Pipe displace ment sensor of optical fibre grating marmen

A technology of displacement sensor and memory alloy, which is applied in the field of sensing to achieve the effects of low cost, high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

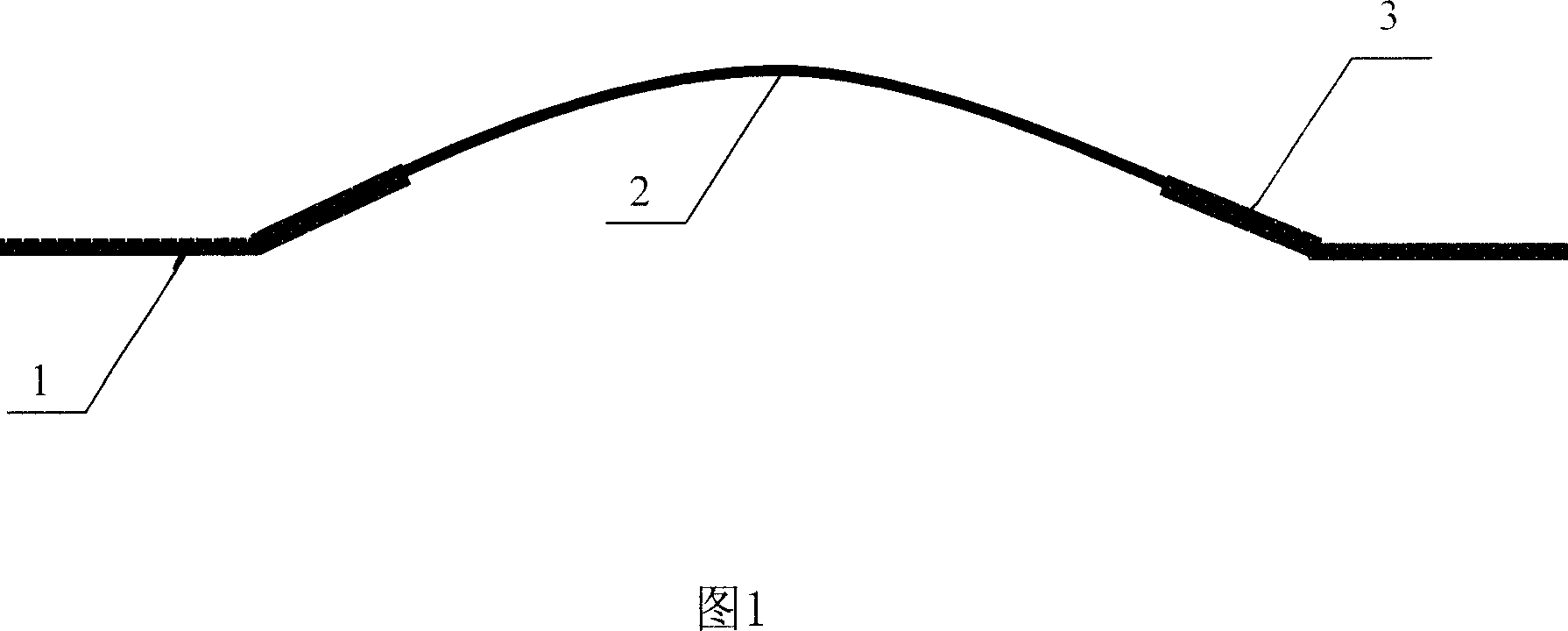

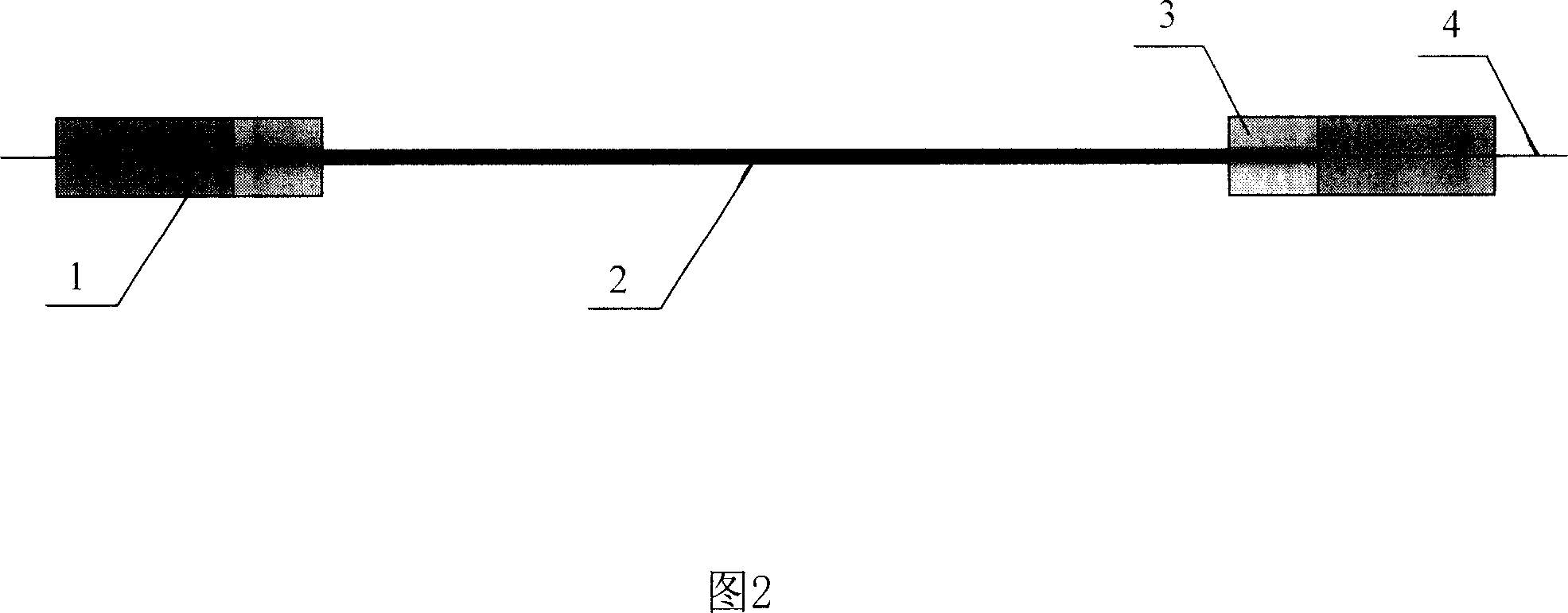

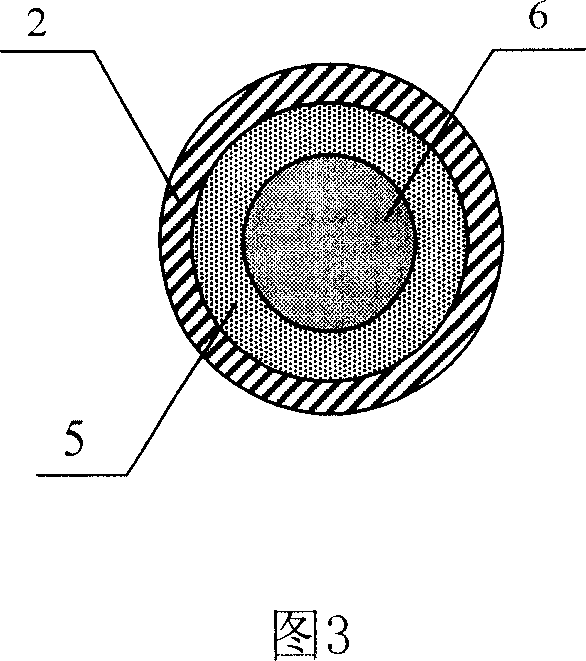

[0018] The fiber grating displacement sensor proposed by the present invention is shown in Figure 1 in lateral cross-section, and the top view of the sensor is shown in Figure 2, and the packaged shape memory alloy tube involved in the cross-section is shown in Figure 3. The cross-sectional view of the slotted copper sheet involved is shown in FIG. 4 .

[0019] The specific method of welding the shape memory alloy tube and the copper sheet base is to firstly use the shape memory alloy tube 2 to extrude a semicircular groove on the thin copper sheet with a thickness of 0.2mm to make the copper sheet 3 with the groove; The memory alloy tube 2 is placed in the groove and easily fixed on the copper sheet base 1; one end of the grooved copper sheet 3 is heated with an electric soldering iron, and the solder is placed on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com