Long carbon chain nylon hot melt glue and its synthesis method

A synthesis method and hot-melt adhesive technology, applied in the direction of adhesives, etc., can solve the problems of poor washing resistance of hot-melt adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

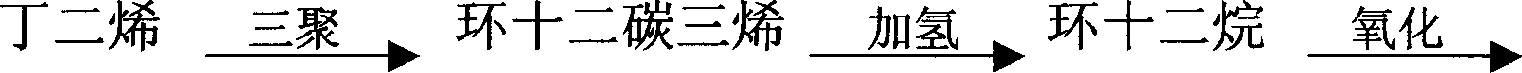

Method used

Image

Examples

Embodiment 1

[0045] Add 40kg of tridecanedioic acid produced by the fermentation method into a reactor with agitated distillation, heat at 130°C to melt the tridecanedioic acid, feed ammonia gas, and control the flow rate of ammonia gas at 60m 3 After 10 hours of dehydration reaction, the temperature was raised to 350° C., kept for 4 hours, distilled under reduced pressure, and tridecanedinitrile was distilled off.

[0046] Add 30kg of tridecanedinitrile, 60kg of ethanol, 3.0kg of skeleton nickel, and 20kg of liquid ammonia into the high-pressure reactor, depressurize and extract the gas in the reactor, feed hydrogen into the reactor and keep the pressure at 3MPa, and raise the temperature to make the temperature of the reactor The temperature is controlled at 120°C, and the temperature is lowered to 40°C after 1 hour, and the pressure in the reactor is lowered to normal pressure, the catalyst is filtered out, ethanol and ammonia are distilled off to obtain tridecanediamine.

[0047] Add t...

Embodiment 2

[0050] Add 40kg of tetradecanedioic acid produced by fermentation into a reaction kettle with agitated distillation, heat at 130°C to melt the tetradecanedioic acid, feed ammonia gas, and control the flow rate of ammonia gas at 60m 3 After 13 hours of dehydration reaction, the temperature was raised to 330° C., kept for 6 hours, distilled under reduced pressure, and tetradecanedinitrile was distilled off.

[0051] Add 30kg of tetradecanedinitrile, 70kg of ethanol, 3.6kg of skeleton nickel, and 24kg of liquid ammonia into the high-pressure reactor, decompress and extract the gas in the reactor, feed hydrogen into the reactor and keep the pressure at 2.5MPa, and raise the temperature to make the reactor The temperature is controlled at 120°C, and after 1 hour, the temperature is lowered to 50°C, and the pressure in the reactor is lowered to normal pressure, the catalyst is filtered out, and ethanol and ammonia are distilled off to obtain tetradecanediamine.

[0052] Add the refi...

Embodiment 3~7

[0055] Under the same process conditions as in Example 1, different formulations composed the synthesized polyamide hot-melt adhesives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com