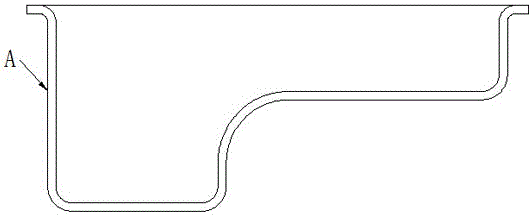

Anti-extrusion medium for hydraulic drawing forming of draft angle-free oil pan

A technology of oil pan and draft angle, applied in the petroleum industry, lubricating composition, etc., can solve the problems of uneven material thickness, cracking, wrinkling, etc., achieve the effect of slight abrasion and solve friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

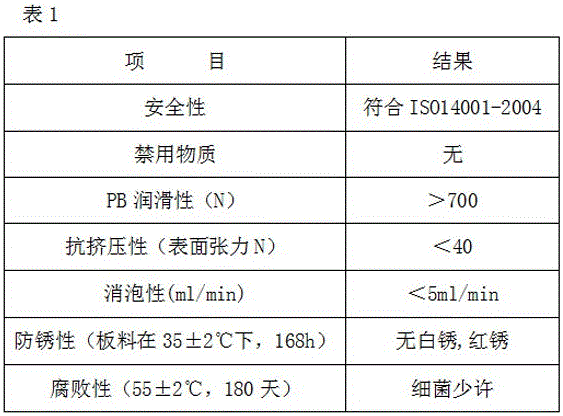

Examples

Embodiment 1

[0013] Anti-extrusion medium for hydrodrawing of oil sumps without draft angle, consisting of the following components by mass percentage: 30% mineral oil, 10% carboxylate, 10% boric acid or borate , 20% alkanolamine, 9% sodium petroleum sulfonate, 11% propylene glycol ether, 9% nonionic surfactant, 0.5% defoamer, 0.5% organic sulfur fungicide; The components are mixed uniformly to obtain the finished product.

Embodiment 2

[0015] Anti-extrusion medium for hydrodrawing of oil sumps without draft angles, consisting of the following components, by mass percentage: 31% mineral oil, 9% carboxylate, 8% boric acid or borate , 21% alkanolamine, 11% sodium petroleum sulfonate, 9% propylene glycol ether, 10% nonionic surfactant, 0.7% defoamer, 0.3% organic sulfur fungicide; The components are mixed uniformly to obtain the finished product.

Embodiment 3

[0017] Anti-extrusion medium for hydraulic drawing of oil sumps without draft angle, consisting of the following components, by mass percentage: 29% mineral oil, 11% carboxylate, 9% boric acid or borate , 19% alkanolamine, 9% sodium petroleum sulfonate, 11% propylene glycol ether, 11% nonionic surfactant, 0.3% defoamer, 0.7% organic sulfur fungicide; The components are mixed uniformly to obtain the finished product.

[0018] In the present invention, the carboxylate is selected from one of formate, acetate or oxalate; the sodium or potassium salt of formic acid, the sodium or potassium salt of acetic acid, the sodium of oxalate salt or potassium salt.

[0019] In the present invention, the borate is selected from one of sodium borohydride and ammonium hydrogen borate.

[0020] In the present invention, when boric acid or borate is selected, boric acid is preferred.

[0021] In the present invention, the alkanolamine is selected from one of N,N-diethylethanolamine, N,N-dimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com