Process for forming artificial leg made of carbon fiber composite materials

A composite material and molding process technology, applied in the direction of artificial legs, etc., can solve the problems of difficult production and small deformation, and achieve the effect of light weight, small deformation and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] The process of the present invention includes prepreg, cutting, laying up (or claiming molding), thermoforming, grinding and sandblasting.

[0029] Prepreg: including the following materials:

[0030] Unidirectional carbon fiber prepreg: carbon fiber content 100g / m 2 , The content of epoxy resin containing acid anhydride curing agent is 20%-40%.

[0031] 3K carbon fiber bundle woven fabric prepreg: carbon fiber content 200g / m 2 , The content of epoxy resin containing acid anhydride curing agent is 20% to 45%.

[0032] Resin film: highly elastic modified epoxy resin (for example: high elastic epoxy resin GF-630 type), its content is 25g / m 2 -85g / m 2 , with acid anhydride curing agent as curing agent and triethylamine as accelerator.

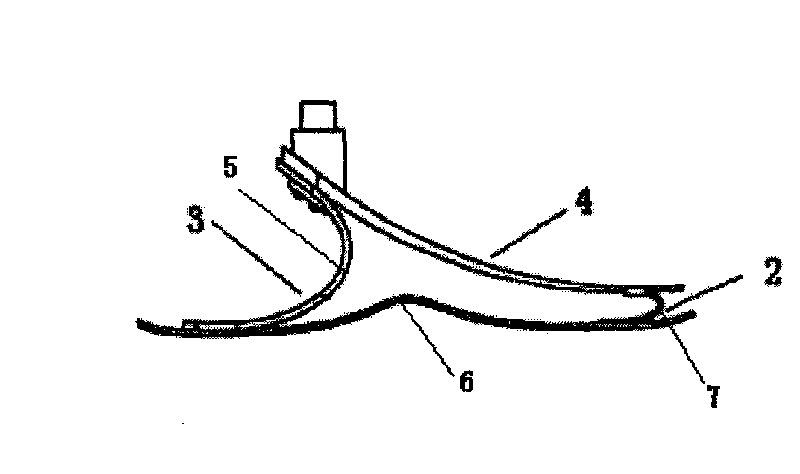

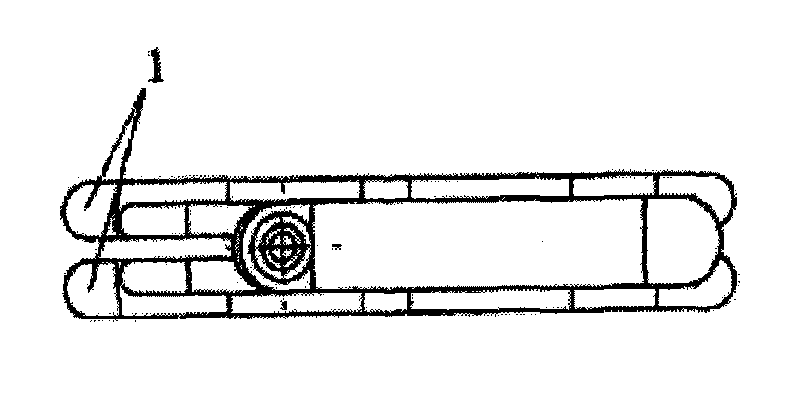

[0033] Cutting process: Cut the above prepregs into the shapes of double lower panels 1, U-shaped front keel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com