Safe and steady power plug-socket system

A power plug and socket system technology, applied in the direction of circuits, electrical components, bases/housings, etc., can solve problems such as poor contact of flat plugs, loose plugs and sockets, lack of versatility of sockets, etc., to prevent rust and corrosion Short circuit, good electrical contact, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

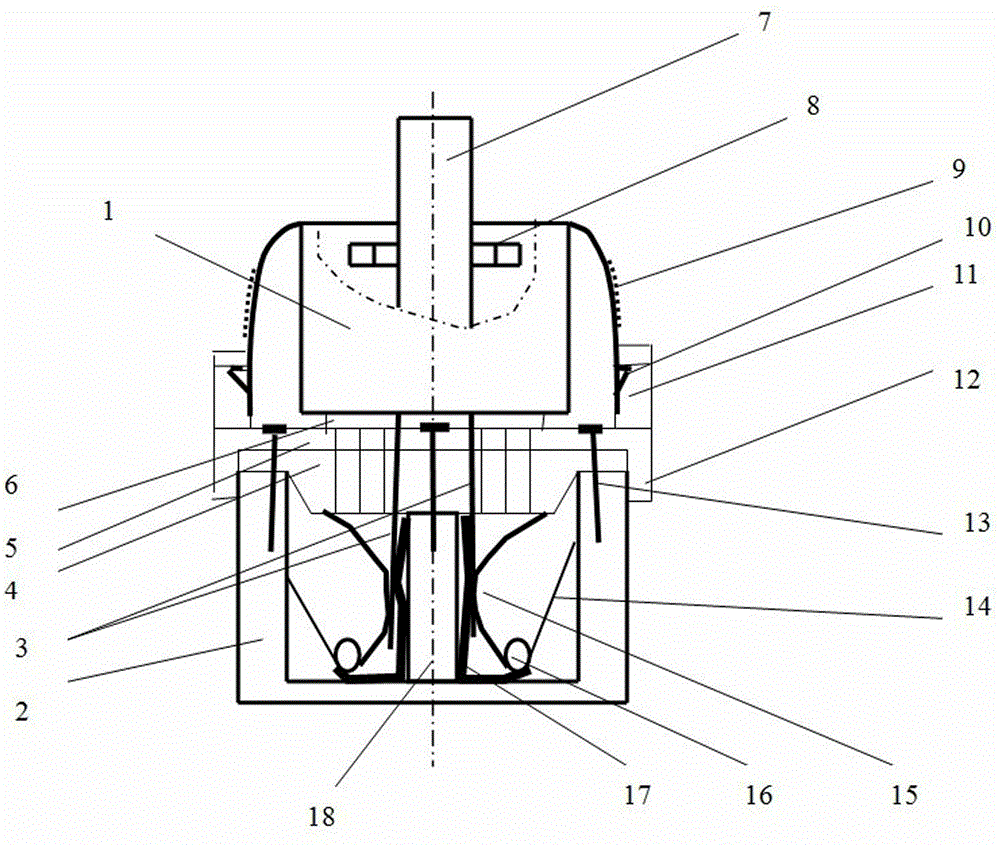

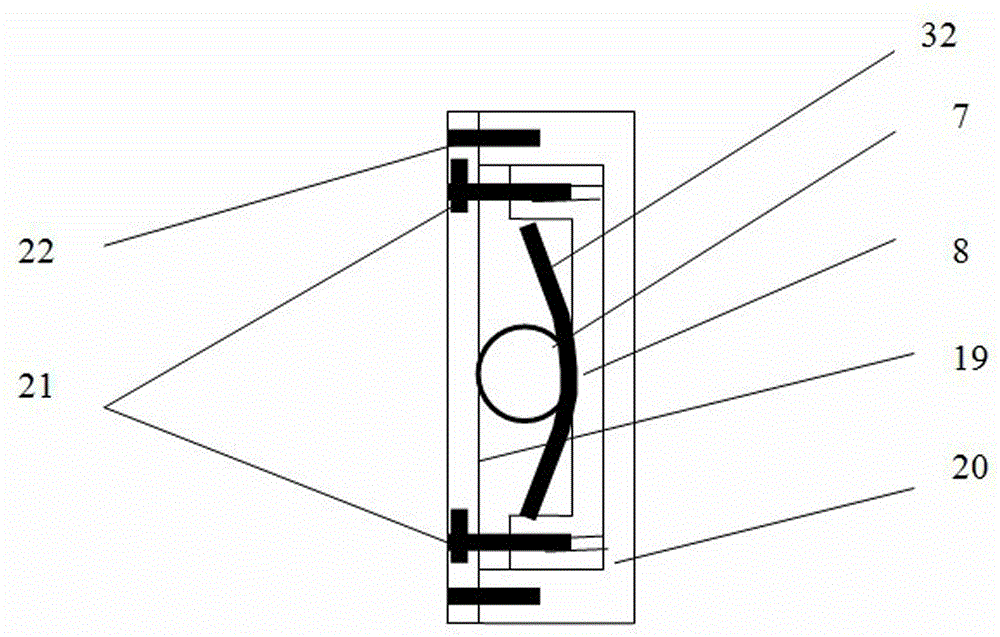

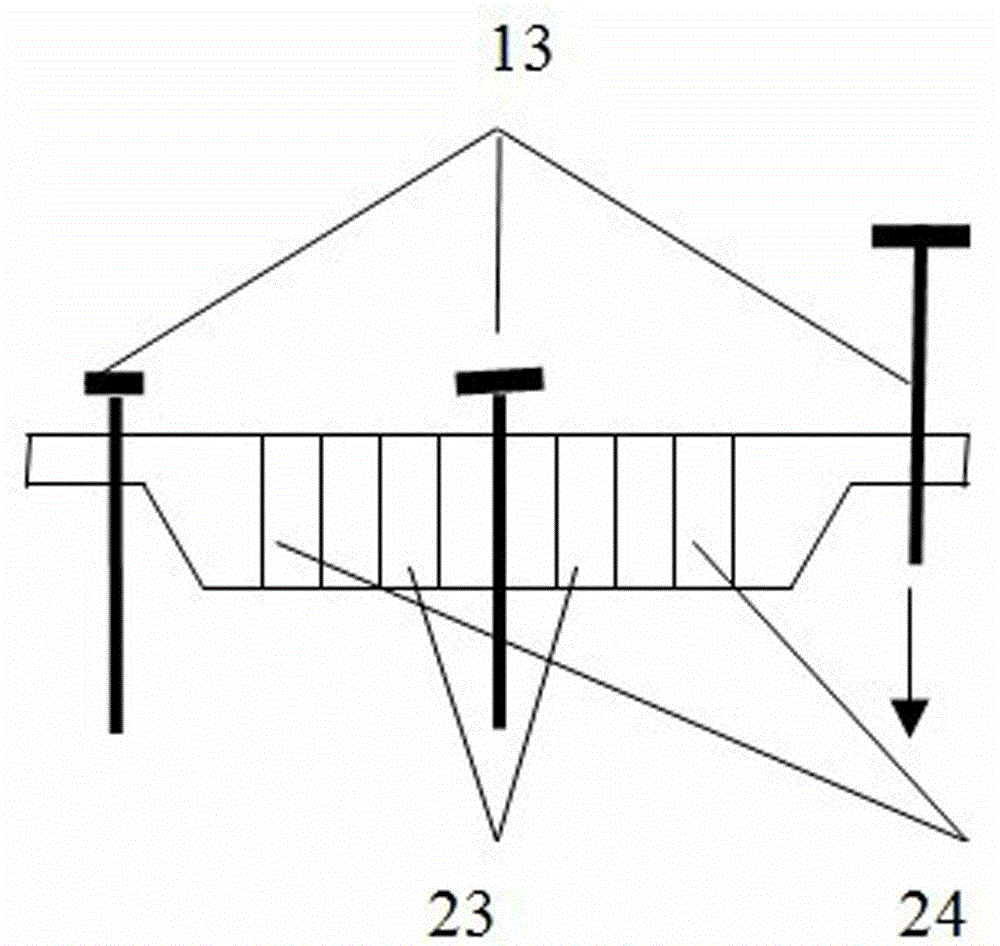

[0023] The corresponding relationship between the parts and components represented by the numbers in the attached drawings is as follows:

[0024] 1-plug, 2-socket, 3-insert, 4-socket rubber sheet, 5-partition, 6-plug rubber sheet, 7-wire, 8-slider, 9-clutch shrapnel, 10-clutch shrapnel protruding Part, 11-clutch holder side hole, 12-clutch holder, 13-socket screw, 14-torsion spring, 15-clip movable piece, 16-torsion spring torsion shaft hole, 17-clip fixed piece, 18- Socket fixing plate, 19-plug cover, 20-plug box, 21-clamping screw, 22-cover screw, 23-socket rubber sheet flat hole, 24-socket rubber sheet flat hole, 25-torsion spring arm, 26 -rotating shaft head, 27-rotating shaft, 28-clip fixed piece gap, 29-clamp fixed piece crimping, 30-clip movable piece gap, 31-clip movable piece crimping, 32 slide rubber sheet.

[0025] See figure 1 .

[0026] The two sides of the plug 1 are provided with elastic clutch shrapnel 9 with a bottom hooking device, the plug rubber sheet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com