Iron plate finishing coat spraying process

An iron plate and process technology, applied in the field of iron plate topcoat spraying technology, can solve problems such as unfavorable construction personnel and the environment, multiple VOCs, etc., and achieve the effects of good environmental protection effect, shortened construction time, and high paint utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

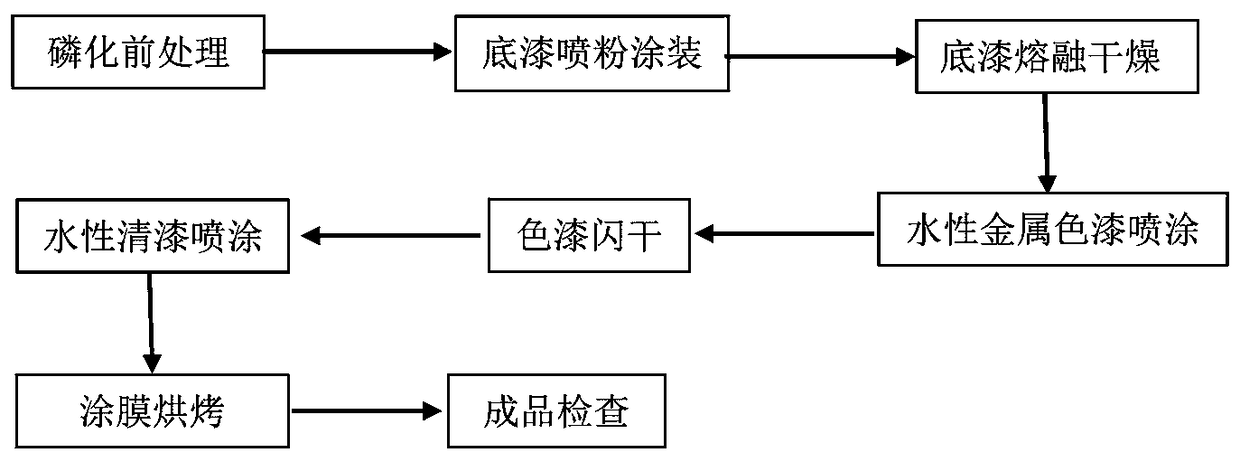

[0027] Iron plate water-based topcoat spraying process:

[0028] Pre-treatment→dusting→curing→inspection→water-based metallic paint→flash-drying→water-based varnish→baking→finished product

[0029] 1.1 Pre-processing

[0030] The powder can be sprayed only after the iron plate is pre-treated to remove the oil and dust on the surface. At the same time, the surface treatment of the workpiece enhances the adhesion after powder spraying. The film thickness of the surface treatment is 1.5-2g / m 2 .

[0031] The pre-treated workpiece is completely dried and cooled to below 35°C to ensure the physical and chemical properties and appearance quality of the iron plate after powder spraying. The drying of the pre-treatment iron plate is heated by spiral fins, kept at a temperature below 55-65°C for 25-30 minutes and the circulation fan is turned on.

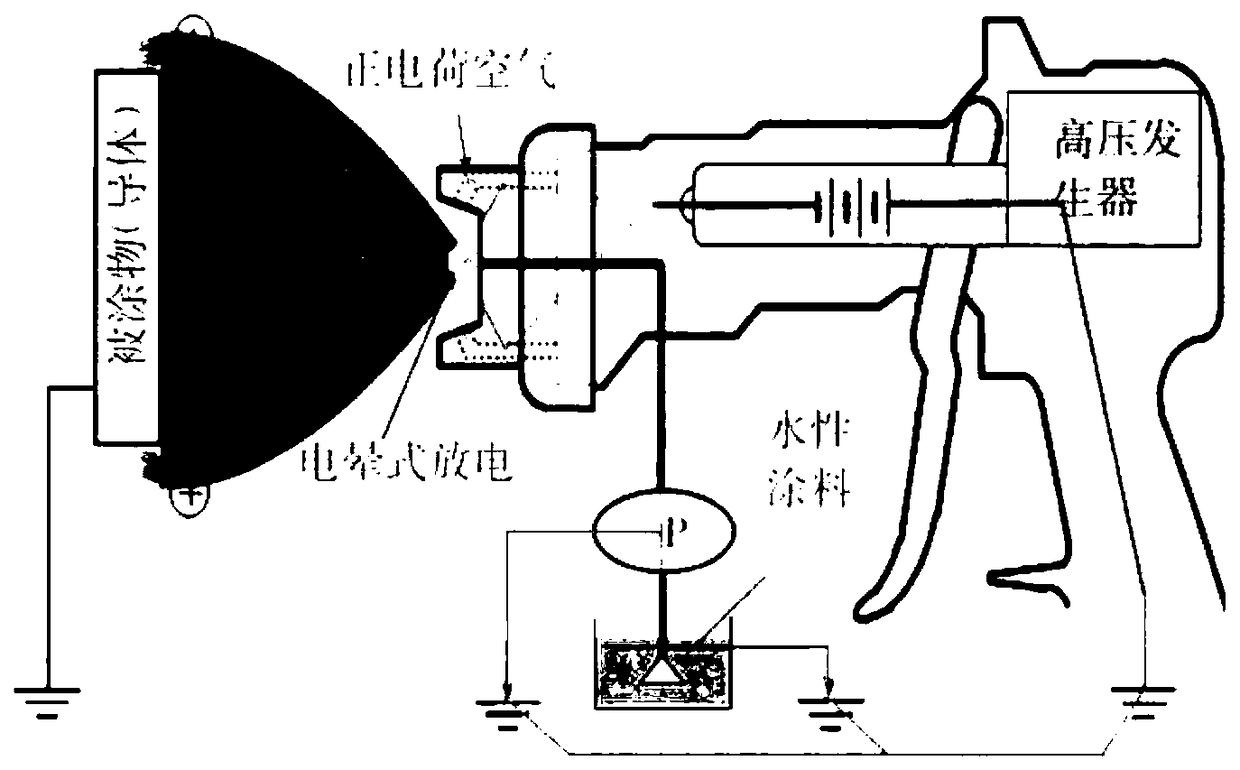

[0032] 1.2 Powder coating

[0033] The construction process powder of electrostatic spraying is specifically glitter powder, and its co...

Embodiment 2

[0063] A kind of iron plate topcoat spraying process, comprises the following steps:

[0064] 1) Use normal temperature shot blasting and sanding treatment, dry and cool for later use;

[0065] 2) Electrostatically spray powder on the iron plate obtained in step 1), then solidify, check the appearance and thickness requirements, if there is any defect, it needs to be sprayed and solidified again; the powder described is glitter powder, and the surface temperature of the workpiece entering the powder spraying room is: ≤50℃, interfering air flow lateral velocity within 2 m near the workpiece in the powder spraying chamber: ≤0.3m / s; electrostatic voltage 60-90kV, current 10-20μA, flow rate pressure 0.30-0.55MPa, atomization pressure 0.30-0.45MPa , The gun cleaning pressure is 0.5MPa, the fluidization pressure of the powder supply barrel is 0.04~0.10MPa, and the distance from the nozzle of the spray gun to the workpiece is 150~300mm. When curing, it is heated by high far infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com