High-speed continuous rolling type lithium vacuum evaporation equipment and method for realizing base material lithium evaporation by utilizing equipment

A winding, high-speed technology, applied in the direction of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of large pollution range and low utilization rate of metal lithium, and achieve cost saving, cooling and evaporation Coating thickness, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

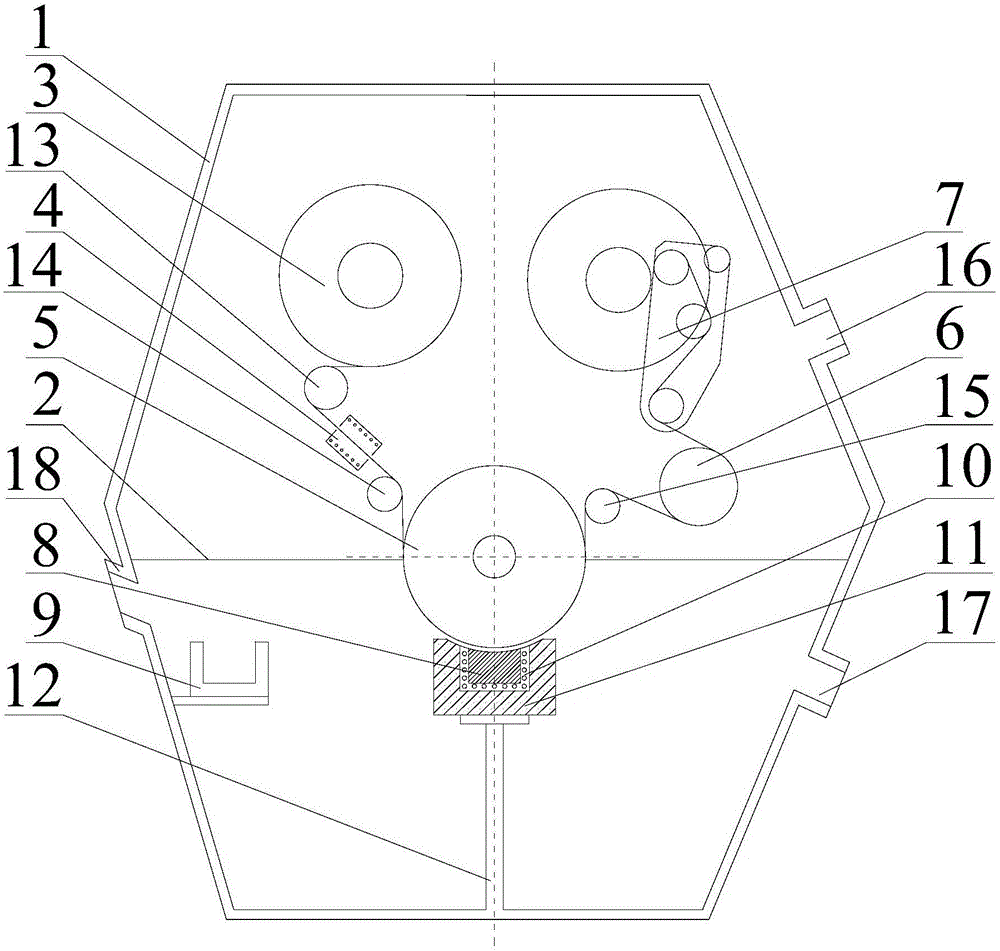

[0018] Specific implementation mode one: combine figure 1 , this embodiment is a high-speed continuous winding vacuum evaporation lithium equipment, which includes a body shell 1, a cavity baffle 2, an unwinding system 3, a substrate heater 4, a main roll 5, a cooling roll 6, and a winding system 7. Crucible 8, crucible fixing frame 9, crucible heater 10, insulation layer 11, crucible traverse lifting platform 12, unwinding transition roller 13, heating transition roller 14, cooling transition roller 15, upper cavity vacuum valve 16, lower cavity Vacuum valve 17 and feeding viewing window 18;

[0019] The high-speed continuous winding vacuum evaporation lithium equipment is divided into an upper cavity and a lower cavity by the cavity baffle 2 and the body shell 1. The unwinding system 3, substrate heater 4, cooling roll 6 and winding System 7 is set in the upper cavity of high-speed continuous winding vacuum evaporation lithium equipment, the unwinding transition roll 13 is ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 The difference between this embodiment and the first embodiment is that the unwinding system includes an unwinding roller, a deviation correction system, a transition roller system, a substrate evaporation speed control system, a tension control system and a flattening system. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 The difference between this embodiment and the first or second embodiment is that the winding system includes a winding roller, a mechanical expansion shaft, an AC drive motor, a frequency conversion controller, SKF bearings, a magnetic fluid seal, and a feeding gallows. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com