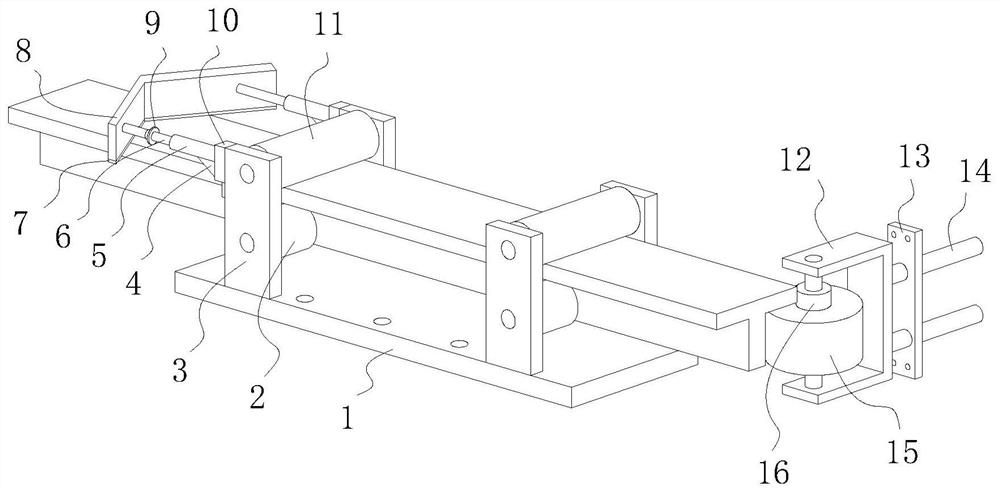

Continuous bending machining machine for steel structure sectional materials

A technology for processing machinery and steel structures, applied in the field of steel processing, can solve the problems of unbalanced force on the pressure roller, affecting the service life of the pressure roller, damage, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

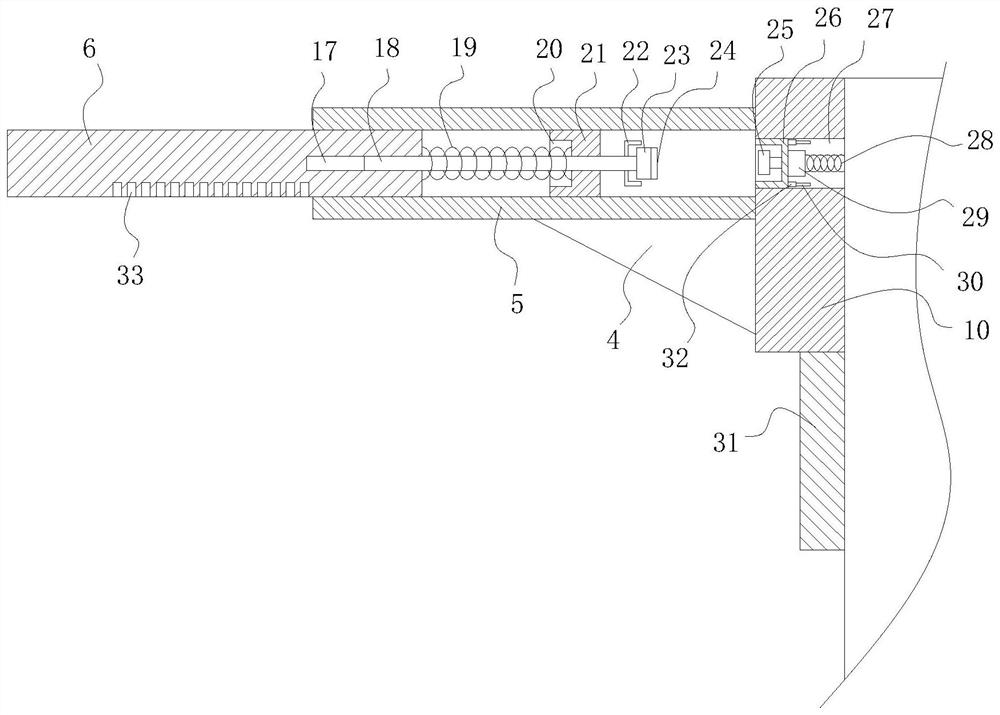

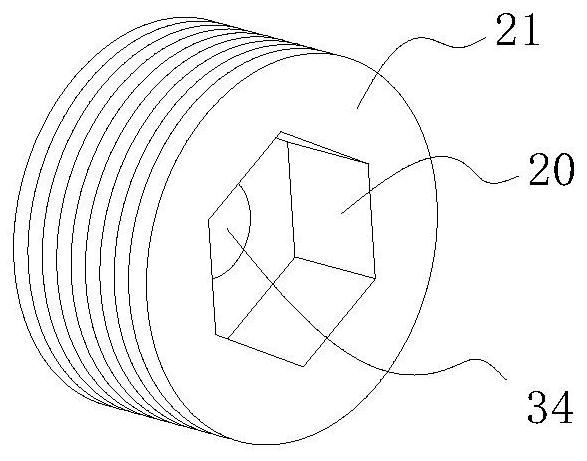

[0039] The specific embodiment: the V-shaped plate 8 in contact with the T-shaped steel horizontal section is set at the feed side of the pressure roller 11, and then when the T-shaped steel moves under the drive of the drive equipment, the V-shaped plate 8 is on the T-shaped steel surface relative to the T-shaped steel. Sliding, so that the dirt on the upper surface of the T-shaped steel horizontal section is pushed down by the V-shaped plate 8, which realizes convenient cleaning of the remaining dirt on the upper surface of the T-shaped steel horizontal section, and prevents the dirt from accumulating on the pressure roller 11 and affecting the use of the pressure roller 11 life.

[0040] After inserting the plunger 6 into the sleeve 5, when there are hard objects such as welding slag on the upper surface of the T-shaped steel horizontal section, the protruding hard objects cannot pass under the V-shaped plate 8, so the V-shaped plate 8 follows the The T-shaped steel moves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com