Waterborne photocuring floor coating and preparation method thereof

A light-curing, water-based technology, applied in the field of coatings, can solve the problems of easy to cover the characteristics of floor logs, inconvenient use, complicated operation, etc., and achieve the effect of overcoming long curing time, high efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

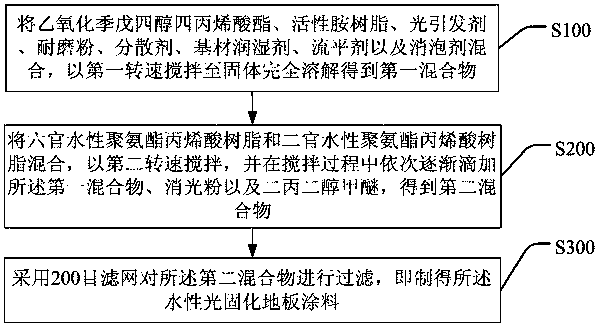

[0036] Further, the present invention also provides a preparation method of water-based light-cured floor coating, characterized in that, as figure 1 shown, including steps:

[0037] S100. Mix ethoxylated pentaerythritol tetraacrylate, active amine resin, photoinitiator, wear-resistant powder, dispersant, substrate wetting agent, leveling agent and defoamer, and stir at the first speed until the solid is completely dissolved to obtain the first mixture;

[0038] S200. Mix the hexafunctional water-based polyurethane acrylic resin and the difunctional water-based polyurethane acrylic resin, stir at the second rotational speed, and gradually add the first mixture, matting powder and dipropylene glycol methyl ether dropwise during the stirring process, to obtain the second mixture;

[0039] S300. Filter the second mixture with a 200-mesh filter to obtain the water-based photocurable floor coating.

[0040]In this embodiment, by using a 200-mesh filter to filter the second mixtu...

Embodiment 1

[0044] A water-based light-curing floor coating, wherein, by weight percentage, comprises 55% hexafunctional water-based polyurethane acrylic resin, 10% difunctional water-based polyurethane acrylic resin, 8% ethoxylated pentaerythritol tetraacrylate, and 2% active amine Resin, 5% photoinitiator 1173, 1% photoinitiator BP, 2% matting powder, 5% wear-resistant powder, 0.5% dispersant, 1% substrate wetting agent, 0.4% fluid Leveling agent, 0.1% defoamer and 10% dipropylene glycol methyl ether.

Embodiment 2

[0046] A water-based light-curing floor coating, wherein, by weight percentage, comprises 57% hexafunctional water-based polyurethane acrylic resin, 8% difunctional water-based polyurethane acrylic resin, 7% ethoxylated pentaerythritol tetraacrylate, and 2.5% active amine Resin, 5% photoinitiator 1173, 1.5% photoinitiator BP, 3% matting powder, 4% wear-resistant powder, 0.5% dispersant, 1% substrate wetting agent, 0.4% fluid Leveling agent, 0.1% defoamer and 10% dipropylene glycol methyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com