Patents

Literature

44results about How to "High pressure resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

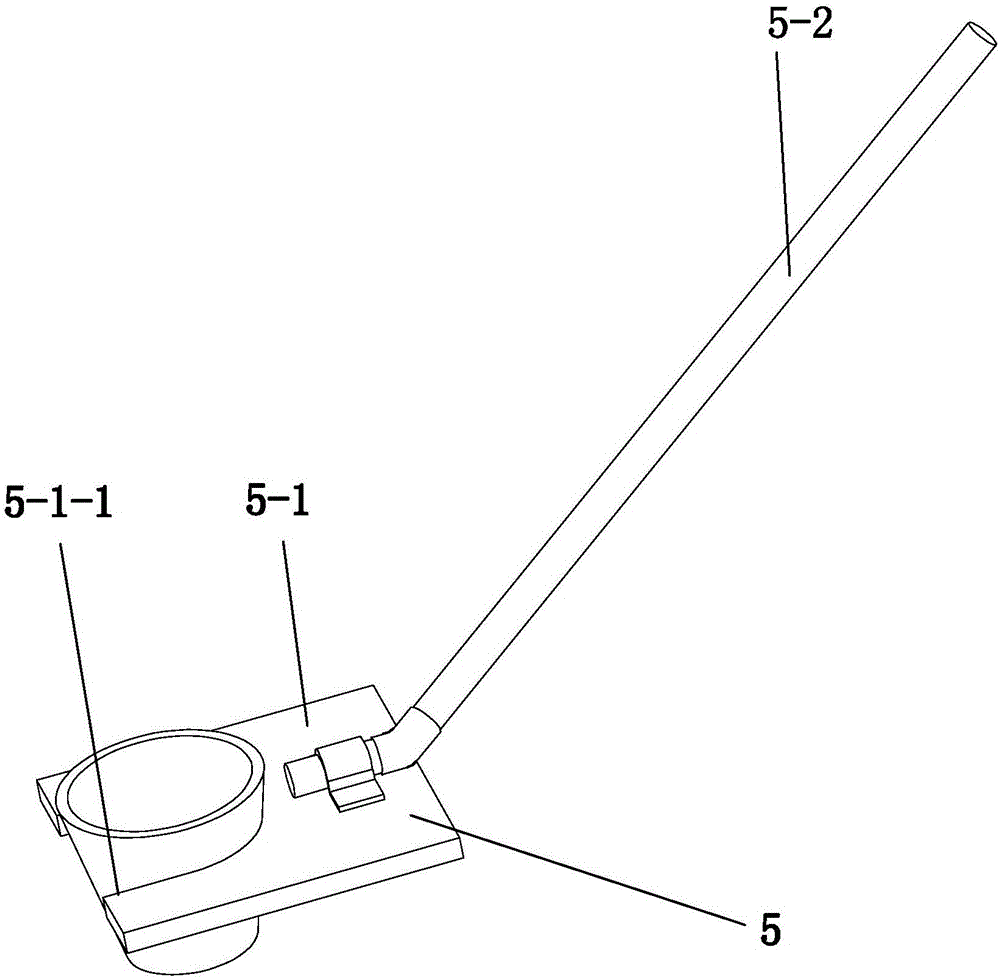

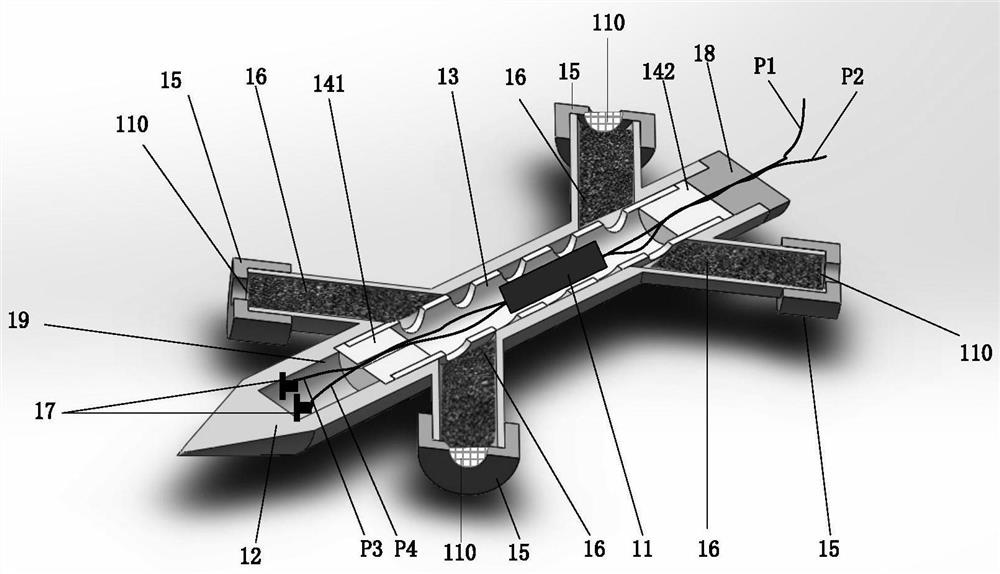

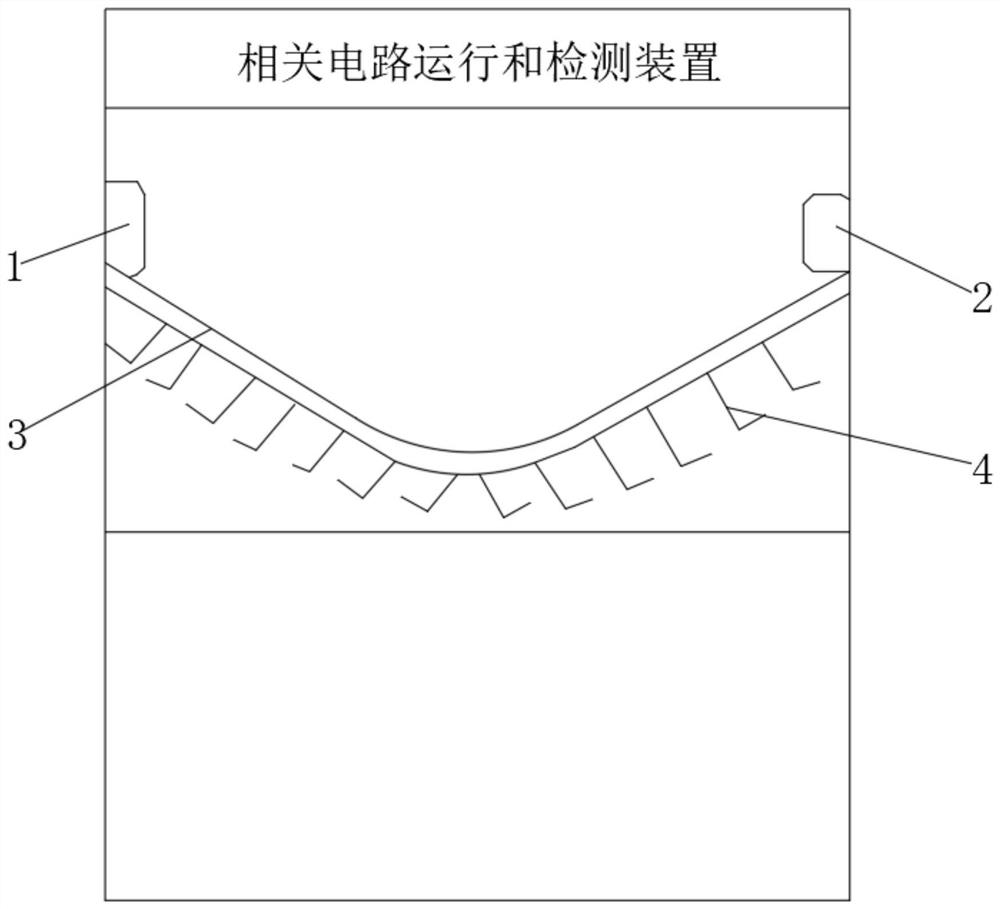

Device for measuring in-situ flow rate change of marine cold seep gas seepage

InactiveCN102012246AWide range of measured fluid velocityHigh pressure resistantStationary measuring chambersOcean bottomMeasurement device

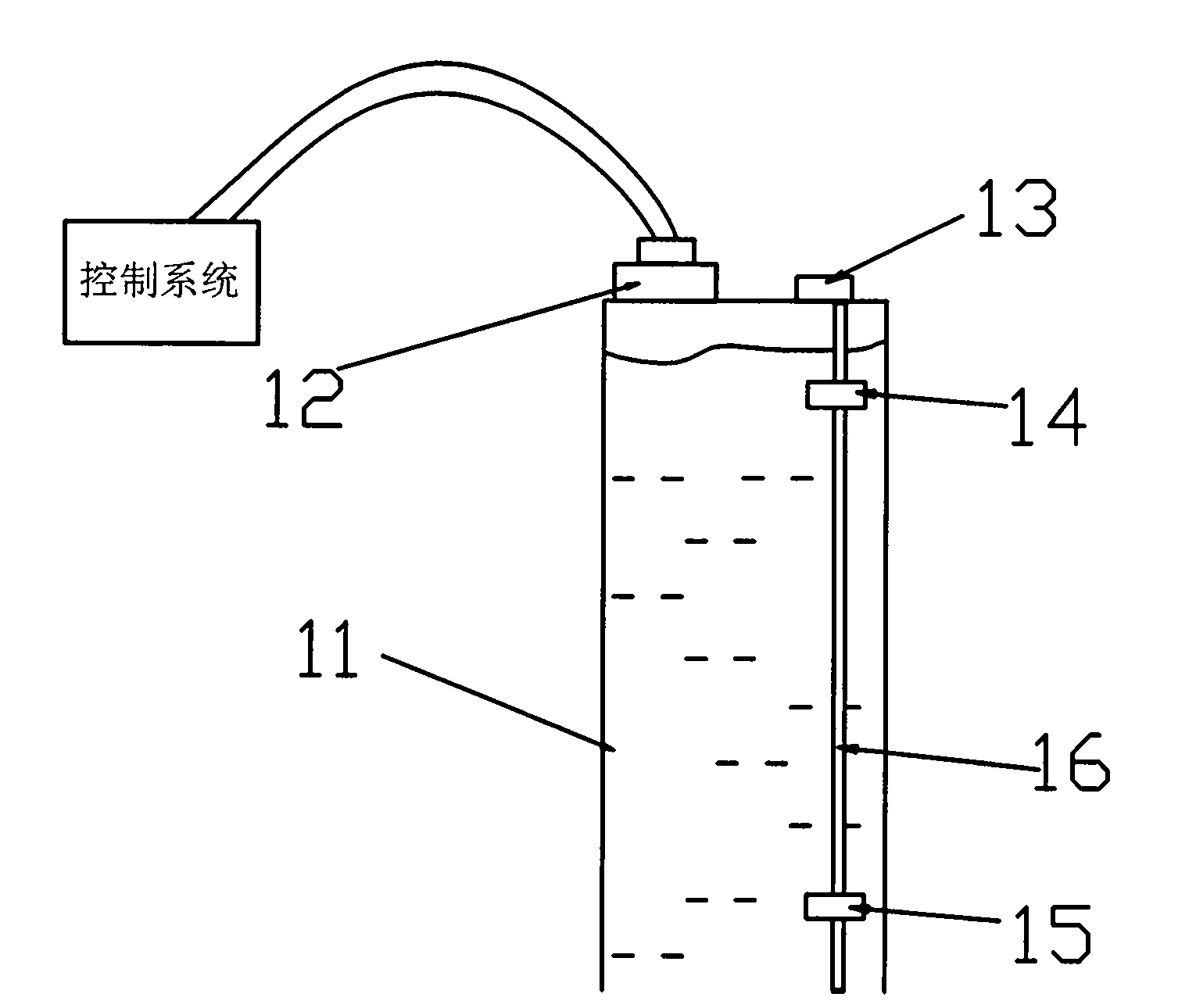

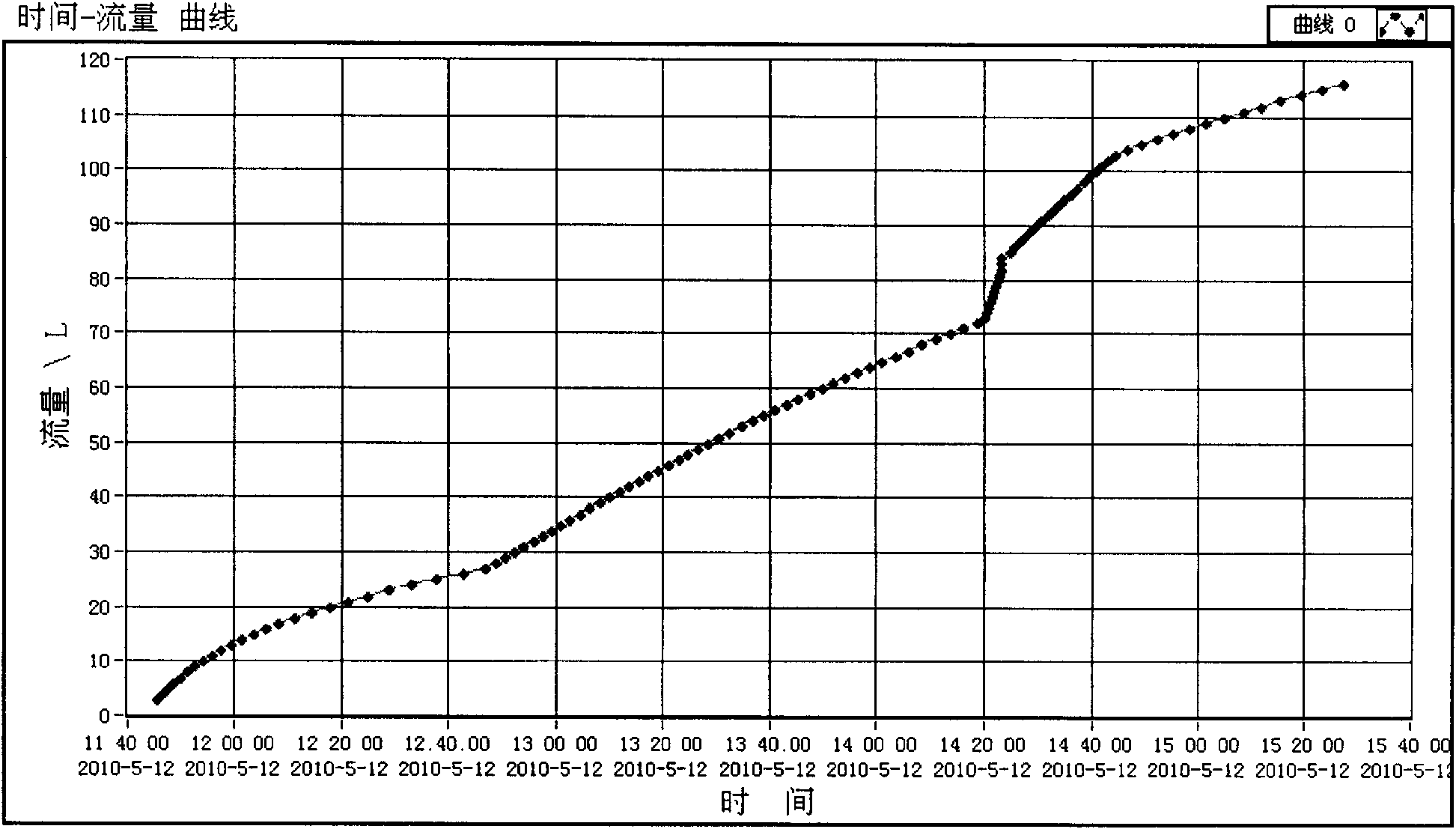

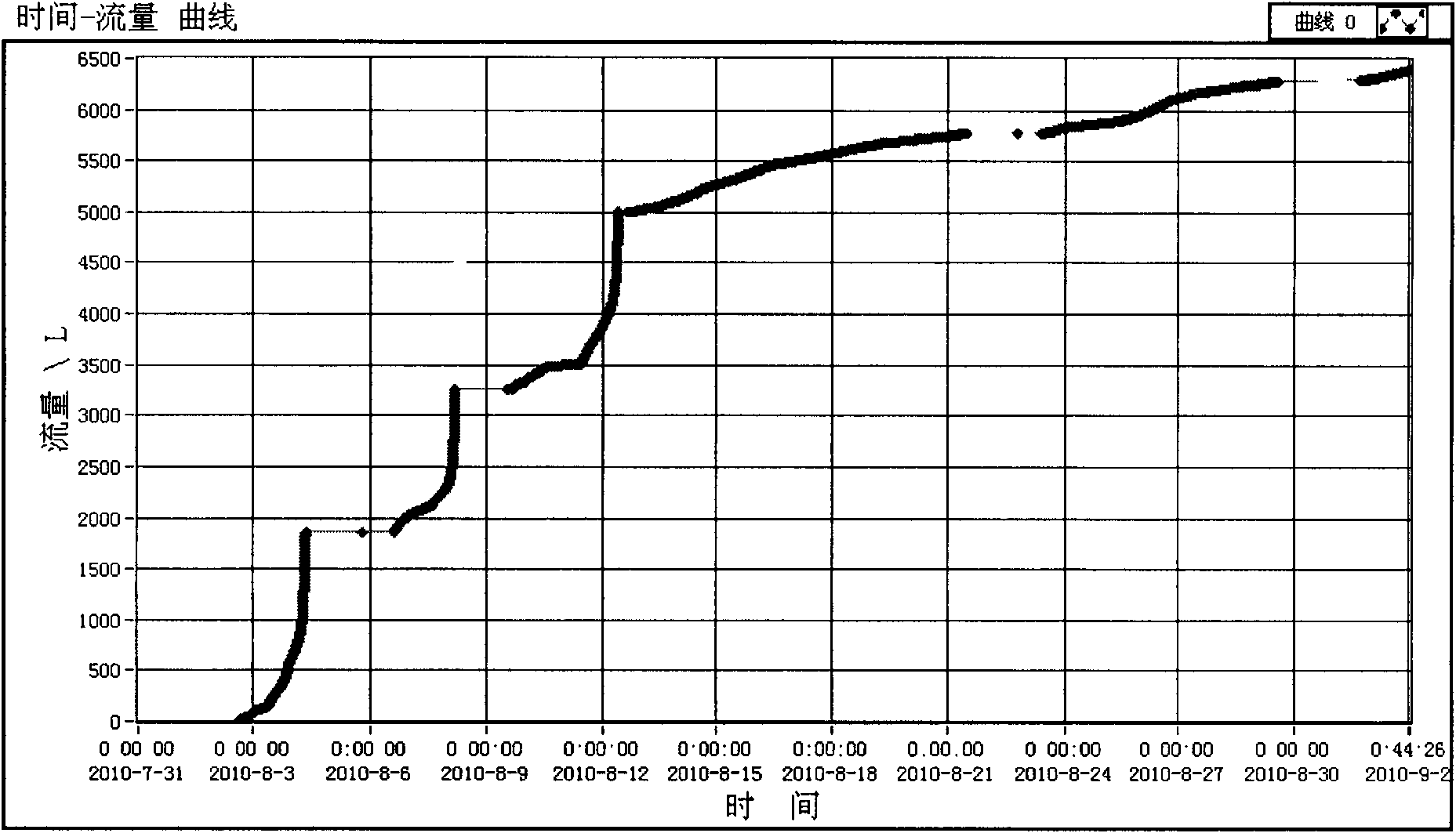

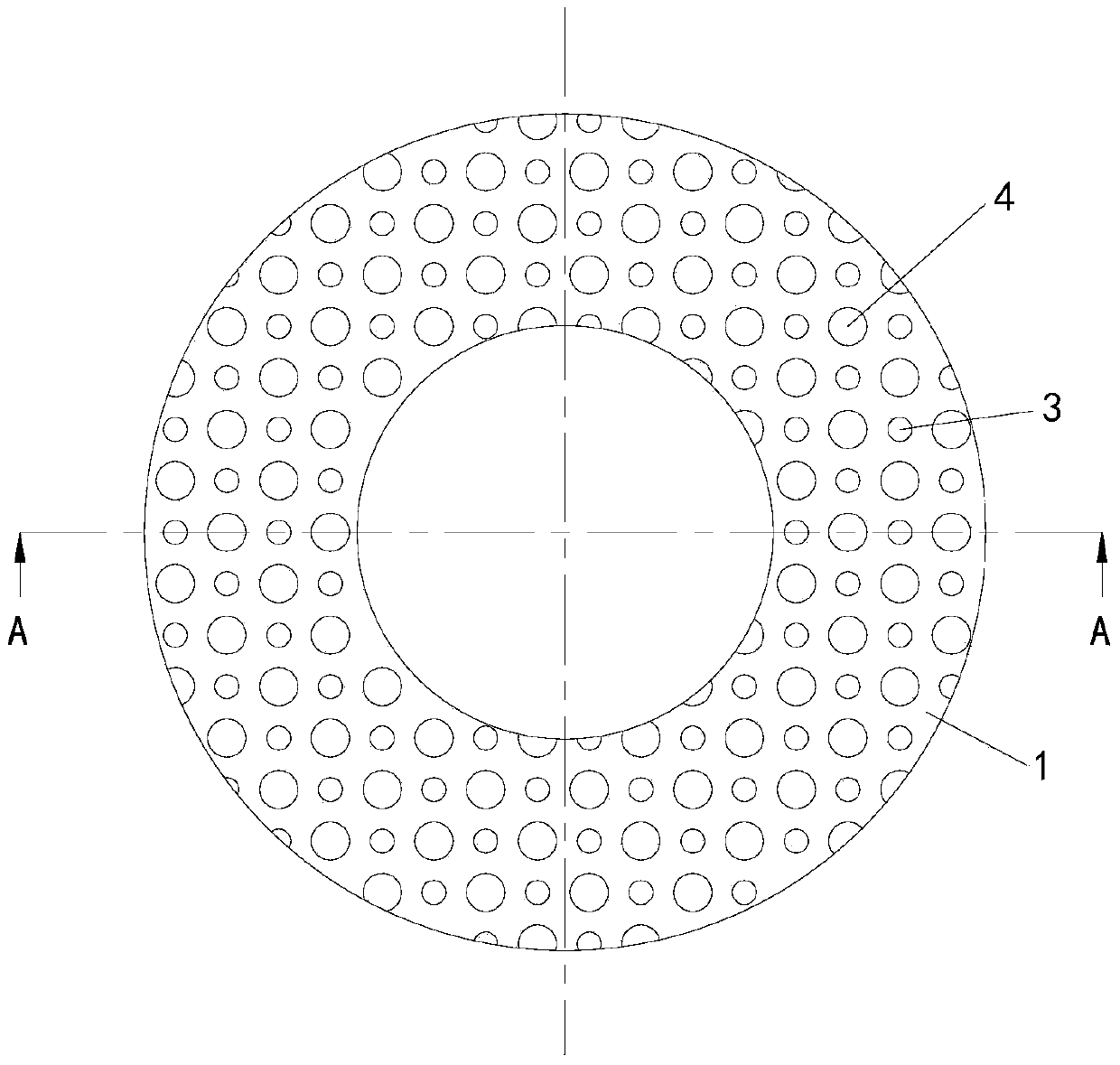

The invention discloses a device for measuring in-situ flow rate change of marine cold seep gas seepage, which comprises a fixed support, wherein a leaking tent cover is arranged in the fixed support; the top end of the leaking tent cover is communicated with a volume emptying method flowmeter; the side face of the leaking tent cover close to the bottom is provided with a water seepage grid; the side face of the leaking tent cover close to the volume emptying method flowmeter is provided with a bubble breaking grid; the volume emptying method flowmeter comprises a gas collecting chamber communicated with the leaking tent cover; the gas collecting chamber is respectively provided with an electromagnetic valve and a liquid level switch; a connecting rod connected with the liquid level switch is arranged in the gas collecting chamber longitudinally; the upper part of the connecting rod is provided with an upper part liquid level sensor probe, while the lower part is provided with a lower part liquid level sensor probe; and the electromagnetic valve is connected to a control system. The observation device can better continuously observe the flow rate change of fluid in the marine natural gas hydrate leakage area, and can continuously record and store natural gas flow rate change values.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

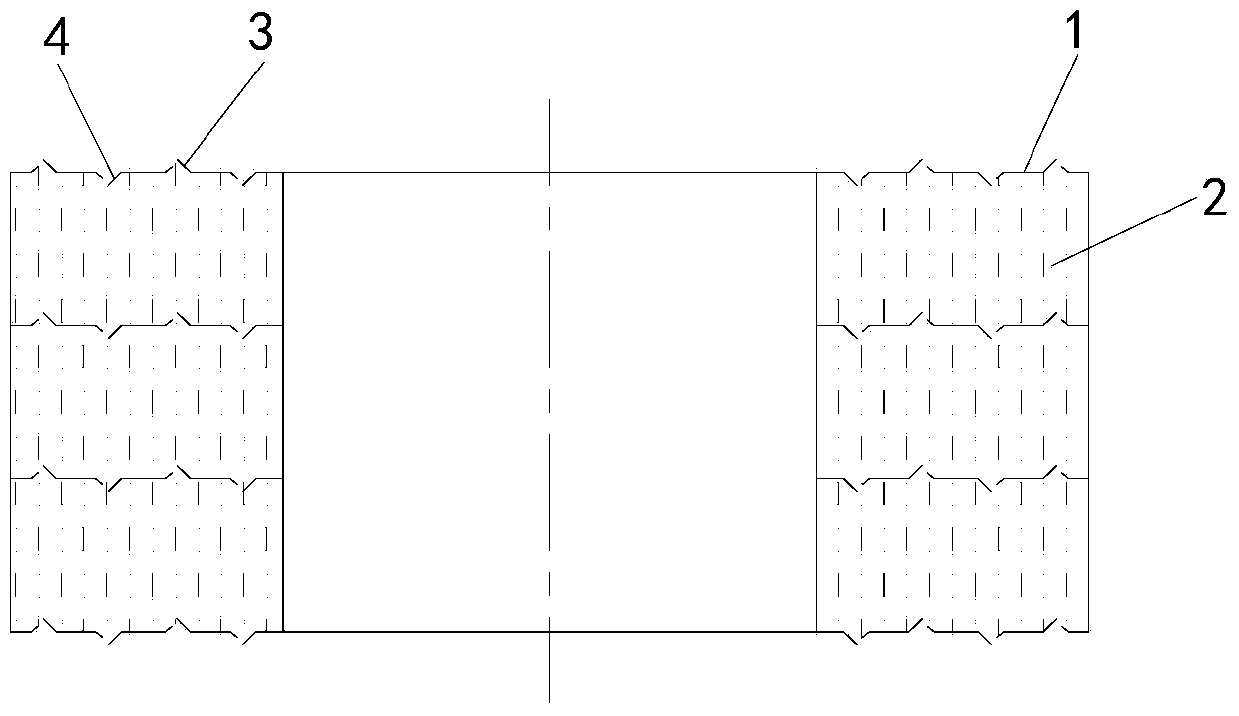

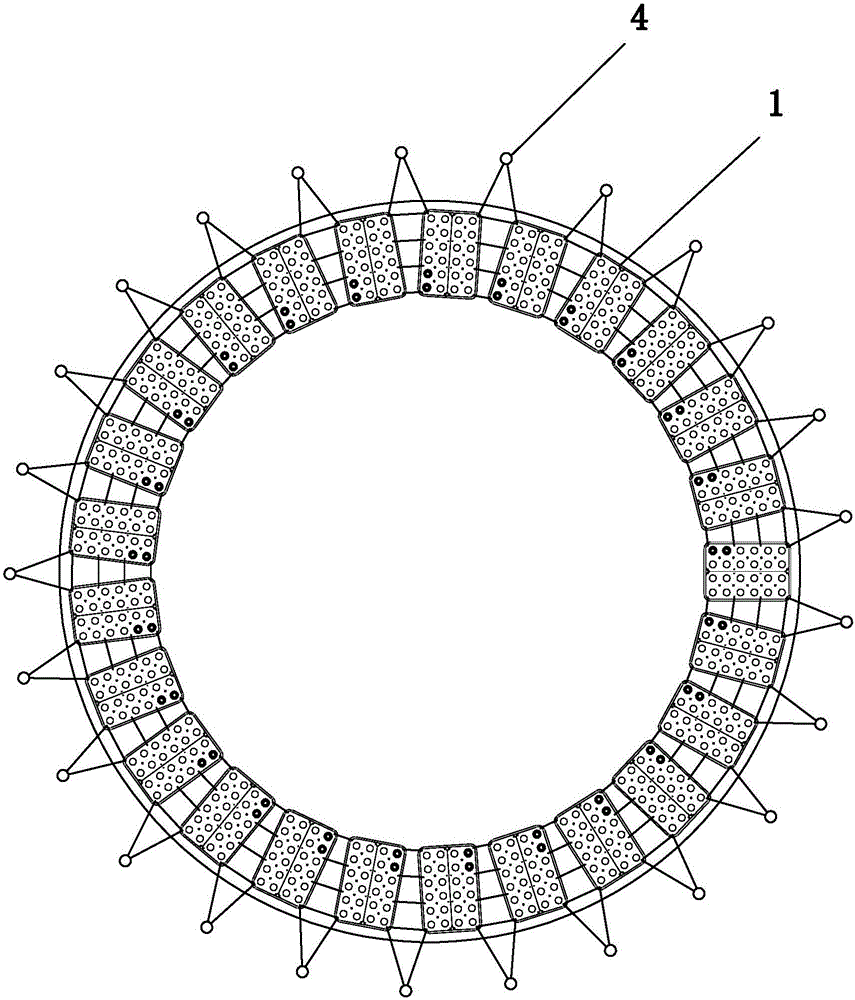

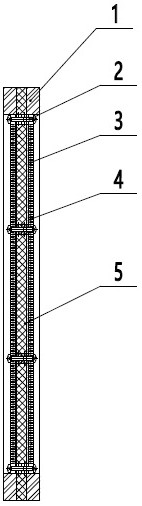

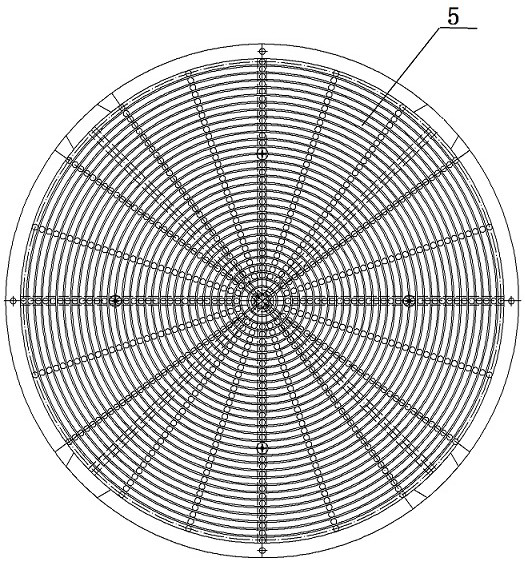

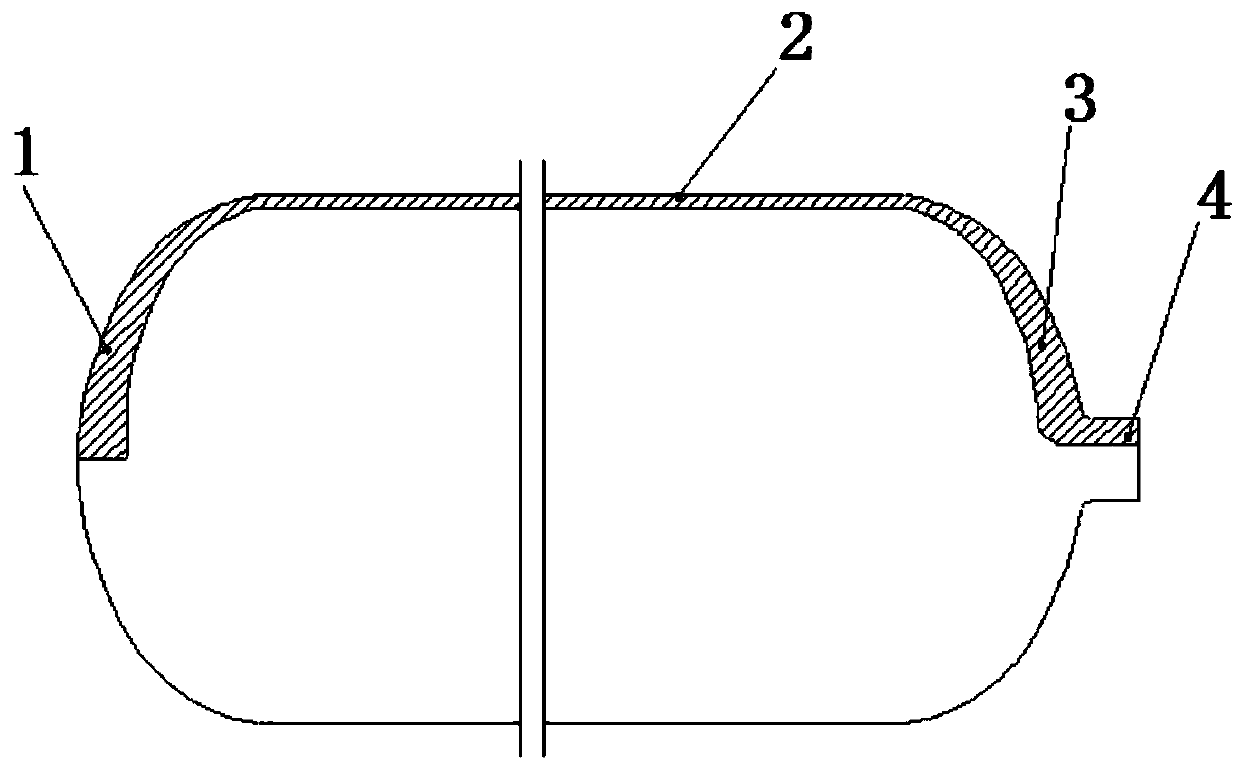

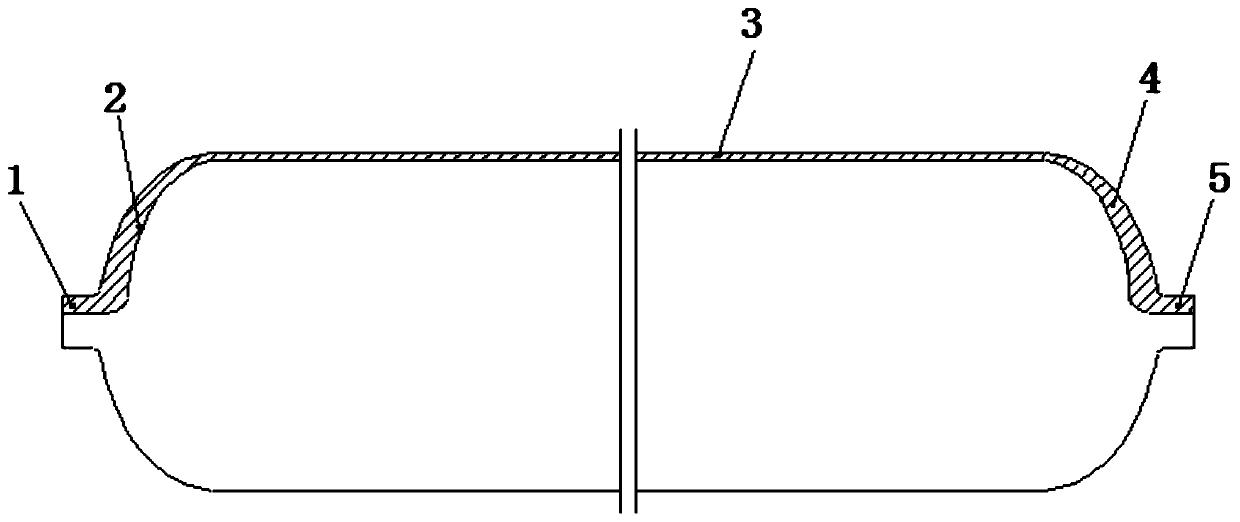

Sealing packing ring

The invention relates to a sealing packing ring. The sealing packing ring comprises a plurality of layers of metal slices and a plurality of flexible material layers; the topmost layer and the bottommost layer of the sealing packing ring are the metal slices; each flexible material layer is arranged between two corresponding adjacent metal slices; and a plurality of projections and a plurality of recesses which are formed by punching are uniformly distributed on each metal slice. By using the technical scheme, the sealing packing ring is formed by combining the flexible sealing material layers and the layers of the metal punched slices. The sealing packing ring has the advantages of high structural strength, high material binding force, high pressure resistance and wear resistance.

Owner:SUZHOU BMC SEALING TECH CO LTD +1

High-speed continuous rolling type lithium vacuum evaporation equipment and method for realizing base material lithium evaporation by utilizing equipment

ActiveCN107177820AExplosion-proofImprove sealingVacuum evaporation coatingSputtering coatingLithiumThermal insulation

The invention discloses high-speed continuous rolling type lithium vacuum evaporation equipment and a method for realizing base material lithium evaporation by utilizing the equipment, and aims to solve the problems that existing base material lithium evaporation equipment is low in utilization rate on metal lithium, evaporation thickness is smaller than or equal to 1 [mu]m, and pollution range during evaporation is great. The high-speed continuous rolling type lithium vacuum evaporation equipment comprises a machine body housing, a cavity baffle plate, an unrolling system, a base material heater, a main roller, a cooling roller, a rolling system, a crucible, a crucible fixing frame, a crucible heater, a thermal insulation layer, a crucible transverse-moving lifting platform, an unrolling transition roller, a heating transition roller, a cooling transition roller, an upper cavity vacuum valve, a lower cavity vacuum valve and a charging visible window. The method has the advantages that evaporation thickness is guaranteed to be adjustable anytime within a range of 1 [mu]m to 100 [mu]m, and the highest utilization rate of metal lithium can be 90% or higher. The high-speed continuous rolling type lithium vacuum evaporation equipment is mainly used for base material lithium evaporation.

Owner:哈尔滨光宇电子有限公司

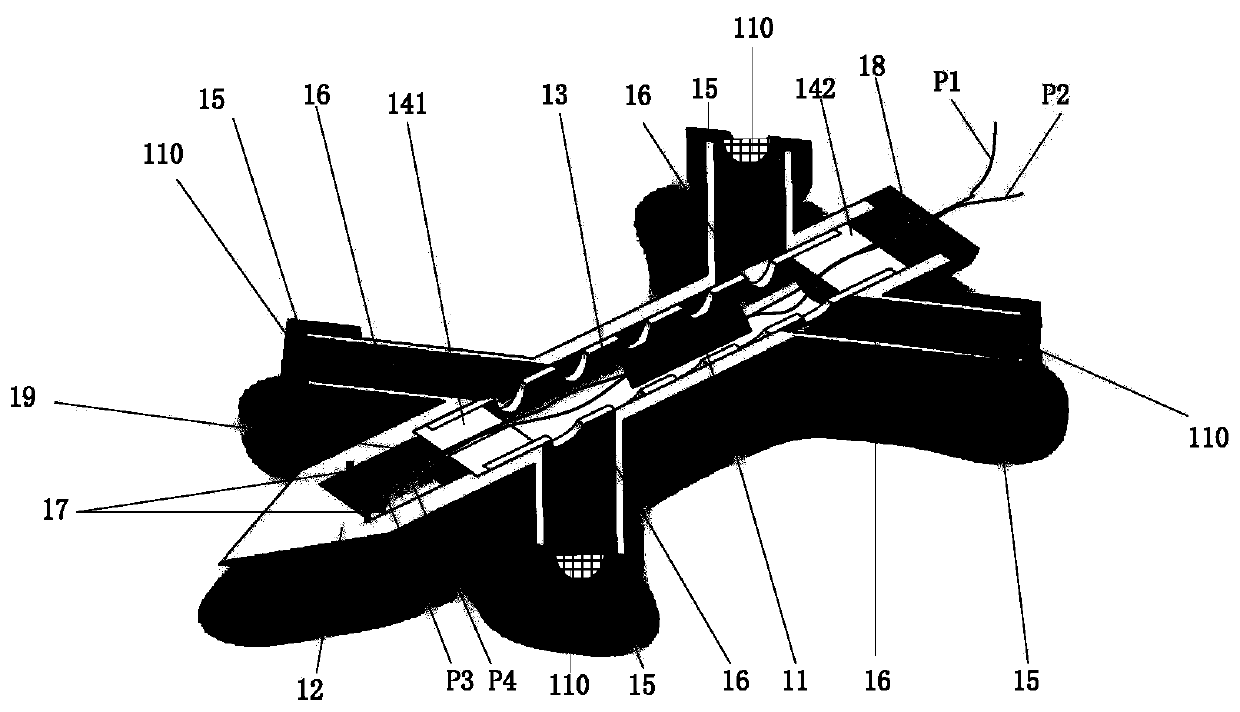

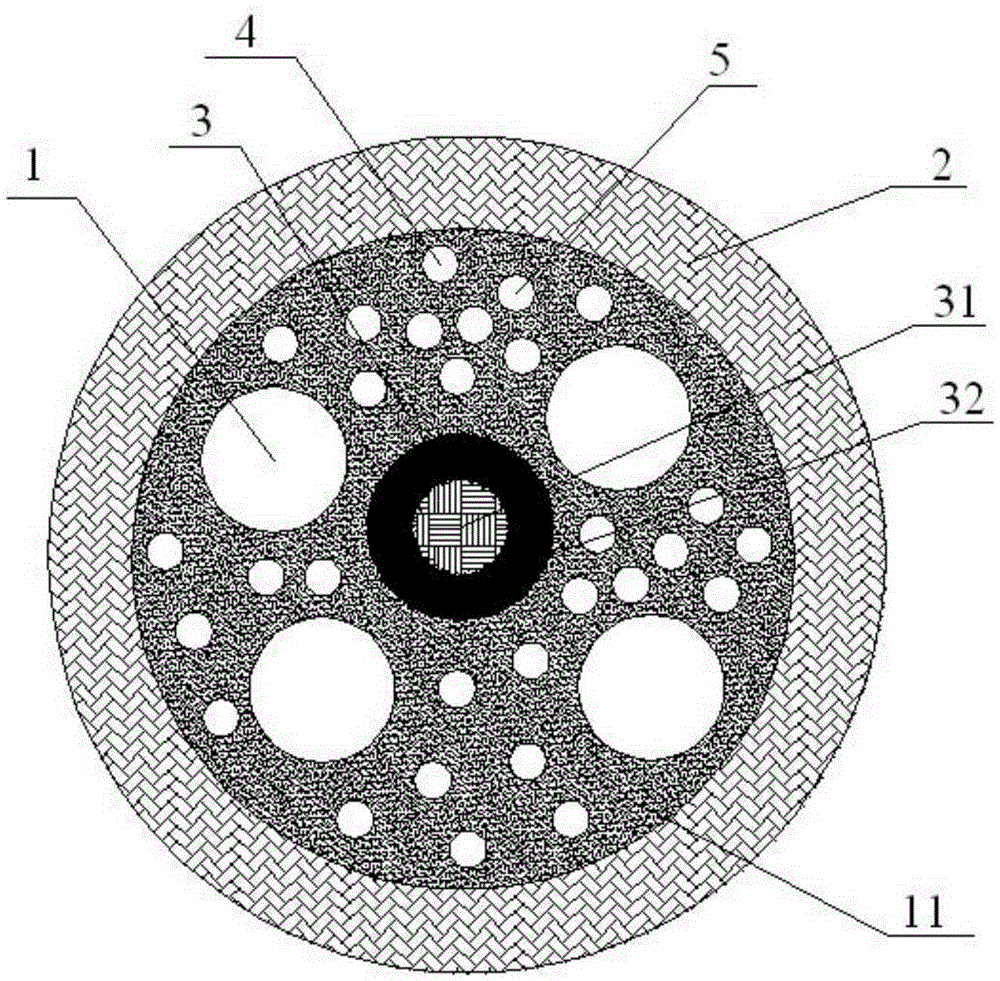

All-fiber temperature-salinity-depth sensor based on micro-nano fiber coupler interferometer

ActiveCN110864742AHigh sensitivityCompact structureMeasuring open water depthConverting sensor output opticallyFiberPlankton

The invention aims to overcome the defects that micro-nano optical fibers and micro-nano optical fiber couplers are relatively weak in mechanical strength and are easily influenced by pollution and anexisting temperature-salinity-depth sensor is large in size and low in precision. An all-fiber temperature-salinity-depth sensor based on a micro-nano fiber coupler interferometer is designed. The sensor is composed of a micro-nano fiber coupler, a sensor outer protective sleeve, a sensor inner protective sleeve, two sensor inner protective sleeve caps, four sensor water inlet groove sleeve caps,four sensor water purification filter elements, two reflector films, a sensor outer protective sleeve cap, an optical fiber storage groove and four filter screens. The sensor can realize high-sensitivity sensing of three parameters of seawater temperature, salinity and depth at the same time, has the performance advantages of zero electronic element, compact structure, high sensitivity, convenient integration and the like, can block the influence of plankton, seaweed, silt and the like on the performance of the sensor, and has good pressure resistance and stability.

Owner:NAT UNIV OF DEFENSE TECH

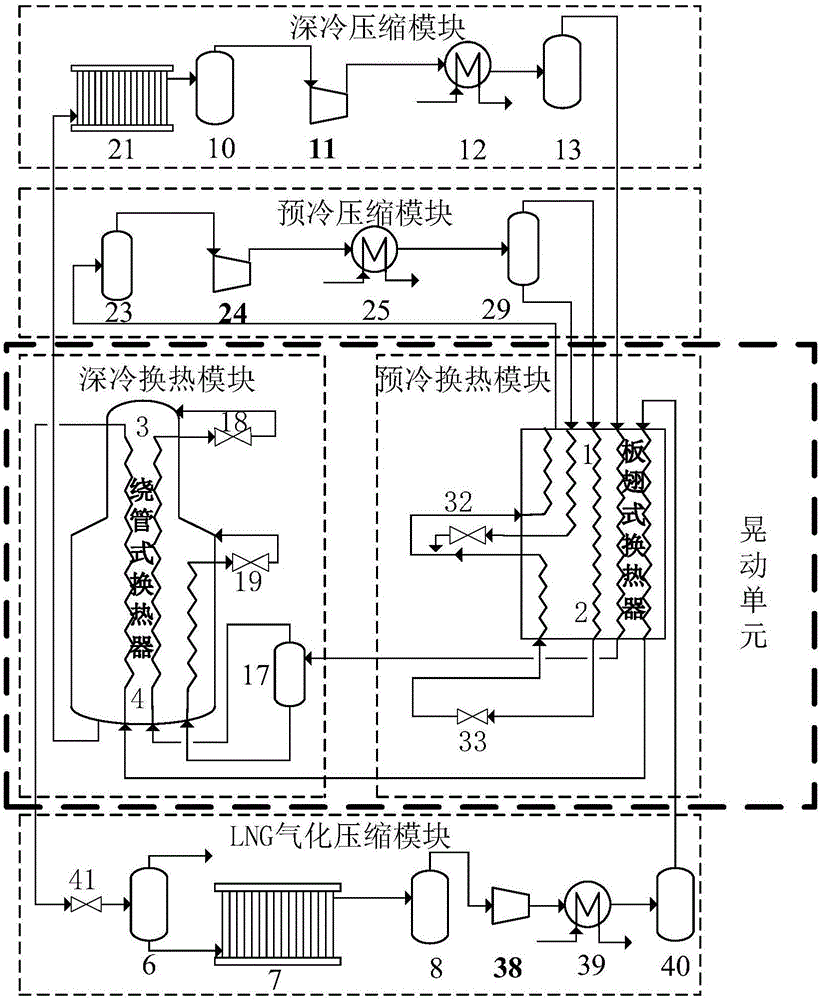

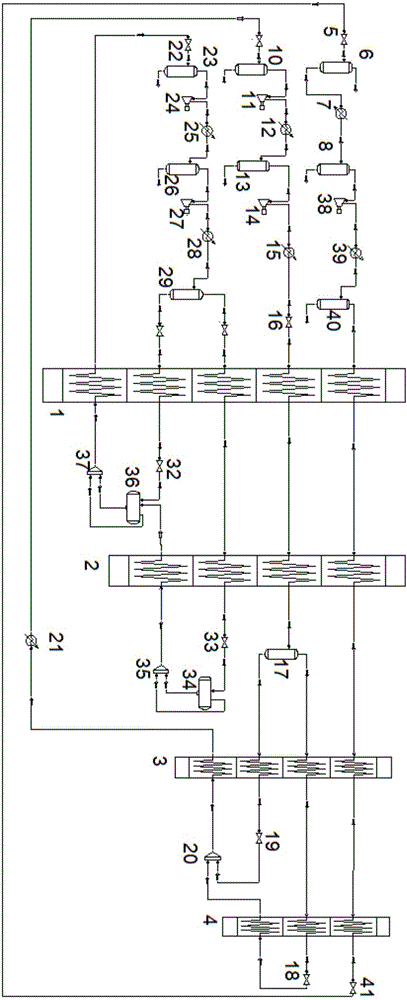

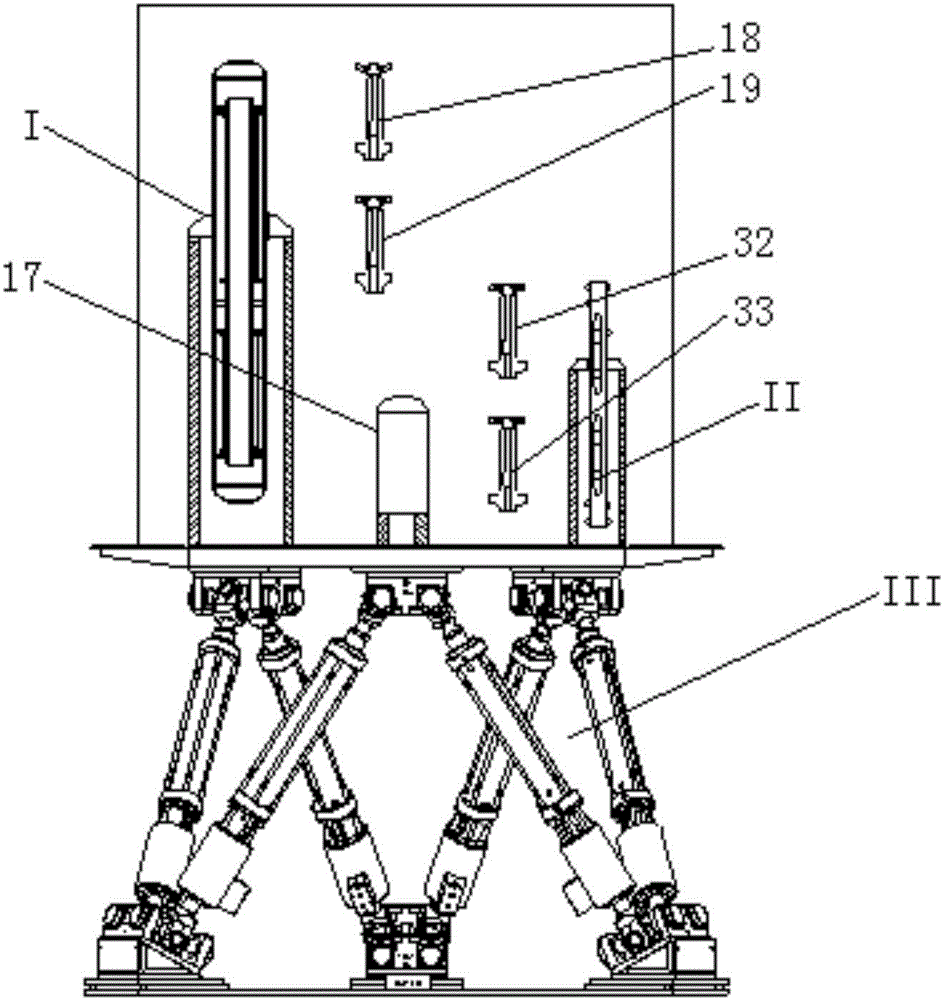

Floating type test platform of natural gas liquefaction system

InactiveCN106441964ASmaller than power consumptionImprove liquefactionSolidificationLiquefactionVapor–liquid separatorEngineering

The invention discloses a floating type test platform of a natural gas liquefaction system. The test platform comprises a deep freeze compression module, a pre-cooling compression module, and an LNG vaporization compression module, the deep freeze compression module is connected with a pre-cooling heat exchange module and a deep freeze heat exchange module in sequence to form a circulation, the pre-cooling compression module is connected with the pre-cooling heat exchange module to form a circulation, the LNG vaporization compression module is connected with the pre-cooling heat exchange module and the deep freeze heat exchange module in sequence to form a circulation, and the pre-cooling heat exchange module and the deep freeze heat exchange module are arranged on a shake unit. The test platform can be used for testing the operation performance of core equipment such as a plate-fin heat exchanger, a coiled-pipe heat exchanger, a throttle valve, and a gas-liquid separator etc. in the natural gas liquefaction system in a marine environment, and the adaptability of the natural gas liquefaction system.

Owner:CNOOC GAS & POWER GRP +1

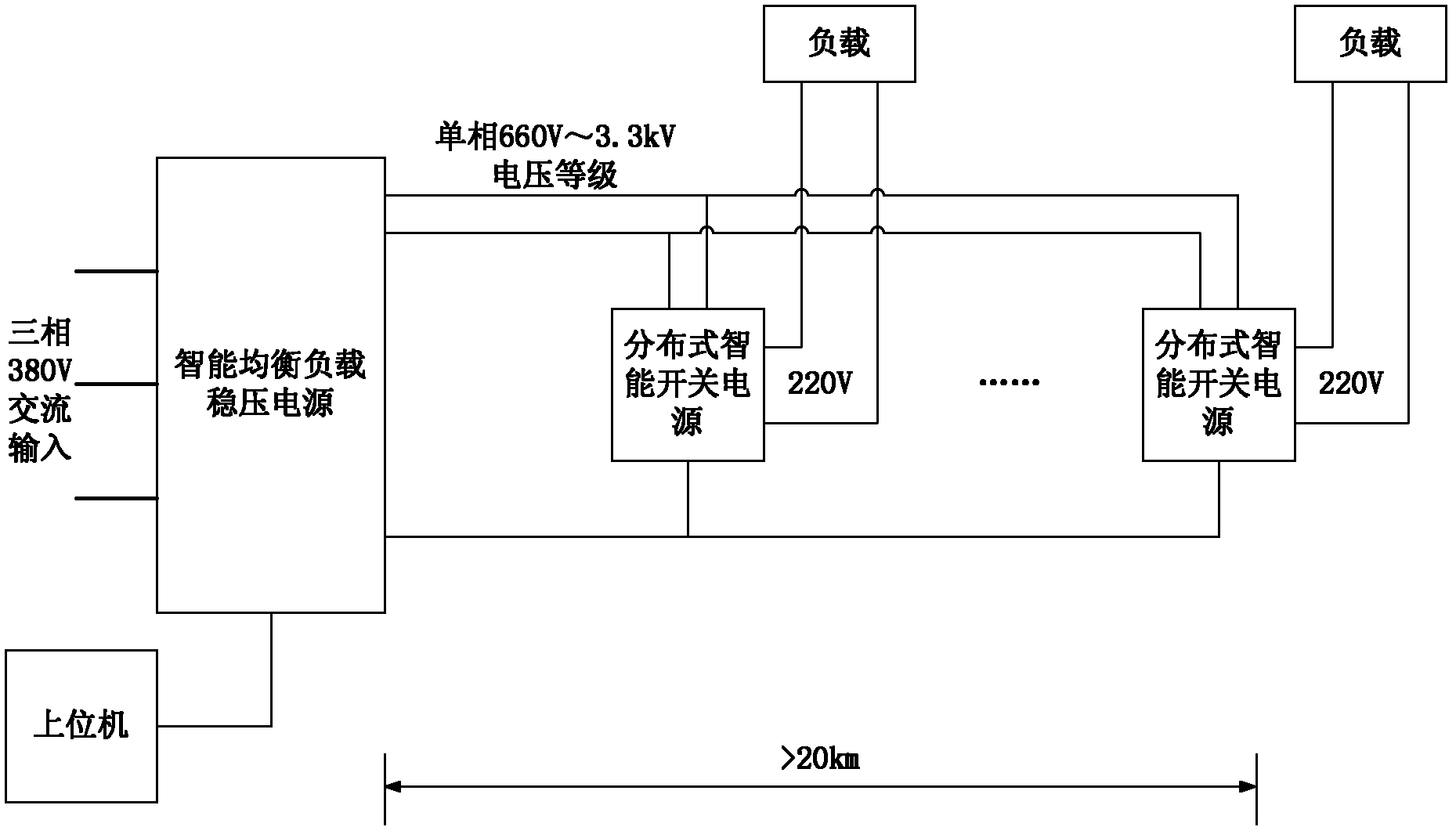

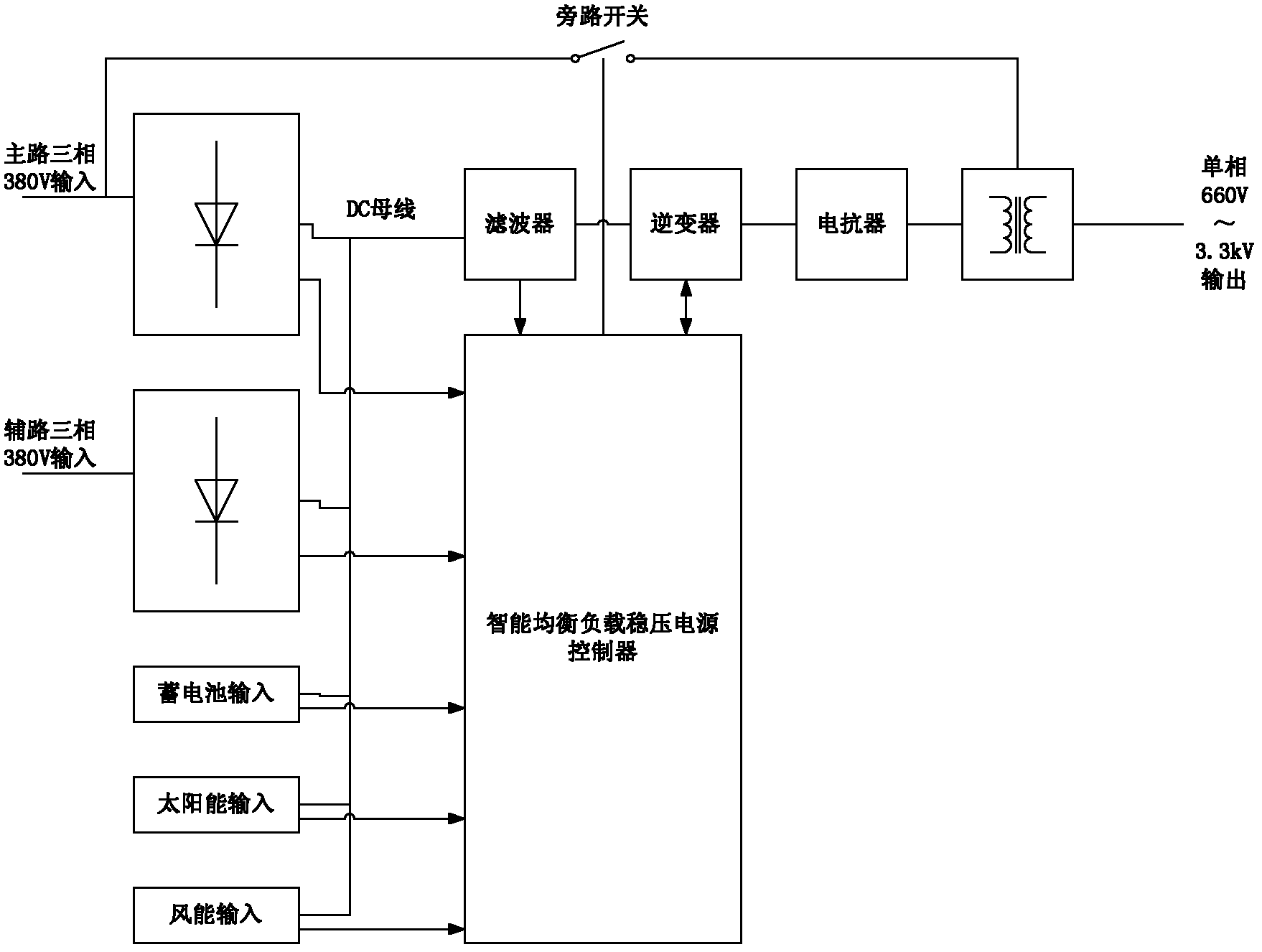

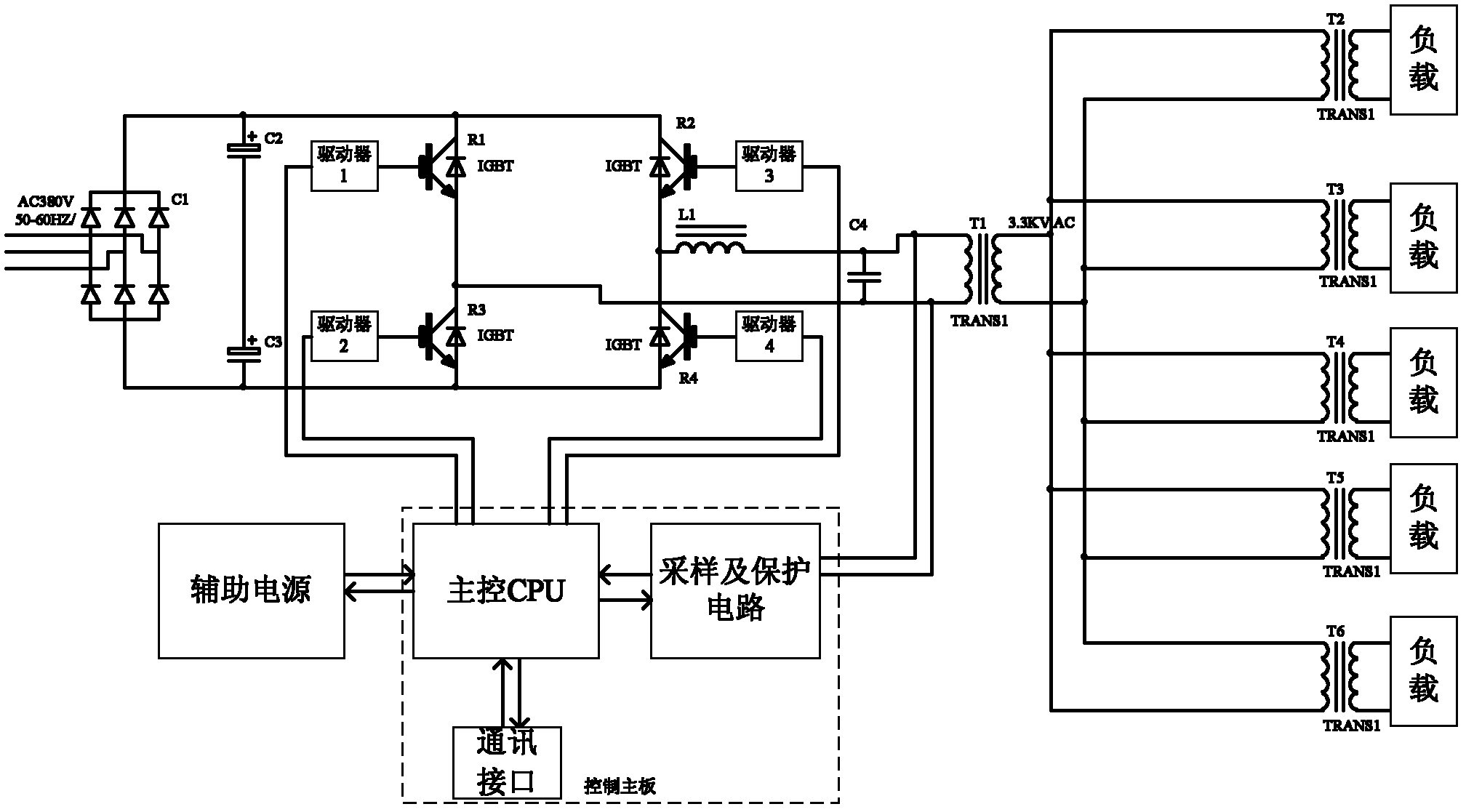

Single-phase 660V-3.3KV long-distance distributed direct power supply system

ActiveCN102624019AReliable power supplyLow comprehensive costElectric power transfer ac networkSingle phaseThree-phase

The invention discloses a single-phase 660V-3.3KV long-distance distributed direct power supply system, which comprises an intelligent load balancing stabilized power supply, distributed intelligent switching power supplies and an upper computer, wherein the intelligent load balancing stabilized power supply sequentially rectifies, filters, inverts and transforms three-phase 380V alternating current, outputs single-phase 660V-3.3KV alternating current according to needs, can automatically regulate the output to keep the output stable, and comprises a control mainboard, and a rectifier, a filter, an inverter, a reactor and a transformer, which are sequentially connected; each distributed intelligent switching power supply converts the 660V-3.3KV alternating current into 220V alternating current, can automatically regulate output to keep the output stable, and comprises an adjustable transformer and an intelligent switching controller; and the upper computer transmits a control instruction to the intelligent load balancing stabilized power supply and the distributed intelligent switching power supplies, and receives and stores local state parameters uploaded by the intelligent load balancing stabilized power supply and the distributed intelligent switching power supplies. The system is low in cost and stable and reliable in power supply.

Owner:北京西迈特科技有限公司

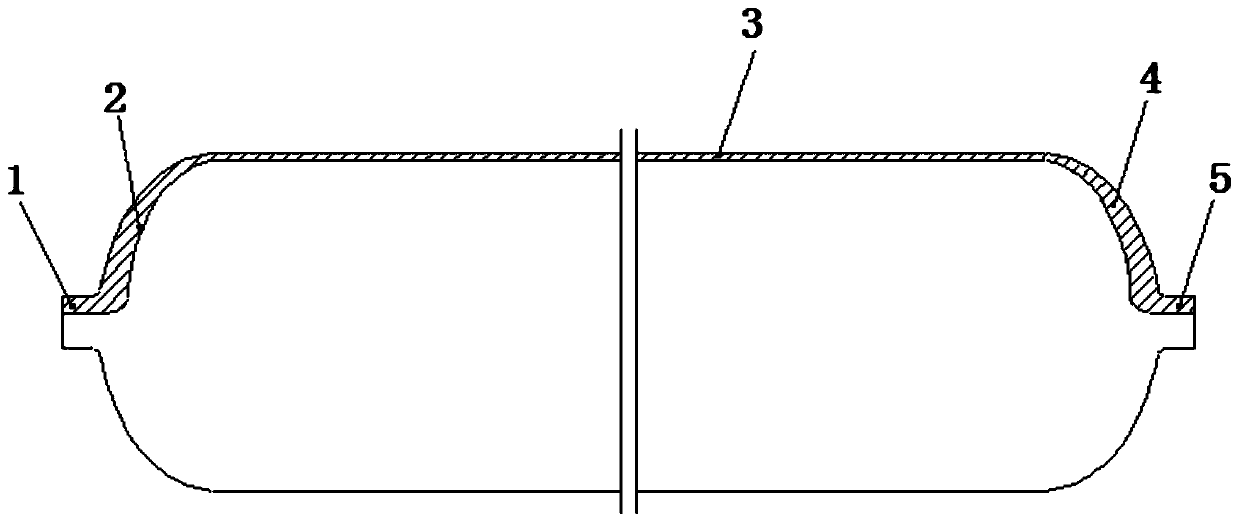

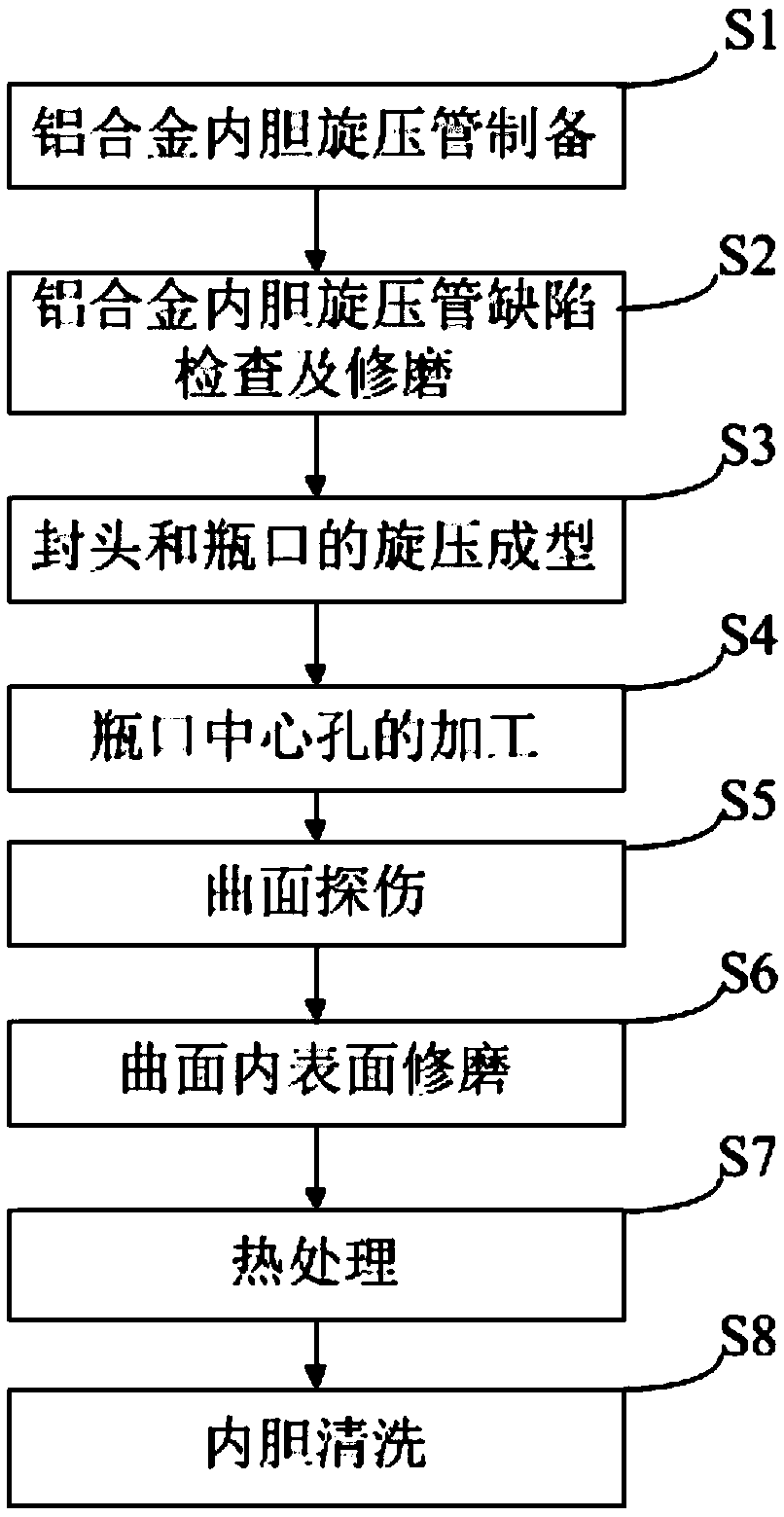

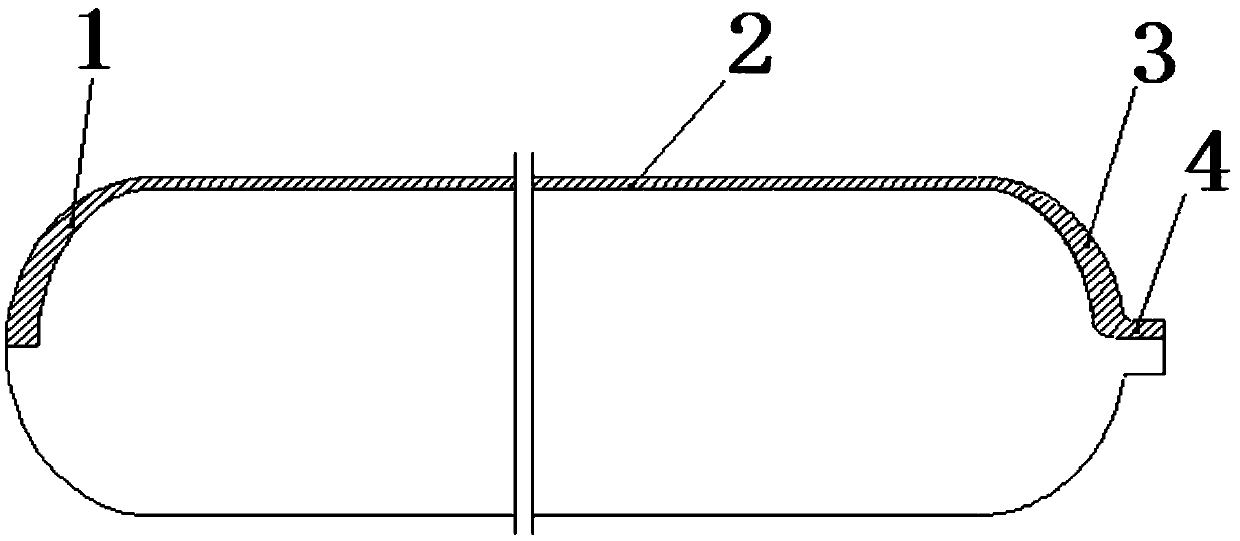

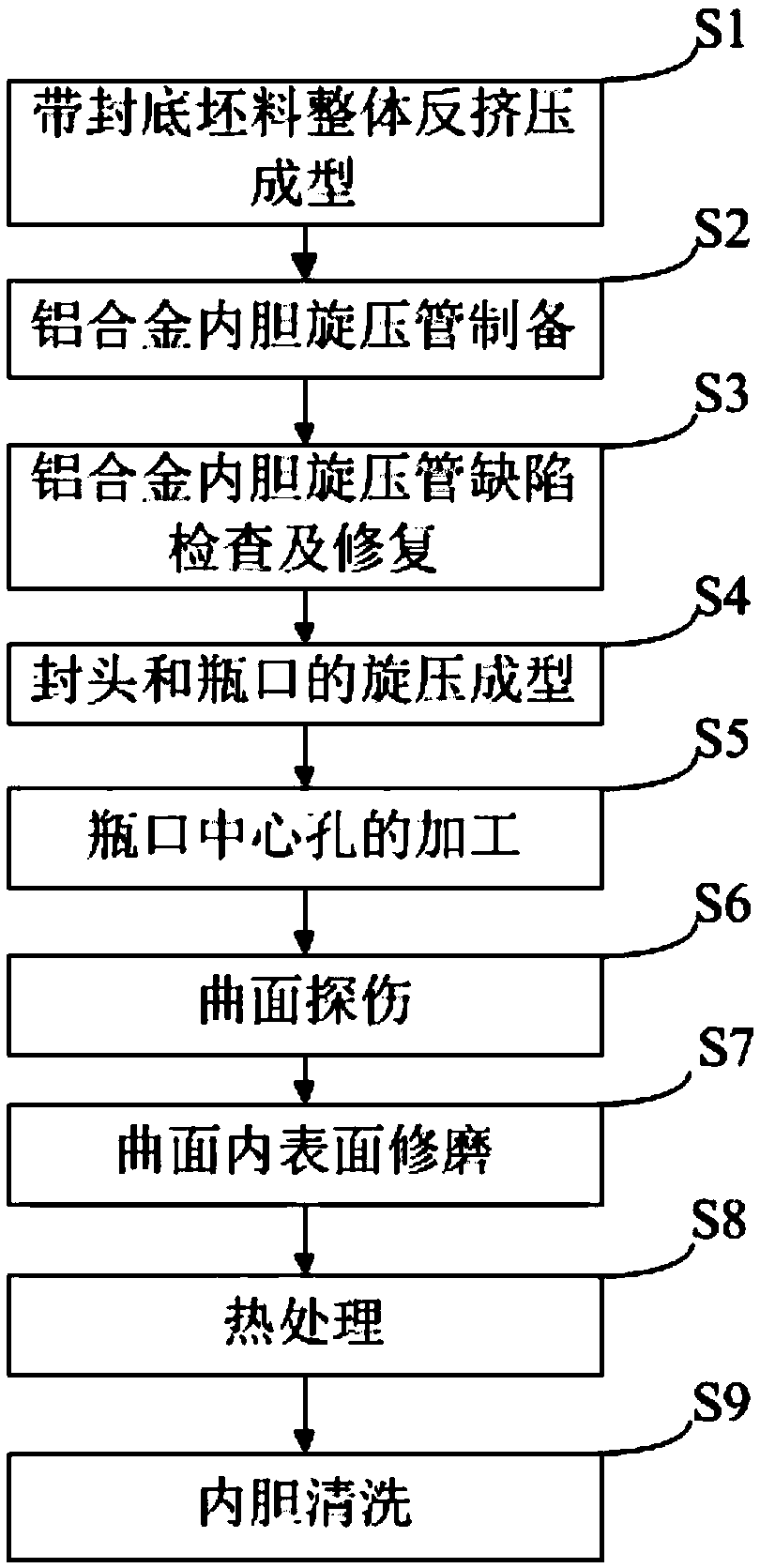

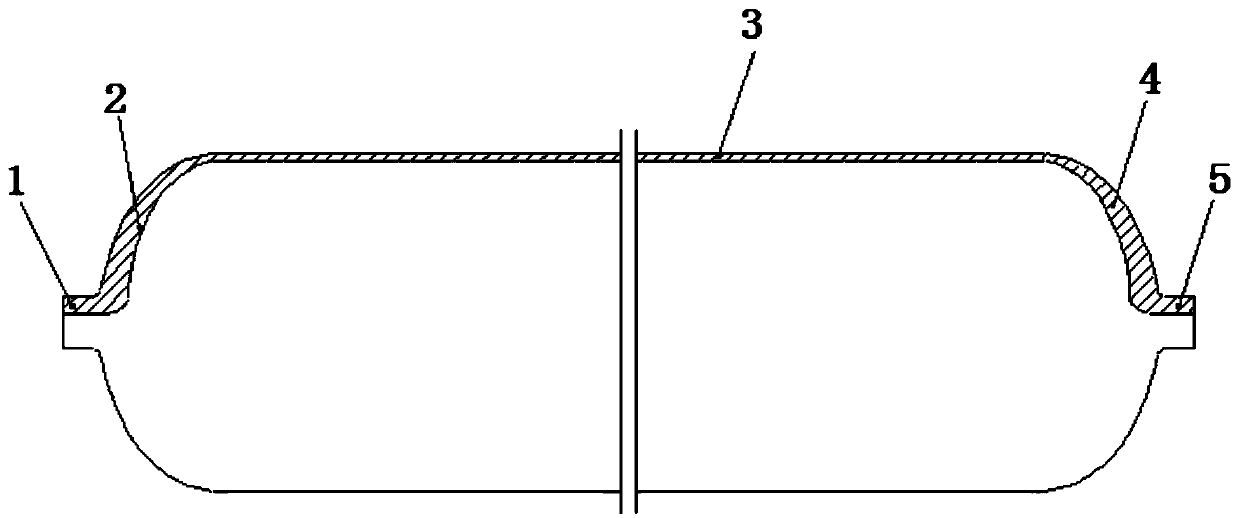

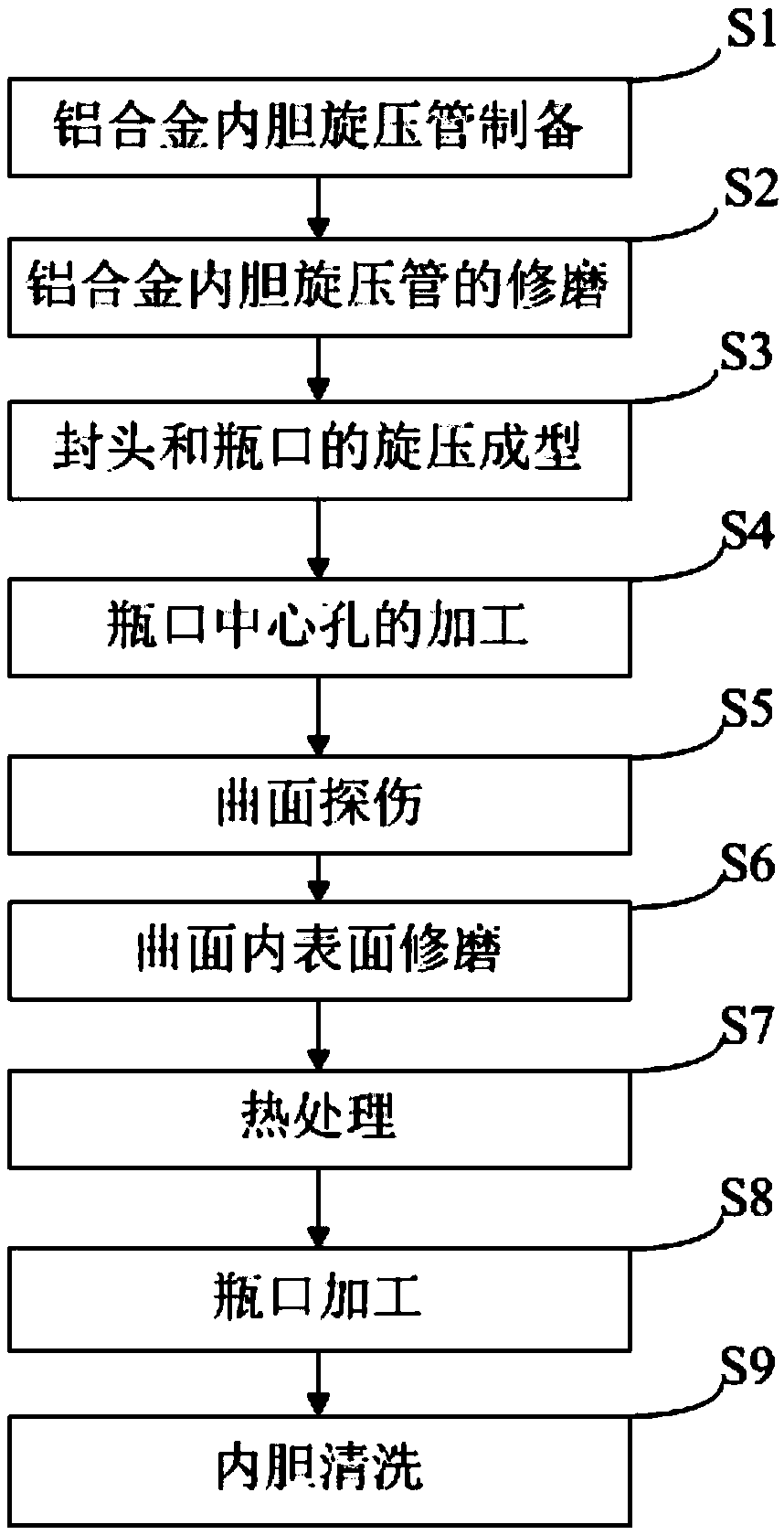

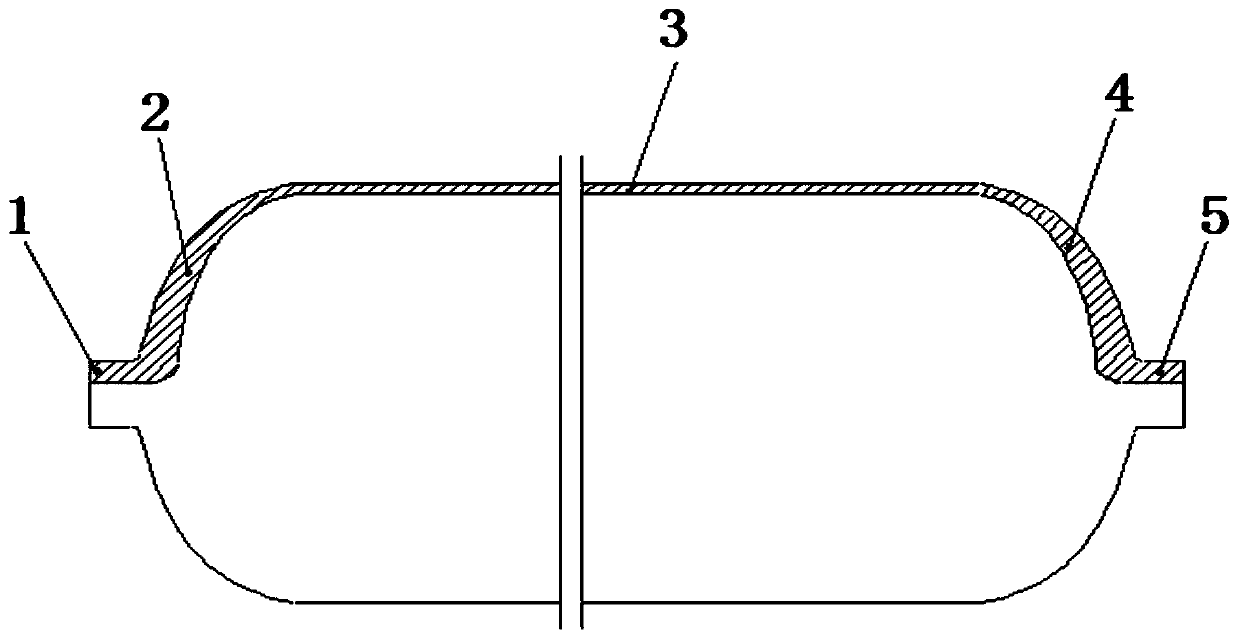

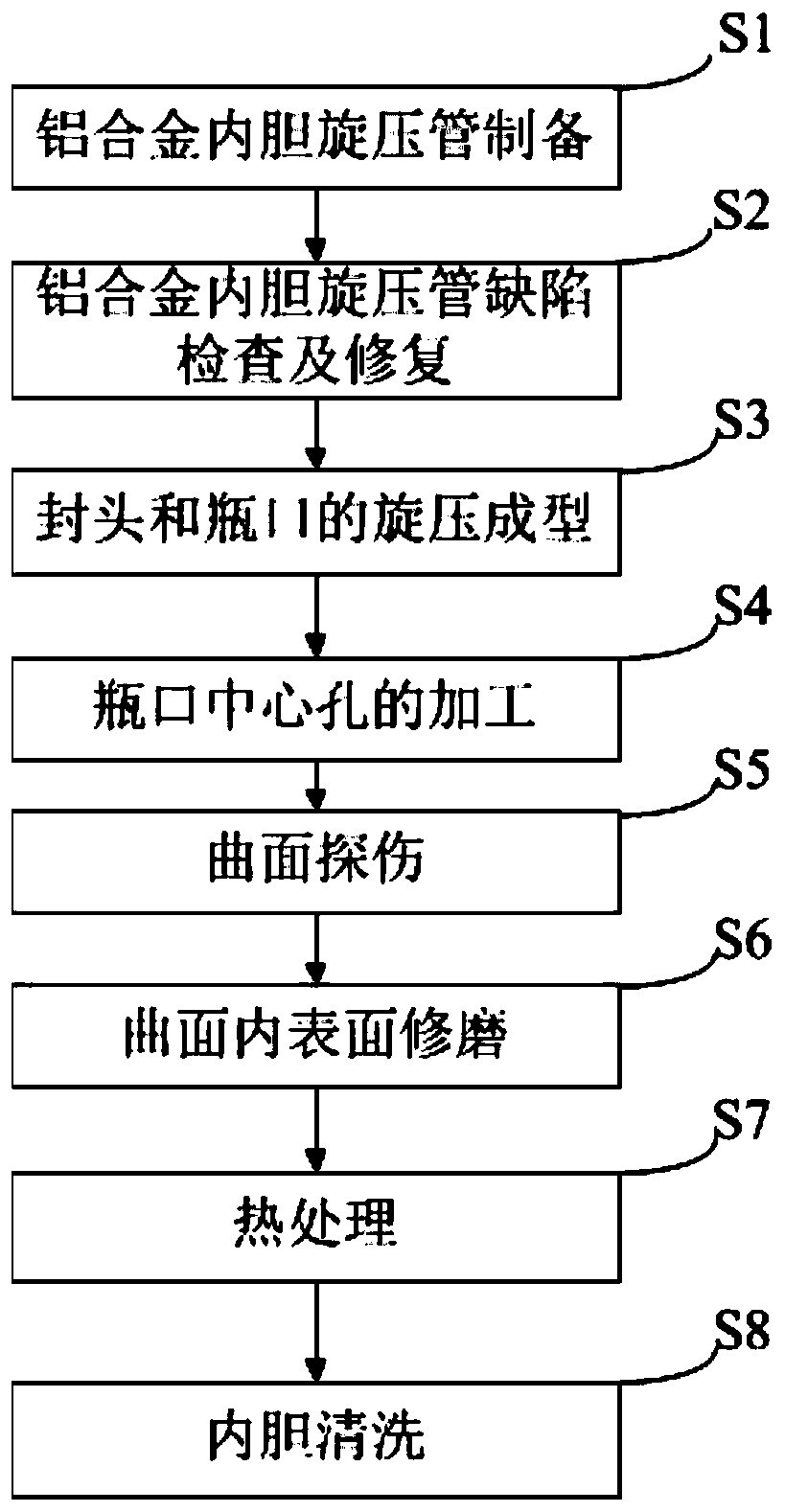

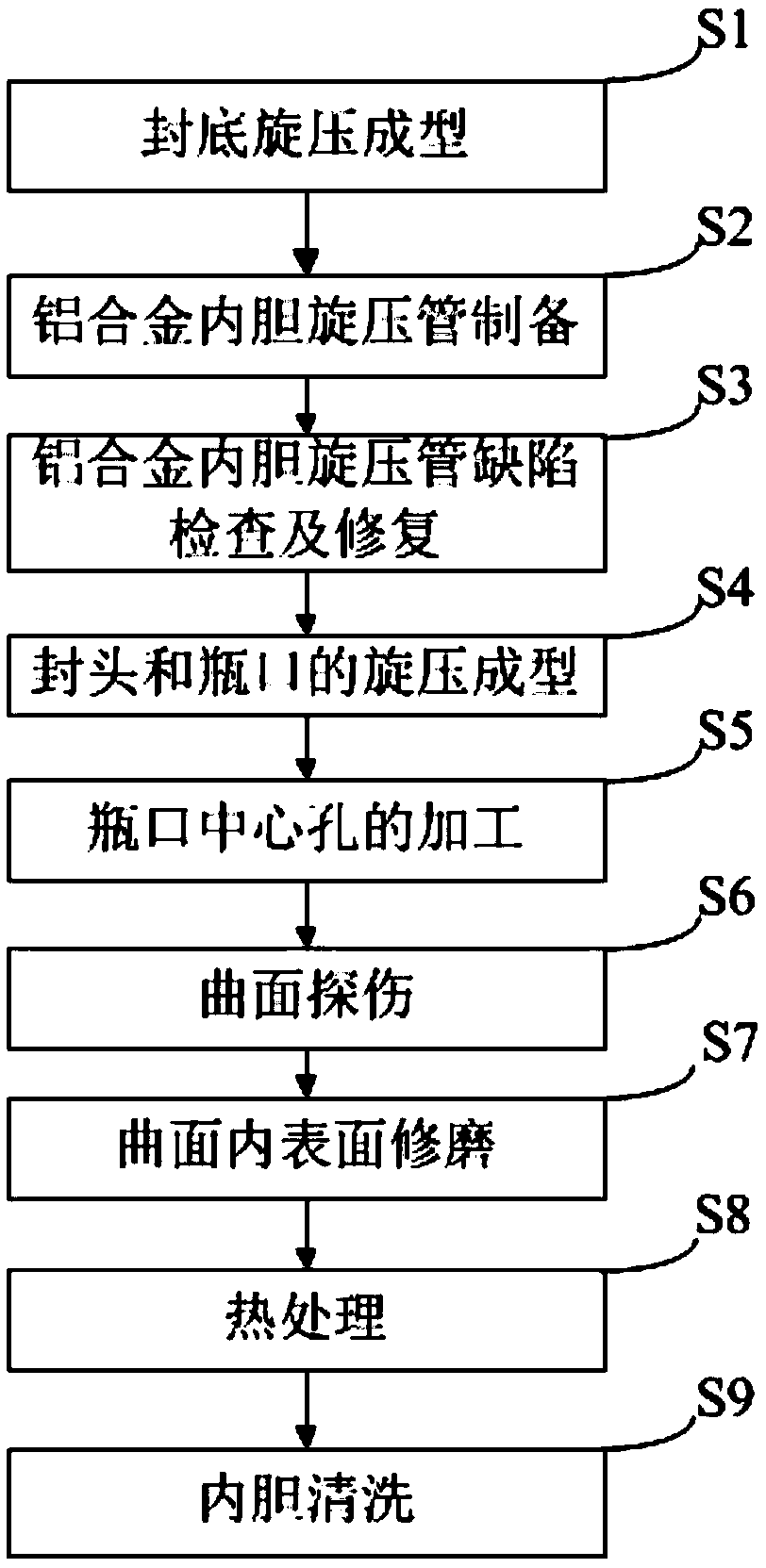

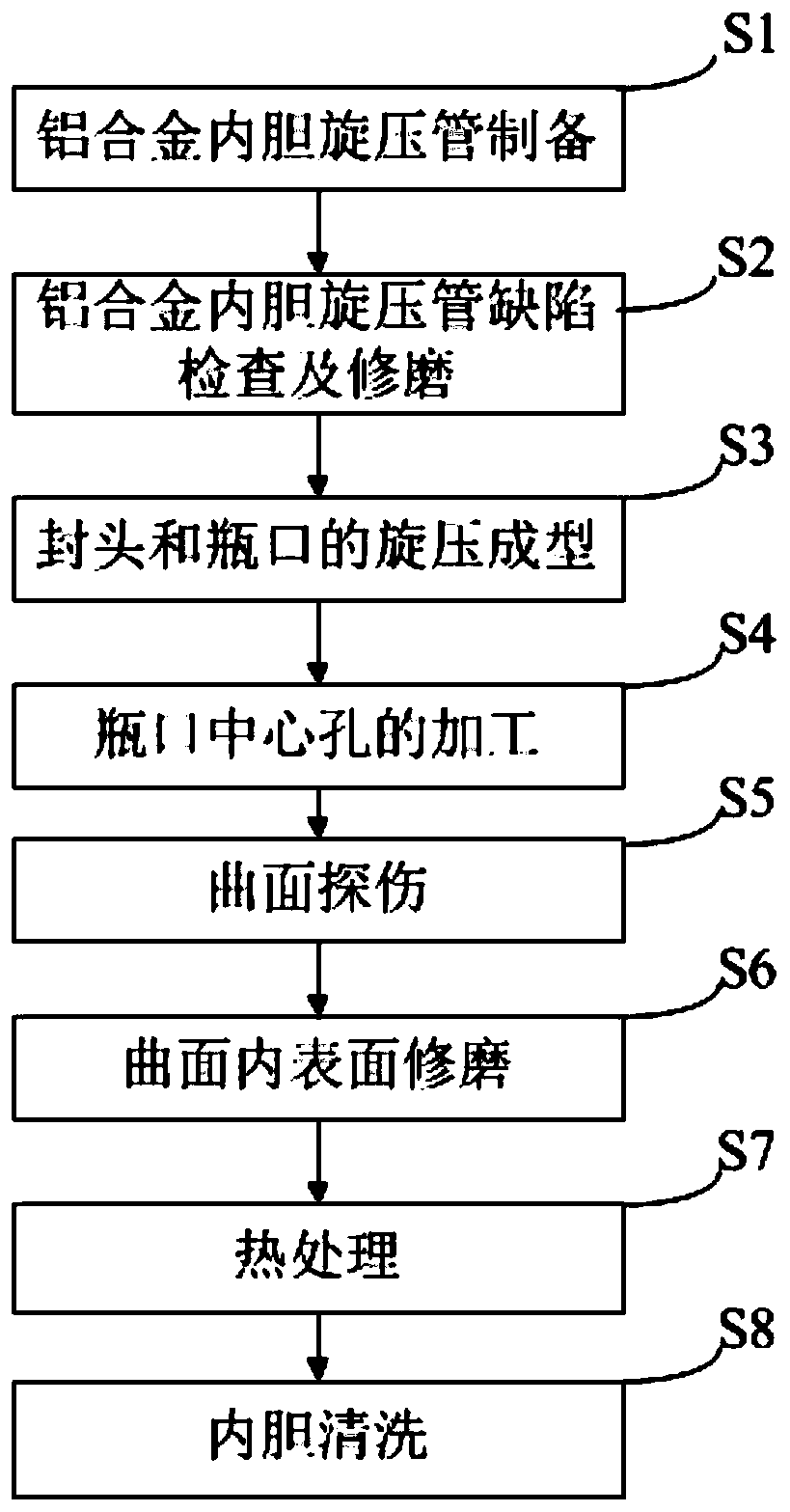

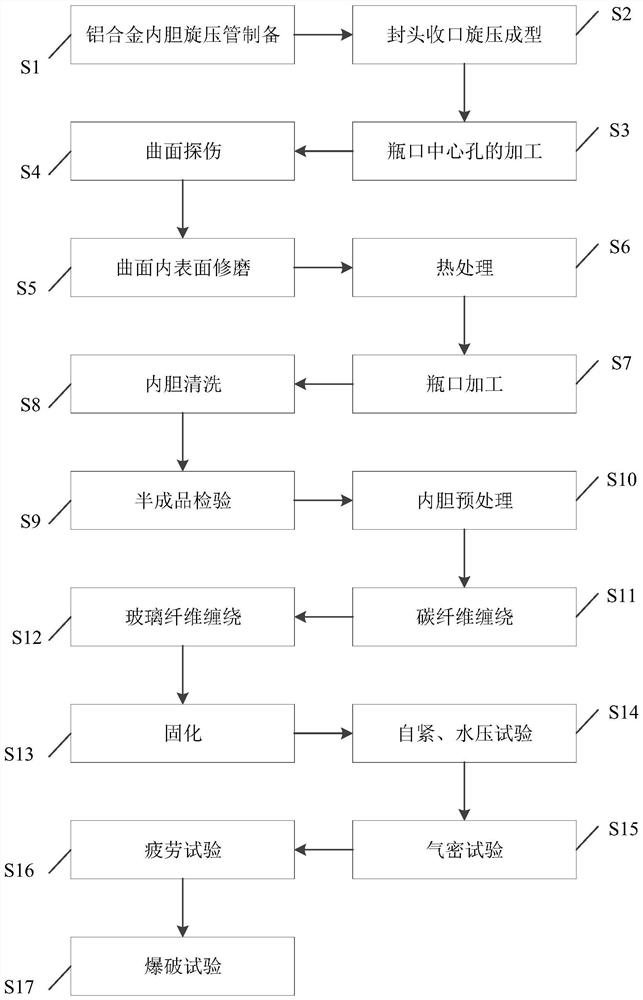

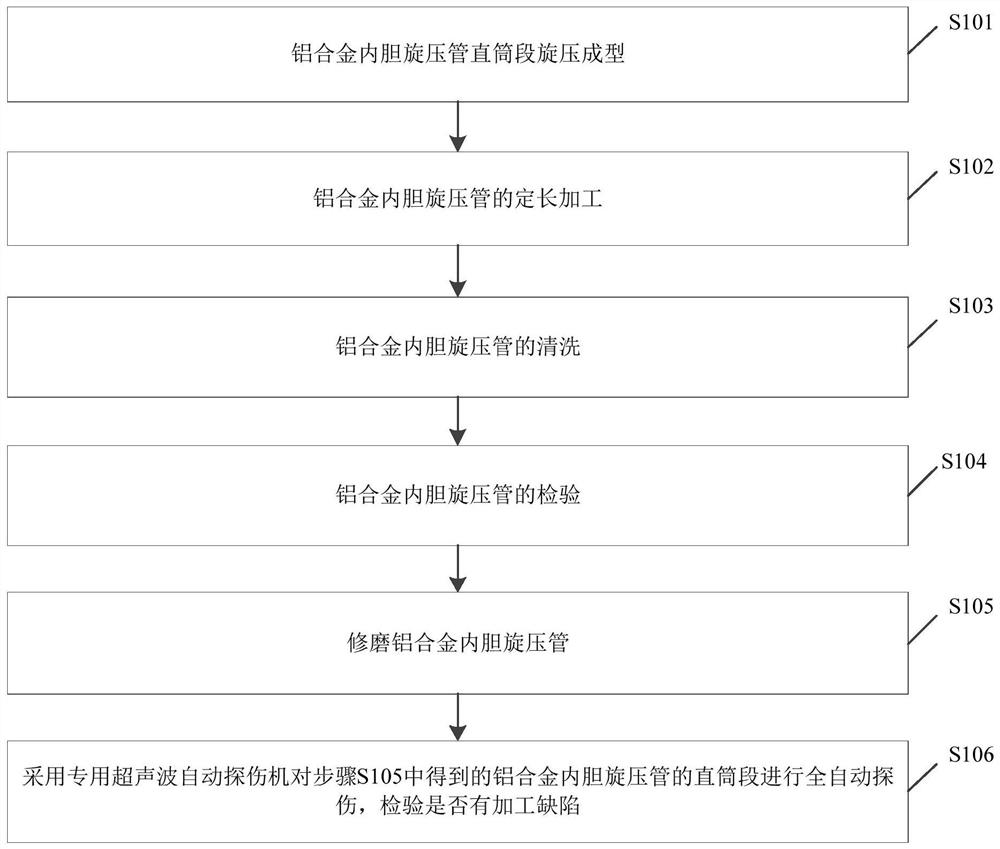

Double-end-seal ultra-large-size ultrahigh-pressure gas cylinder liner and manufacturing method thereof

ActiveCN109595462AImprove machining accuracyNo weldVessel manufacturingContainer filling methodsGas cylinderEngineering

The invention provides a double-end-end ultra-large-size ultrahigh-pressure gas cylinder liner and a manufacturing method thereof. The double-end-seal ultra-large-size ultrahigh-pressure gas cylinderliner comprises a straight cylinder section, a seal head A and a seal head B, wherein the seal head A and the seal head B are positioned at the two ends of the straight cylinder section respectively,a bottle opening A and a bottle opening B are located on the sealing head A and the sealing head B respectively; the inner container of the ultrahigh-pressure gas cylinder is an aluminum alloy inner container with the length of 5-13 m, the nominal outer diameter of the straight cylinder section ranges from phi 300-phi 850 mm, and the rated pressure of the ultrahigh-pressure gas cylinder ranges from 35-70 Mpa. According to the double-end-end ultra-large-size ultrahigh-pressure gas cylinder liner and the manufacturing method thereof, the spinning processing method is adopted, the whole product is free of weld joints, the preparation process is simple, the operation is convenient, the energy consumption is low, the pollution is small, the loss of raw materials is less, and the raw material cost is saved; the double-end-seal ultra-large-size ultrahigh-pressure gas cylinder liner and the manufacturing method has the characteristics of being large in size, high in reliability and thin in wall, and light in weight; and the inner material structure is uniform and compact, the overall strength effect is excellent, and the double-end-seal ultra-large-size ultrahigh-pressure gas cylinder liner has the high-pressure-resistant characteristic and has important significance in the manufacturing of the ultrahigh-pressure gas cylinder.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

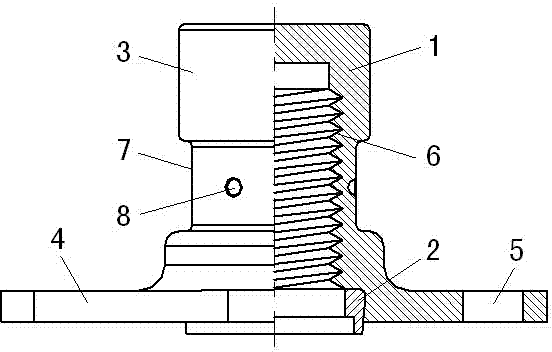

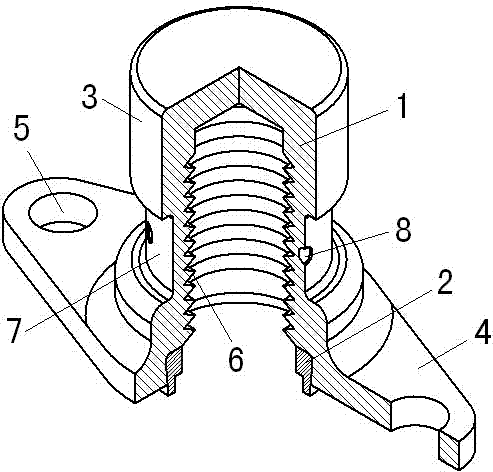

Sealing self-locking nut assembly and manufacturing method

The invention discloses a sealing self-locking nut assembly and a manufacturing method. The sealing self-locking nut assembly comprises a sealing self-locking nut (1) and a sealing ring (2). The sealing self-locking nut (1) comprises a sealing sleeve (3), connecting flanges (4) are arranged at the bottom of the sealing sleeve (3), and a connecting hole (5) is formed in each connecting flange (4). Inner threads (6) are arranged in the sealing sleeve (3), a sealing groove is formed in the position of an opening of the sealing sleeve (3), and the sealing ring (2) is arranged in the sealing groove. By means of the sealing self-locking nut assembly, the weight of the nut can be reduced to be about 15% of original weight, and significant contributions are made to the loading capacity of an aircraft. The sealing self-locking nut assembly in the structure mode further has the good sealing performance and has the advantage of being resistant to the high pressure, the high temperature and corrosion. A preset tightening force moment value can be achieved by controlling the close-in amount of a close-in point, and the nut can be prevented from loosening under strong vibration. The work reliability of the aircraft and a submersible is improved. The sealing self-locking nut assembly and the manufacturing method are good in prospect and have the popularization value.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

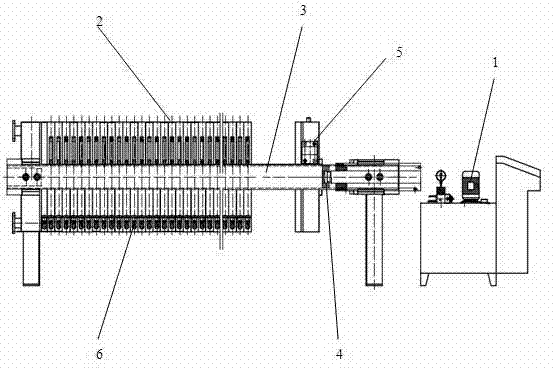

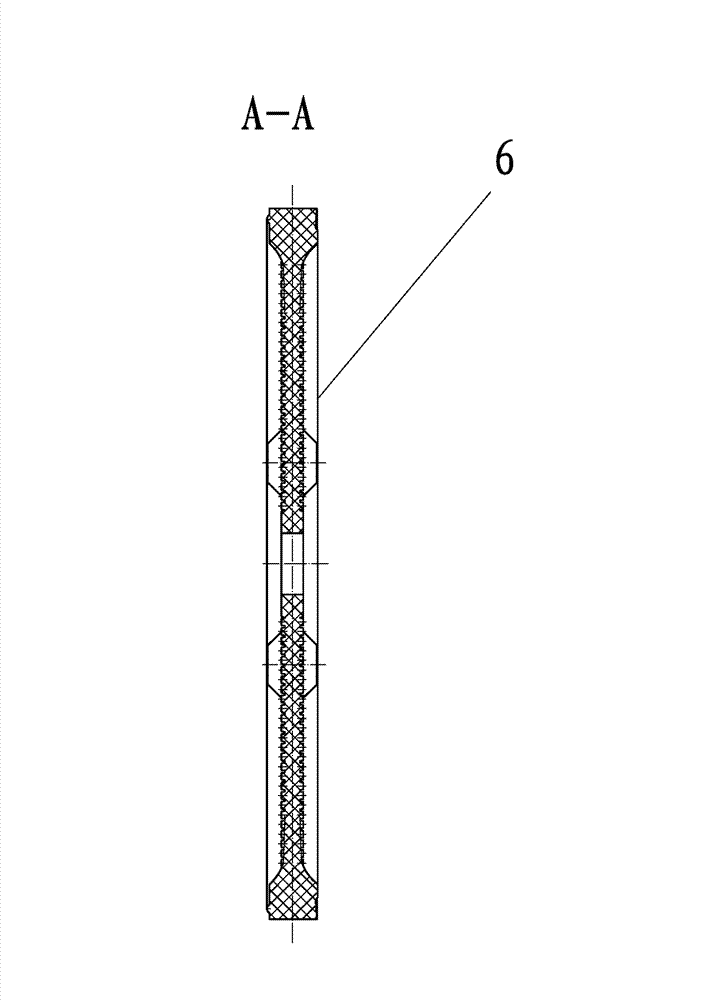

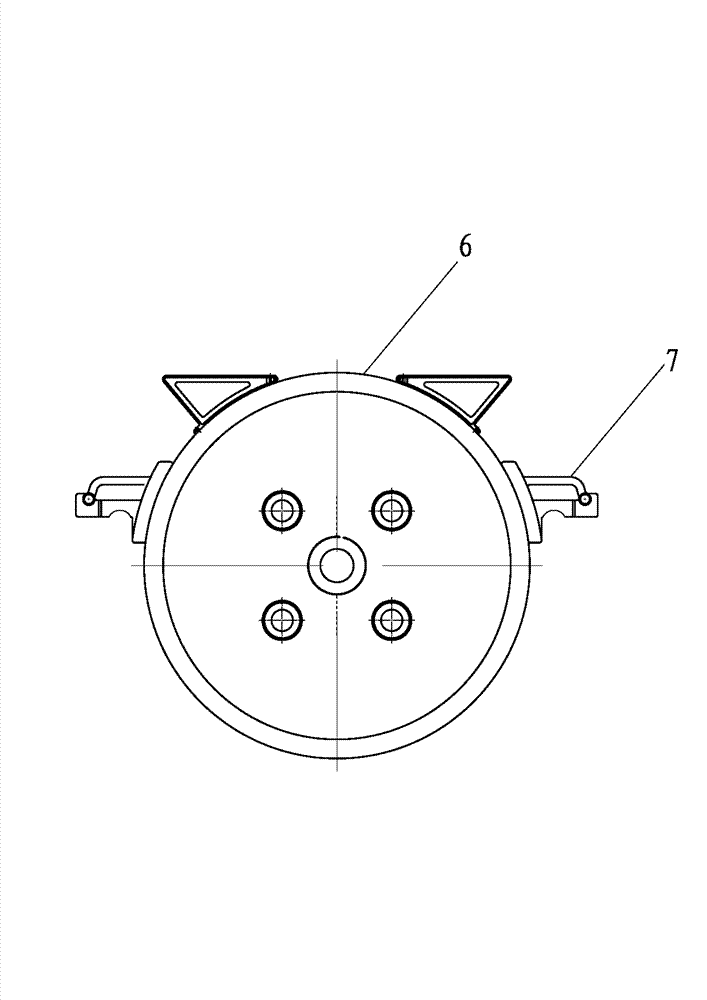

Ceramic filter pressing plate, manufacturing method thereof and filter press using same

InactiveCN102701643ASave energyHigh pressure resistantCeramic shaping apparatusFiltration separationFilter pressPolypropylene

The invention relates to the technical field of the filter pressing plate of a filter press, in particular to a ceramic filter pressing plate, a manufacturing method thereof and a filter press using the ceramic filter pressing plate. The ceramic filter pressing plate is formed by pressing the mixture of ceramic waste residues and polypropylene. Compared with the prior art, the ceramic filter pressing plate and the filter press using the ceramic filter pressing plate are characterized in that: the ceramic waste residues are reused so that no pollution is caused to the environment, in addition, the energy consumption of polypropylene or polyethylene material is lowered, and the cost is saved.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

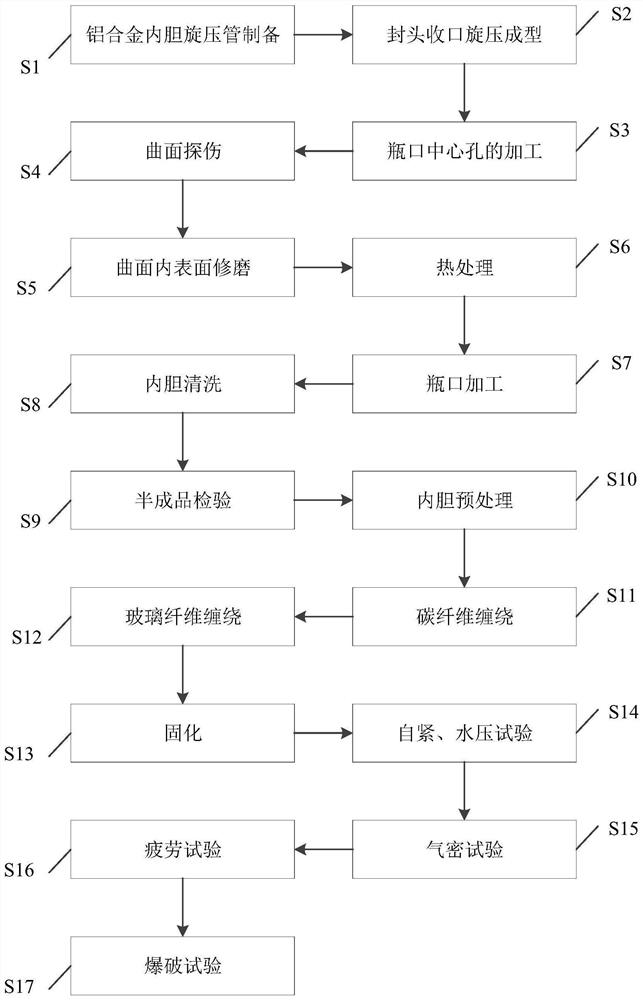

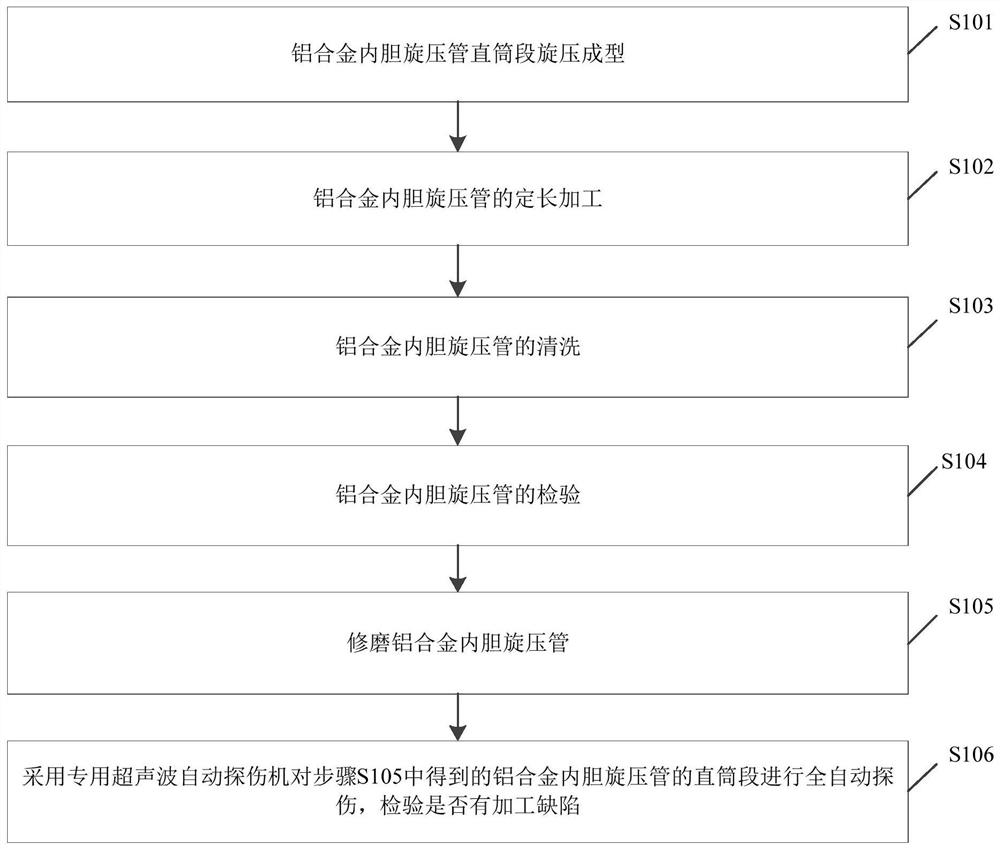

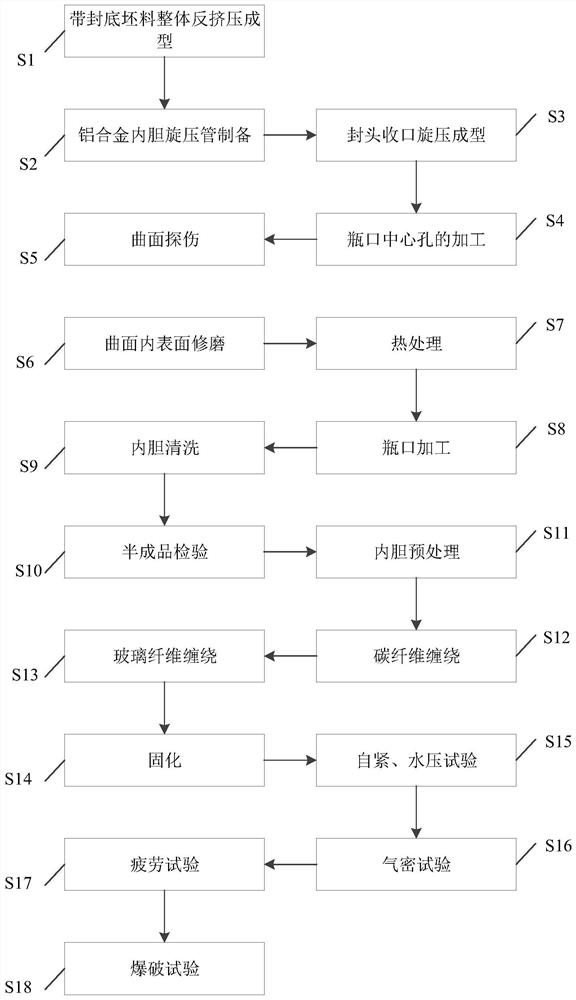

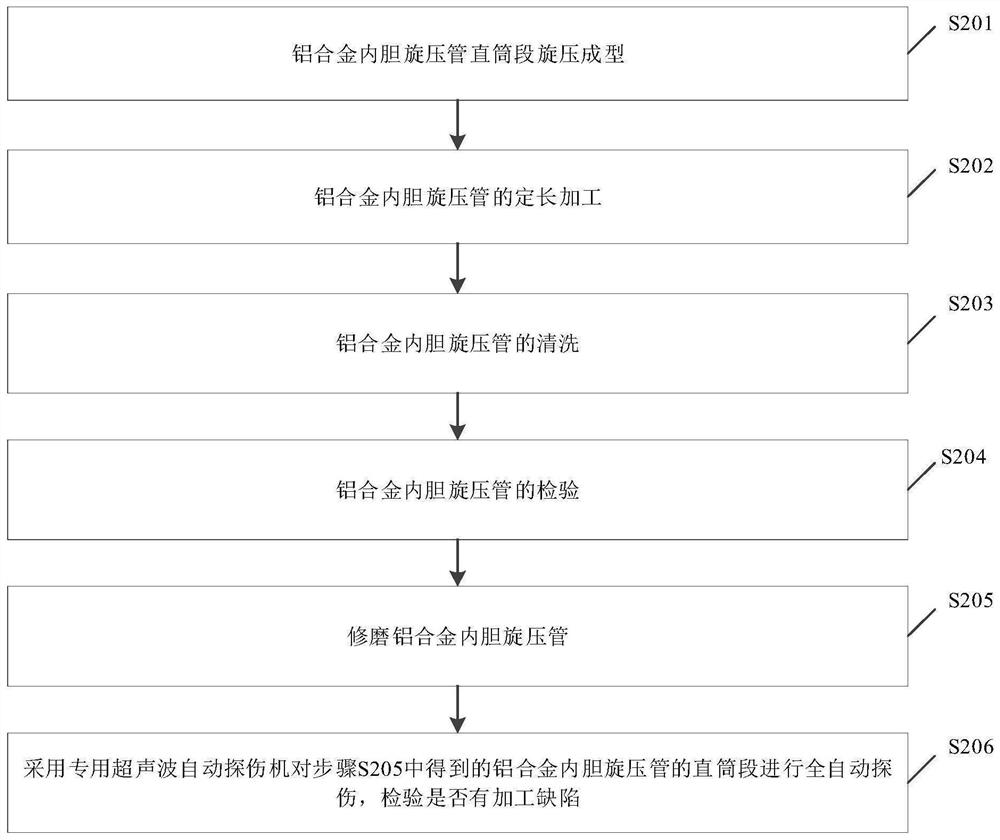

Large-scale ultrahigh-pressure gas cylinder liner and manufacturing method thereof

ActiveCN109668051AReduce lossLow costVessel manufacturingVessel geometry/arrangement/sizeEngineeringUltra high pressure

The invention provides a large-scale ultrahigh-pressure gas cylinder liner and a manufacturing method thereof. The large-scale ultrahigh-pressure gas cylinder liner is characterized in that on end ofthe liner is bottom sealed, and the other end of the liner is formed a sealing head and a bottle opening by closing, and the liner is an integrated seamless structure of a aluminum alloy liner, the liner comprises a straight cylinder section, a sealing bottom and a sealing head, wherein the sealing bottom and the sealing head are located at the two ends of the straight cylinder section respectively, the bottle opening is located on the sealing head; and the length of the aluminum alloy liner is 5-13m, the nominal outside diameter of the straight cylinder section is Phi 300-Phi 500 mm, the nominal pressure of the ultrahigh-pressure gas cylinder is 35-70 Mpa. According to the method, a slab is adopted as a raw material, a spinning method is adopted overall, the product does not have a weld joint, the preparation process is simple, the operation is convenient, the energy consumption is low, the pollution is small, the loss of raw materials in the manufacturing process is less, and the rawmaterial cost is saved. The aluminum alloy liner processed by the manufacturing method has the advantages of being huge in size, high in reliability, thin in wall, and light in weight; the internal material is uniform and compact in structure and excellent in overall strength effect, and has the characteristics of ultrahigh pressure resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Anti high-pressure, high temperature resistant oxidation lubricant and preparation method thereof

InactiveCN1687338AHigh pressure resistantHigh temperature oxidation resistanceLubricant compositionCorrosionMetal deactivator

The present invention discloses a lubricating oil capable of resisting high pressure and resisting high temperature oxidation for deep-weel electric pump and its preparation method. Its composition includes base oil, alpha-olefin synthetic oil, at least an antioxidant corrosion-resisting agent, extreme pressure phosphorus or sulfur contained ashless antiwear agent, amine high-temperature antioxidant and metal deactivator, metal cleaning agent, rust-resisting agent and pour point reducer. Said invention also can be used for making hydraulic transmission mechanical lubricating oil.

Owner:JILIN UNIV

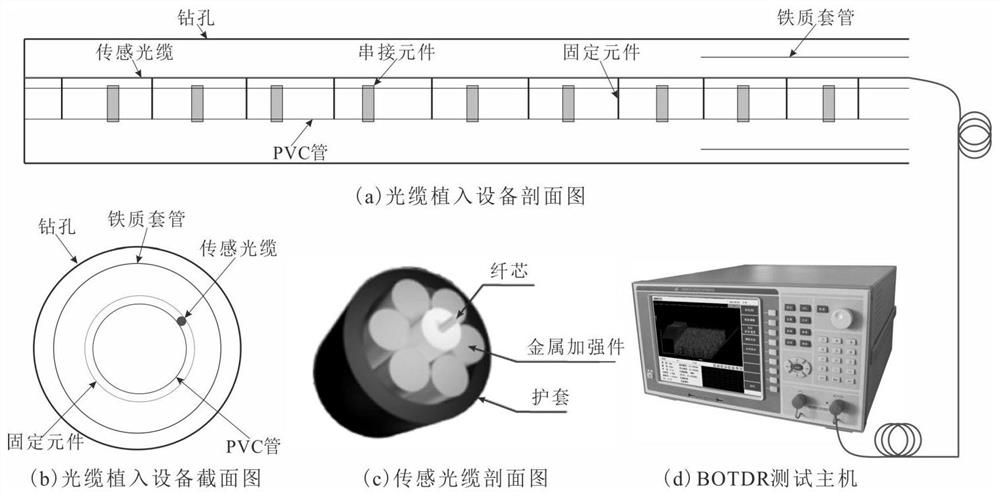

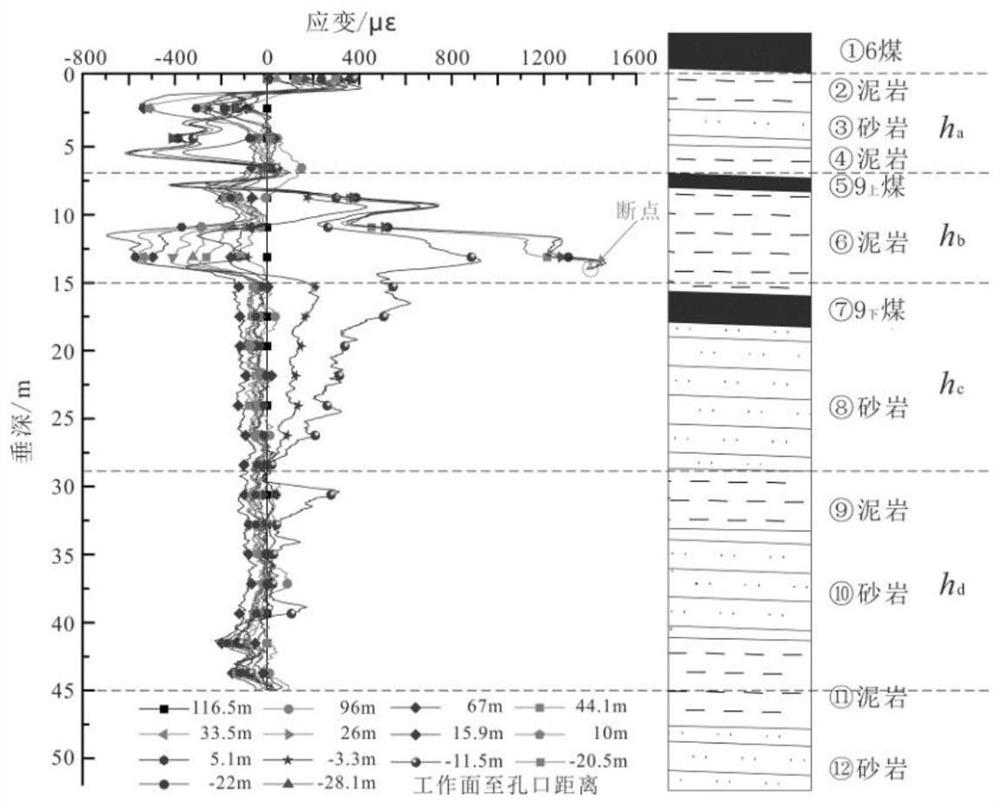

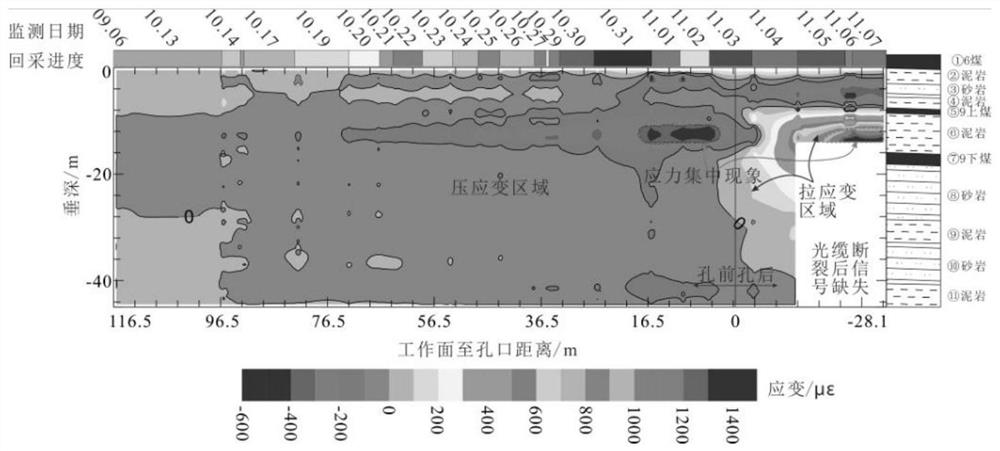

Method for reconstructing advanced support pressure evolution model of deep stope based on DFOS strain

ActiveCN112016201AHigh pressure resistantWith anti-electromagnetic interferenceData processing applicationsDesign optimisation/simulationData acquisitionMonitoring system

The invention discloses a method for reconstructing an advanced support pressure evolution model of a deep stope based on DFOS strain. The method comprises the following steps: construction of a monitoring system, strain body data acquisition of advance support pressure, processing and analysis of massive strain data bodies, reconstruction of a stope advance support pressure evolution model, correction of the stope advance support pressure evolution model and the like. In the method for reconstructing an advanced support pressure evolution model of a deep stope based on DFOS strain, a BOTDR technology in a DFOS technology is adopted; a strain state of a rock stratum in a certain depth range of a stope bottom plate is dynamically captured in a coal seam stoping process; the two-dimensionalgeological model of advance support pressure distribution in the mining process is established, the method has the advantages of being high in applicability and convenient and fast to operate, and good safety guarantee can be provided for preventing roadway surrounding rock instability, rock burst, coal and gas outburst and the like.

Owner:ANHUI UNIV OF SCI & TECH

Aluminum alloy inner container for ultra-large high-pressure air bottle and manufacturing method thereof

ActiveCN109578800AReduce lossLow costVessel geometry/arrangement/sizeContainer filling methodsGas cylinderHigh pressure

The invention provides an aluminum alloy inner container for an ultra-large high-pressure air bottle and a manufacturing method. The aluminum alloy inner container comprises a straight cylinder segment, a seal head A and a seal head B, wherein the seal head A and the seal head B are located on the two ends of the straight cylinder segment, a bottle opening A and a bottle opening B are located on the seal head A and the seal head B correspondingly, the length of the aluminum alloy inner container for the ultra-large high-pressure air bottle is 5 to 13 m, the nominal outside diameter of the straight cylinder segment is phi 300 mm to phi 850 mm, and the rated pressure of the high-pressure air bottle is 20 to 30 Mpa. The rotary pressure machining method is adopted generally, the product is wholly free of welding line, the preparing process is simple, operation is convenient, energy consumption is low, the pollution is small, in the whole manufacturing process, the losses of the raw material are small, the raw material cost is saved, and the aluminum alloy inner container for the ultra-large high-pressure air bottle obtained through the manufacturing method has the advantages of being thin in wall, and small in mass. The inner material structure is compact and uniform, the whole strength effect is excellent, the high pressure resistance is achieved, and the method has the importantsignificance in high-pressure air bottle manufacturing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

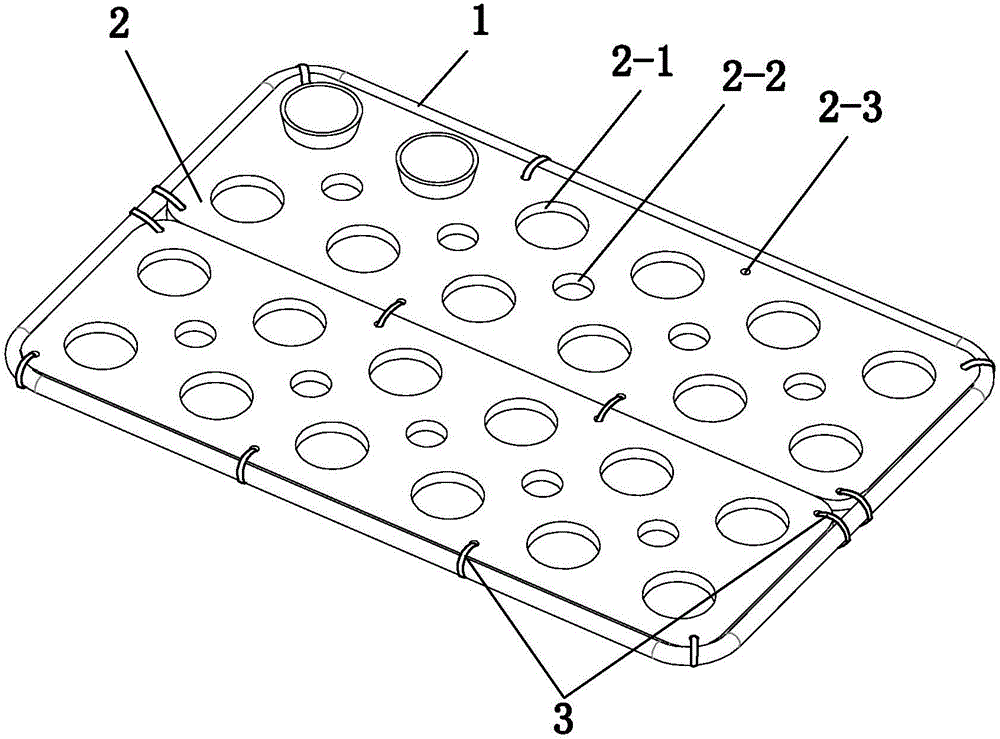

Method for purifying water quality by using pennisetum purpureum and ecological floating bed applying method

PendingCN106745789AGrow fastLarge biomassWater contaminantsBiological treatment apparatusPennisetum purpureumPolyvinyl chloride

The invention provides a method for purifying water quality by using pennisetum purpureum and an ecological floating bed applying the method. The pennisetum purpureum is planted on the ecological floating bed, and is used for absorbing, adsorbing, retaining and degrading contaminant through growth, so as to realize the purification of water quality. The method specifically comprises the steps of winding the stem base of a pennisetum purpureum cutting with a sponge bar absorbing enough water, fixing in a flower pot, placing the flower pot with plants in planting holes distributed along the water level of an water edge through a pot transferring device, when the pennisetum purpureum grows to 1 to 1.3m in height, reserving stubble with the length of 5 to 6cm and cradling. The ecological floating bed designed for the method consists of PVC (polyvinyl chloride) pipes and PS extruded sheets, and has the advantages of being wind and wave-resistant, antioxidant, extrusion resistant, long in service life, low-cost and the like. According to the method provided by the invention, the characteristics of large biomass, quick growth, developed root systems, cradle resistance and the like, and feeding and electricity generation functions of the pennisetum purpureum are utilized, and by applying the pennisetum purpureum into an ecological floating bed system, not only can water quality be effectively purified, but also economic output can be realized, so that the method is worthy of large-scale promotion.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

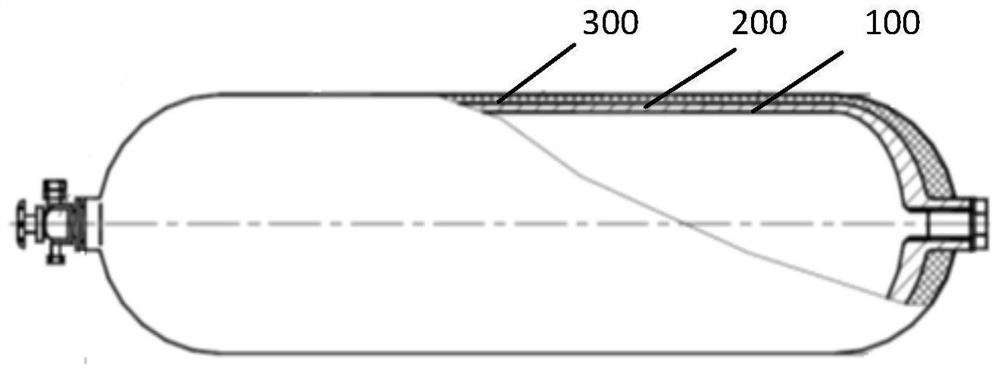

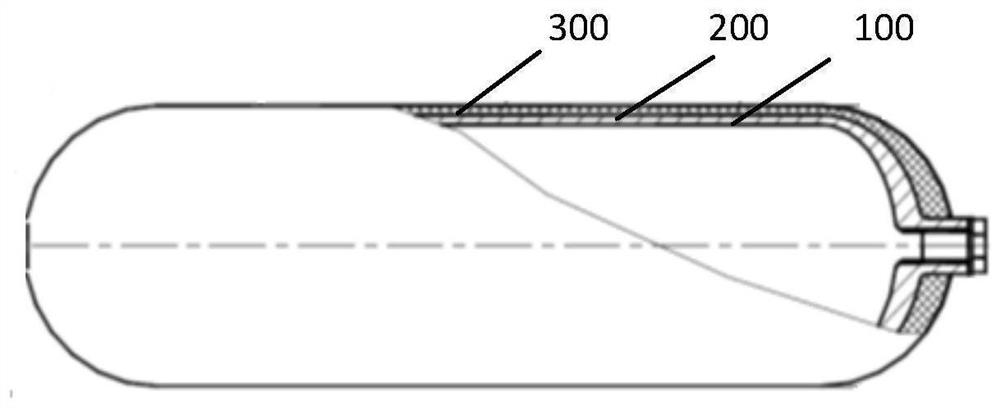

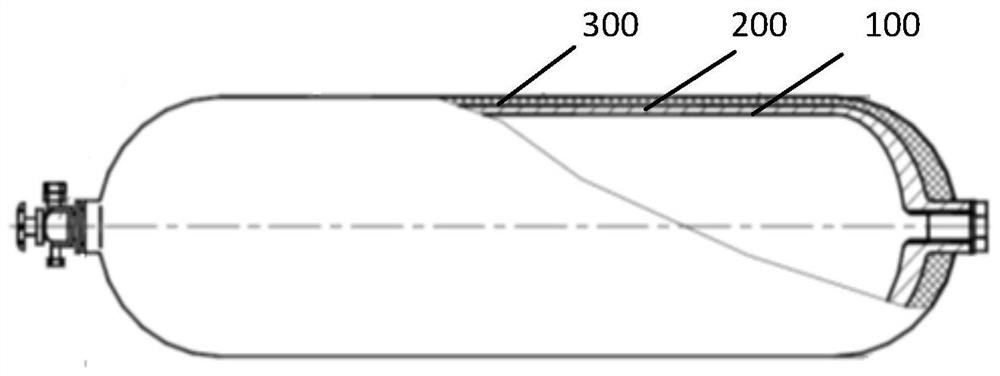

Aluminum alloy inner container ultrahigh-pressure full-wrapped gas cylinder and manufacturing method thereof

The invention provides an aluminum alloy inner container ultrahigh-pressure full-wrapped gas cylinder and a manufacturing method thereof. The aluminum alloy inner container ultrahigh-pressure full-wrapped gas cylinder comprises an aluminum alloy inner container, a composite material reinforcing layer and an external protective layer; the aluminum alloy inner container is of an integrated seamless structure with the two ends closed to form closure heads and cylinder openings, the first closure head and the second closure head are located at the two ends of a straight cylinder section respectively, and the first cylinder opening and the second cylinder opening are located on the first closure head and the second closure head respectively; the length of the gas cylinder is not greater than 5 m, the nominal outer diameter is (406, 850) mm, and the working pressure is (30, 90) MPa; the outer side of the aluminum alloy inner container is coated with the composite material reinforcing layer, and the composite material reinforcing layer is formed by winding carbon fibers in a spiral and annular combined winding mode and then performing curing by using resin; and the outer side of the composite material reinforcing layer is coated with the external protective layer, and the external protective layer is formed by winding glass fibers in a spiral and annular combined winding mode and then performing curing by using resin.

Owner:海鹰空天材料研究院(苏州)有限责任公司

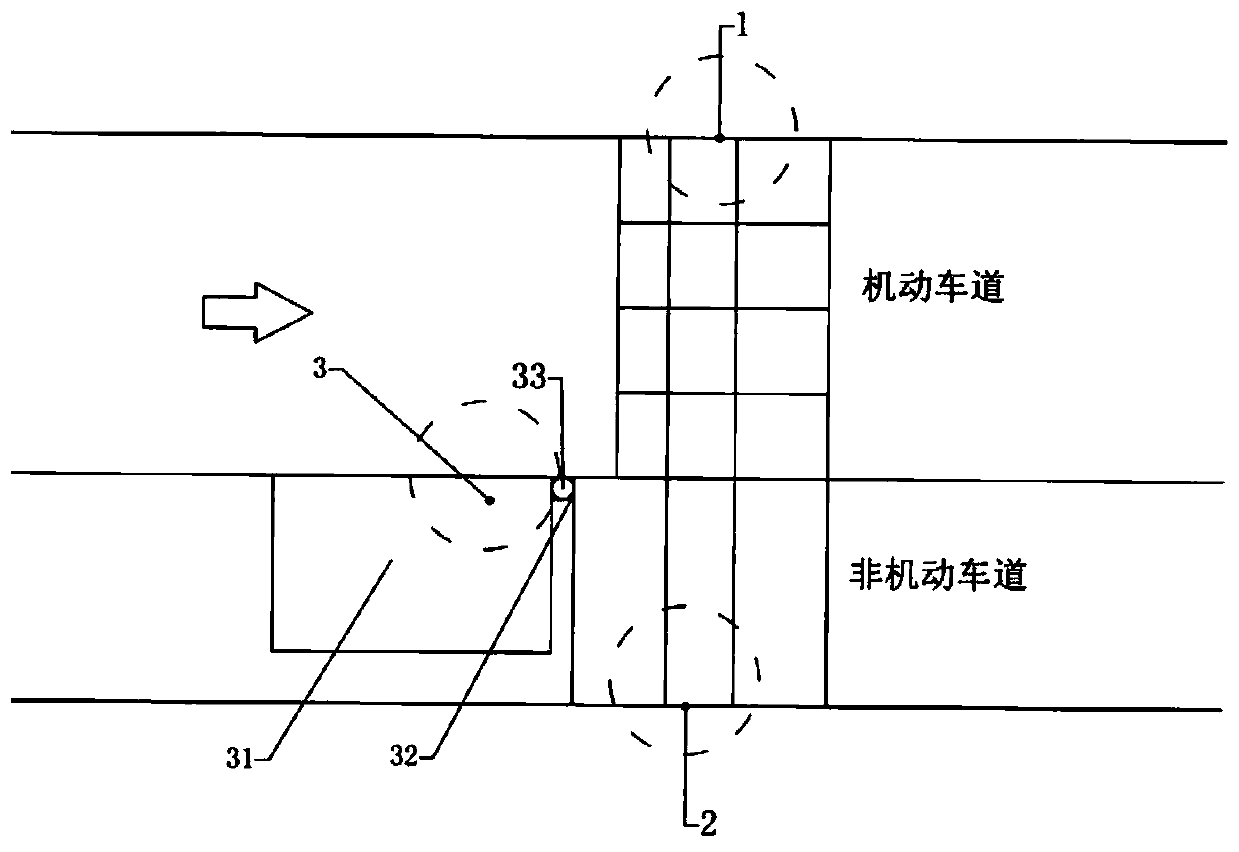

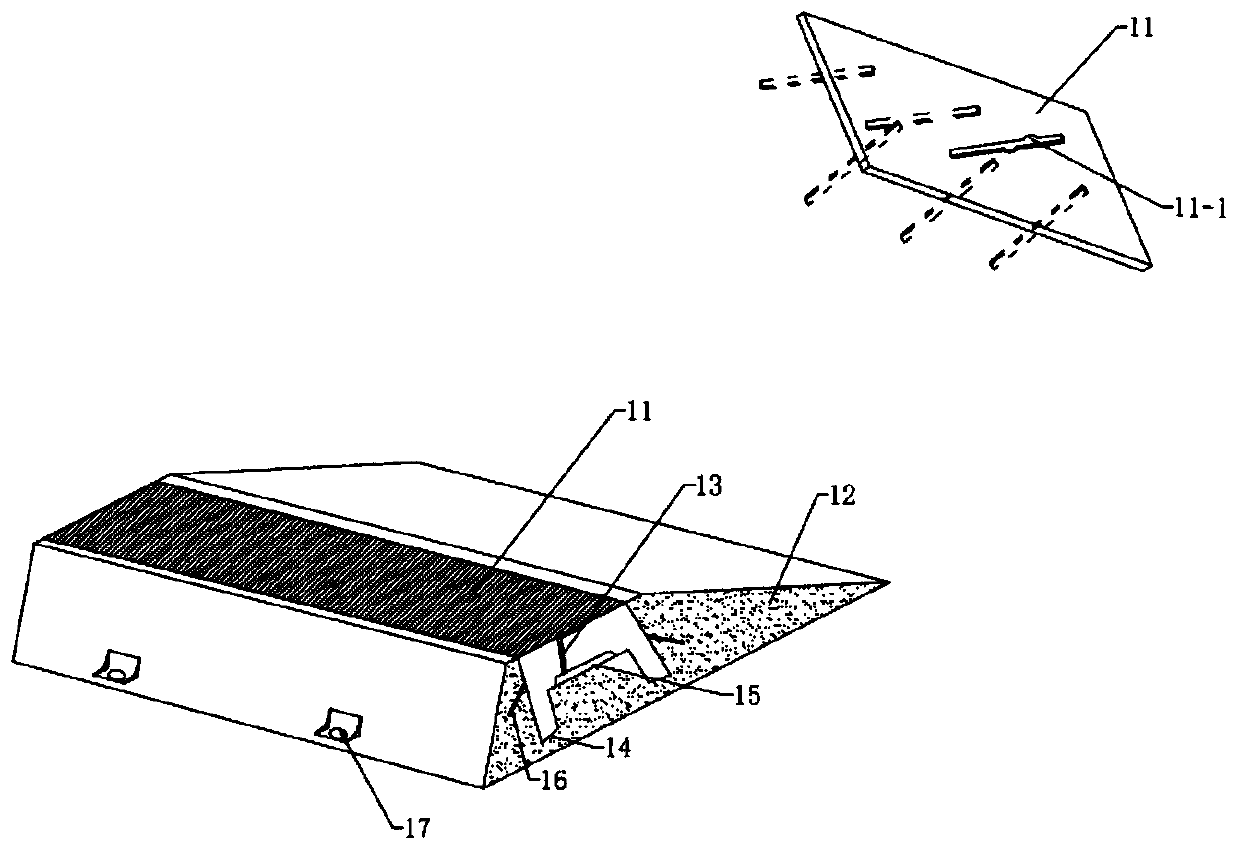

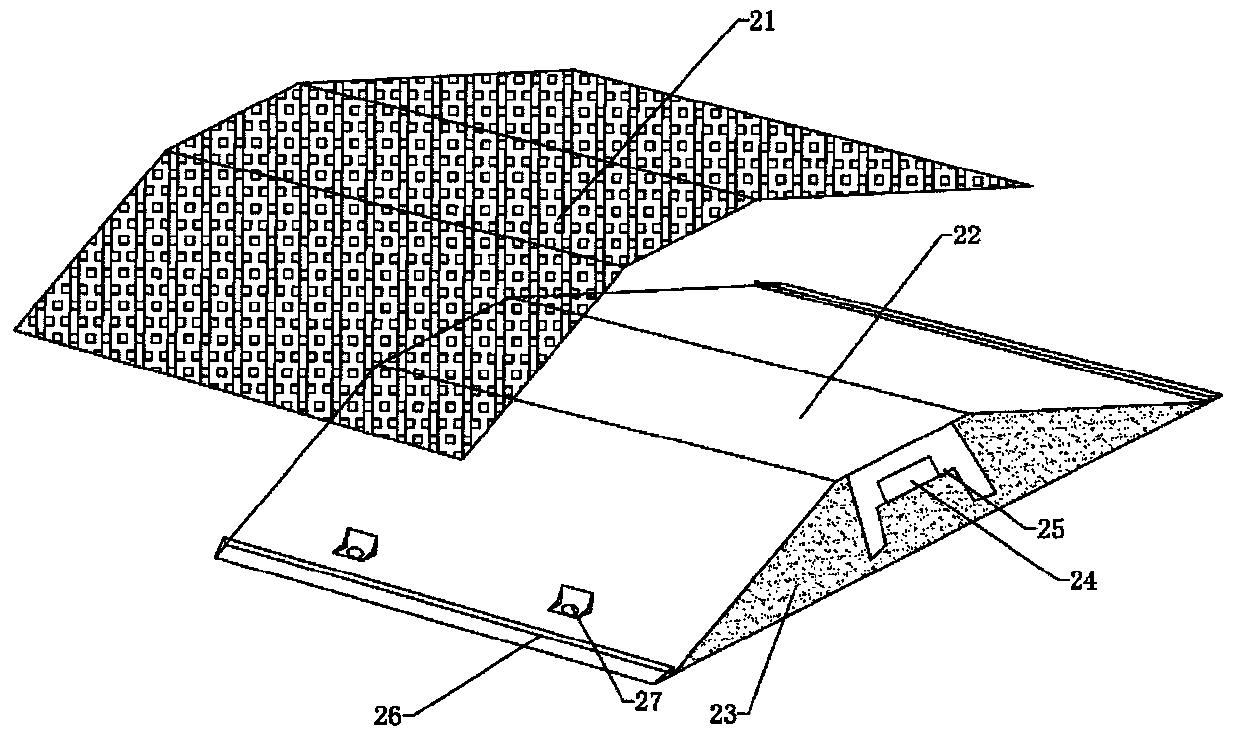

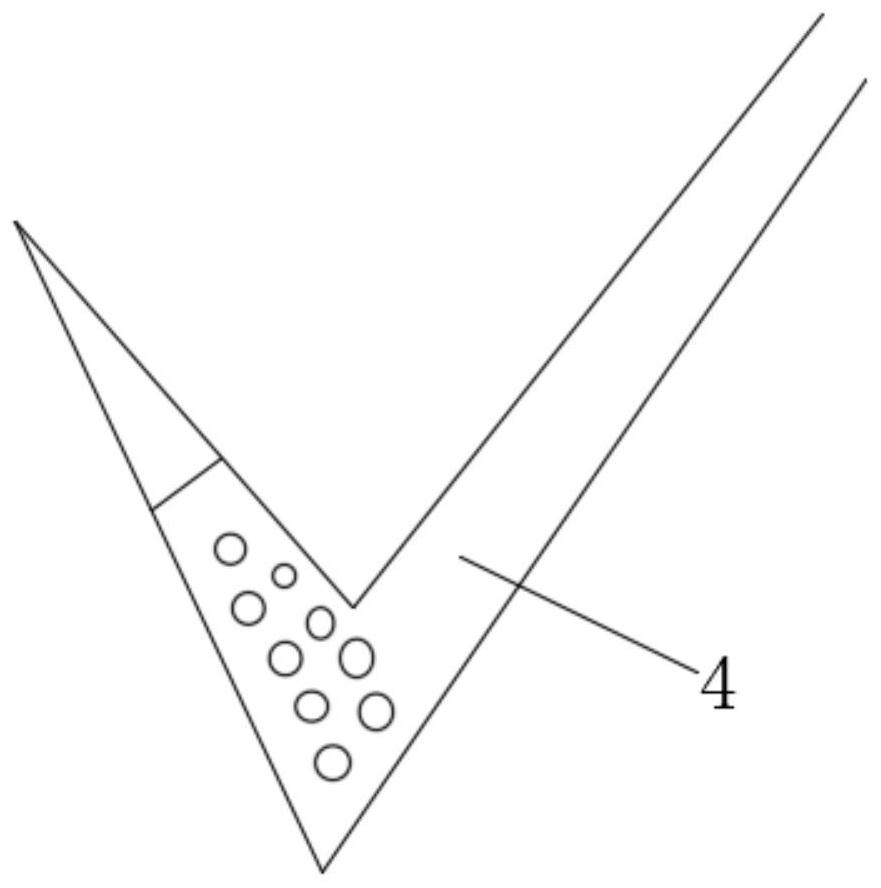

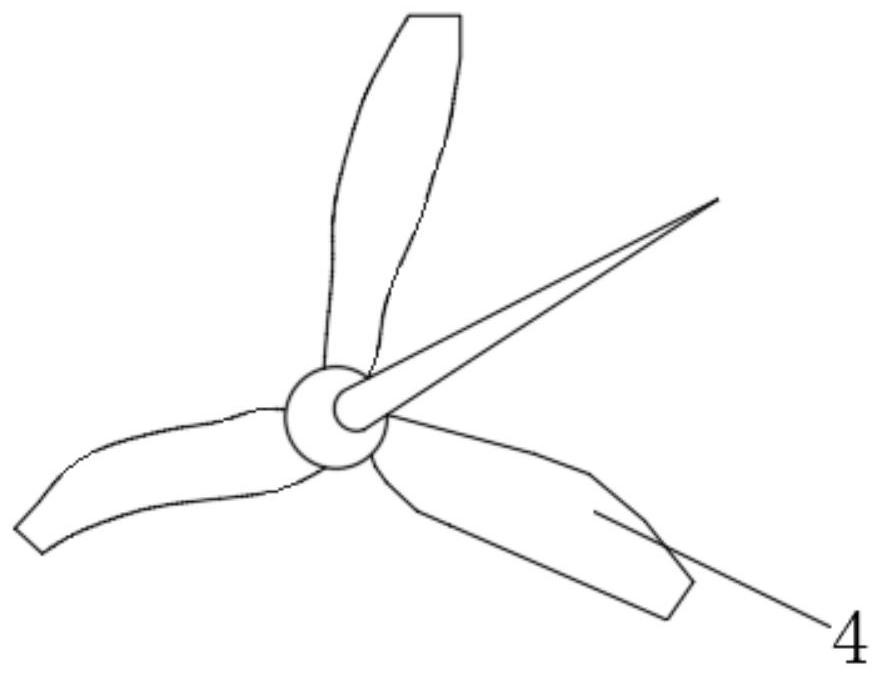

Motor vehicle and non-motor vehicle hybrid bump and method for preventing motor vehicle from crossing boundary

PendingCN111021271AEnsure comfortable and safe passageGood shock absorptionTraffic signalsEmbedding padsSpeed bumpVehicle driving

The invention discloses a motor vehicle and non-motor vehicle hybrid bump and a method for preventing a motor vehicle from crossing a boundary. The motor vehicle and non-motor vehicle hybrid bump comprises a motor vehicle bump, the end part of the motor vehicle bump is connected with a non-motor vehicle bump, and a boundary-crossing-preventing driving system is arranged in the vehicle driving direction of the non-motor vehicle bump; the boundary-crossing-preventing driving system comprises a pressure sensing area used for sensing the pressure value of a vehicle to the ground, an automatic lifting device used for automatically lifting according to the detected pressure value, and a boundary-crossing-preventing limiting device arranged at the top of the automatic lifting device. Aiming at the dynamic characteristics of the motor vehicle and the non-motor vehicle, the motor vehicle bump and the non-motor vehicle bump are respectively arranged, so that the motor vehicle can be prevented from crossing the boundary to occupy the position of the non-motor vehicle bump to run under normal conditions, and the motor vehicle bump is allowed to temporarily occupy the position of the non-motorvehicle bump under special conditions (such as fire fighting truck entry); and meanwhile, a good shock absorption function is achieved, and motor vehicles and non-motor vehicles can pass comfortably and safely.

Owner:CHANGAN UNIV

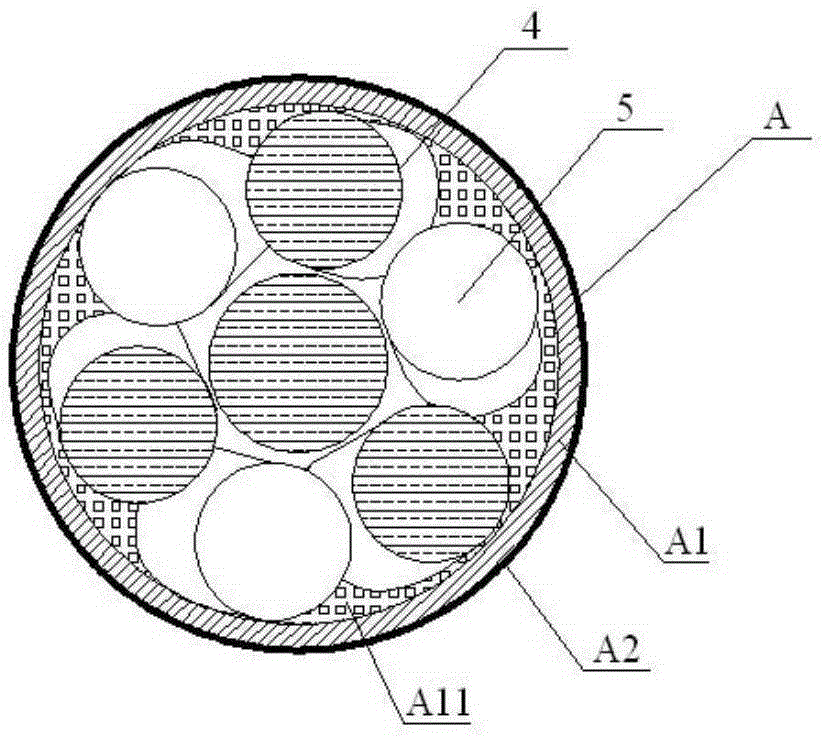

Safe composite high-pressure conveying cable

InactiveCN105387290AHigh pressure resistantAnti-extrusionInsulated cablesFibre mechanical structuresFiberHigh intensity

The invention relates to the field of cable preparation, in particular to a safe composite high-pressure conveying cable. The safe composite high-pressure conveying cable comprises a high-pressure conveying pipe and a woven sheath located outside the high-pressure conveying pipe, and further comprises a reinforcing cable, optical fibers and a cable, wherein the reinforcing cable, the optical fibers and the cable are located in the woven sheath; the reinforcing cable comprises a woven layer in the center and a high-strength plastic layer located outside the woven layer; flat and straight fibers are arranged among the reinforcing cable, the optical fibers and the cable and arranged around the optical fibers and the cable in parallel. The safe composite high-pressure conveying cable is unique in design, and the reinforcing cable is introduced into the composite high-pressure conveying cable, so that a conveying pipeline has the functions of resisting high pressure and squeezing and being not prone to deformation. The safe composite high-pressure conveying cable further has the advantages of being reasonable in design, novel in concept, simple in structure, economical, environmentally friendly, and capable of achieving industrial production easily, effectively overcoming the defects in the prior art and market products, and meeting the demand of the market.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

Ultrahigh-pressure full-winding gas cylinder with aluminum alloy inner container sealed at one end and manufacturing method of ultrahigh-pressure full-winding gas cylinder

PendingCN113898869AReduce lossLow costDetection of fluid at leakage pointVessel mounting detailsGlass fiberFiber

The invention provides an ultrahigh-pressure full-winding gas cylinder with an aluminum alloy inner container sealed at one end and a manufacturing method of the ultrahigh-pressure full-winding gas cylinder. The ultrahigh-pressure full-winding gas cylinder with the aluminum alloy inner container sealed at one end comprises the aluminum alloy inner container, a composite material reinforcing layer and an external protection layer; the aluminum alloy inner container is of an integrated seamless structure with one end sealed and the other end closed to form an end socket and a bottle opening, the end socket and the sealed bottom are located at the two ends of a straight cylinder section correspondingly, and the bottle opening is located on the end socket; the length of the aluminum alloy inner container is smaller than 5 meters, the nominal outer diameter of the straight cylinder section is phi 406-phi 850 mm, and the rated pressure of the ultrahigh pressure gas cylinder is 30-90 Mpa; the outer side of the aluminum alloy inner container is coated with the composite material reinforcing layer, and the composite material reinforcing layer is formed by winding carbon fibers in a spiral and annular combined winding mode and curing the carbon fibers through resin; and the outer protection layer is coated on the outer side of the composite material reinforcing layer, and is formed by winding glass fibers in a spiral and annular combined winding mode and curing the glass fibers by using resin.

Owner:海鹰空天材料研究院(苏州)有限责任公司

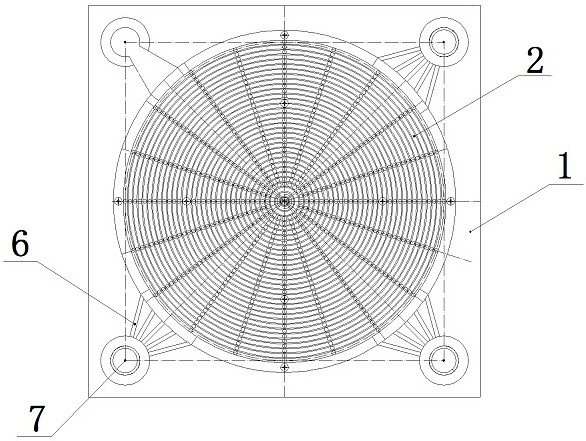

Plate core embedded type stainless steel combined filter plate and corresponding compartment type filter mechanism

PendingCN112138439AFast liquidSave valuable resourcesFiltration separationRemanufacturingStructural engineering

The invention discloses a plate core embedded type stainless steel combined filter plate and a corresponding compartment type filter mechanism. The combined filter plate comprises a square plate frame, a detachable filter disc and a filter disc bracket, has a symmetrical double-sided structure and is made of a stainless steel material; the key points of the innovative scheme are as follows: a filter plate is improved into a cavity overhead type, and a plate core is replaceable; the filter disc support is embedded in a cavity of the square plate frame, the detachable filter disc is installed onthe filter disc support, namely, the filter disc is erected by the support to form a cavity overhead layer, and the flow guide net groove is not blocked any more. When the filter disc is corroded anddamaged, the filter disc can be detached and replaced to prevent the whole filter plate from being scrapped; the invention has the advantages that high temperature resistance and high pressure resistance are achieved, the cavity is overhead and unblocked, liquid discharging is fast, and the plate core is replaceable. The compartment type filter mechanism uses the combined filtering plate, so thatthe technical problems that a stainless steel filtering plate flow guide net groove is easy to block, a plate core cannot be partially replaced, and remanufacturing cannot be realized are solved; theoverhead cavity is formed, so that the filtering efficiency and effect are improved, the plate core is replaceable, precious resources are saved, and the use cost is reduced; and the invention is thedevelopment direction of remanufacturing of the stainless steel filter press.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

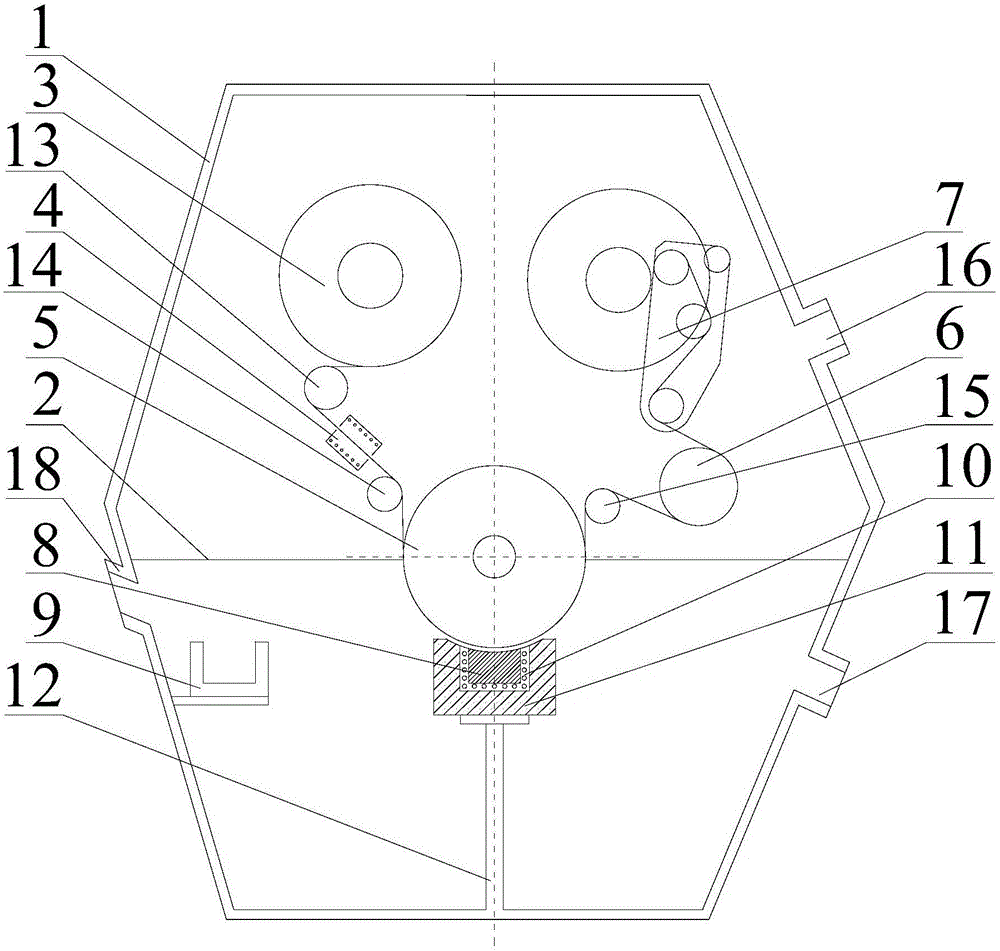

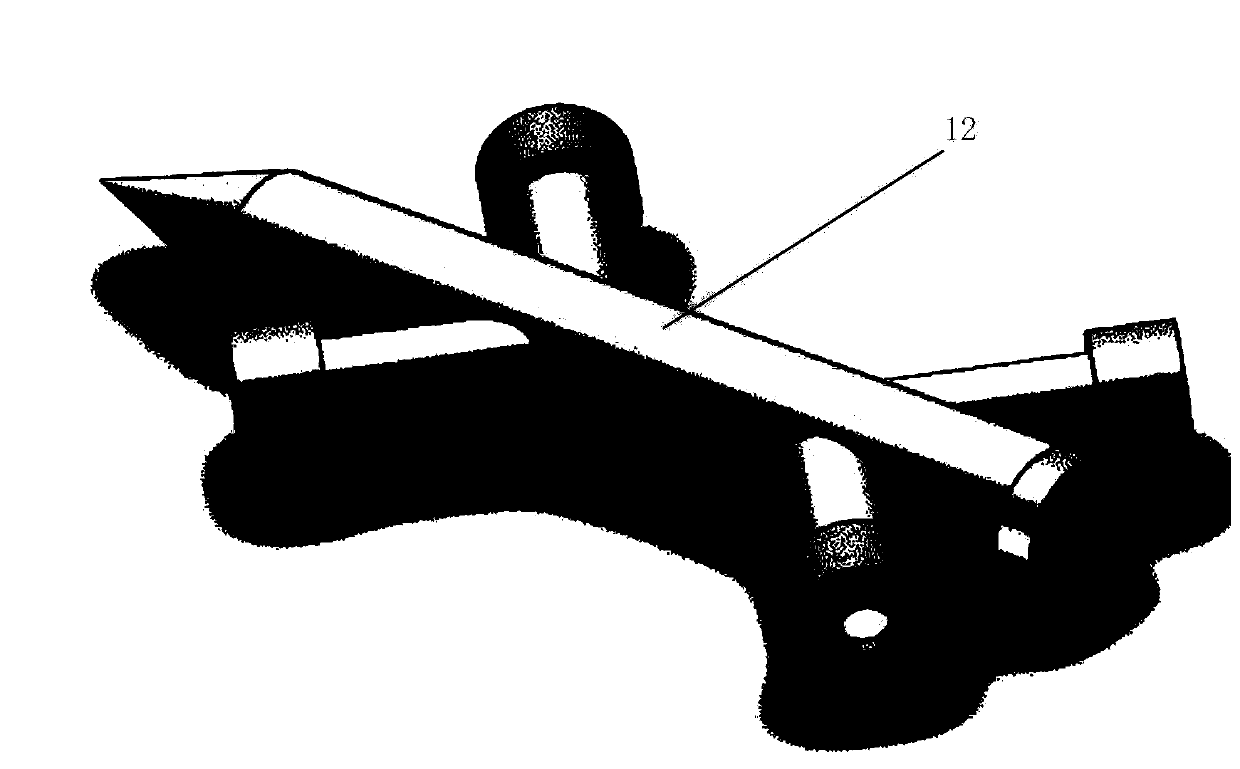

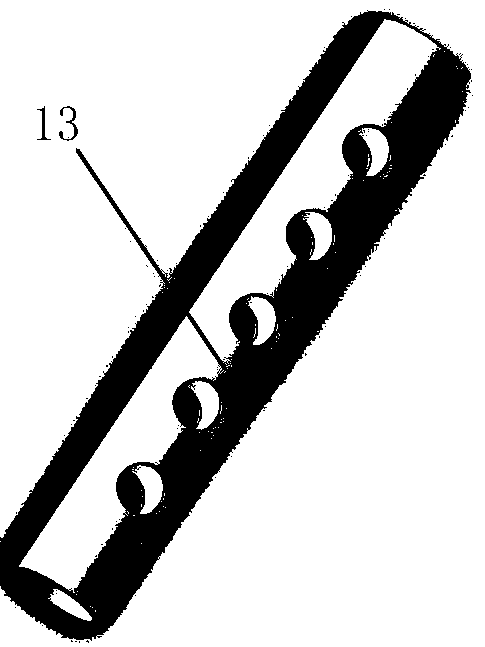

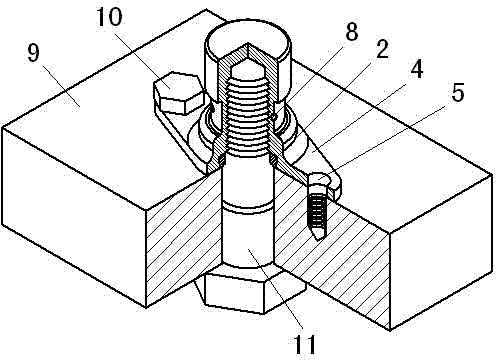

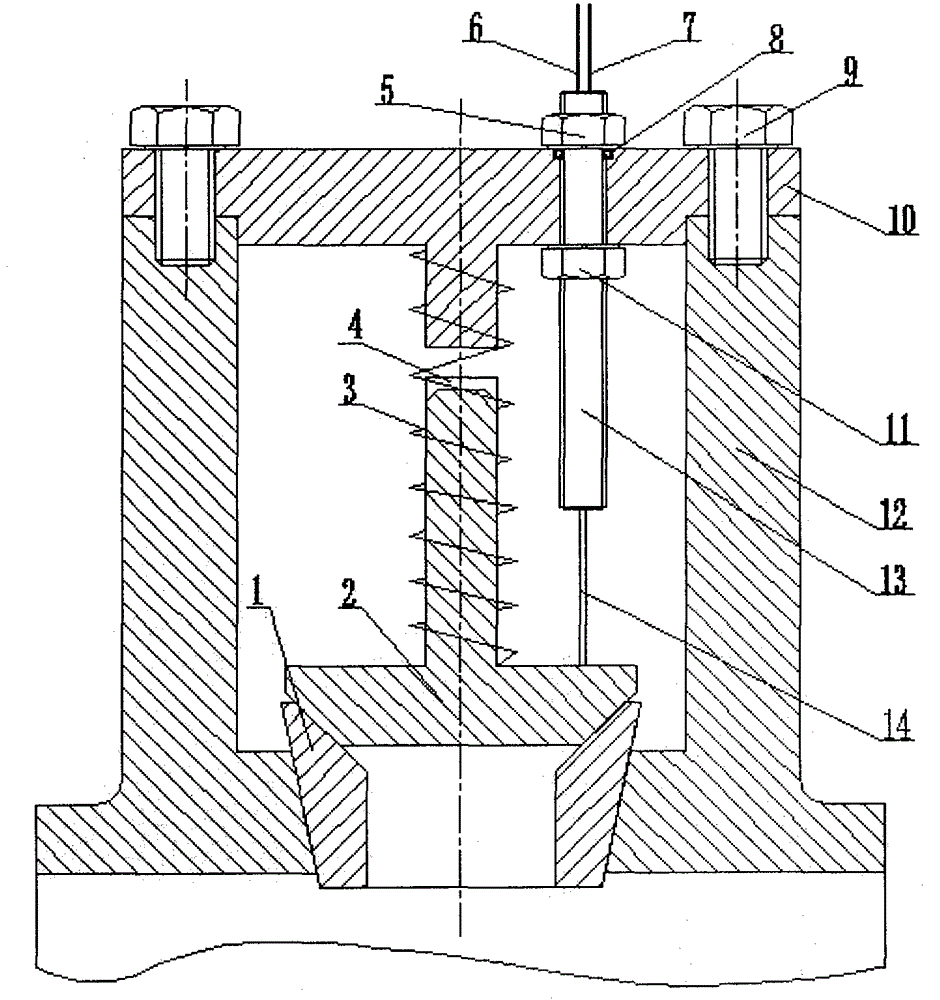

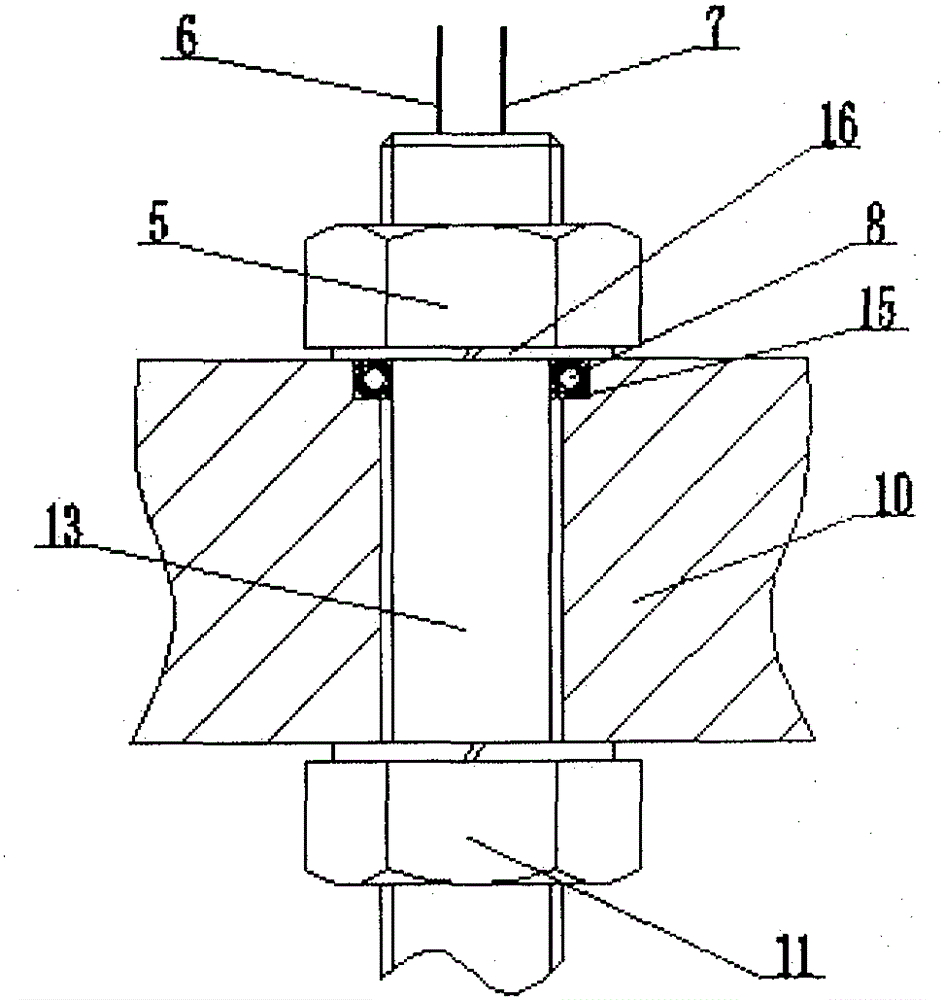

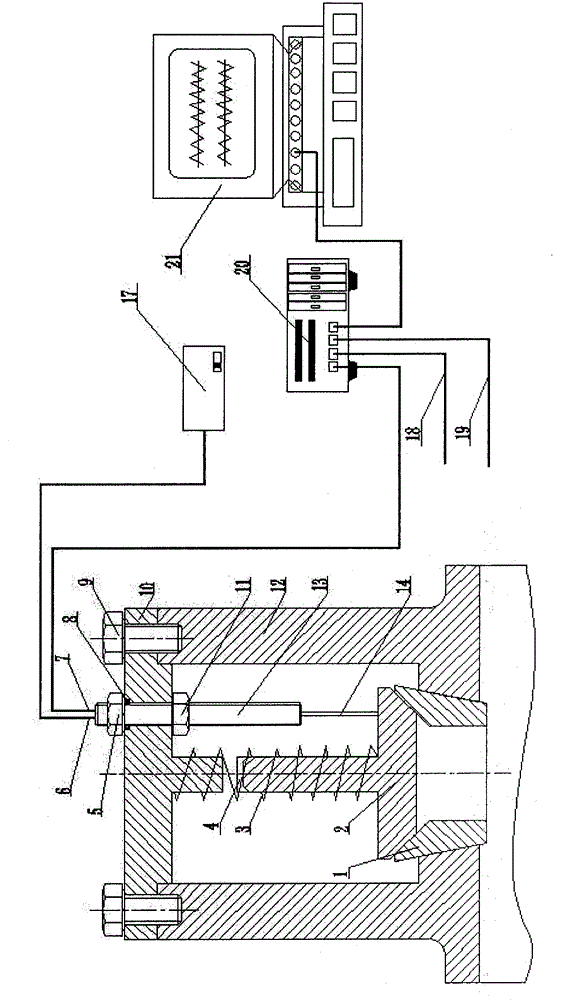

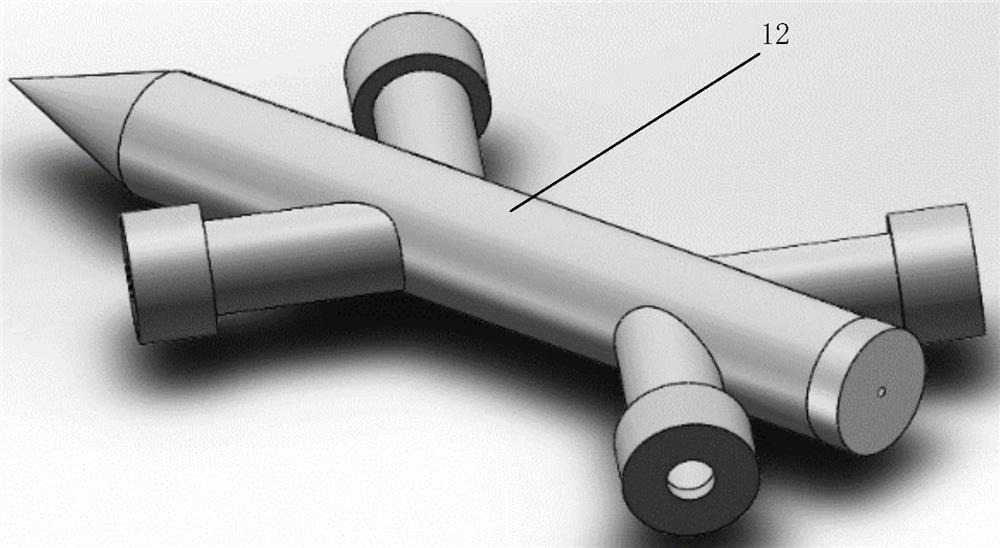

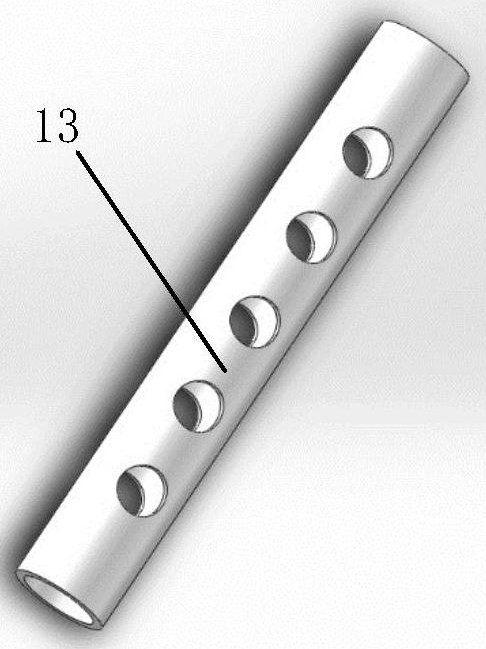

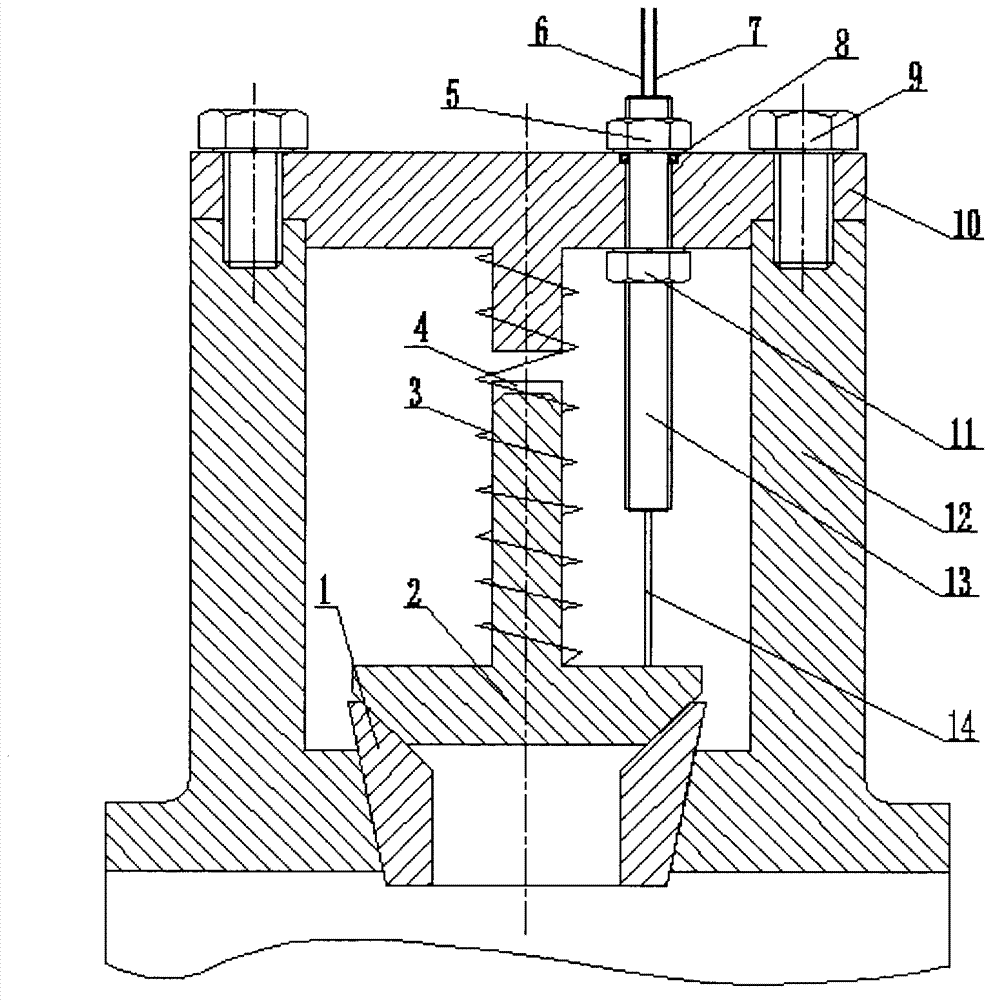

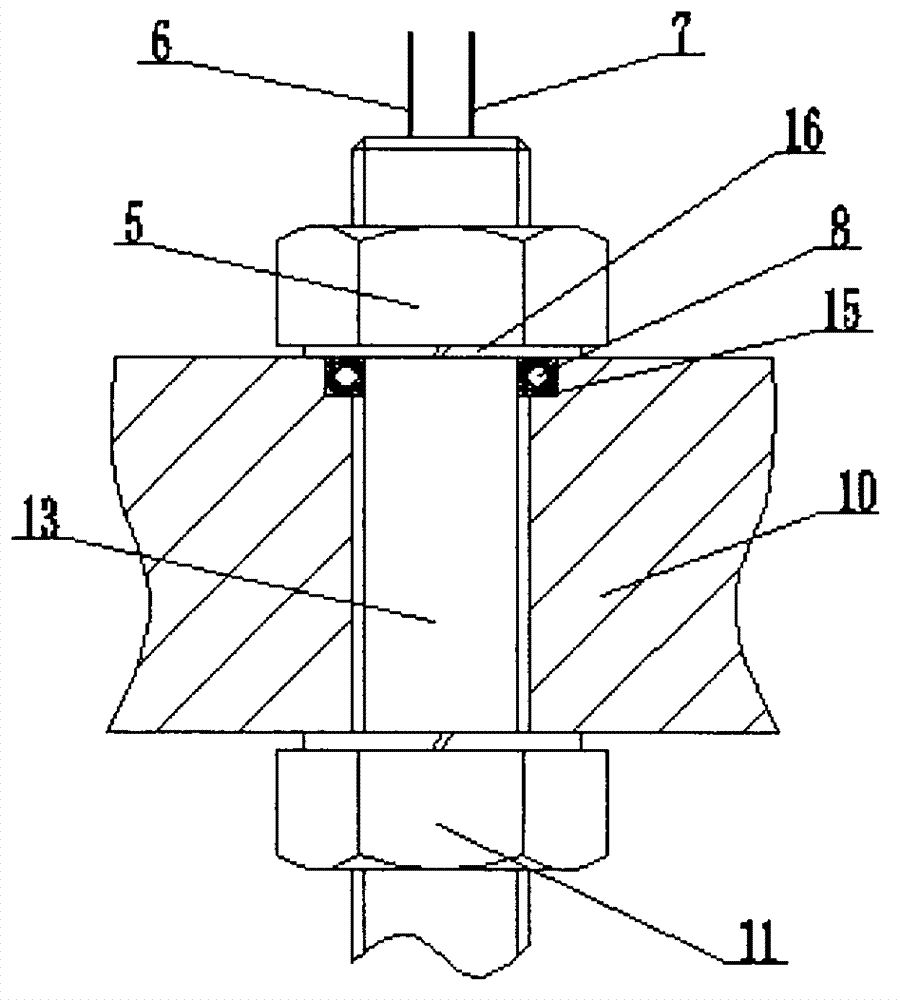

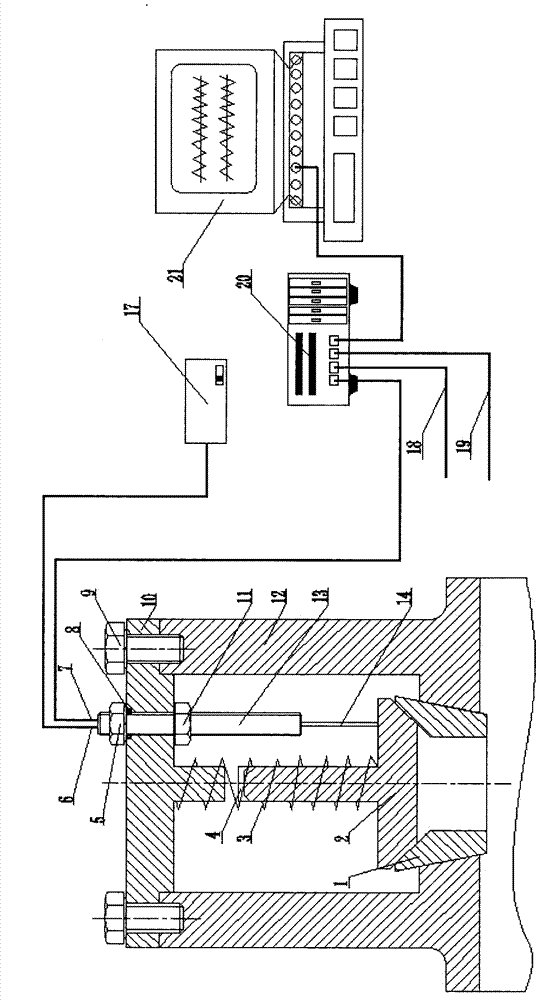

A device for measuring the displacement of the valve disc of a reciprocating pump

ActiveCN102768009BMeasured displacement changeLight in massUsing electrical meansHydraulic cylinderData acquisition

The invention discloses a device for measuring the valve disc displacement of a reciprocating pump valve. The device consists of a valve seat 1, a valve disc 2, a spring 3, an upper guide rod 4, an outer nut 5, an induction frequency modulation type displacement sensor power line 6, an induction frequency modulation type displacement sensor signal line 7, an O-shaped sealing ring 8, a bolt 9, a cylinder cover 10, an inner nut 11, a hydraulic cylinder 12, an induction frequency modulation type displacement sensor 13, an induction frequency modulation type displacement sensor guide rod 14, an induction frequency modulation type displacement sensor direct current power supply 17, a reciprocating pump flow signal 18, a reciprocating pump pressure signal 19, a data acquisition device 20, a computer and valve disc displacement testing and analyzing system 21 and the like, wherein a valve disc displacement signal output by the induction frequency modulation type displacement sensor 13, the reciprocating pump flow signal 18 and the reciprocating pump pressure signal 19 are transmitted into the computer 21 through the data acquisition device 20 and are processed by the valve disc displacement testing and analyzing system which is autonomously developed, and a change rule of the valve disc displacement of the pump valve under different flows and pressures is obtained.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

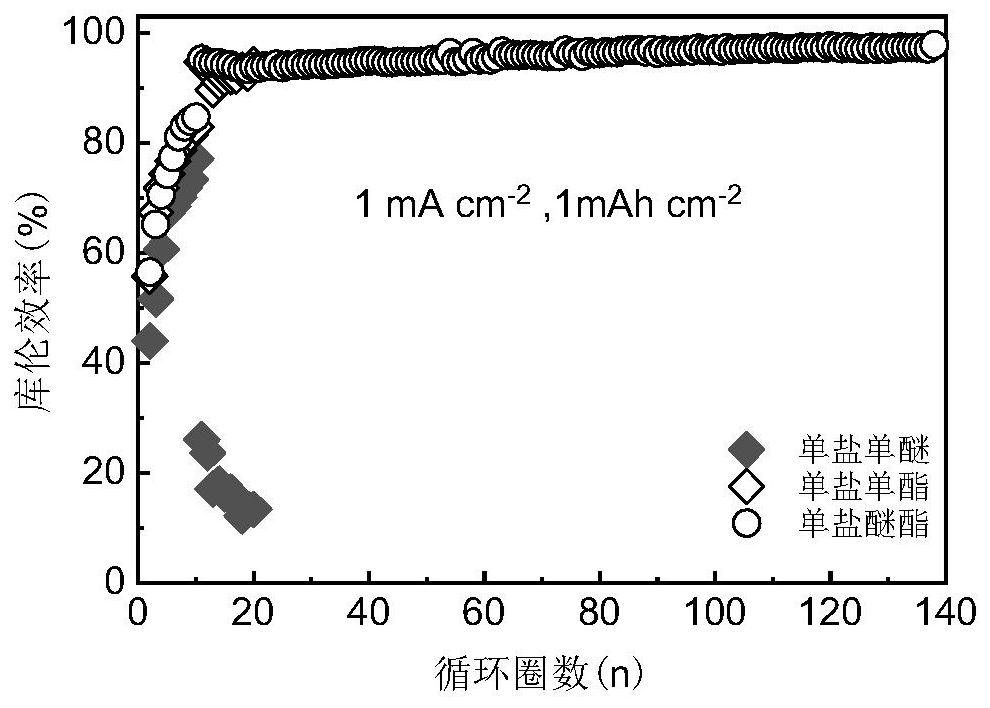

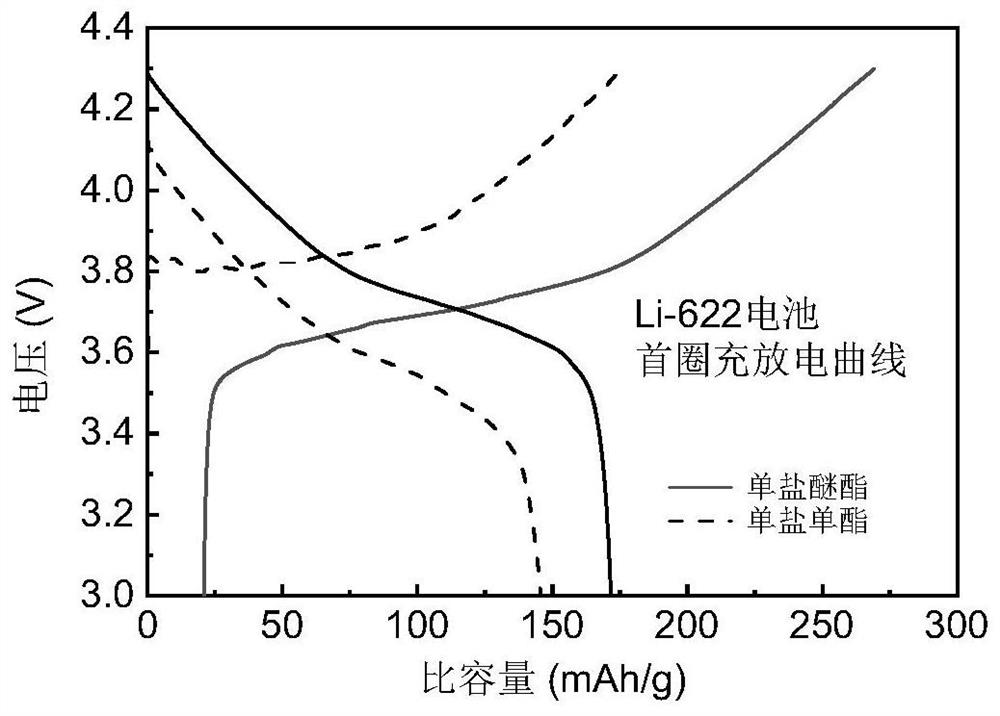

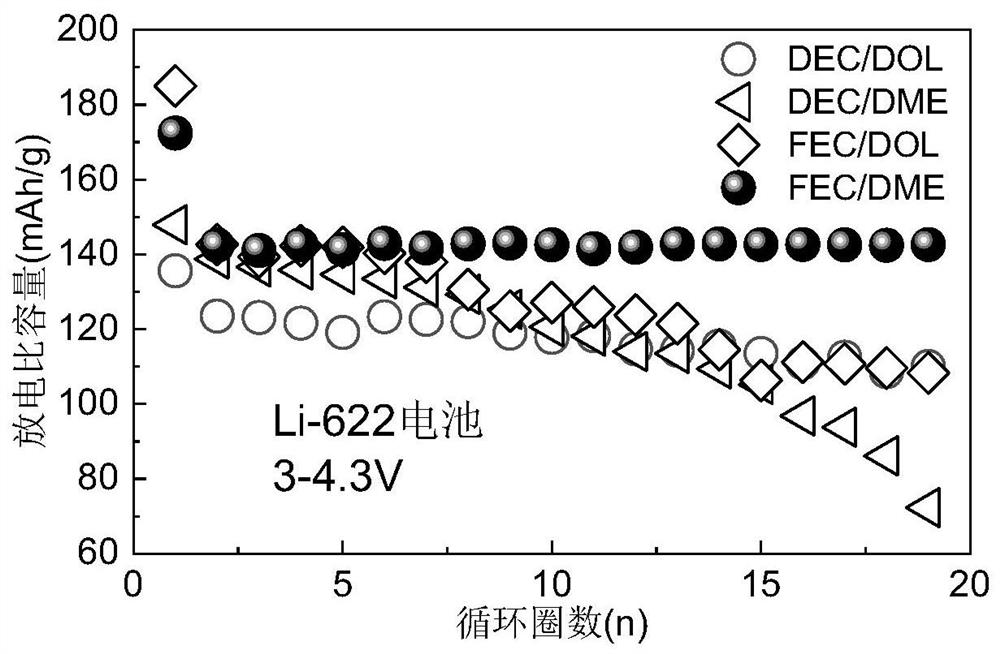

Difunctional lithium metal battery electrolyte and application thereof

InactiveCN113851721AStable high voltage cathodeHigh-voltage cathode realizationElectrolytesLi-accumulatorsElectrolytic agentElectrical battery

The invention discloses a difunctional lithium metal battery electrolyte and application thereof, and belongs to the field of secondary batteries. The electrolyte contains single fluorine-rich lithium salt, ether ester mixed solvent for dissolving the lithium salt and an additive, and has the effect of stabilizing a high-voltage positive electrode and a lithium metal negative electrode at the same time; the ester solvent capable of forming a film on the positive electrode is introduced, so that the high-voltage positive electrode can be stabilized; by introducing the ether solvent, on one hand, the viscosity of the electrolyte is improved, and the conductivity and the electrode wettability are effectively improved, so that the high and low temperature performance of the electrolyte can be improved; on the other hand, the stability of the lithium negative electrode can be enhanced; the adopted single fluorine-rich lithium salt can be effectively combined with the ether solvent to inhibit the decomposition of the ether solvent, and can form a film at the lithium negative electrode to further enhance the stability of the lithium negative electrode; and the introduction of the ether solvent can significantly improve the solubility of the electrolyte, so that an efficient additive which cannot be dissolved in a traditional ester electrolyte can be introduced, and the performance of the battery is improved again.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Ultra-high pressure gas cylinder liner with end caps and manufacturing method thereof

ActiveCN109630863BReduce lossLow costVessel manufacturingPressure vesselsUltra high pressureSpinning

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

All-fiber temperature, salt and depth sensor based on micro-nano fiber coupler interferometer

ActiveCN110864742BAchieving high-sensitivity sensingHigh pressure resistantMeasuring open water depthConverting sensor output opticallyFiberPlankton

The present invention aims at the defects of micro-nano optical fiber and micro-nano optical fiber coupler that are weak in mechanical strength and easily affected by pollution, and the existing temperature, salt and depth sensors are bulky and have low precision, and design an interferometer based on micro-nano optical fiber coupler The all-fiber temperature, salt and depth sensor consists of micro-nano optical fiber coupler, sensor outer protective sleeve, sensor inner protective sleeve, two sensor inner protective sleeve caps, four sensor water inlet tank caps, four sensor water purification filter elements, Composed of two mirror films, sensor outer protective caps, optical fiber storage slots, and four filters, the sensor can simultaneously realize high-sensitivity sensing of three parameters of seawater temperature, salinity, and depth, with zero electronic components and a compact structure , high sensitivity, convenient integration and other performance advantages, and can block the influence of plankton, seaweed, sediment, etc. on sensor performance, and has good pressure resistance and stability.

Owner:NAT UNIV OF DEFENSE TECH

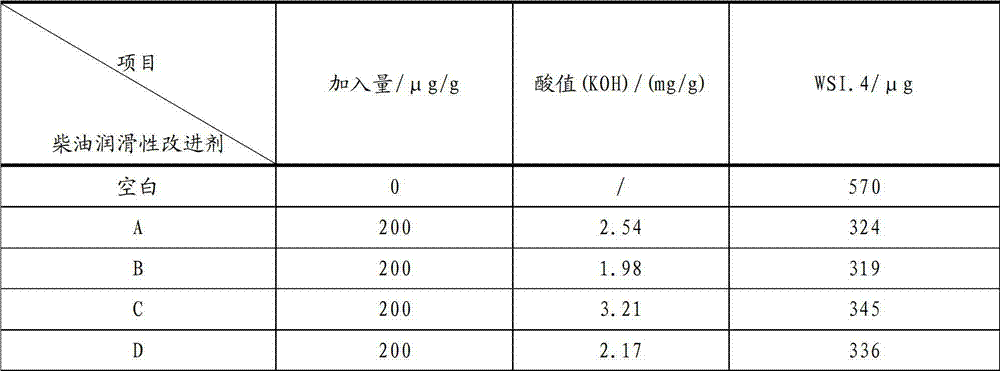

Diesel oil lubricity improving agent

ActiveCN102977945BImprove the lubrication effectExtended service lifeLiquid carbonaceous fuelsFuel additivesHazardous substanceHigh pressure

The invention relates to the technical field of chemical engineering, in particular to an environment-friendly diesel oil lubricity improving agent. After the diesel oil lubricity improving agent is added into diesel oil, lubricity of the diesel oil can be obviously improved. The diesel oil lubricity improving agent is obtained by alcohols and fatty acids under a catalytic reaction. After the diesel oil lubricity improving agent is used, the problems that poor lubricity leads to excessive abrasion of precision parts of an engine, poor atomization of the diesel oil, insufficiency of power of the engine, and the like can be solved. The diesel oil lubricity improving agent has the advantages of being resistant to high pressure and resistant to friction, reducing discharging hazardous substances, being energy-saving, environment-friendly, and capable of well improving lubricity of the diesel oil and prolonging the service life of the engine, and the like.

Owner:山东京博众诚清洁能源有限公司

Ultrahigh pressure gas bottle inner container and manufacturing method

ActiveCN109578801AFulfil requirementsHigh pressure resistantVessel geometry/arrangement/sizeContainer filling methodsGas cylinderHigh pressure

The invention provides an ultrahigh pressure gas bottle inner container and a manufacturing method. The gas bottle inner container is an integrated seamless structure aluminum alloy inner container with one end with a seal bottom and the other end closed up to form a seal head and a bottle opening; the inner container comprises the seal bottom, a straight cylinder segment, the seal head and the bottle opening, the seal bottom and the seal head are located on the two sides of the straight cylinder segment, the bottle opening is located on the seal head, the length of the aluminum alloy inner container is smaller than 5 m, the nominal outside diameter of the straight cylinder segment is phi 406 mm to phi 850 mm, and the rated pressure of the high-pressure gas bottle is 35 to 70 Mpa. The blank is adopted as the raw material, the rotary pressure machining method is adopted, the product is wholly free of welding line, the preparing process is simple, operation is convenient, energy consumption is low, the pollution is small, in the whole manufacturing process, the losses of the raw material are small, and the gas bottle obtained through the manufacturing method has the advantages of being high in reliability, thin in wall, and small in mass. The inner material structure is compact and uniform, the whole strength effect is excellent, the high pressure resistance is achieved, and themethod has the important significance in high-pressure gas bottle manufacturing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Device for measuring valve disc displacement of reciprocating pump valve

ActiveCN102768009AMeasured displacement changeLight in massUsing electrical meansHydraulic cylinderData acquisition

The invention discloses a device for measuring the valve disc displacement of a reciprocating pump valve. The device consists of a valve seat 1, a valve disc 2, a spring 3, an upper guide rod 4, an outer nut 5, an induction frequency modulation type displacement sensor power line 6, an induction frequency modulation type displacement sensor signal line 7, an O-shaped sealing ring 8, a bolt 9, a cylinder cover 10, an inner nut 11, a hydraulic cylinder 12, an induction frequency modulation type displacement sensor 13, an induction frequency modulation type displacement sensor guide rod 14, an induction frequency modulation type displacement sensor direct current power supply 17, a reciprocating pump flow signal 18, a reciprocating pump pressure signal 19, a data acquisition device 20, a computer and valve disc displacement testing and analyzing system 21 and the like, wherein a valve disc displacement signal output by the induction frequency modulation type displacement sensor 13, the reciprocating pump flow signal 18 and the reciprocating pump pressure signal 19 are transmitted into the computer 21 through the data acquisition device 20 and are processed by the valve disc displacement testing and analyzing system which is autonomously developed, and a change rule of the valve disc displacement of the pump valve under different flows and pressures is obtained.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

Closed container liquid level position detection device

InactiveCN112345035AGood real-time performancePrecise measuring systemMachines/enginesLevel indicatorsInterdigital transducerEngineering

The invention belongs to the technical field of liquid level detection devices, and particularly relates to a closed container liquid level position detection device which comprises a sound source, aninterdigital transducer, a double-layer structure flexible body and a hollow plastic pipe, the sound source and the interdigital transducer are distributed in a bilateral symmetry mode, and the double-layer structure flexible body is arranged below the sound source and the interdigital transducer. The lower end of the double-layer structure flexible body is fixedly connected with a hollow plasticpipe. The liquid level changes the propagation plane, the height of the liquid level is measured by changing the detected current after the piezoelectric effect, the device has the advantages of goodreal-time performance, high voltage resistance, electromagnetic interference resistance, wireless transmission and the like, the measurement system is accurate, and the system is more stable due to the double-layer structure.

Owner:彭瞳生

Double-head ultra-large-sized ultra-high-pressure gas cylinder liner and manufacturing method thereof

ActiveCN109595462BImprove machining accuracyNo weldVessel manufacturingContainer filling methodsUltra high pressureSpinning

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Ultra-large-size aluminum alloy inner container ultrahigh-pressure full-winding gas cylinder and manufacturing method thereof

PendingCN113883406ASimple preparation processEasy to operateVessel mounting detailsVessel manufacturingFiberAluminium alloy

The invention provides an ultra-large-size aluminum alloy inner container ultrahigh-pressure full-winding gas cylinder and a manufacturing method thereof. According to the aluminum alloy inner container ultrahigh-pressure full-winding gas cylinder, the aluminum alloy inner container is of an integrated seamless structure with sealing heads and bottle openings formed through closing-in of the two ends, a first sealing head and a second sealing head are located at the two ends of a straight cylinder section respectively, a first bottle opening and a second bottle opening are located on the first sealing head and the second sealing head respectively, the outer side of the aluminum alloy inner container is coated with a composite material reinforcing layer, and the composite material reinforcing layer is formed by winding carbon fibers in a spiral and annular combined winding mode and curing the carbon fibers through resin, an outer protection layer coats on the outer side of the composite material reinforcing layer, and the outer protection layer is formed by winding glass fibers in a spiral and annular combined winding mode and curing the glass fibers by using the resin. The length of the ultra-large-size aluminum alloy inner container ultrahigh-pressure full-winding gas cylinder is 5-13 m, the nominal outer diameter of the straight cylinder section is phi 300-phi 850 mm, and the use pressure of the high-pressure gas cylinder is 30-90 Mpa.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Thermal insulation metal material

InactiveCN105538795ALow thermal conductivityHigh pressure resistantMetal layered productsThermal insulationMagnesium

The invention discloses a thermal insulation metal material. The thermal insulation metal material comprises a metal plate and thermal insulation layers respectively arranged at the upper plane and the lower plane of the metal plate. The metal plate is provided with filling holes. The inner diameters of two ends of each one of the filling hole are smaller than the inner diameter of the middle of the filling hole. The filling holes are filled with a filler. The thermal insulation layers are compressed to the two surfaces of the metal plate through a hot press. The metal plate is an alloy material layer prepared from iron, titanium, magnesium and copper. The thermal insulation metal material has the advantages of high pressure resistance, moisture resistance, thermal insulation, corrosion resistance and low heat conduction coefficient.

Owner:TAICANG SIPUNING PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com