Composite type coal cutter cable with optical fiber and electric signal

An electrical signal, composite technology, applied in the direction of communication cables, insulated cables, cables, etc., can solve the problems of inability to meet the requirements of monitoring data accuracy, timeliness and security, inability to achieve timely control, and complex lines. Small loss of optical signal strength, low cost, and the effect of protecting optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

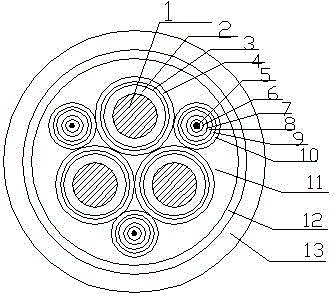

[0015] Such as figure 1 As shown, a composite shearer cable with an optical fiber and an electric signal disclosed by the present invention includes a cable core, an inner sheath 11 coated outside the cable core in turn, a steel tape armor layer 12 and an outer sheath. Sheath 13, the cable core includes multiple power cores and multiple control cores twisted with each other, the power cores include power core conductors 1, and the power wires wrapped outside the power core conductors 1 are insulated Layer 2, high-strength wrapping layer 3 and metal shielding layer 4, the control line core includes optical fiber core 5, optical fiber protective layer 6, metal elastic protective sleeve 7, optical fiber insulating layer 8, control line core 9 and control line insulation Layer 10.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com