Method for melting snow and ice based on carbon fiber-glass fiber composite braiding net

A technology of glass fiber and woven mesh, which is applied in the direction of electric heating devices, roads, pavement details, etc., can solve the problems of slow speed of slippery vehicles, slow removal speed, fluctuation of heating power, etc., to reduce the difficulty of on-site construction and achieve uniform heating Rapid and stable heating power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The best embodiment of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

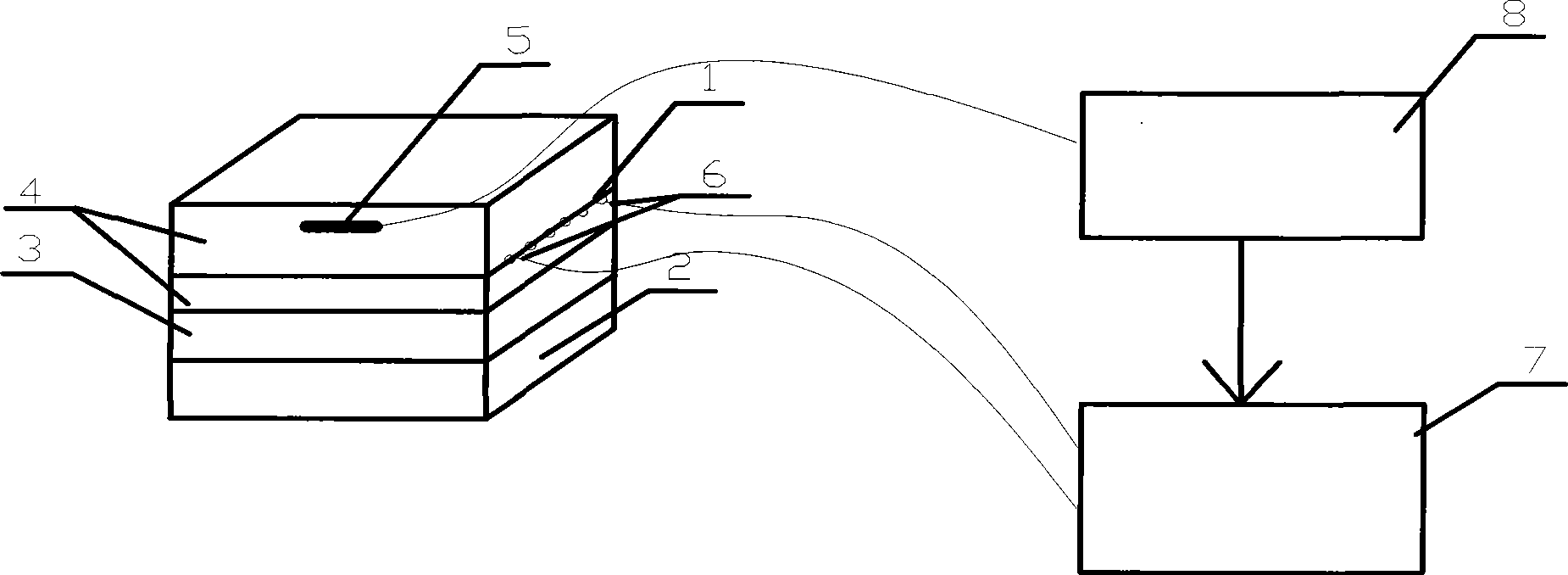

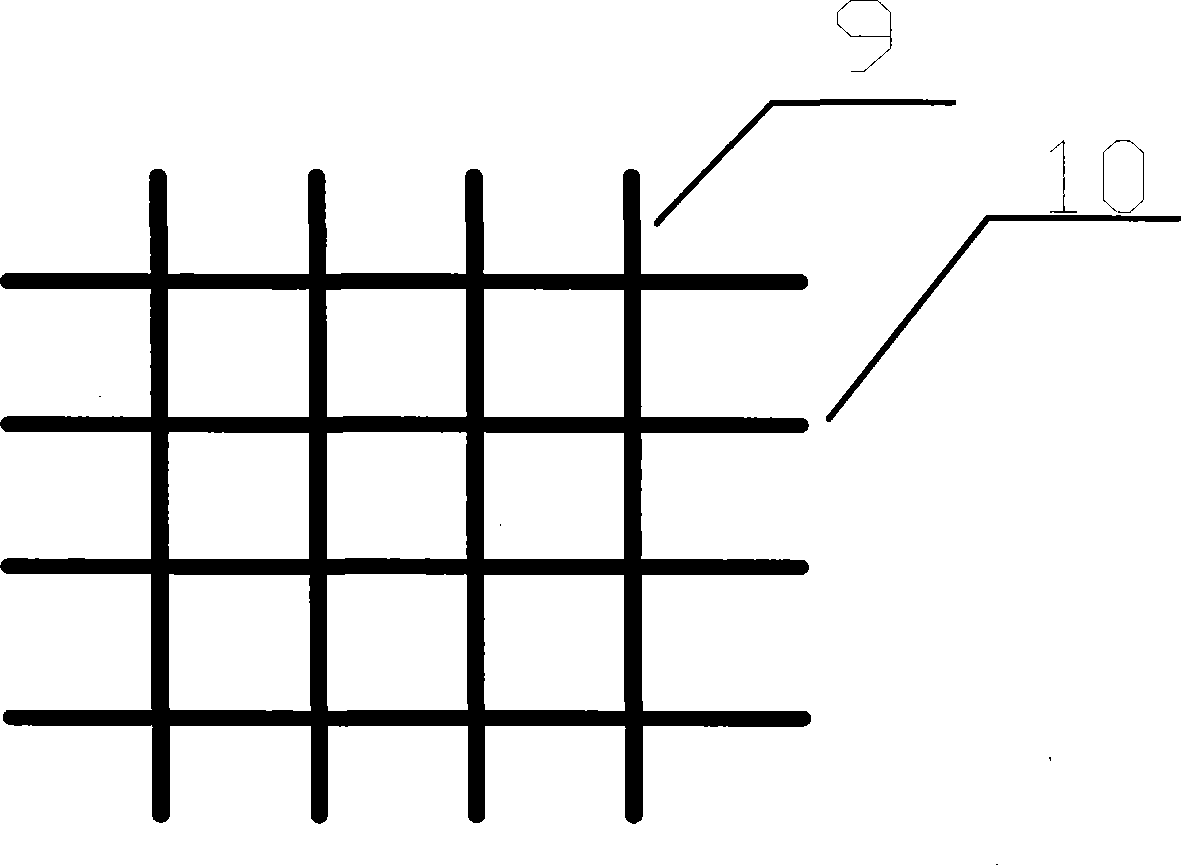

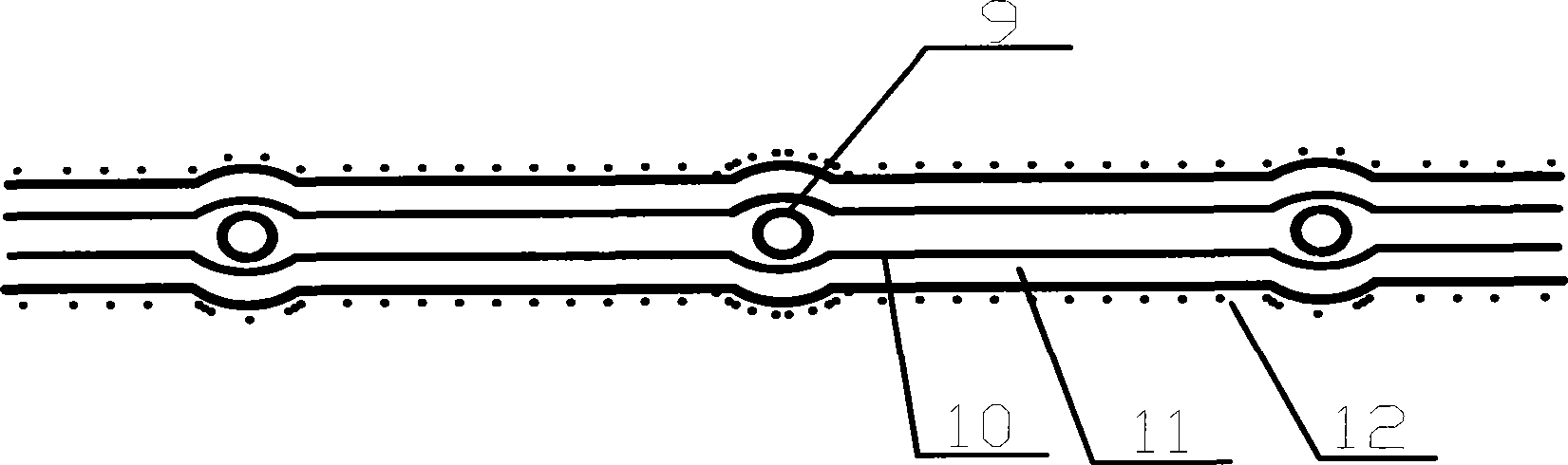

[0015] Attached figure 1 An automatic control system for snow melting and ice melting based on carbon fiber-glass fiber composite woven mesh is given. The construction method of the carbon fiber-glass fiber composite woven mesh is as follows: firstly, a heat insulation layer 3 is set on the base layer 2 of the body to be heated, and the thickness is controlled at 10-30mm to reduce the heat loss transmitted downward; on the heat insulation layer 3 Lay the thermal conductive layer 4 with a thickness of about 5-10mm. It is usually hoped that the material of this layer has a relatively large thermal conductivity; then, the carbon fiber-glass fiber composite woven mesh 1 that has been electrically insulated and sand-sticky is spread flat, and the composite woven mesh is The warp carbon fiber bundle heating body 9 is parallel to the short ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com