Prefabricated concrete bottom plate with stiffening cold-bending thin wall type steel ribs and made composite slab

A technology for cold-formed thin-walled steel and concrete bottom plates, which is applied in the directions of floors, building materials, building components, etc., can solve the problems of poor sound insulation and heat insulation performance of floors, increase the bearing capacity of floors, and cumbersome construction processes, and reduce the cost of floor slabs. The effect of quality, saving formwork and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

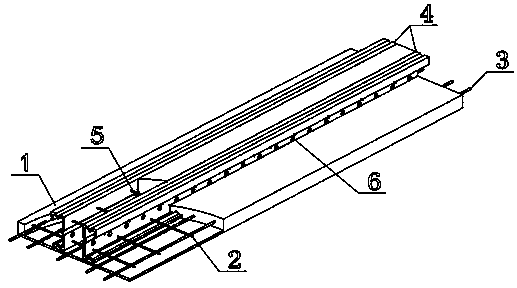

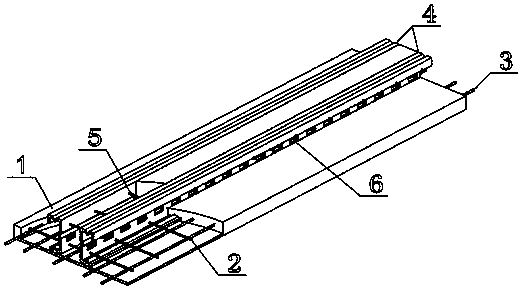

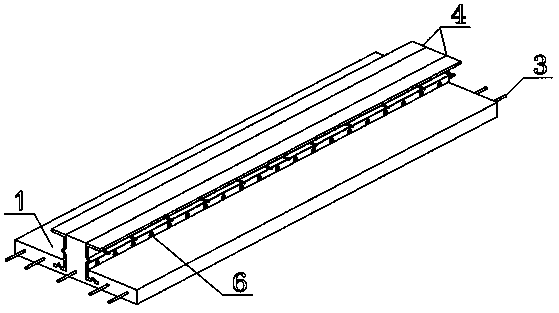

[0024] Embodiment 1: as Figure 1-7 As shown, a prefabricated concrete bottom slab with reinforced cold-formed thin-walled steel ribs, including prefabricated bottom slab transverse structural steel bars 2, prefabricated bottom slab longitudinal stress steel bars 3, longitudinal stiffened cold-formed thin-walled steel ribs 4, stiffened cold-formed thin-walled steel ribs Rib structural steel bars 5; two longitudinal stiffened cold-formed thin-walled steel ribs 4 of the same shape pass through the holes reserved in the lower part of the ribs through the prefabricated floor transverse structural steel bars 2 and connect the two through stiffened cold-formed thin-walled steel rib structural steel bars 5 The upper part of the ribs, between the longitudinally stiffened cold-formed thin-walled steel ribs 4, the transverse structural reinforcement 2 of the prefabricated floor, and the longitudinal stress reinforcement 3 of the prefabricated floor are pre-embedded in the high-strength c...

Embodiment 2

[0031] Embodiment 2: as Figure 1-7 As shown, a prefabricated concrete bottom slab with reinforced cold-formed thin-walled steel ribs, including prefabricated bottom slab transverse structural steel bars 2, prefabricated bottom slab longitudinal stress steel bars 3, longitudinal stiffened cold-formed thin-walled steel ribs 4, stiffened cold-formed thin-walled steel ribs Rib structural steel bars 5; two longitudinal stiffened cold-formed thin-walled steel ribs 4 of the same shape pass through the holes reserved in the lower part of the ribs through the prefabricated floor transverse structural steel bars 2 and connect the two through stiffened cold-formed thin-walled steel rib structural steel bars 5 The upper part of the ribs, between the longitudinally stiffened cold-formed thin-walled steel ribs 4, the transverse structural reinforcement 2 of the prefabricated floor, and the longitudinal stress reinforcement 3 of the prefabricated floor are pre-embedded in the high-strength c...

Embodiment 3

[0038] Embodiment 3: as Figure 1-7As shown, a prefabricated concrete bottom slab with reinforced cold-formed thin-walled steel ribs, including prefabricated bottom slab transverse structural steel bars 2, prefabricated bottom slab longitudinal stress steel bars 3, longitudinal stiffened cold-formed thin-walled steel ribs 4, stiffened cold-formed thin-walled steel ribs Rib structural steel bars 5; two longitudinal stiffened cold-formed thin-walled steel ribs 4 of the same shape pass through the holes reserved in the lower part of the ribs through the prefabricated floor transverse structural steel bars 2 and connect the two through stiffened cold-formed thin-walled steel rib structural steel bars 5 The upper part of the ribs, between the longitudinally stiffened cold-formed thin-walled steel ribs 4, the transverse structural reinforcement 2 of the prefabricated floor, and the longitudinal stress reinforcement 3 of the prefabricated floor are pre-embedded in the high-strength co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com