Safe composite high-pressure conveying cable

A technology of high-pressure transmission and high-pressure transmission pipes, which is applied in the direction of cables, insulated cables, rigid pipes, etc., can solve the problems of low safety factor, easy damage, flattening of air transmission pipes, etc. The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

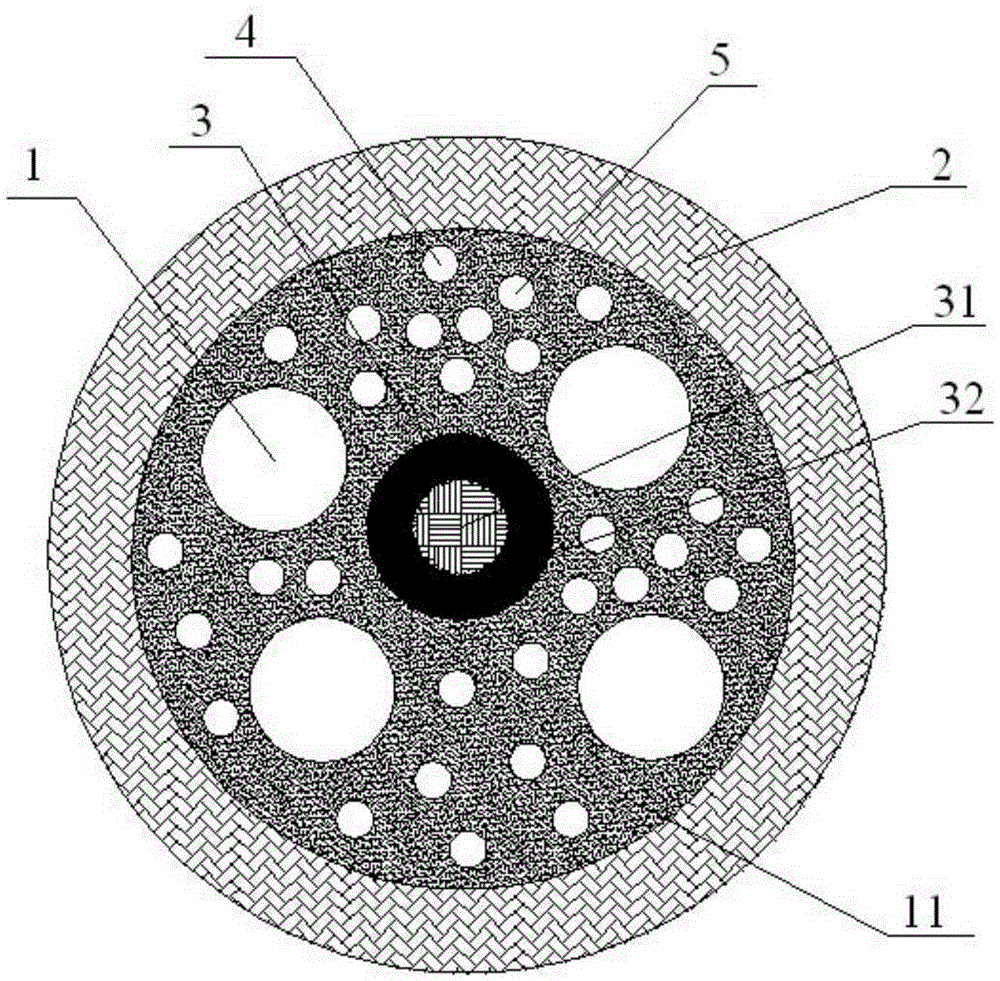

[0015] The technical solution adopted by the present invention to achieve the above purpose is: a safe composite high-voltage transmission cable, including a high-pressure transmission pipe 1 and a braided sheath 2 located outside the high-pressure transmission pipe. In order to ensure that the delivery pipeline 1 has the functions of anti-high pressure, anti-extrusion and not easily deformed. The present invention also includes a reinforcing cable 3, an optical fiber 4, and a cable 5, the reinforcing cable 3, the optical fiber 4, and the cable 5 are located in the braided sheath 2, and the reinforcing cable 3 includes a central braiding layer 31 and a braiding layer outside the braiding layer 31. The high-strength plastic layer 32, the braided layer 31 is made of polyester or aramid, which ensures the strength and elasticity of the reinforcing cable 3. Straight fibers 11 are arranged between the reinforcing cables 3 , the optical fibers 4 and the cables 5 , and the straight f...

Embodiment 2

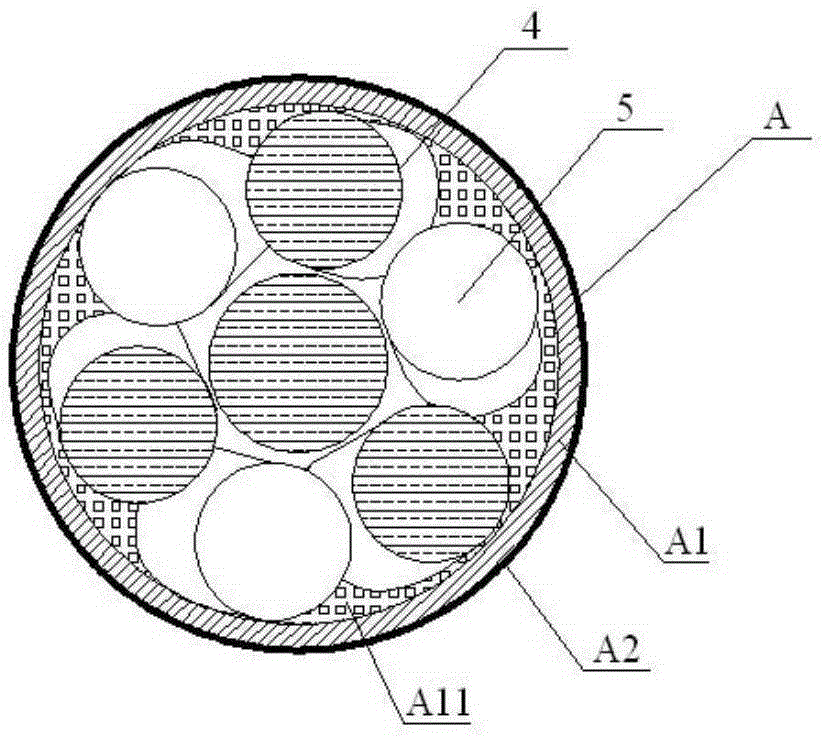

[0018] The difference from the first embodiment is that the optical fiber 4 and the cable 5 are twisted as a whole to form a convoluted structure A, and a reinforcing layer A1 is arranged outside the convoluted structure A, and the gap between the reinforcing layer A1 and the convoluted structure A The gaps are filled with functional fibers A11, and an insulating protective layer A2 is arranged outside the reinforcing layer A1. The use of the convoluted structure A above makes the present invention more extensible, coupled with the high strength of the reinforcing cable, so that the conveying pipeline has the functions of high pressure resistance, extrusion resistance and not easy deformation.

[0019] The invention is easy to realize industrialized production, effectively makes up for the defects of the prior art and commercially available products, and satisfies market demands. The invention is unique in design, simple in design and has broad market economic prospect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com