Optical fiber grating intelligent steel strand and its manufacture method

An intelligent steel strand and fiber grating technology, which is applied in the fiber mechanical structure, the coupling of optical waveguides, and the use of optical devices to transmit sensing components, can solve the problems of poor shear resistance and fragile fiber grating sensors, and achieve easy processing. Forming, good lead handling, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

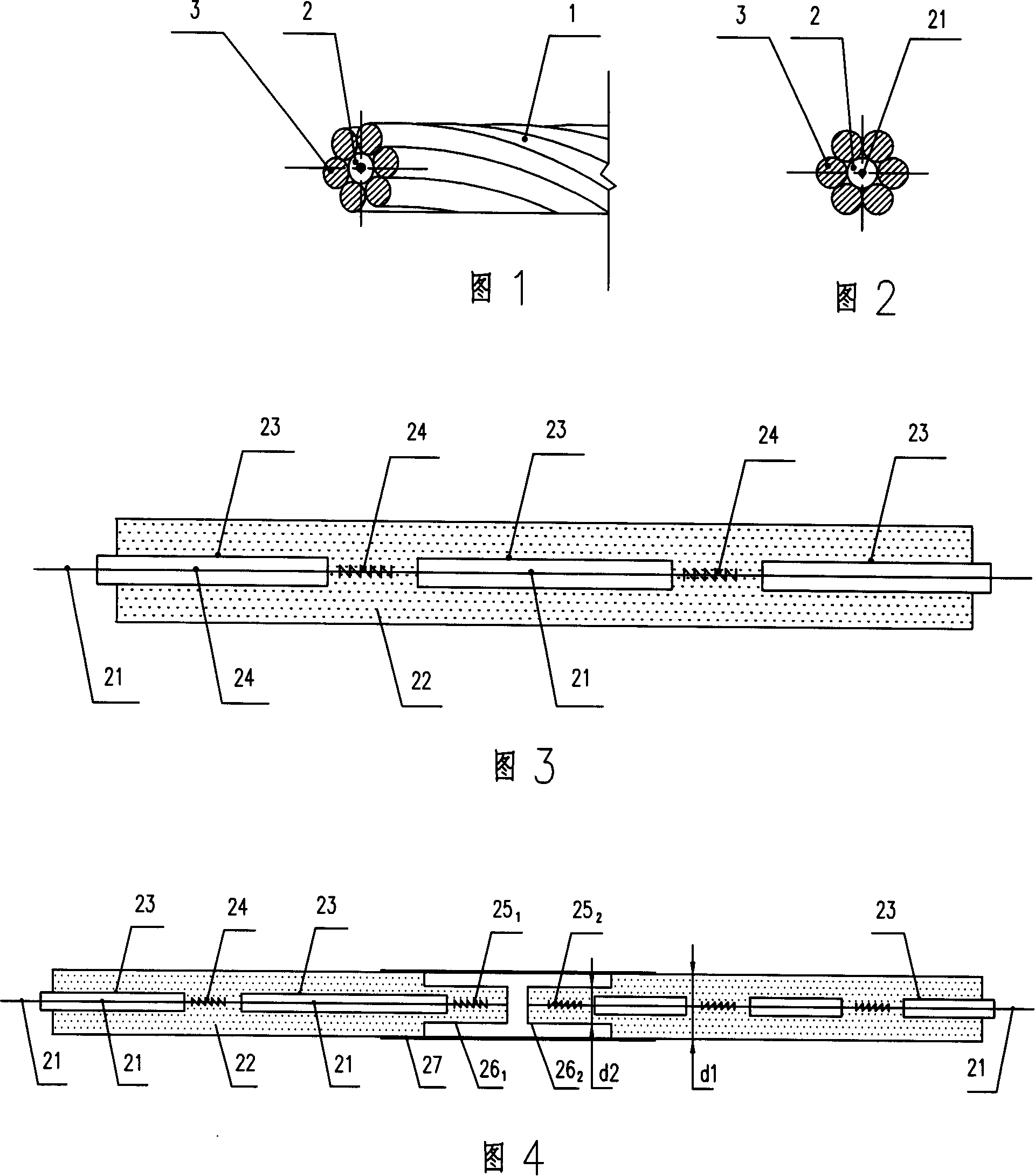

[0031] Embodiment 1: An optical fiber grating intelligent steel strand.

[0032] The smart steel strand is formed by twisting a central wire and side wires wound around the central wire, the side wires are ordinary high-strength steel wires 3, and the central wire is a fiber grating fiber-reinforced composite containing a fiber grating sensor Smart rib 2 (referring to Fig. 1, Fig. 2), this smart rib 2 comprises fiber reinforced rib 22 and the optical fiber 21 and fiber grating sensor 24 that are distributed in the fiber reinforced rib along the length direction, and the optical fiber coat of non-grating section is covered with plastic pine. Sleeve 23, the plastic loose tube 23 isolating the optical fiber is connected with the fiber reinforcing rib 22, and the optical fiber grating sensor transmission optical fiber 21 is drawn from the end of the steel strand (see FIG. 3).

[0033] As a transformation of Embodiment 1 of the present invention, a temperature-compensated fiber gra...

Embodiment 2

[0036] Embodiment 2: The manufacturing method of the fiber Bragg grating intelligent steel strand of the present invention.

[0037] The method includes the following steps:

[0038] A. Fabrication of Fiber Bragg Grating Fiber Reinforced Composite Smart Rib:

[0039]1) Calculate the blanking length of the fiber-reinforced polymer rib 2, and determine the fiber grating sensors 24, 25 1 、25 2 The position in the length direction of the steel strand and connected in series in the optical fiber, and calculate the minimum length of the exit optical fiber,

[0040] 2) Put 1 to 20 plastic loose sleeves 23 tubes on the tubes containing grating sensors 24, 25 1 、25 2 There is no grating section in the optical fiber, and then the thermal extrusion method will contain the grating sensor 24, 25 1 、25 2 The optical fiber is pulled together with the fiber, so that the plastic loose tube 23 is connected with the fiber reinforced rib 22, and the fiber reinforced composite smart rib 2 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com