Cross-shaped drainage pipe and mold and machining method for forming drainage pipe once

A technology of drainage tube and cross, which is applied in the field of cross drainage tube and the mold and processing field of forming the drainage tube at one time. Drainage effect, good drainage and drainage effect, good drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Specific steps:

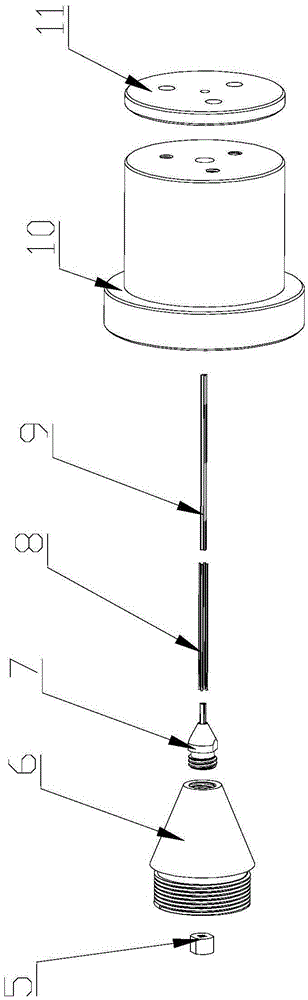

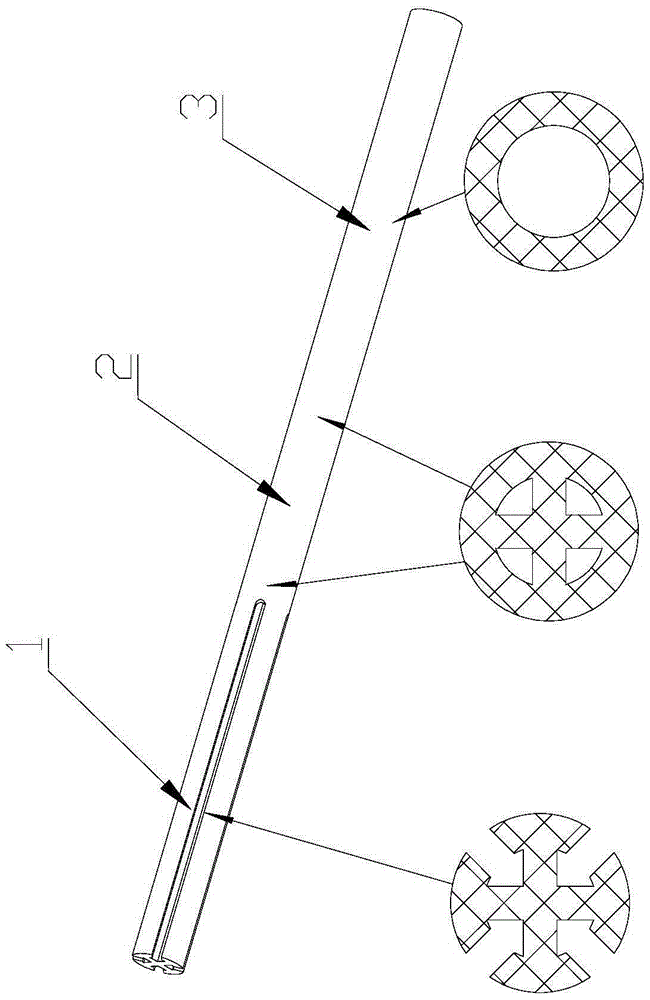

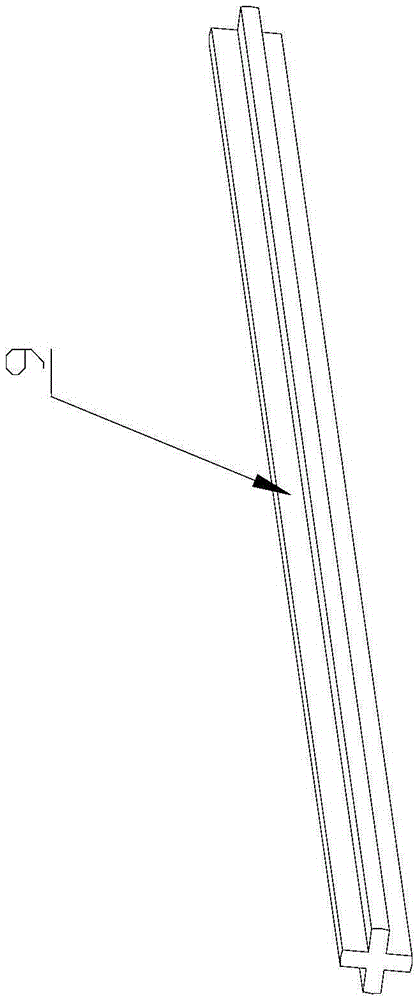

[0068] 1. Die loading: put the needle in the center of the hole corresponding to the mandrel. At the center of the center of the die, the top of the mandrel is flat with the die. Connect the mandrel and the needle with different connecting rods. , the auxiliary machine developing line extrusion rod is connected with the corresponding mouth of the main machine die;

[0069] 2. Take the special medical silicone rubber and add vulcanizing agent in proportion to 0.2%, enter the rubber mixing machine for extrusion and stirring, become translucent, and divide into strips, the width of the silicone strip is 50mm, and the thickness is 12mm;

[0070] 3. Take the mixed silicone rubber, add the blue developing line material in a proportion of 2%, enter the rubber mixer for extrusion, mix evenly and set aside;

[0071] 4. The silicone rubber extrusion vulcanization production line consists of two parts: a silicone rubber extruder and a hot air vulcanization oven....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com