UV curing LED package adhesive resin and synthesis method thereof

A technology of LED packaging and synthesis method, applied in the direction of adhesives, etc., can solve the problems of long curing time and cumbersome glue dispensing process, and achieve the effects of convenient operation, simple synthesis process and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

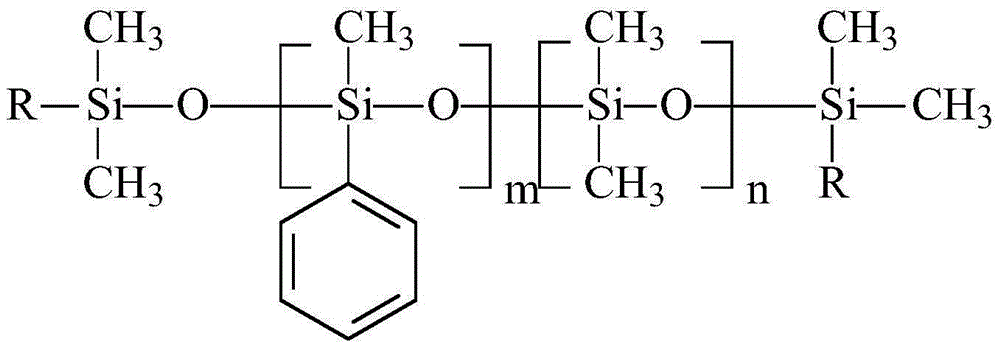

[0031] A kind of synthetic method of UV curing LED encapsulation resin, the steps are as follows:

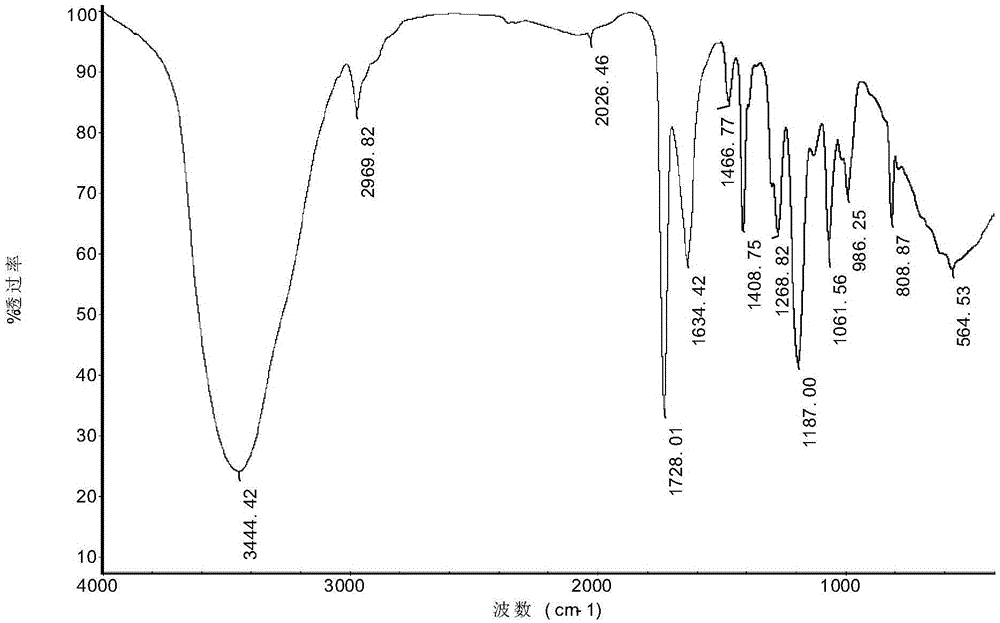

[0032] (1) Mix 100 parts of diphenyldimethoxysilane, 10 parts of dimethyldimethoxysilane, 30 parts of hydrogen-containing double head, 20 parts of distilled water, 100 parts of solvent (benzene and toluene weight ratio 1:1 ), 0.03 parts of 38wt% hydrochloric acid were added to the container successively, the temperature was raised to 60° C., stirred for 4 hours at a constant temperature, then heated to 100° C., stirred for 4 hours at a constant temperature, and the resulting reaction solution was washed with distilled water until neutral, and then the temperature was controlled to Distill under reduced pressure at 200°C and pressure -0.096MPa for 1.0h to remove the solvent and residual moisture to obtain phenyl hydrogen-containing silicone oil.

[0033] (2) 10g of phenyl hydrogen-containing silicone oil and 20g of hyperbranched polyester acrylate are added in a certain proportio...

Embodiment 2

[0041] A kind of synthetic method of UV curing LED encapsulation resin, the steps are as follows:

[0042] (1) 150 parts of diphenyldimethoxysilane, 40 parts of dimethyldimethoxysilane, 50 parts of hydrogen-containing double heads, 60 parts of distilled water, 200 parts of toluene, and 1 part of 98wt% sulfuric acid are added to the In the container, raise the temperature to 90°C, keep the temperature under stirring for 8 hours, then raise the temperature to 120°C, and react at the constant temperature for 4 hours under stirring. Distill under pressure for 3.0h to remove the solvent and residual moisture to obtain phenyl hydrogen-containing silicone oil.

[0043](2) Put 10g of phenyl hydrogen-containing silicone oil and 10g of hyperbranched polyester acrylate into a 500ml three-necked flask, then add 0.005g of polymerization inhibitor, pass in protective gas, stir and heat, raise the temperature to 80°C, add 0.02g of the complex of chloroplatinic acid, stirred at a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com