Polymer composite lightweight rubber and preparation method thereof

A polymer and rubber technology, applied in the field of polymer composite lightweight rubber and its preparation, can solve the problems of unsatisfactory physical properties, poor anti-slip effect, low formula cost, etc., and achieves wide processing methods, convenient processing, and light specific gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

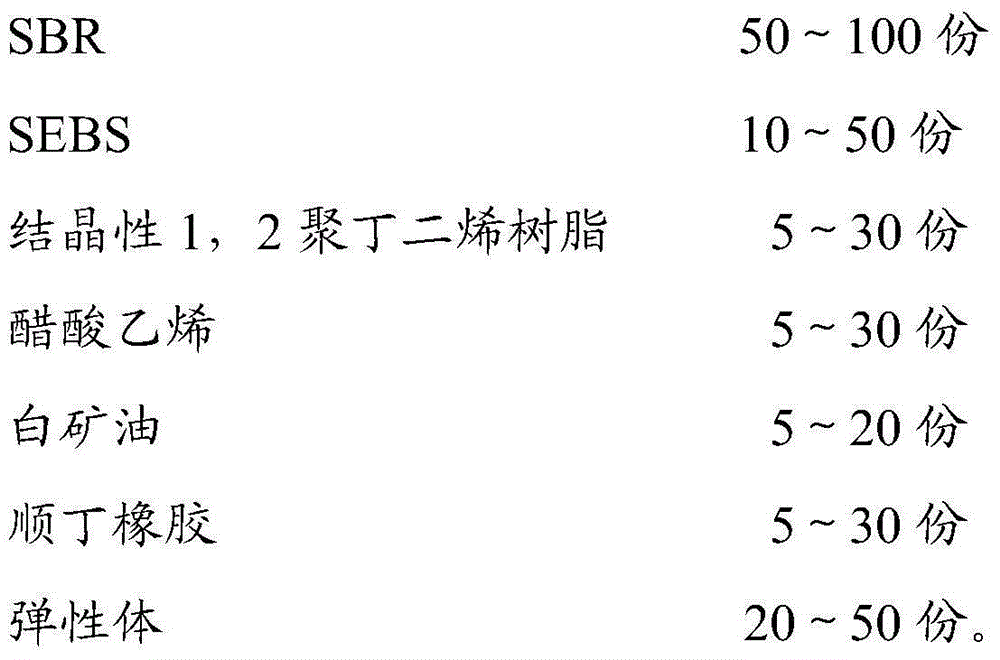

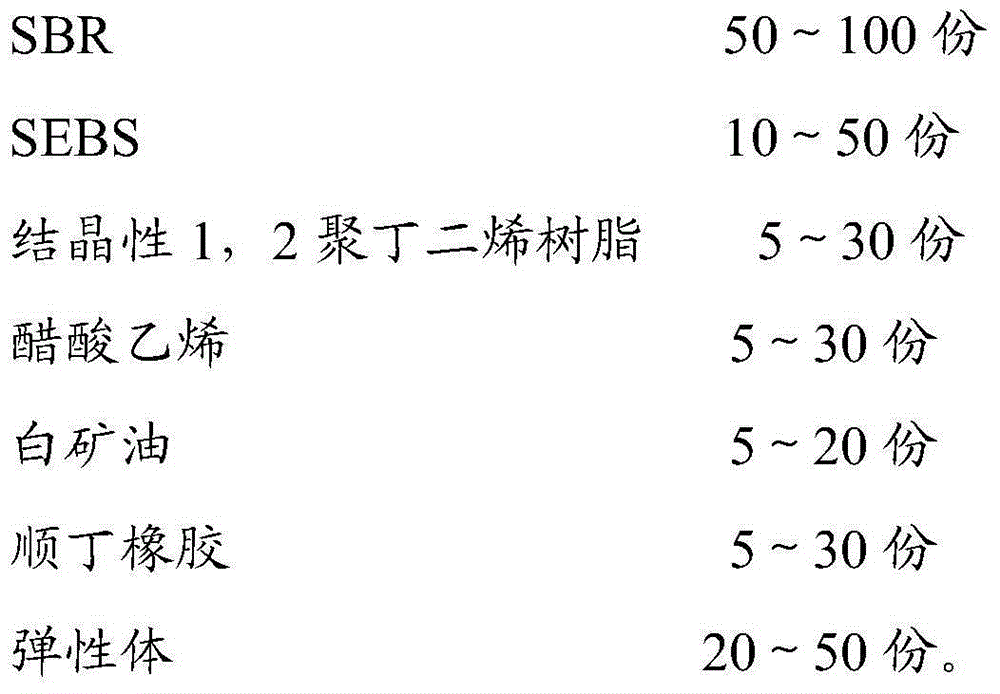

[0036] A polymer composite lightweight rubber, including calculated in parts by weight:

[0037] 50 parts of SBR, 50 parts of SEBS, 5 parts of RB8305, 5 parts of vinyl acetate, 20 parts of white mineral oil, 30 parts of butadiene rubber and 40 parts of elastomer.

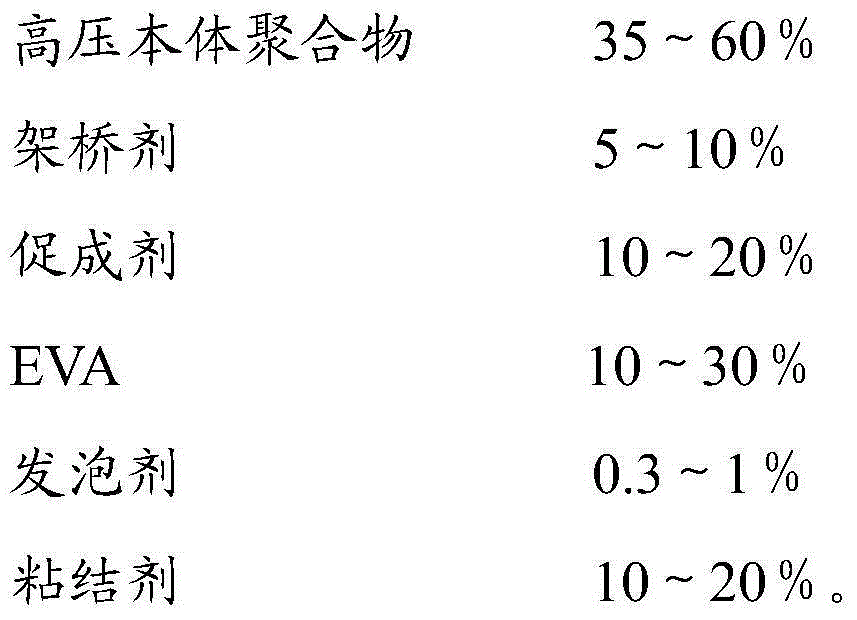

[0038] Wherein said elastomer comprises calculated by weight percentage: high pressure bulk polymer 60%, accelerant (DM) 10%, binding agent 10%, bridging agent 7%, EVA12.7%, blowing agent 0.3 %.

[0039] The preparation method of polymer composite lightweight rubber, the preparation process is as follows:

[0040] A. First mix and stir said amount of SBR, SEBS, RB830, vinyl acetate and butadiene rubber evenly, then add said amount of white mineral oil and continue to stir for 4-5 hours to obtain mixture I;

[0041] B. Add 1 / 3 of the amount of elastomer to the mixture I for plasticizing and banburying to obtain the mixture II; the plasticizing temperature is 110-140°C, and the plasticizing pressure is 6-8MPA; The ...

Embodiment 2

[0046] A polymer composite lightweight rubber, including calculated in parts by weight:

[0047] 100 parts of SBR, 10 parts of SEBS, 30 parts of RB83030, 30 parts of vinyl acetate, 5 parts of white mineral oil, 5 parts of butadiene rubber and 20 parts of elastomer.

[0048] Wherein the elastic body includes: calculated by weight percentage: 40% of high-pressure bulk polymer, 10% of accelerator (CZ), 10% of binder, 9% of bridging agent, 30% of EVA, and 1% of foaming agent.

[0049] The preparation method of the polymer composite lightweight rubber is the same as in Example 1.

Embodiment 3

[0051] A polymer composite lightweight rubber, including calculated in parts by weight:

[0052] 60 parts of SBR, 40 parts of SEBS, 10 parts of RB830, 10 parts of vinyl acetate, 10 parts of white mineral oil, 10 parts of butadiene rubber and 50 parts of elastomer.

[0053] Wherein said elastomer comprises calculated by weight percentage: high pressure bulk polymer 44.5%, accelerant (DM10%, CZ10%) 20%, binding agent 20%, bridging agent 5%, EVA10%, blowing agent 0.5% %.

[0054] The preparation method of the polymer composite lightweight rubber is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com