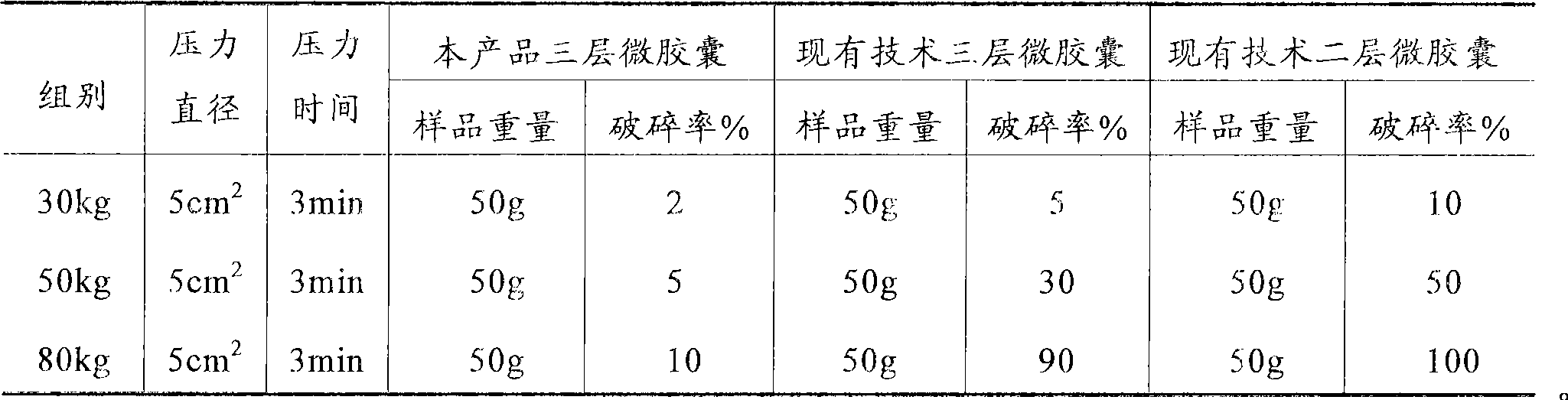

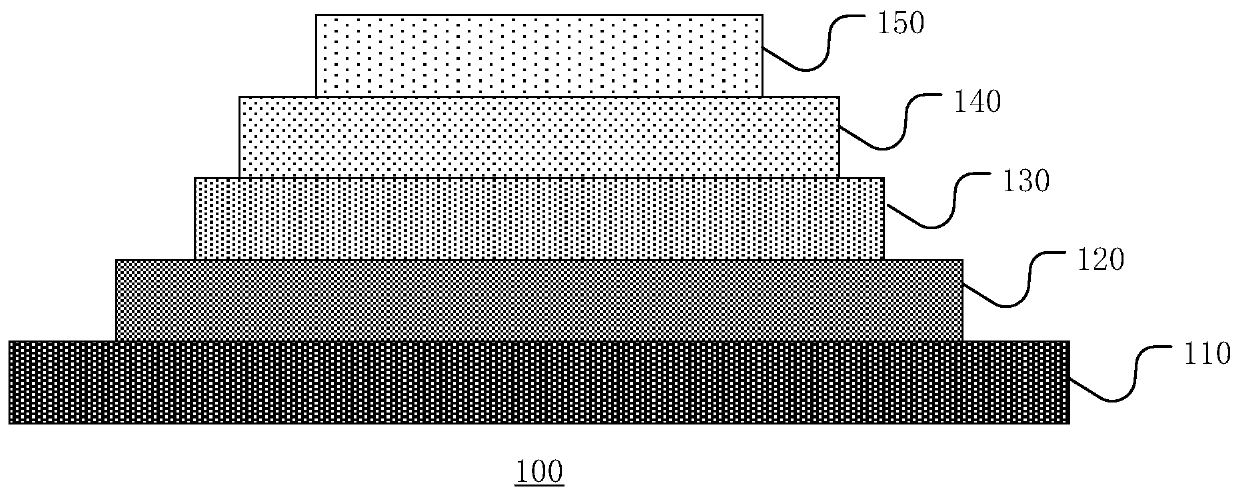

Selenium-rich Enterococcus faecium cernelle three-layer microcapsule and preparation method and use thereof

InactiveCN101416681ACheap and easy to getImproves balanced biological functionAnimal feeding stuffAqueous solutionFermentation

The invention provides a selenium-enriched lactic acid enterococcus faecalis three-layer microcapsule and a preparation method thereof. The microcapsule sequentially comprises a selenium-enriched lactic acid enterococcus faecalis, nutritive layer, an anti-acid anoxybiotic layer and a compression-resisting and breakage-proof layer from the inside to the outside. Wherein culture conditions of the selenium-enriched lactic acid enterococcus faecalis are 25-35 mg / l of selenium, 5-15 g / l of inoculum size, 28-32 h of fermentation time and 4.5-6.3 of pH when fermenting in an anaerobic jar; based on a double-layer embedding, the embedding method of the three-layer microcapsule is mainly mixing the three-layer microcapsule together with 2.0-2.5% of glutin aqueous solution and 0.1-0.3% of sodium alginate aqueous solution to make a suspension; an improved low-temperature spray drying method is adopted to form the compression-resisting and breakage-proof layer and to make the embedded selenium-enriched lactic acid enterococcus faecalis three-layer microcapsule have gastric acid-resisting, storage wearing, thermal stabilizing and compression-resisting and breakage-proof functions based on the original biological function and organic selenium supplementing function. So the microcapsule is widely applied to producing feeds.

Owner:丁岚峰

High-efficiency corrosion resistant pre-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

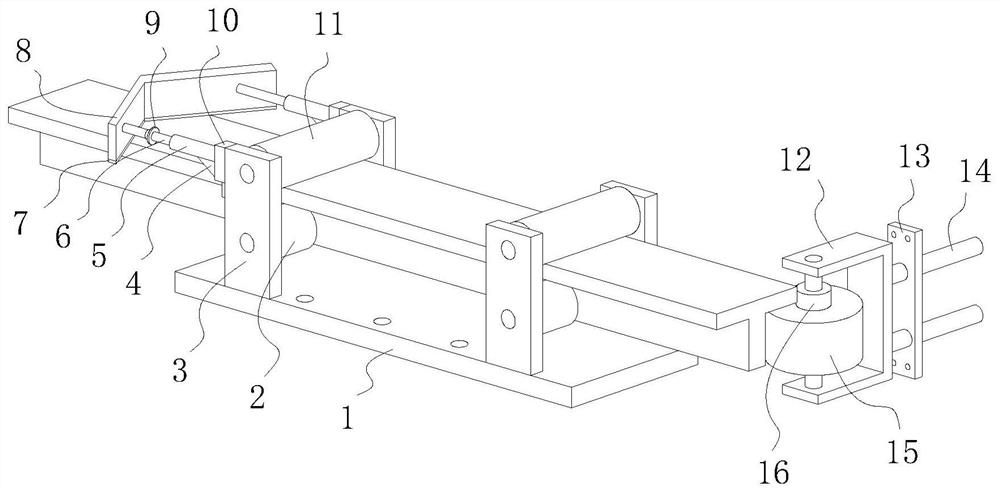

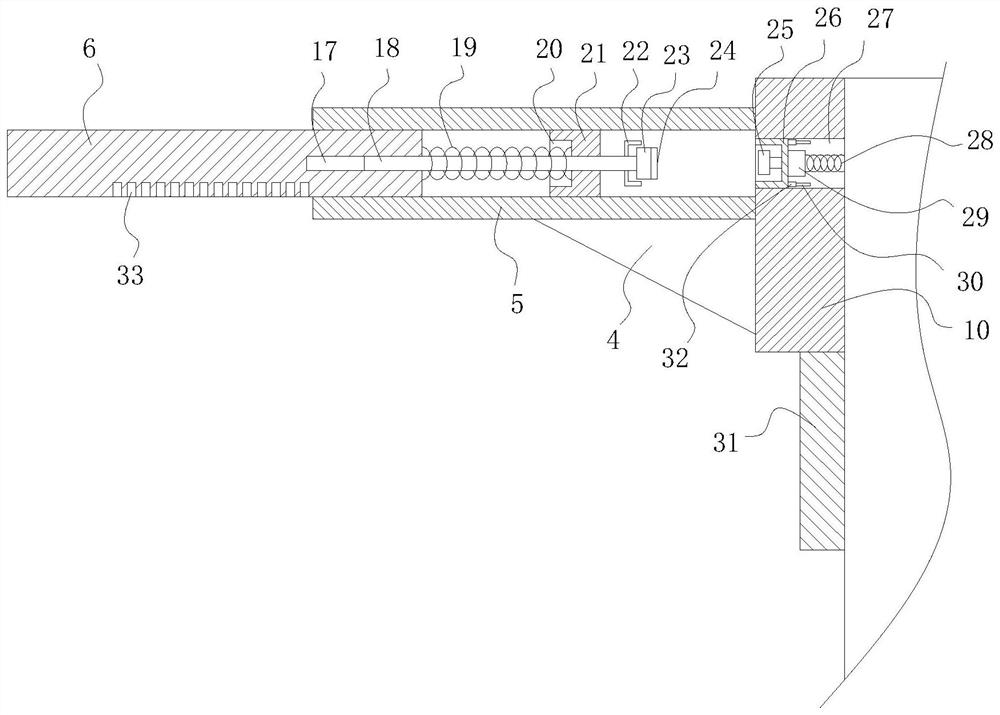

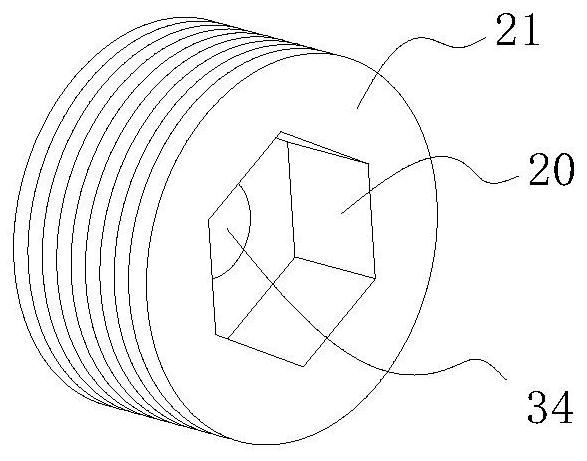

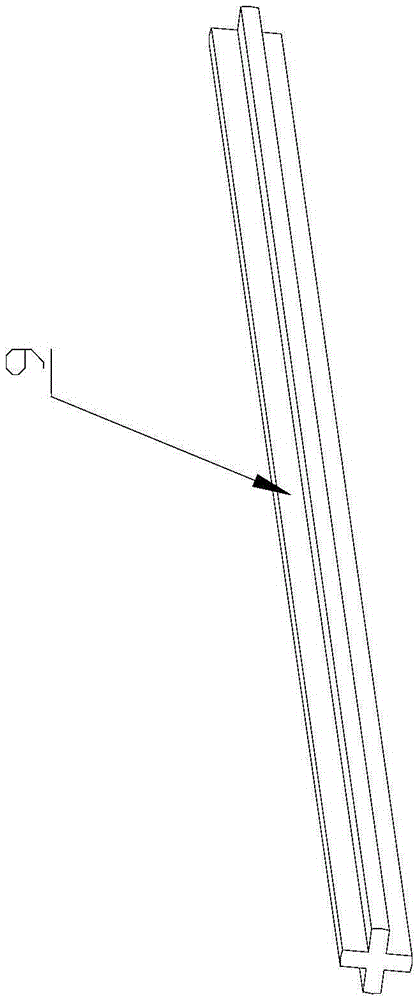

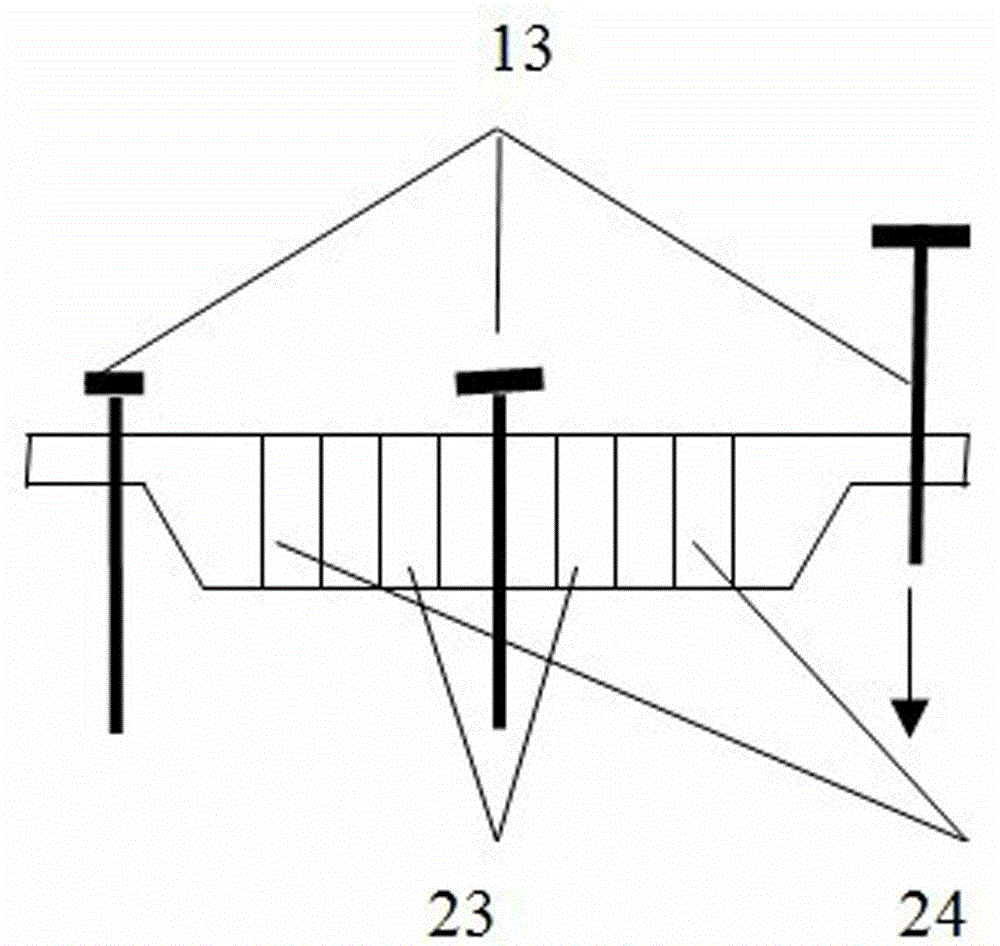

Continuous bending machining machine for steel structure sectional materials

InactiveCN112845721AAffect the service lifeEasy to cleanCleaning using toolsBar pressingScrew thread

The invention relates to the technical field of steel machining, and specifically relates to a continuous bending machining machine for steel structure sectional materials. The continuous bending machining machine comprises a base, two pressing rollers used for pressing T-shaped steel are arranged on the upper side of the base, and a V-shaped plate used for removing sundries on the surface of the T-shaped steel is arranged on the feeding sides of the pressing rollers. Two horizontally-arranged inserting rods are symmetrically installed on the inner surface of the V-shaped plate, the end, away from the V-shaped plate, of each inserting rod is sleeved with a sleeve, the end, away from the corresponding inserting rod, of each sleeve is fixedly connected with a protruding block, and the position, provided with an internal threads, of each sleeve is in threaded connection with an external thread disc. A pin hole communicating with an inner hexagonal hole is formed in the face, away from the corresponding inserting rod, of each outer threaded disc, a pressing rod is inserted in each pin hole, and each pressing rod is sleeved with a reset spring. Compared with the prior art, the continuous bending machining machine has the following beneficial effects that dirt left on the upper surface of the horizontal section of the T-shaped steel is conveniently and rapidly removed, and the situation that due to the fact that the dirt is accumulated at the positions of the pressing rollers, the service life of the pressing rollers is influenced is prevented.

Owner:闫国亚

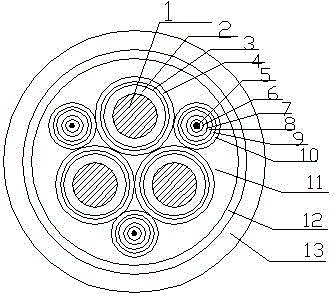

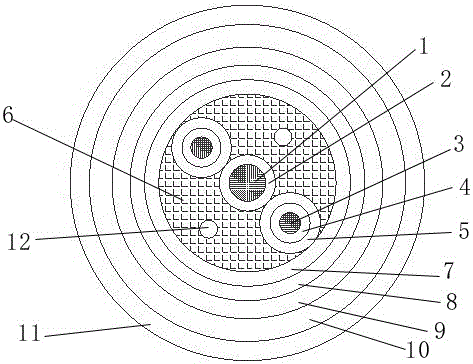

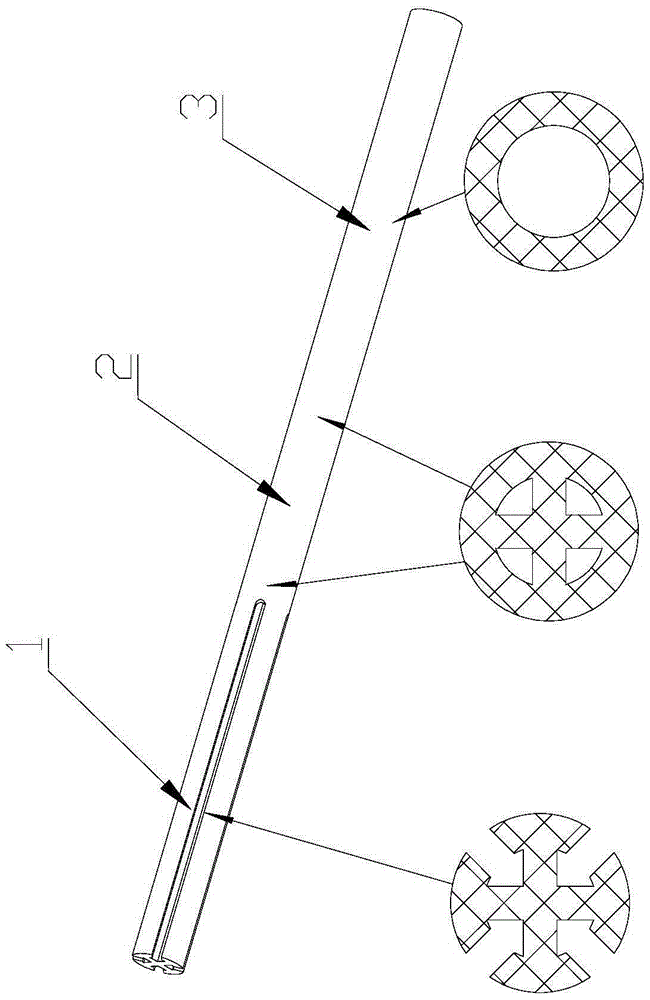

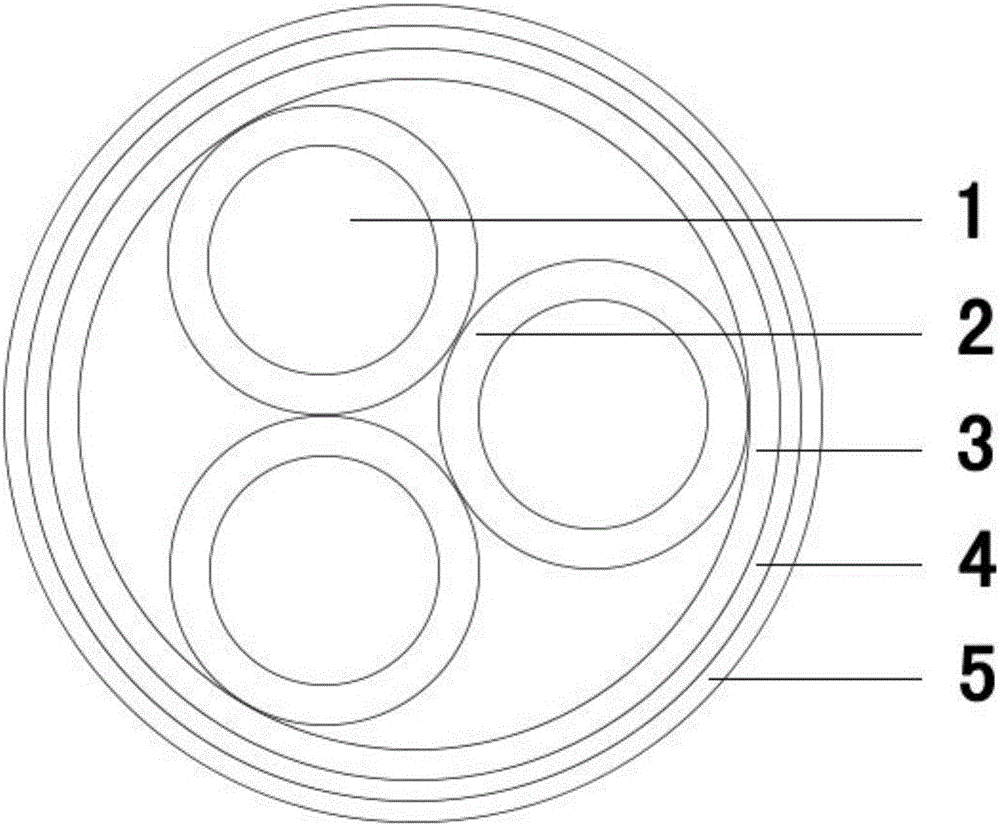

Composite type coal cutter cable with optical fiber and electric signal

ActiveCN104091643AWith bending resistanceNot easy to disconnectCommunication cablesInsulated cablesElectrical conductorControl line

The invention discloses a composite type coal cutter cable with an optical fiber and an electric signal. The composite type coal cutter cable with the optical fiber and the electric signal comprises a line core, an inner jacket, a steel tape armoring layer and an outer jacket, wherein the inner jacket, the steel tape armoring layer and the outer jacket are wrapped outside the cable core in sequence. The line core comprises a plurality of power line cores and a plurality of control line cores, wherein the power line cores and the control line cores are mutually intertwisted. Each power line core comprises a power line core conductor, a power line insulating layer wrapped outside the power line core conductor, a high-strength wrapping layer and a metallic shield layer. Each control line core sequentially comprises an optical fiber core, an optical fiber protective layer, an elastic metal protective sleeve, an optical fiber insulating layer, a control line core body and a control line insulating layer. The composite type coal cutter cable with the optical fiber and the electric signal is resistant to bending and extrusion, and it is guaranteed that the optical fiber and a control line are not prone to breakage. The composite type coal cutter cable with the optical fiber and the electric signal further has the advantages that cost is low, and a circuit is simple.

Owner:上海蓝昊电气江苏有限公司

Cylindrical battery cap

InactiveCN104269501AAnti-extrusionAnti-solder penetrationSmall-sized cells cases/jacketsSecondary cellsEngineeringMechanical vibration

The invention provides a cylindrical battery cap which is mounted at a seal of a steel battery shell. The cylindrical battery cap comprises a cap head and a base, wherein a gasket is arranged between the cap head and the base; an anti-explosion opening aluminum film covers the base; a joint of the cap head and the base is coated with a sealing ring; a plurality of exhaust holes are formed in the side surface of the cap head; an anti-vibration structure capable of endowing axial elasticity on the cap head is arranged on the side surface of the cap head. The anti-vibration structure is arranged on the side surface of the cap head, so that the cap head has certain axial elasticity; under the action of an external force, a part of mechanical vibration impact force can be well released, pressure on the sealing ring is alleviated, the sealing ring is prevented from being damaged, and the safety is improved.

Owner:SUZHOU ANKAO ENERGY

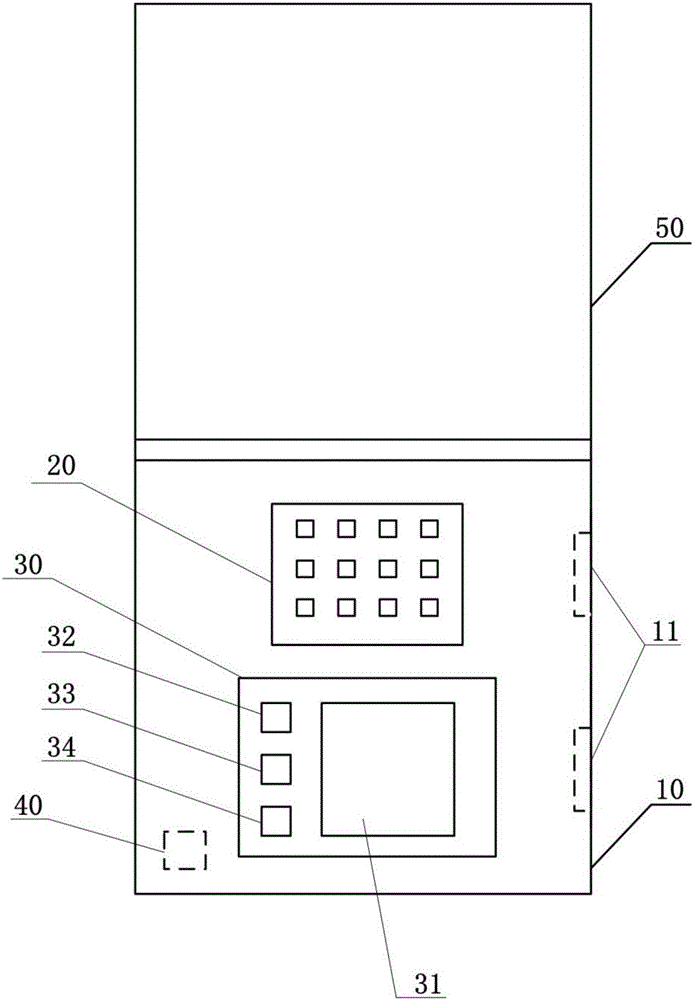

Mobile hard disk with data encryption device

InactiveCN105809006AImprove securityAnti-collisionInternal/peripheral component protectionDigital data authenticationKey pressingComputer hardware

The invention discloses a mobile hard disk with a data encryption device. The mobile hard disc comprises a hard disc body used for storing data and provided with a socket port enabling data transmission, password type-in keys arranged on the hard disc body into an array and used for inputting an encryption password, a fingerprint acquiring component which is located on the hard disc body and comprises a fingerprint acquiring screen used for acquiring fingerprints, and a controller located on the hard disc body, wherein the controller is in communication with the hard disc body, the password type-in keys and the fingerprint acquiring component, and the socket port is electrically connected with the controller, the fingerprint acquiring component and the password type-in keys. Fingerprint and key password dual encryption is achieved, so that security is higher.

Owner:SUZHOU MEITIAN NETWORK TECH CO LTD

Graphene-based thermal insulation carpet

InactiveCN110279277AGood insulationGood heating uniformity and stabilitySynthetic resin layered productsLaminationThermal insulationEngineering

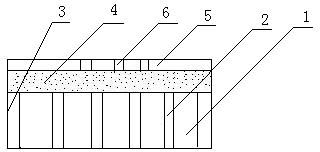

The invention belongs to the field of carpets, and particularly relates to a graphene-based thermal insulation carpet. The graphene-based thermal insulation carpet comprises a carpet bottom layer, a first insulation layer, a heating layer, a second insulation layer and a carpet surface layer which are connected from the bottom to the top, a textile rubber layer is adopted in the carpet bottom layer, a PET polyester film is adopted in the first insulation layer, a frame type graphene thermostatic film is adopted in the heating layer, a thermal conductive silicone-PET polyester composite film is adopted in the second insulation layer, and a fiber soft material is adopted in the carpet surface layer. According to the graphene-based thermal insulation carpet, heating layer combined with the thermal conductive silicone-PET polyester composite film is adopted, heat generated by the heating layer is quickly transmitted to the carpet surface through thermal conductive silicone, and the graphene-based thermal insulation carpe has great thermal insulation performance and heat even stability.

Owner:绍兴市秀臻新能源科技有限公司

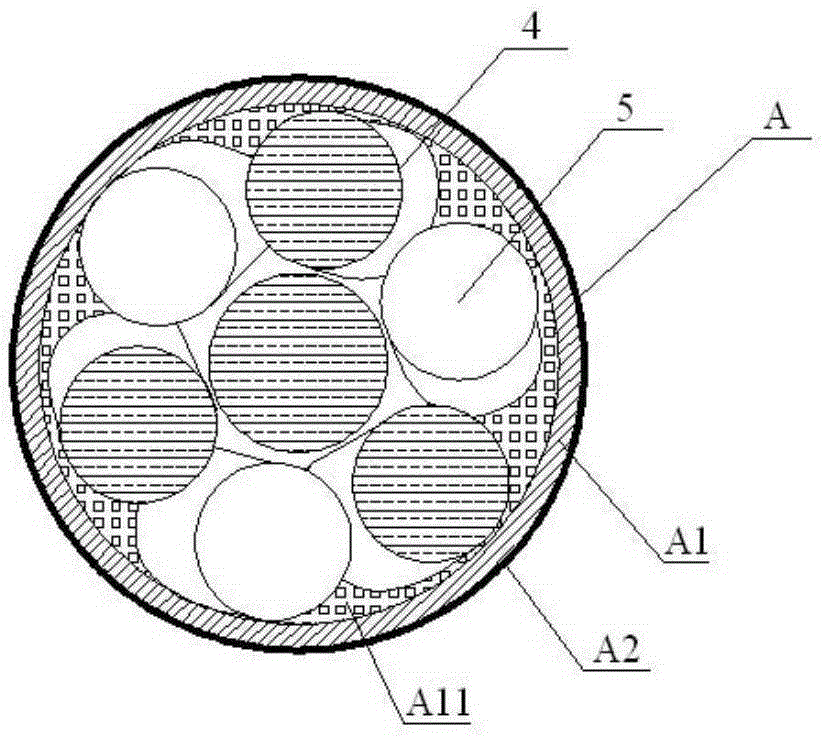

Crosslinked polyethylene insulated multi-core flame retardant cable

InactiveCN105913959AAnti-extrusionAlleviate squeezed spacePower cables with screens/conductive layersFlexible cablesPolyesterInsulation layer

The invention discloses a crosslinked polyethylene insulated multi-core flame retardant cable, which comprises a cable core. The gap of the cable core is provided with an inorganic mineral oxygen barrier layer; the cable core is wrapped with a first polyester tape; a semi-conductive shielding layer is extruded outside the polyester tape; a steel strip armored layer is arranged outside the inner semi-conductive shielding layer; a rock wool heat insulation layer is extruded outside the steel strip armored layer; and the outermost layer of the cable is provided with a silica fireproof sleeve; the cable core is formed by stranding a ground wire and two insulated wire cores arranged symmetrically with the ground wire as an axial center in a horizontal mode; and the cable core is internally provided with a group of through holes symmetrically with the ground wire as the axial center. The crosslinked polyethylene insulated multi-core flame retardant cable has the advantages of good flame retardancy, high temperature resistance, good cooling performance, fire resistance, good insulated performance and the like.

Owner:WUXI NEW SUNSHINE CABLE

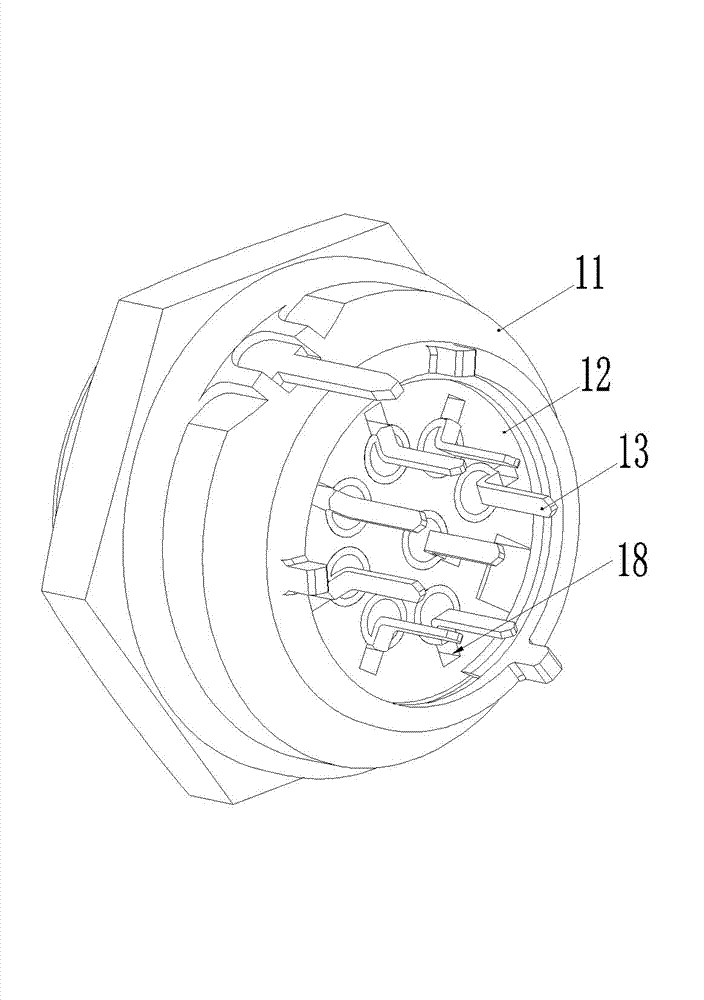

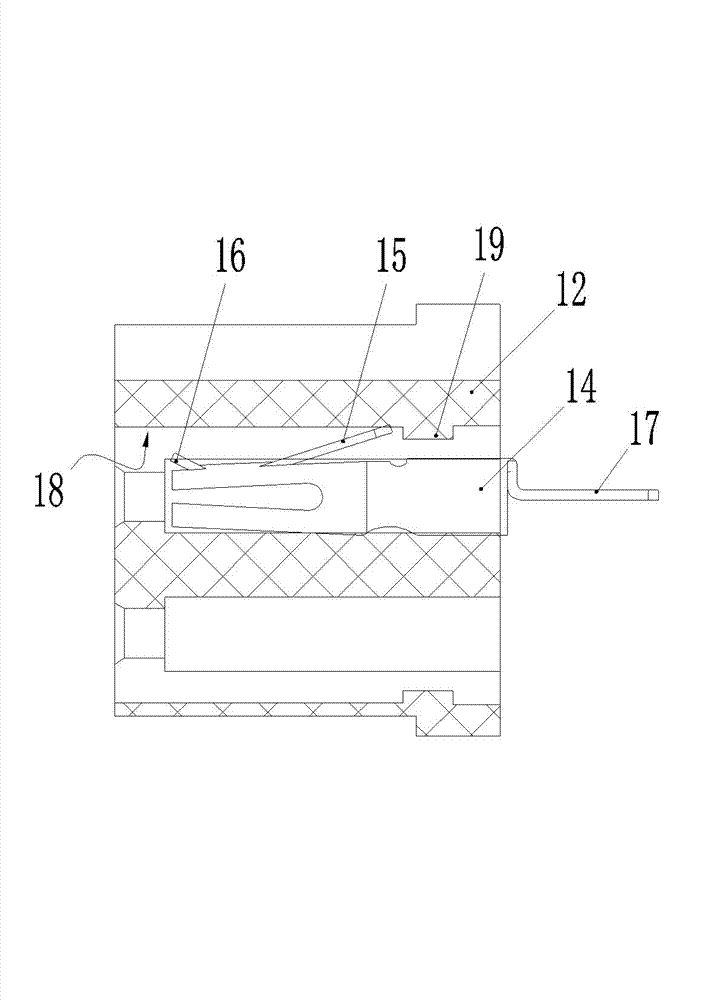

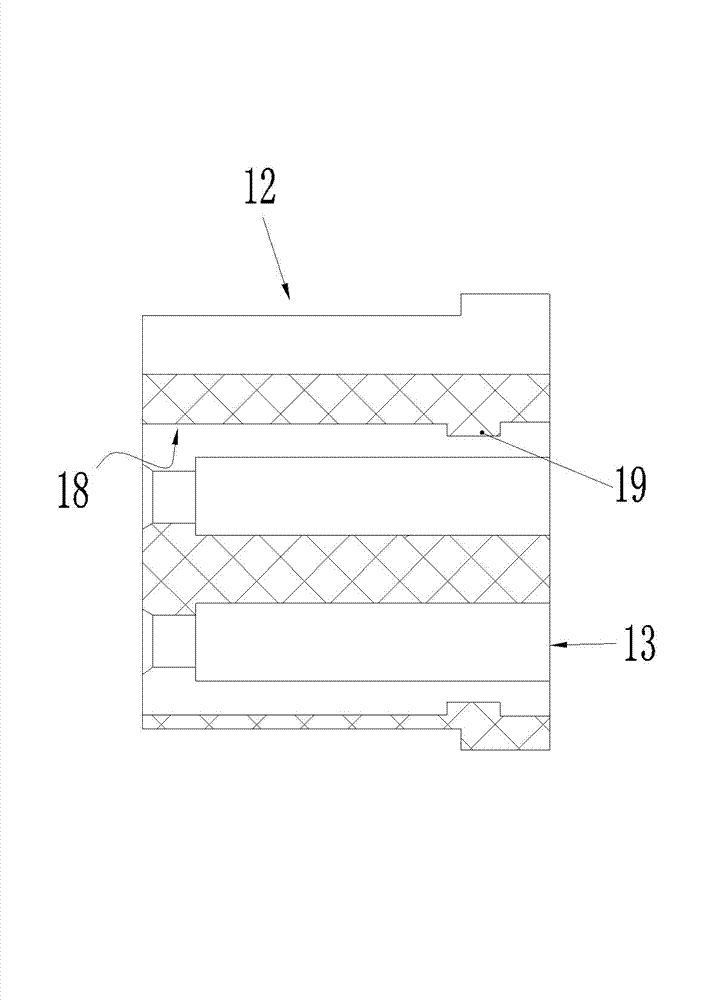

Electrical connector and contact element thereof

InactiveCN102810783AReduce manufacturing costSimple preparation processSecuring/insulating coupling contact membersCouplings bases/casesEngineeringElectrical connector

The invention relates to the field of electrical connectors, in particular to an electrical connector and a contact element thereof. The electrical connector comprises an insulator and contact elements. The insulator is provided with mounting holes. Each contact element is provided with a base part which is spliced into the corresponding mounting hole from back to front. Each base part is provided with a forwards-backwards extended axis. An elastic barb is arranged on the base part of each contact element, and is gradually inclined and overhung towards the radial periphery of the base part from front to back. A forwards-backwards extended guide groove opposite to the elastic barb is formed on the hole wall of each mounting hole. Each elastic barb is matched with the corresponding guide groove to prevent the corresponding contact element from rotating in the corresponding mounting hole. A stopping table is arranged at the rear end of the groove bottom of each guide groove, and is matched with the rear end of the corresponding elastic barb to stop the corresponding contact element to backwards move relative to the insulator. A stepped surface facing a rear part is arranged on the front part of the hole wall of each mounting hole, and stops the front end of the corresponding base part to forwards move relative to the insulator. The production cost of the electrical connector is lowered.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Safe and steady power plug-socket system

InactiveCN103236610AImprove general performanceIncrease contactRelieving strain on wire connectionCouplings bases/casesTorsion springClutch

The invention relates to a safe and steady power plug-socket system. Clutch spring plates are arranged on two sides of a plug. Rubber sheets are fastened around plug inserts. A clutch holder is disposed on the socket. Clutch spring plate retainers which are used with the clutch spring plates of the plug and can be fastened and loosened are disposed on two sides of the clutch holder. The clutch holder is provided with a partition covering the socket. The rubber sheets are arranged below the partition. Both the partition and the rubber sheets are provided with jacks corresponding to socket clips. The socket clips and a socket fixing plate are pressed by the rubber sheets. Fixed plates of the socket clips on two sides of the socket fixing plate are both abutted to the socket fixing plate. Moving plates of the socket clips are abutted to the fixed plates of the socket clips through an arm of force of a torsion spring, and the other arm of force of the torsion spring is abutted to the side wall of the socket. The safe and steady power plug-socket system is waterproof and damp-proof, free of plug-socket loosening, and ensures the fixed plates and moving plates of the clips to tightly contact with the inserted plug inserts.

Owner:齐国成

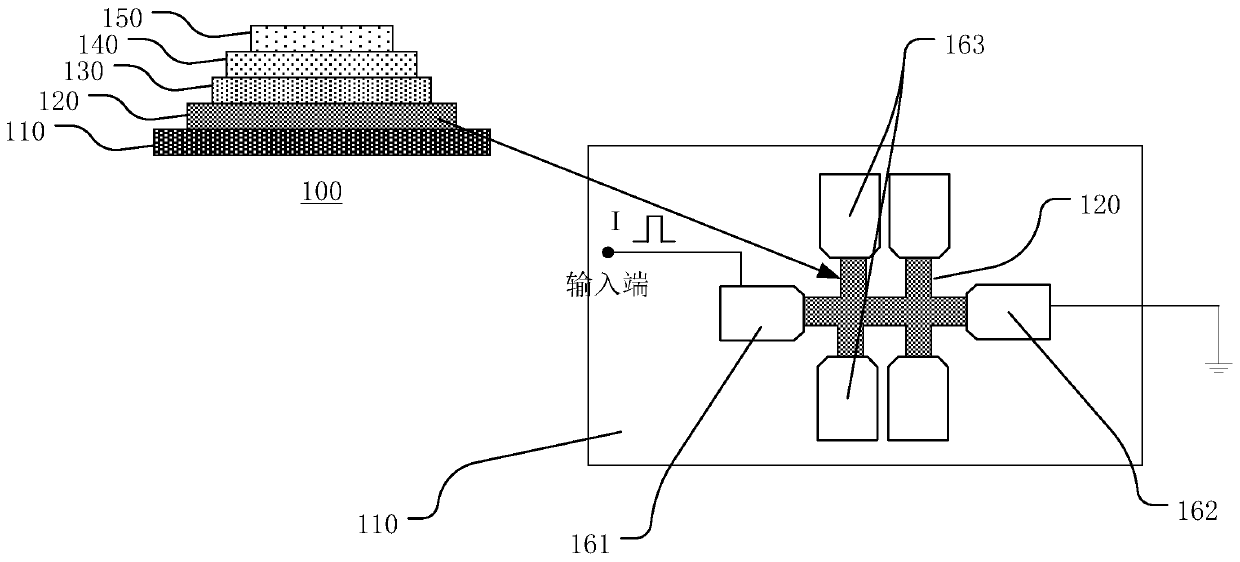

Logic device, logic assembly and manufacturing method of logic device

PendingCN110265479AAnti-extrusionHas a bendableSemiconductor/solid-state device manufacturingGalvano-magnetic device detailsOxidation stateOptoelectronics

The invention provides a logic device and a manufacturing method thereof. The logic device comprises a substrate, a heavy metal layer, a ferromagnetic layer, a multiferroic layer and an oxide layer, wherein the heavy metal layer comprises a cross structure of which the outer side is provided with a corresponding electrode; and the resistance of the heavy metal layer is changed by changing the direction of an electric field applied between the oxide layer and the heavy metal layer. Specifically, the substrate is a flexible substrate, and has the advantages of being resistant to extrusion, bendable and the like; and the control of the electric field on a critical current of spin-orbit coupling is realized at the room temperature through a multiferroic material, so that a spin-orbit coupling signal is effectively controlled. The effect of the logic device is changed by using different oxidation state interfaces (oxide layers), and the control of an input voltage on the critical current of the spin-orbit coupling makes a difference, so that an N-type or P-type logic operation function can be achieved; the light, portable and low-power logic device can be obtained; and logic devices can also be combined to obtain a logic assembly integrating N-type and P-type logic functions.

Owner:叶建国

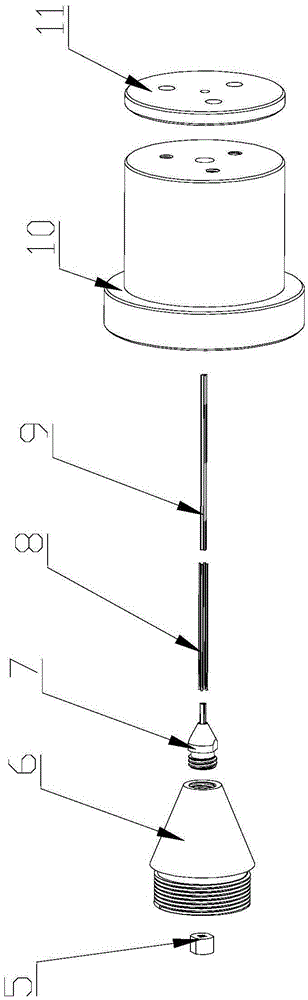

Cross-shaped drainage pipe and mold and machining method for forming drainage pipe once

The invention discloses a cross-shaped drainage pipe and a mold and machining method for forming the drainage pipe once. An open type cross-shaped groove type structural section is arranged on the tail section of the cross-shaped drainage pipe, so that the drainage pipe is not likely to be blocked by blood clots and blood buds, the extrusion resistance effect is achieved, and the drainage effect is good; when the drainage pipe is pulled out, the new blood bud tissue will be disengaged and drained along a channel, the drainage pipe can be easily pulled out, new muscle tissue damage is avoided, and no pain feeling is brought to patients. The middle closed type cross-shaped four-cavity structural section and the front circular pipe hollow structural section achieve the good drainage and liquid discharge effect. According to the mold for forming the drainage pipe once, the cross-shaped drainage pipe is formed once through difference combinations of a core rod, an outer loosing core and a cross-shaped inner loosing core. The machining processes are reduced, machining efficiency is improved and the cost is saved. The cross-shaped drainage pipe is applicable to the field of medical apparatuses and instruments.

Owner:GUANGZHOU CLEAN MEDICAL TECH CO LTD

Stainless steel sheath cable

InactiveCN105118558AAnti-extrusionFireproofInsulated cablesInsulated conductorsLow smoke zero halogenElectrical conductor

The invention discloses a stainless steel sheath cable, comprising a plurality of copper core conductors; the outer wall of each copper core conductor is covered by a mica insulating layer; outer walls of mica insulating layers are covered by an inner sheath layer; the inner sheath layer is covered by an oversheath layer; the inner wall of the oversheath layer is uniformly provided with a stainless steel sheath layer; the ratio between the thickness of the stainless steel sheath layer and the diameter of the cable is 1:8. The cable has reasonable structure design, employs stainless steel sheath materials, possesses the condition of being used under harsh environments, and has the characteristics of extrusion prevention and fire resistance; meanwhile the cable employs an oversheath of low smoke halogen-free polyolefin materials, and allows the surface of the cable to form a wearing resistant layer, thereby enhancing a cable wearing resistance property, guaranteeing cable use quality, and prolonging the service life of the cable.

Owner:ANHUI YIHE CABLE

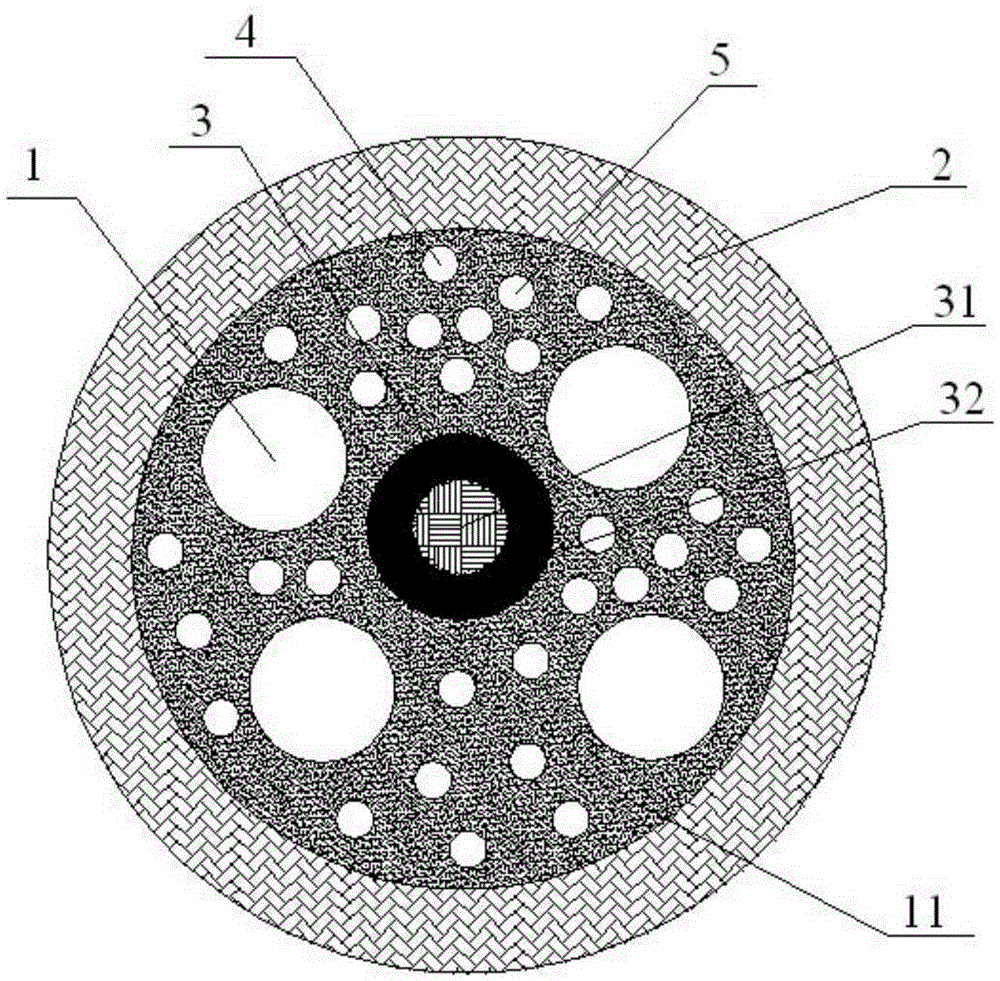

Safe composite high-pressure conveying cable

InactiveCN105387290AHigh pressure resistantAnti-extrusionInsulated cablesFibre mechanical structuresFiberHigh intensity

The invention relates to the field of cable preparation, in particular to a safe composite high-pressure conveying cable. The safe composite high-pressure conveying cable comprises a high-pressure conveying pipe and a woven sheath located outside the high-pressure conveying pipe, and further comprises a reinforcing cable, optical fibers and a cable, wherein the reinforcing cable, the optical fibers and the cable are located in the woven sheath; the reinforcing cable comprises a woven layer in the center and a high-strength plastic layer located outside the woven layer; flat and straight fibers are arranged among the reinforcing cable, the optical fibers and the cable and arranged around the optical fibers and the cable in parallel. The safe composite high-pressure conveying cable is unique in design, and the reinforcing cable is introduced into the composite high-pressure conveying cable, so that a conveying pipeline has the functions of resisting high pressure and squeezing and being not prone to deformation. The safe composite high-pressure conveying cable further has the advantages of being reasonable in design, novel in concept, simple in structure, economical, environmentally friendly, and capable of achieving industrial production easily, effectively overcoming the defects in the prior art and market products, and meeting the demand of the market.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

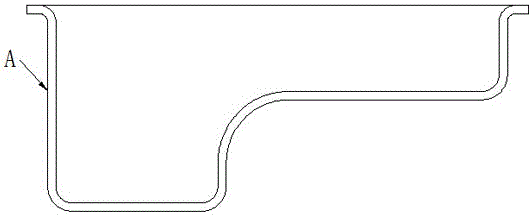

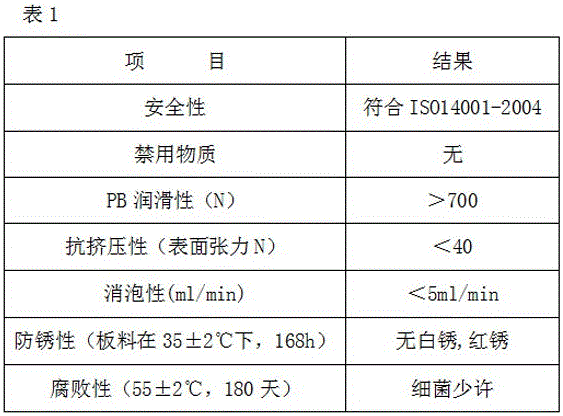

Anti-extrusion medium for hydraulic drawing forming of draft angle-free oil pan

InactiveCN106635327ASlight scratchesResolve frictionLubricant compositionCarboxylic saltCarboxylic acid

The invention provides an anti-extrusion medium for hydraulic drawing forming of a draft angle-free oil pan. The anti-extrusion medium is prepared from the following components in percentage by mass: 29 to 31 percent of mineral oil, 9 to 11 percent of carboxylate, 8 to 12 percent of boric acid or borate, 19 to 21 percent of alkyl alcohol amine, 9 to 11 percent of petroleum sodium sulfonate, 9 to 11 percent of propylene glycol ether, 8 to 10 percent of nonionic surfactant, 0.3 to 0.7 percent of defoamer and 0.3 to 0.7 percent of organosulfureous fungicide. The anti-extrusion medium is applied to a die cavity in hydraulic drawing forming of the draft angle-free oil pan to replace existing drawing oil, and drawing forming of the draft angle-free oil pan is realized in the same drawing die; the product yield reaches 98 percent, parts are slightly scratched, the defects that a cold stamping die rubs a material unevenly, and the thickness change of the material is uneven are overcome, limit cracking is avoided, and the size meets the drawing requirements.

Owner:湖北凸凹模具科技股份有限公司

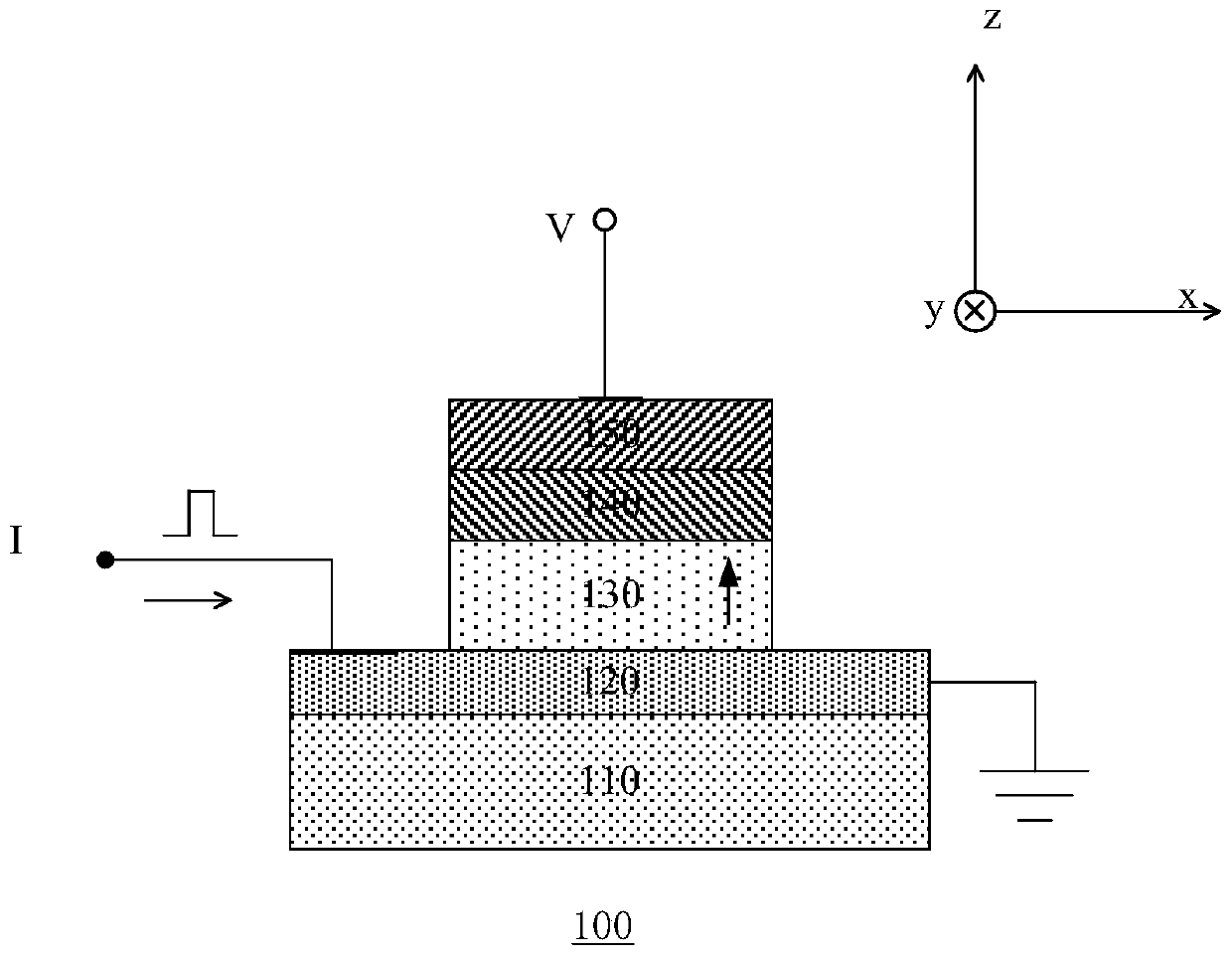

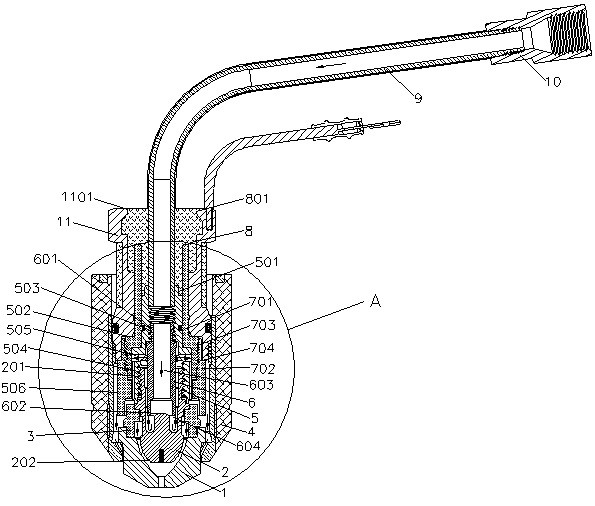

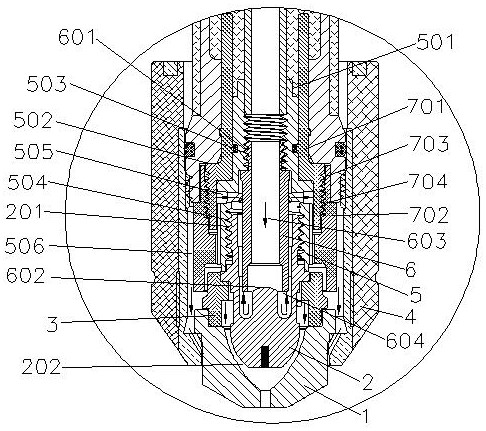

High-frequency plasma cutting gun

PendingCN111843144AAnti-extrusionWith characteristicsPlasma welding apparatusEngineeringPlasma cutting

The invention discloses a high-frequency plasma cutting gun. An injection molded body, an insulator, a diverter, a diversion tube, an electrode and a cutting nozzle are arranged inside a large inner diameter cylindrical structure of a gun head body, the injection molded body is matched with the large inner diameter cylindrical structure in a standstill locking mode, a diverter boss is inserted into the injection molded body, the diversion tube is installed in an inner cavity of the diverter, a diversion cavity is arranged inside the diversion tube, the electrode is arranged outside the diversion tube, an annular airflow gap is arranged between the electrode and the diversion tube, a first diversion channel is arranged on the diverter, the first diversion channel is communicated with the inner cavity of the diverter, a second diversion channel is arranged between the insulator and a protective cap, the cutting nozzle is connected to the bottom of the electrode, a vortex ring is arrangedbetween the cutting nozzle and the diverter, vortex holes are formed in the surface of the vortex ring, and a plasma arc gap is arranged between the electrode and the cutting nozzle. The high-frequency plasma cutting gun has the characteristics of anti-falling-out and anti-rotation, a gun head can be replaced, airflow fully flows back to the gun head everywhere in a surrounding mode, the high temperature of the gun head and consumables is effectively reduced, and the service life is prolonged.

Owner:无锡汉特机电有限公司

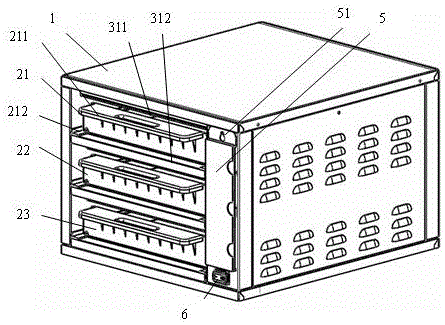

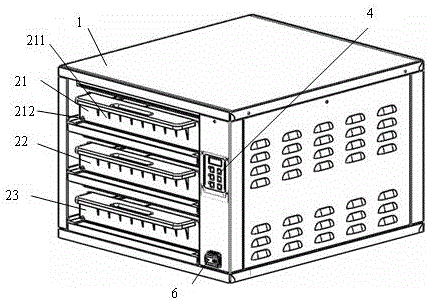

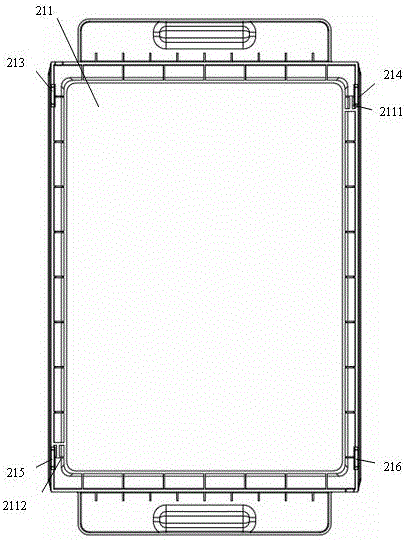

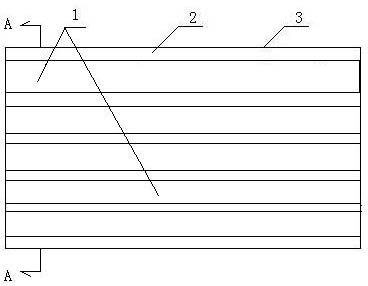

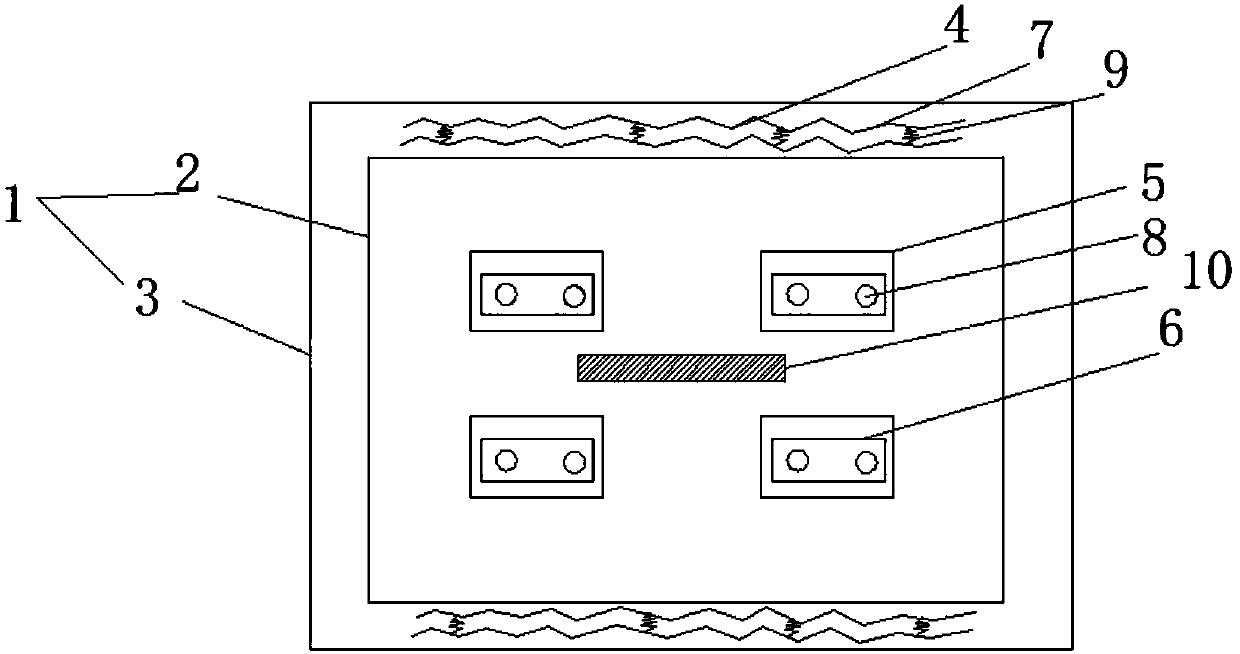

Food insulation cabinet

ActiveCN106214014APlay a thermal insulation effectAnti-extrusionCooking vesselsControl systemEngineering

The invention discloses a food insulation cabinet. The food insulation cabinet comprises a cabinet body, a plurality of tray structures, a plurality of infrared heaters, a control system, an operation panel, a paper card placing groove and a switch, wherein the front and rear sides of the cabinet body run through each other; the plurality of tray structures are arranged inside the cabinet body and comprise trays and tray supports; the trays are arranged on the tray supports; tray feet are respectively arranged at the four corners at the bottoms of the trays and four tray grooves are formed in the corresponding positions on the tray supports; two locating pillars are also arranged on each tray support; two tray block pieces are arranged at the bottom of each tray; the control system comprises a plurality of temperature probes; and each temperature probe is connected with each top heater or each bottom heater. The food insulation cabinet has the beneficial effects that the trays can break away from the bottom heaters when pulled out, thus avoiding friction between the trays and the heaters; and the trays can fall into the tray supports to come into contact with the bottom heaters when pushed back, thus better achieving the insulation effects; the tray supports can be bidirectionally pulled and have structures preventing the tray supports from coming off.

Owner:CORNELIUS TIANJIN CO LTD

Fresh medlar package box

InactiveCN102424209AHas ecological space requirementsRealize long-distance transportationLiving organism packagingClosuresEngineeringSpace requirements

The invention relates to a fresh medlar package box, which belongs to the field of package boxes and is provided with a box upper, wherein a box cover is covered on the box upper. The fresh medlar package box is characterized in that a box body is arranged in the box upper, a long groove is distributed on the box body, a sponge carrier is covered above the long groove, and vent holes are processed on the box cover. The fresh medlar package box has the advantages that the structure is simple, the ecological space requirements required after the fresh fruit picking are provided, the functions of corrosion prevention, fresh keeping, extrusion and pressing prevention, adhesion prevention, ventilation, shock prevention, transportation convenience and the like are realized, the long-distance transportation, storage and market sale of soft fresh fruits can be realized.

Owner:戴振东

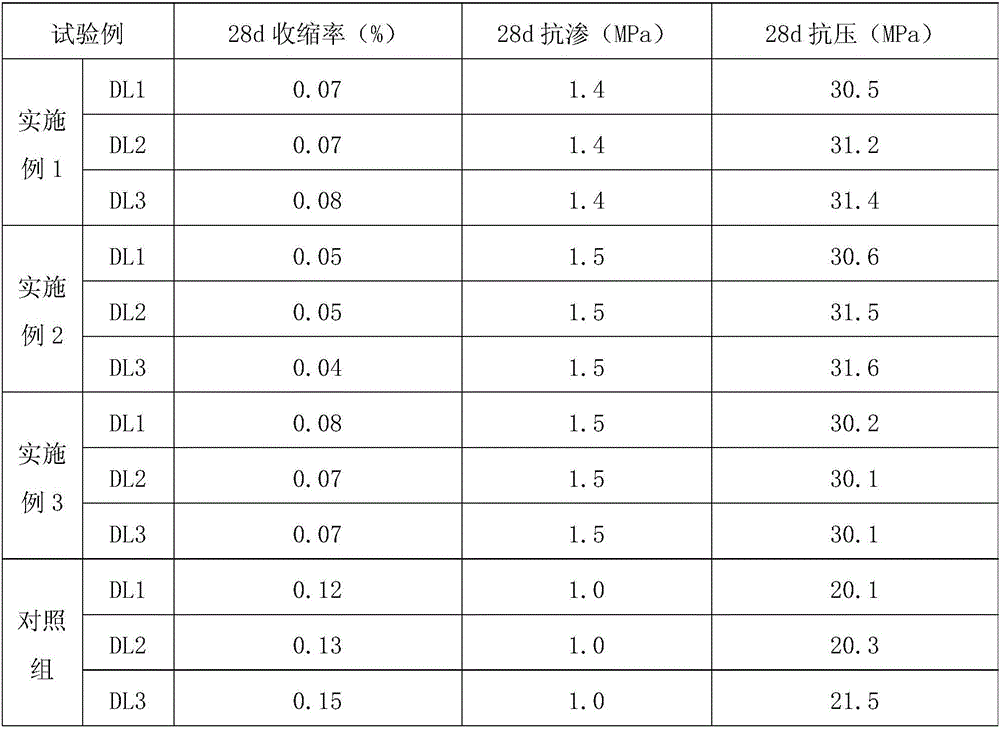

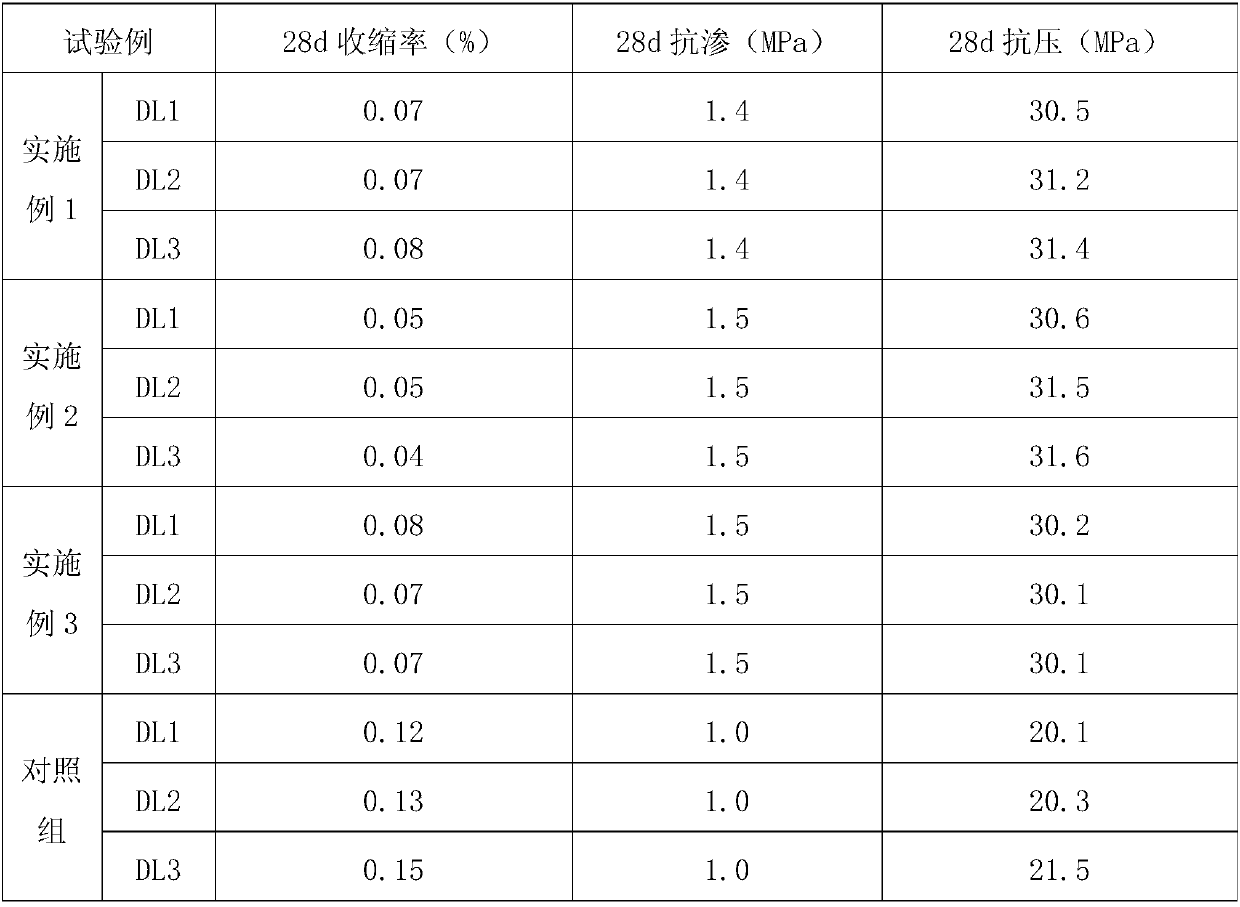

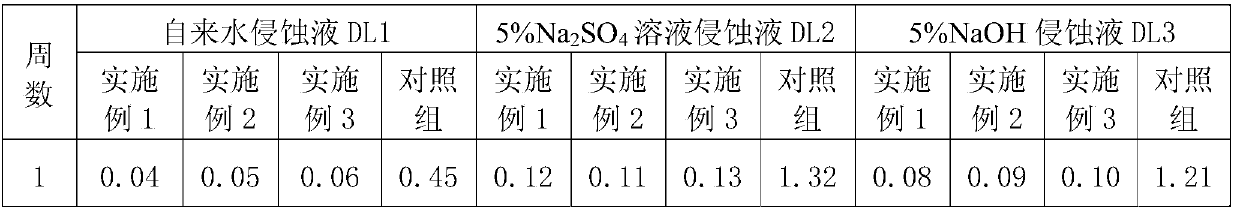

A high-efficiency corrosion-resistant ready-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

A method for manufacturing a roll-pressed non-asbestos composite board

ActiveCN105216420BAnti-stressAnti-extrusionLaminationLamination apparatusPolymer scienceThermal insulation

A method for manufacturing a roll-pressed non-asbestos composite board, relating to a composite board, comprising 9 steps, the main feature is to prepare a large material layer from toluene, nitrile rubber, 244 neoprene, mineral fiber and aramid fiber; Leather prepared from toluene, nitrile rubber, 244 neoprene, zinc oxide, stearic acid, 2‑mercaptobenzothiazole, N‑phenyl‑2‑naphthylamine, talc, light calcium and mineral fibers layer; and then use the rolling method to roll the five layers of large material layer, leather material layer, support layer, leather material layer and large material layer into a composite board. Compared with the prior art, the beneficial effect of the present invention is that the composite board manufactured by the method of the present invention has the performance of heat insulation, insulation and heat preservation not inferior to asbestos boards, and at the same time, compared with other thermal insulation boards, the composite board is also It has the characteristics of compression resistance, extrusion resistance, high elasticity and good resilience. It solves the problem that the performance of the existing asbestos substitute board heat insulation material is low, and the strength cannot reach the standard.

Owner:NINGBO HAISHAN CLORING SEALING PROD

A kind of bionic double-layer dressing and preparation method thereof

ActiveCN109481737BAchieve preparationImprove tensile propertiesPharmaceutical delivery mechanismTissue regenerationWound healingIntestinal submucosa

The invention provides a bionic double-layer dressing, which comprises a decellularized animal small intestinal submucosa and a gel layer cross-linked on the film layer, and the film layer and the gel layer together form a bionic double-layer dressing with a double-layer structure; The preparation steps include preparation of decellularized small intestinal submucosa, preparation of decellularized small intestinal submucosa powder, preparation of decellularized small intestinal submucosa solution and preparation of bionic double-layer dressing. To the surface of the submucosa of the decellularized small intestine, the bionic double-layer dressing was obtained after freezing and cross-linking. The bionic double-layer dressing prepared by the invention not only has excellent tensile properties, but also has a semi-permeable barrier, which can prevent water evaporation and bacterial penetration. At the same time, the bionic double-layer dressing prepared by the invention is beneficial to the healing of the wound, can significantly increase the healing speed of the wound, and the wound healing rate is obviously accelerated on the 3rd day and the 7th day after the operation.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

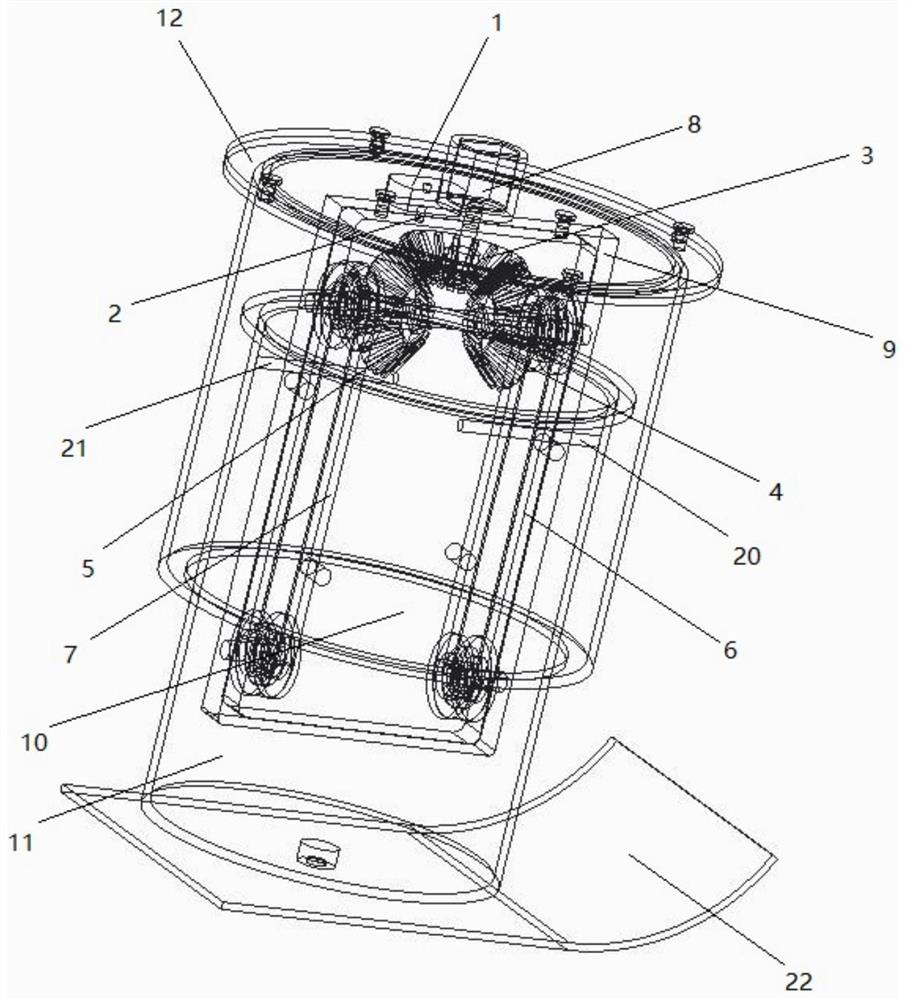

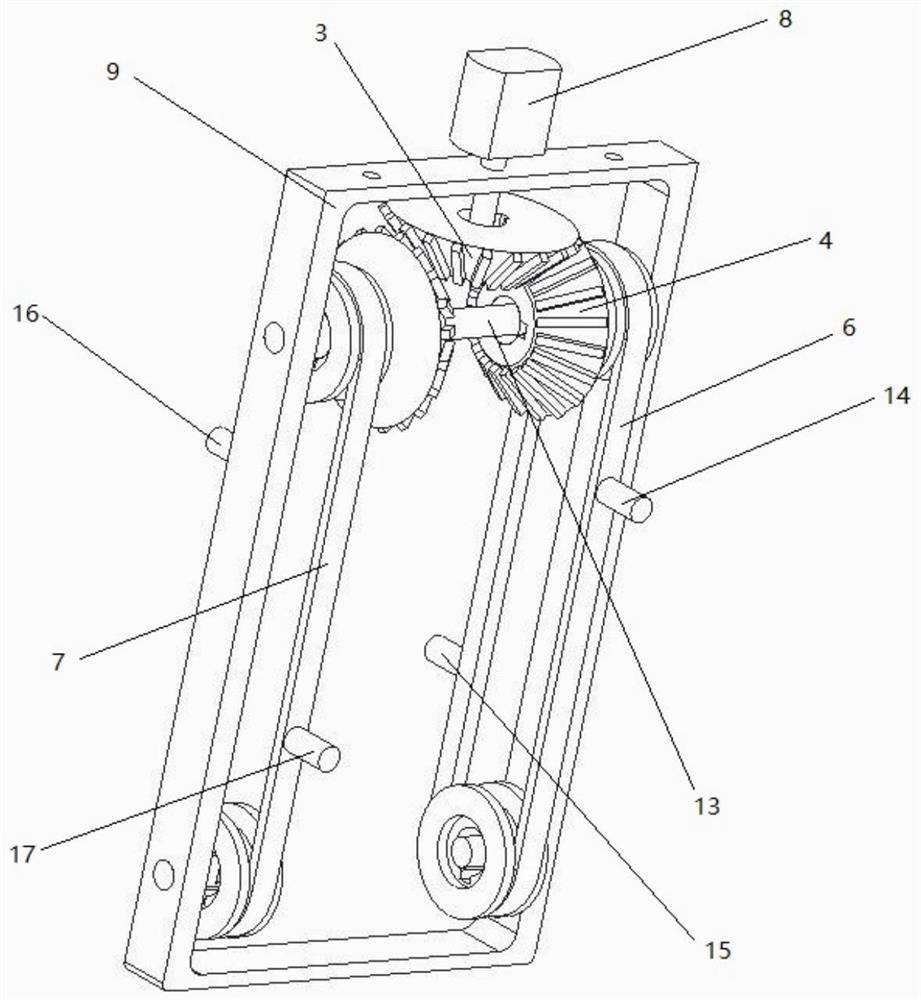

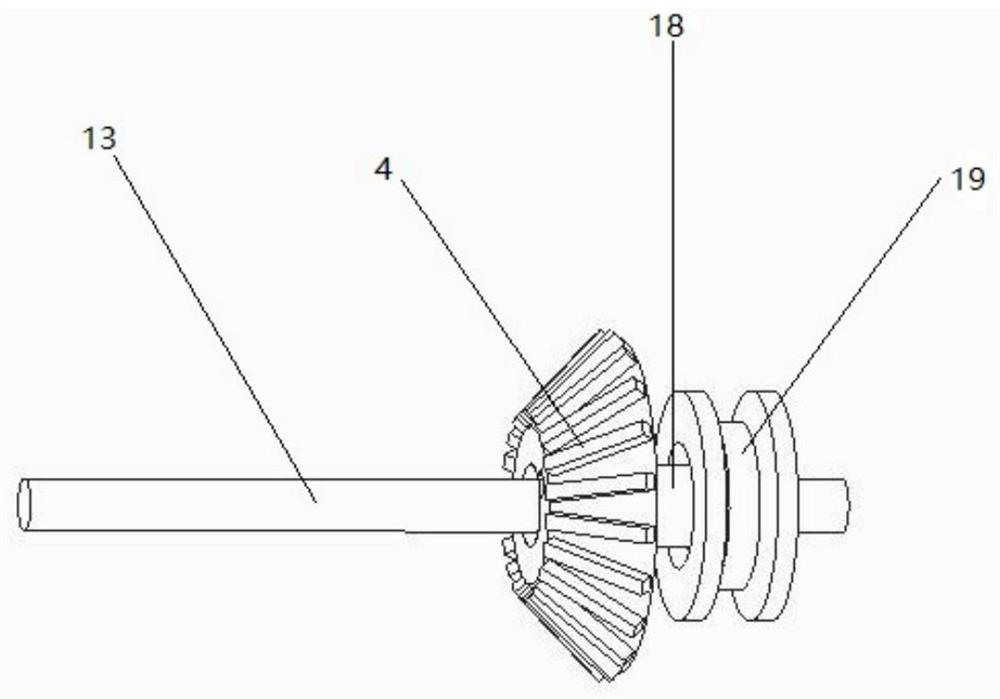

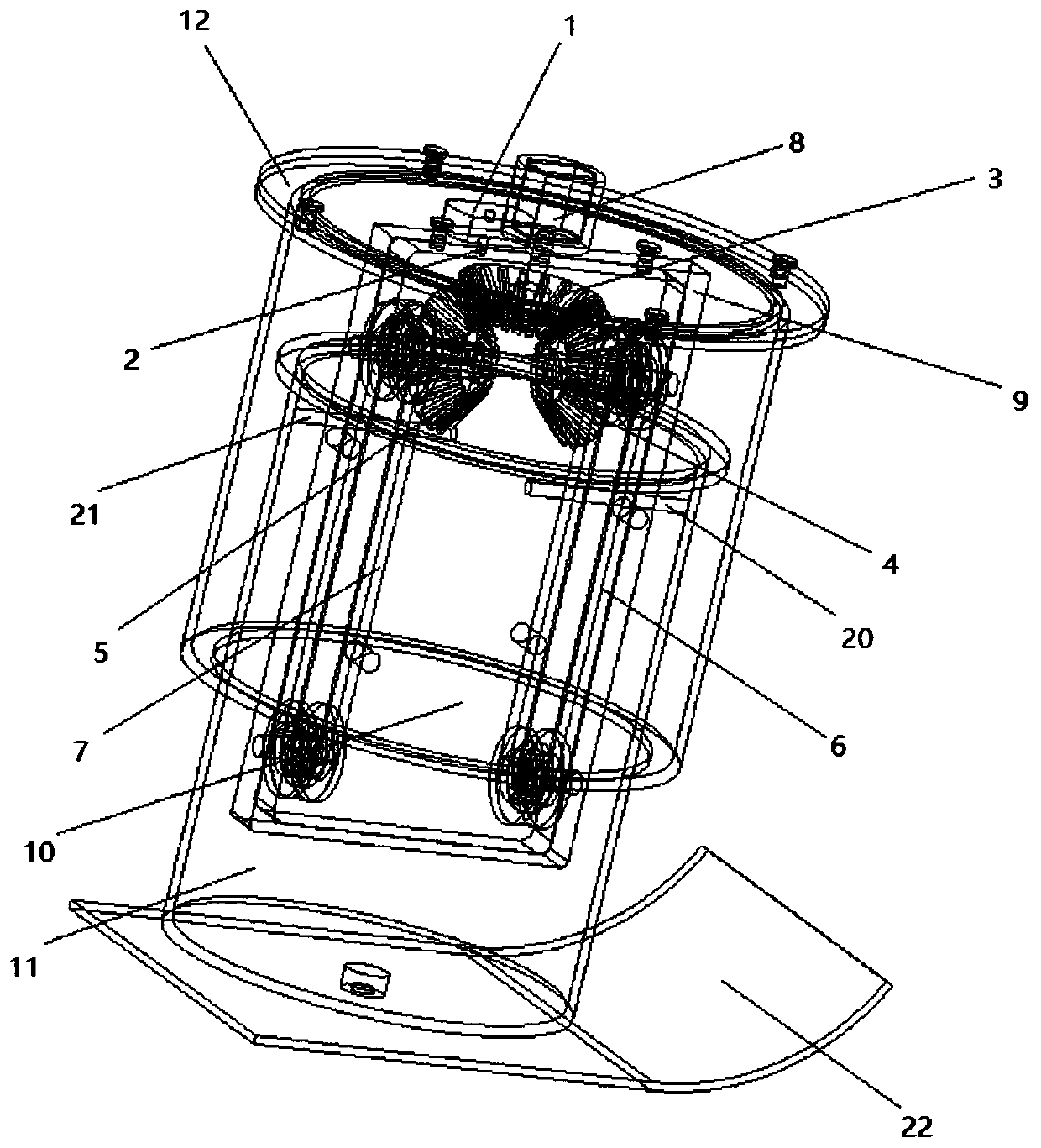

A Tea Ridge Depth Detection Device Based on Infrared Ranging

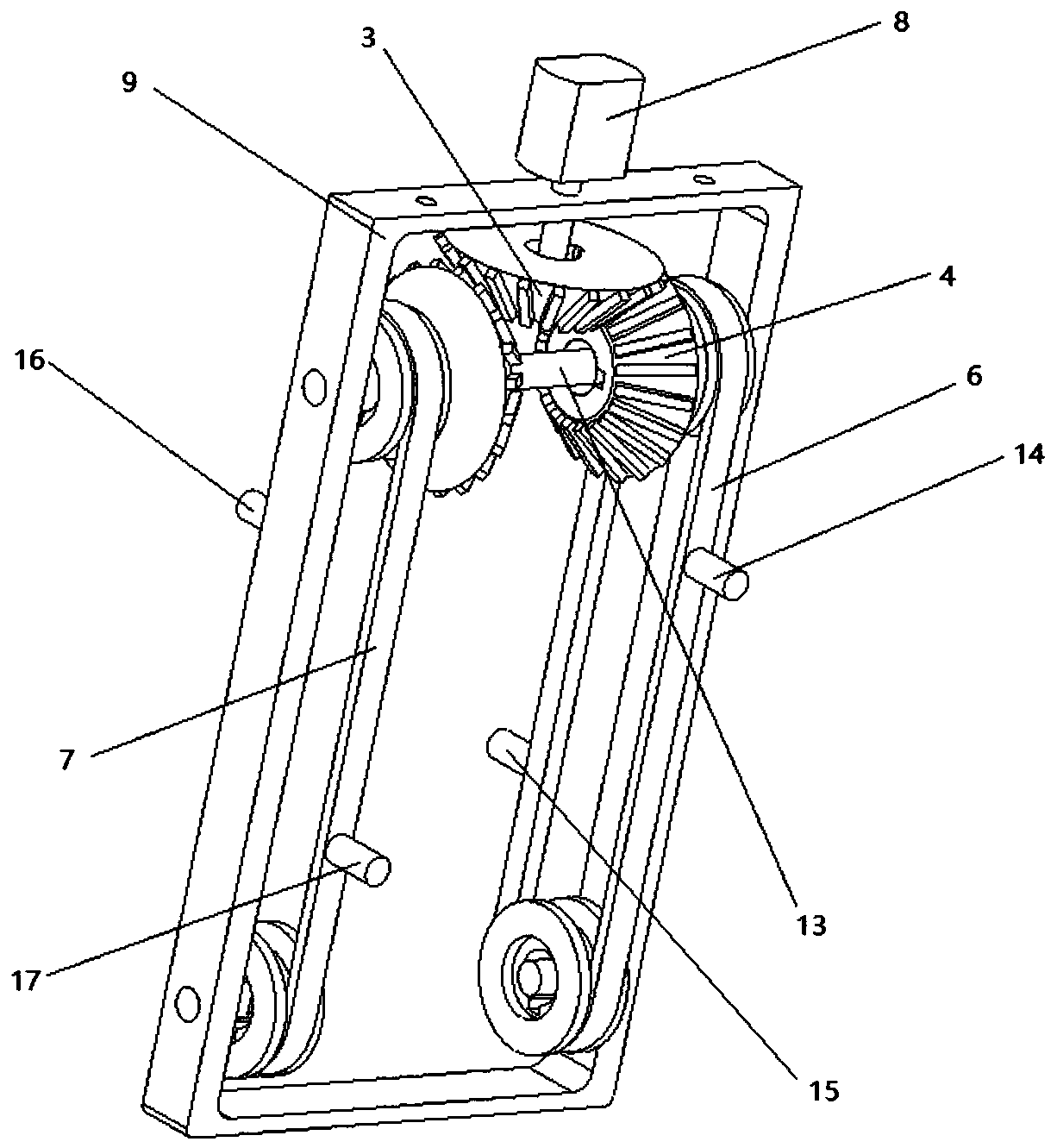

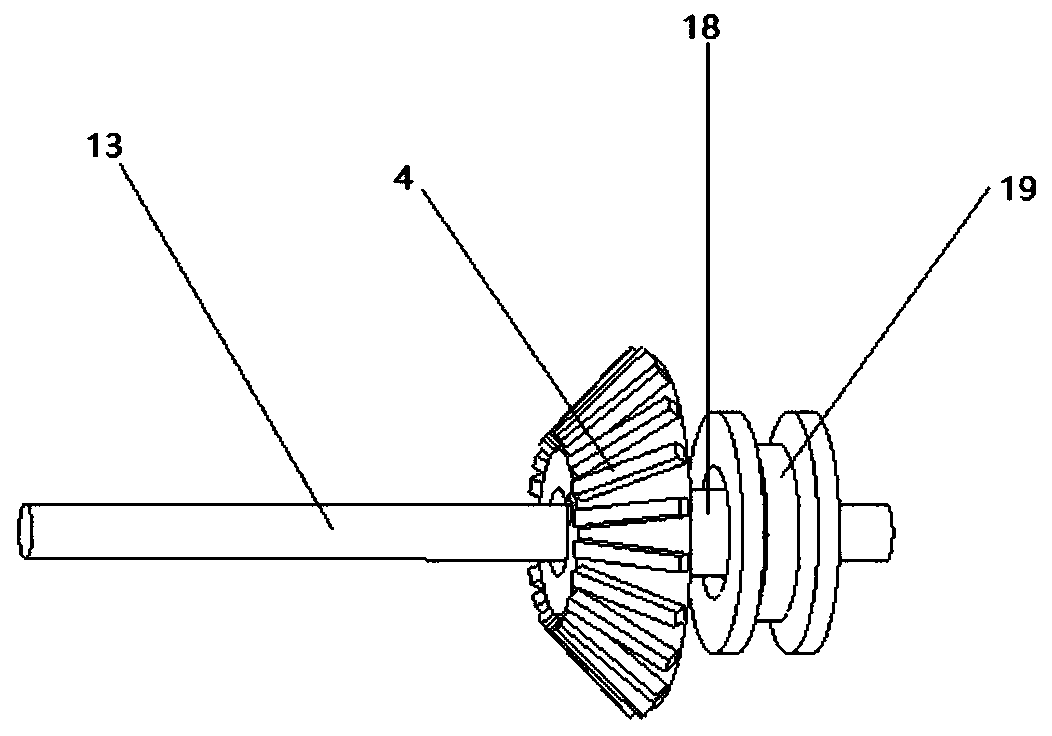

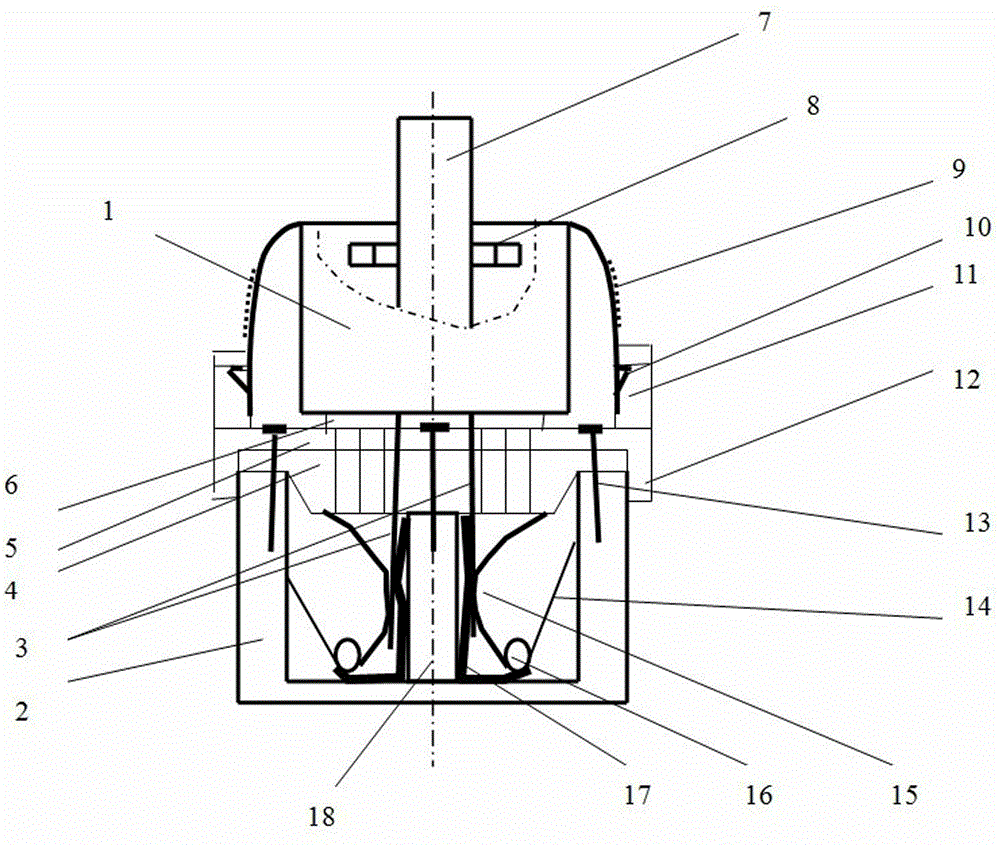

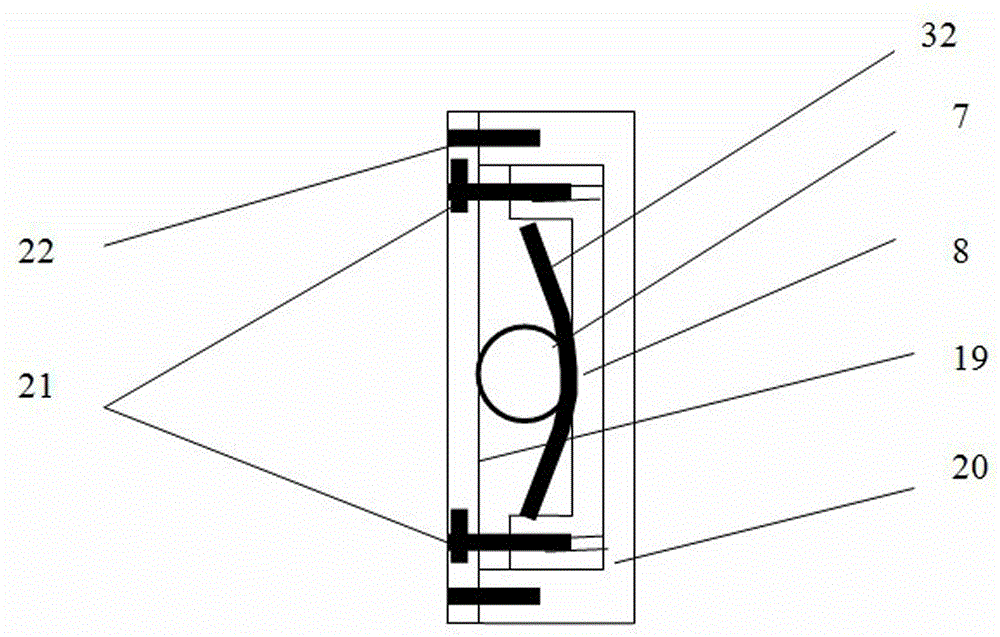

A tea ridge depth detecting device based on infrared range finding is formed by a microprocessor module, a range finding module, a transmission module and a shell module. The microprocessor module isformed by a stm32f103c8 microprocessor and a peripheral circuit. The range finding module selects an infrared range finding sensor GP2Y0A21. The transmission module is formed by a driving bevel gear,a 1# driven bevel gear, a 2# driven bevel gear, a 1# belt transmission device, a 2# belt transmission device, an LX371WG motor and a carrying frame. The shell module is formed by a steel top cover, anouter cylinder made of a polypropylene material, an inner cylinder, and a contact piece. Left and right sides of an inner wall of a cylinder, which are close to a top end, are symmetrically and fixedly connected to a steel 1# lifting rod and a 2# lifting rod through a screw thread. The microprocessor module is fixed on an inner surface of the top cover in the shell module and is used for drivingthe LX371WG motor in the transmission module. The range finding module is placed directly under the microprocessor module and is directly connected to the microprocessor module. The device has characteristics of accurate and rapid range finding, and high stability.

Owner:SICHUAN AGRI UNIV

Tea ridge depth detecting device based on infrared range finding

A tea ridge depth detecting device based on infrared range finding is formed by a microprocessor module, a range finding module, a transmission module and a shell module. The microprocessor module isformed by a stm32f103c8 microprocessor and a peripheral circuit. The range finding module selects an infrared range finding sensor GP2Y0A21. The transmission module is formed by a driving bevel gear,a 1# driven bevel gear, a 2# driven bevel gear, a 1# belt transmission device, a 2# belt transmission device, an LX371WG motor and a carrying frame. The shell module is formed by a steel top cover, anouter cylinder made of a polypropylene material, an inner cylinder, and a contact piece. Left and right sides of an inner wall of a cylinder, which are close to a top end, are symmetrically and fixedly connected to a steel 1# lifting rod and a 2# lifting rod through a screw thread. The microprocessor module is fixed on an inner surface of the top cover in the shell module and is used for drivingthe LX371WG motor in the transmission module. The range finding module is placed directly under the microprocessor module and is directly connected to the microprocessor module. The device has characteristics of accurate and rapid range finding, and high stability.

Owner:SICHUAN AGRI UNIV

Safe and steady power plug-socket system

InactiveCN103236610BAvoid disadvantagesSimple structureRelieving strain on wire connectionCouplings bases/casesEngineeringRubber sheet

The invention relates to a safe and steady power plug-socket system. Clutch spring plates are arranged on two sides of a plug. Rubber sheets are fastened around plug inserts. A clutch holder is disposed on the socket. Clutch spring plate retainers which are used with the clutch spring plates of the plug and can be fastened and loosened are disposed on two sides of the clutch holder. The clutch holder is provided with a partition covering the socket. The rubber sheets are arranged below the partition. Both the partition and the rubber sheets are provided with jacks corresponding to socket clips. The socket clips and a socket fixing plate are pressed by the rubber sheets. Fixed plates of the socket clips on two sides of the socket fixing plate are both abutted to the socket fixing plate. Moving plates of the socket clips are abutted to the fixed plates of the socket clips through an arm of force of a torsion spring, and the other arm of force of the torsion spring is abutted to the side wall of the socket. The safe and steady power plug-socket system is waterproof and damp-proof, free of plug-socket loosening, and ensures the fixed plates and moving plates of the clips to tightly contact with the inserted plug inserts.

Owner:齐国成

Extrusion-resistant wash bag

The invention discloses an extrusion-resistant wash bag. The extrusion-resistant wash bag comprises a main body, wherein the main body comprises an inner layer and an outer layer; an elastic device isarranged between the inner layer and the outer layer; multiple cavities are uniformly arranged at the inner part of the inner layer; sponge bodies are arranged at the inner parts of the cavities. According to the extrusion-resistant wash bag disclosed by the invention, the technical problem of poor extrusion resistance of a wash bag in the prior art is solved.

Owner:扬州市杭集创意设计园有限公司

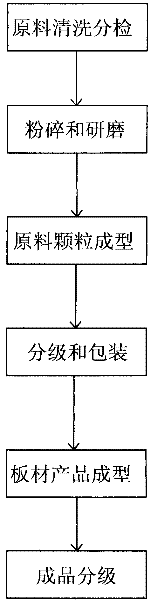

Silicon-plastic composite cylindrical particles prepared from power plant waste and method for preparing plastic plate thereof

InactiveCN101817987BReduce or eliminate the occurrence ofReasonable workmanshipPlastic recyclingPrillCoal

The invention discloses silicon-plastic composite cylindrical particles prepared by using power plant waste, such as coal ash, waste plastics, calcium carbonate and the like, as raw materials through a plastic extruder, wherein the silicon-plastic composite cylindrical particles are prepared from the following raw materials in percentage by weight: 50%-60% of waste plastics, 30%-40% of coal ash and 5%-15% of calcium carbonate. A method for preparing a plastic plate of the silicon-plastic composite cylindrical particles comprises the steps of: (1) crushing and grinding the raw materials; (2) forming particles; (3) classifying and packaging cylindrical particles; and (4) forming a plate product. By using the method, the process is reasonable and simple, the process flow is shortened greatly, the production cost is reduced, high yield is achieved, the surfaces of the particles are smooth, coal ash is reduced or avoided in the processes of charging and blending in production, and no secondary pollution is caused in the production process. The product has the advantages of no toxicity, no smell, ageing resistance, less environmental pollution, ecological balance friendliness, shock resistance, crushing resistance and high strength, and can be used as templates, green belt cover plates, and the like.

Owner:吉林市大成广盛塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com