A Tea Ridge Depth Detection Device Based on Infrared Ranging

A technology of infrared distance measurement and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as laborious use, reduced tea quality, difficult algorithm processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

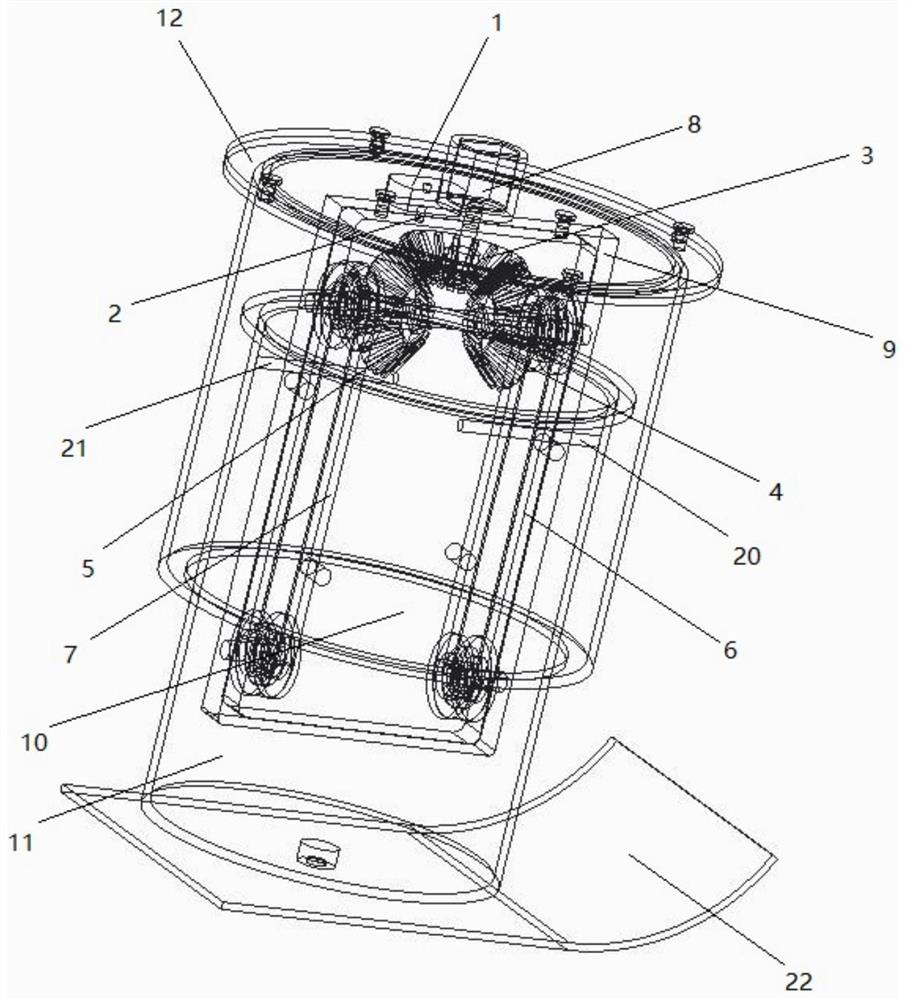

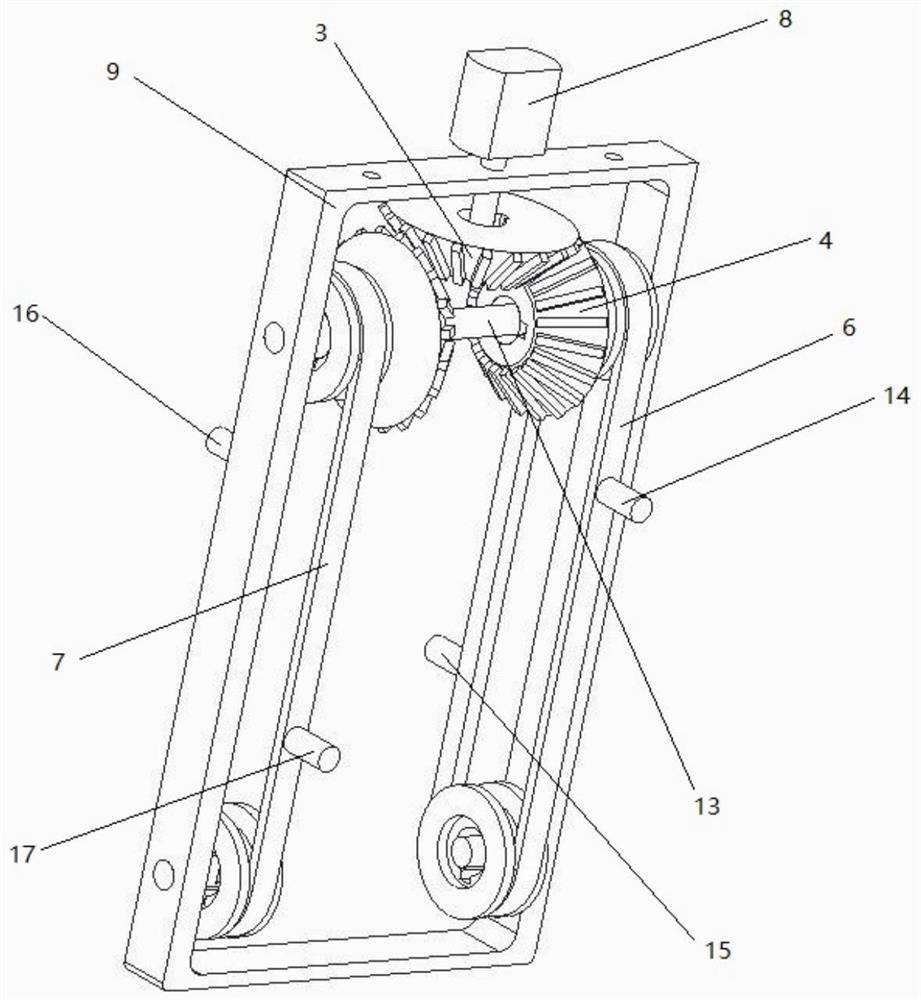

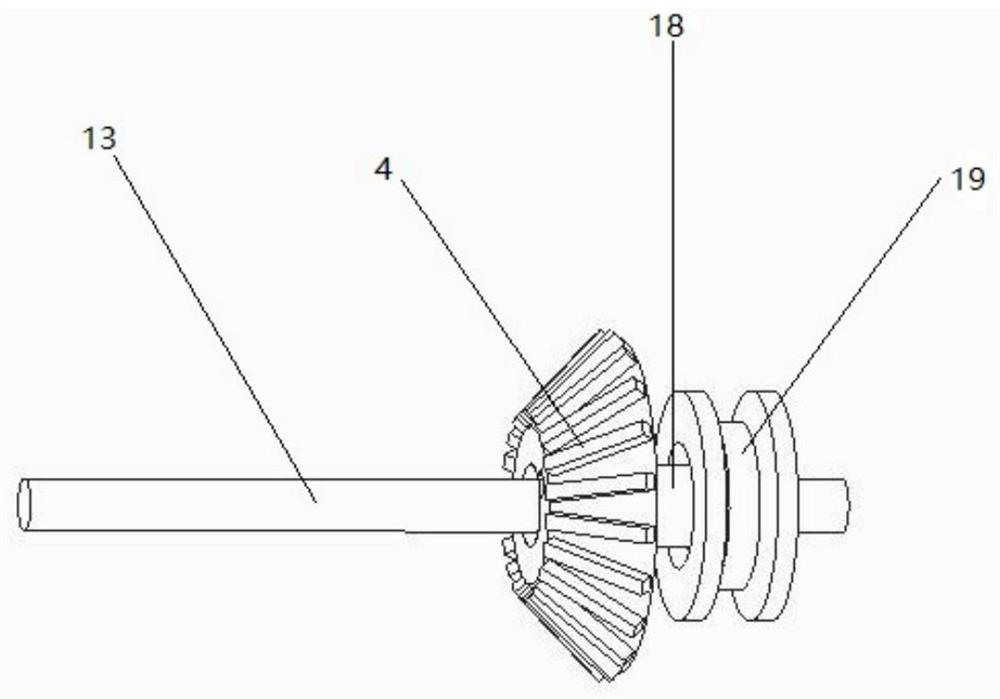

[0015] refer to figure 1 , a tea ridge depth detection device based on infrared distance measurement is composed of a microprocessor module 1, a distance measurement module 2, a transmission module and a housing module; the microprocessor module 1 is composed of a stm32f103c8 microprocessor and its peripheral circuits The distance measuring module 2 selects the infrared distance measuring sensor GP2Y0A21; the transmission module is composed of the active bevel gear 3, 1# driven bevel gear 4, 2# driven bevel gear 5, 1# belt transmission device 6, 2# belt The transmission device 7, the LX371WG motor 8 and the carrying frame 9 are composed; the shell module is composed of a steel top cover 12, an outer cylinder 10 made of polypropylene material, an inner cylinder 11 and a contact piece 22, and the inner wall of the inner cylinder 11 is close to The left and right sides of the top are symmetrically fixed with steel 1# lifting rod 20 and 2# lifting rod 21 through threads; the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com