Open-cut construction method for assembly type flat-top column-contained underground structure

An underground structure and construction method technology, applied in underwater structures, infrastructure engineering, excavation, etc., can solve the problems of extremely high requirements for hoisting and assembling equipment, large volume of prefabricated components, and low degree of assembly, and achieve industrialization. The effect of promoting application, saving templates and scaffolding, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

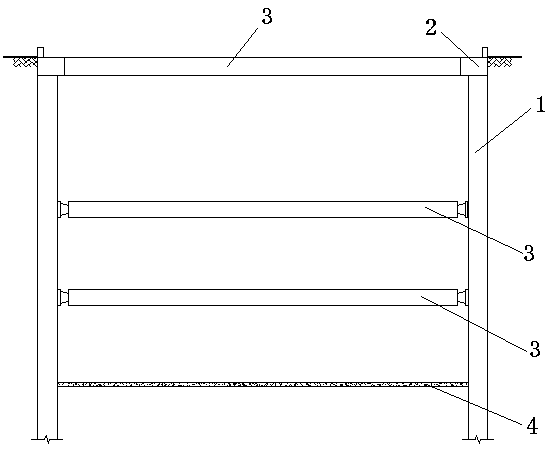

[0052] like Figure 1-12 As shown, this embodiment provides an open-cut construction method for an assembled flat-roofed underground structure with columns, which is suitable for main structural projects such as urban rail transit underground stations, basements, and comprehensive pipe corridors. Taking the three inner supports as an example for illustration, the construction method includes the following steps:

[0053] 1) After the construction of the two enclosure structures 1 is completed, construction 2 is constructed using the open-cut method, and three internal supports 3 are erected while excavating between the two enclosure structures 1, and excavated to the bottom of the foundation pit, such as figure 1 shown;

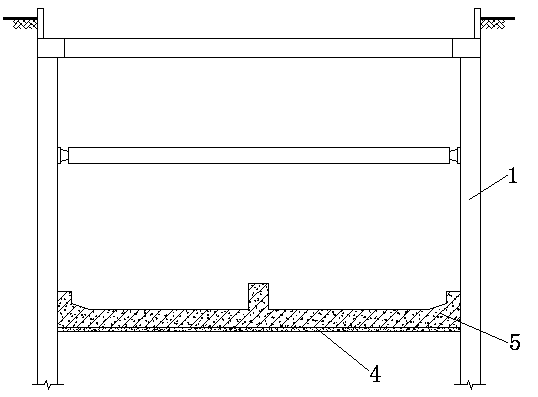

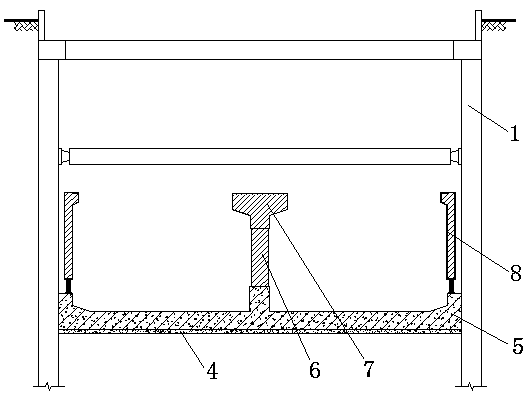

[0054] 2) Concrete cushion 4 is first constructed at the bottom of the foundation pit, and then a waterproof layer is constructed on the concrete cushion 4 to improve the waterproof performance of the fabricated underground structure, and then the constructi...

Embodiment 2

[0068] like Figure 13-15 As shown, this embodiment provides a connection method between the prefabricated part and the cast-in-place concrete layer, which can be used when the first side wall adopts a laminated structure and the first layer adopts a fully cast-in-place or laminated structure in Embodiment 1. The connection between the first side wall prefabricated part 12 and the first cast-in-place layer 11 or the first cast-in-place laminate can also be used for the second side wall to adopt a laminated structure, and the second laminate to adopt a fully cast-in-place or laminated structure. The connection between the second side wall prefabricated part 8 and the second layer slab cast-in-place layer or the reinforced concrete cast-in-place layer 5 during the structure; Example for illustration, the connection method of the first side wall prefabricated part 12 and the first cast-in-place laminate, the connection method of the second side wall prefabricated part 8 and the s...

Embodiment 3

[0079] This embodiment provides a method for connecting prefabricated parts to prefabricated parts, which can be used for the connection between the first plywood prefabricated part 10 and the first plywood prefabricated part 10 when the first plywood adopts a superimposed structure in the first embodiment. Connection, the connection between the second layer prefabricated part and the second layer prefabricated part when the second layer adopts the superimposed structure, the flat top layer prefabricated part 16 and the flat top layer prefabricated part 16 when the flat top layer adopts the superimposed structure The connection between; now take the connection method of two first layer prefabricated parts 10 when the first layer board adopts a superimposed structure as an example to illustrate, the connection method of two second layer board prefabricated parts, the two flat top layer boards The connection method of the prefabricated parts 16 is the same, and will not be descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com