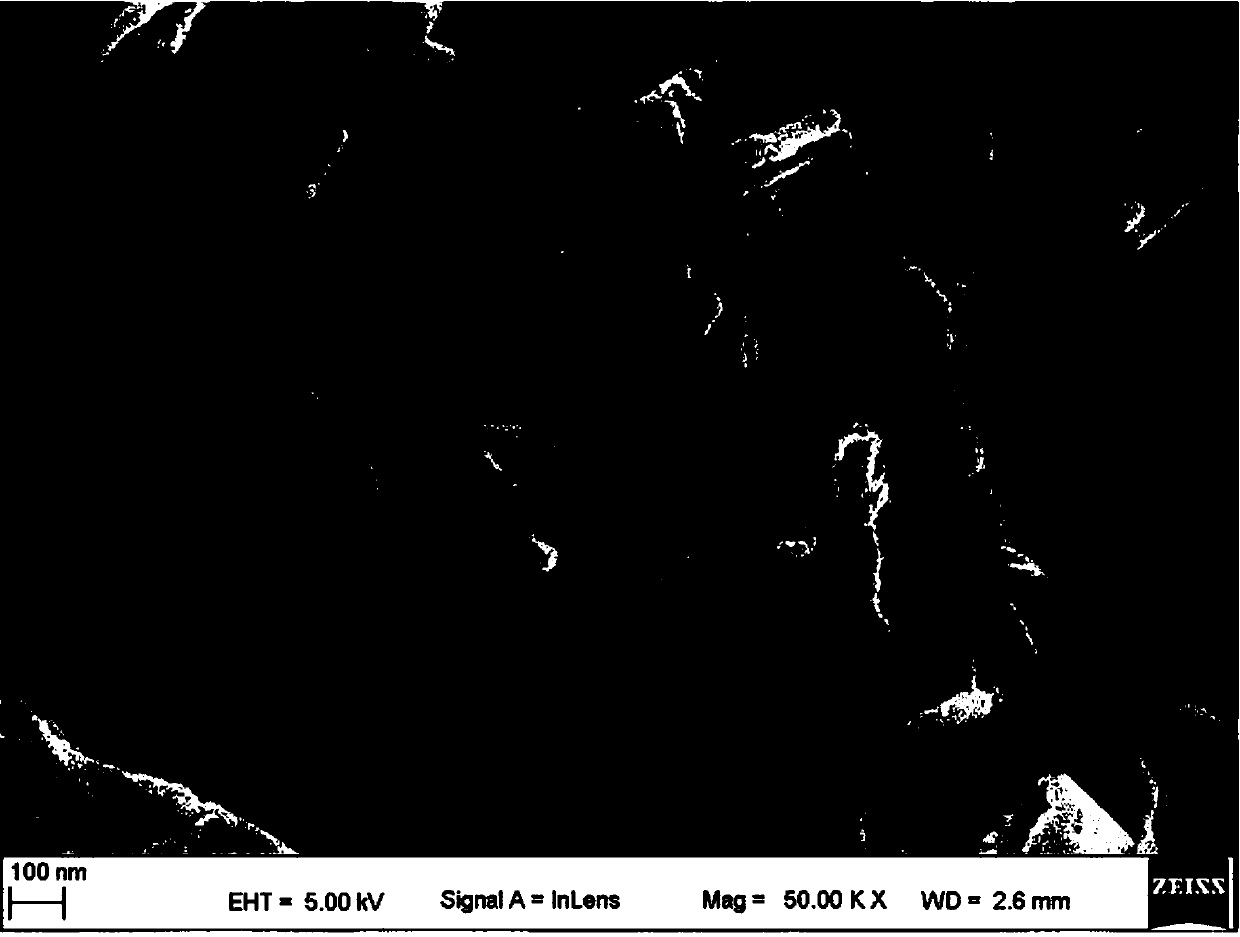

Preparation and purification method of coal-based carbon nanotubes

A purification method and technology of carbon nanotubes, applied in the direction of carbon nanotubes, chemical instruments and methods, nano-carbon, etc., can solve the problems of high environmental risk, uneconomical, harsh conditions, etc., to achieve perfect technology and purification process, reduce coal Base template, effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

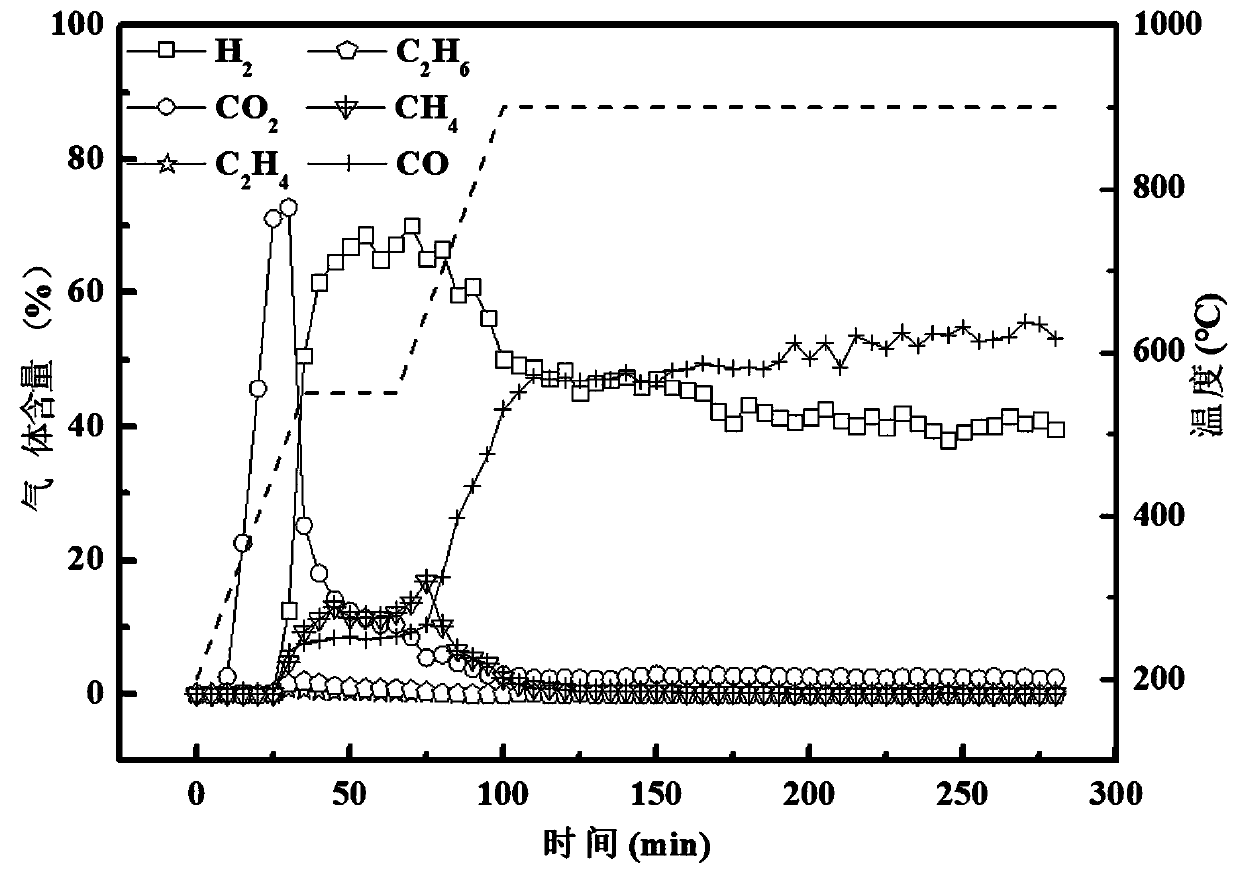

[0028] Embodiment 1: step 1, a bituminous coal is crushed and screened to a particle size range of 0.01-1 mm, and 5 parts of mixed potassium iodide and potassium chloride are added in 100 parts of coal after crushing and screening Catalyst, the mass fraction ratio of potassium iodide and potassium chloride catalyst is 1:0.01, after the catalyst and coal are fully mixed evenly, the mixture is evenly spread in the reactor;

[0029] Step 2, feed the generating gas A of equimolar methane and carbon monoxide in the reactor of step 1, the space velocity of generating gas A is 10000h -1 , when the microwave heating power is 1-30KW and the microwave wavelength is 121.704mm, the coal material is heated intermittently to 800-1050°C with a total heating cycle of 0.5 h, and the interval between two heatings is 10 min. For 5 minutes, a small amount of coal-based carbon nanotubes are obtained on the coal surface;

[0030] Step 3: When the temperature of the coal-based carbon nanotubes prod...

Embodiment 2

[0034] Embodiment 2: Step 1, a bituminous coal is crushed and screened to a particle size range of 0.5-1 mm, and 10 parts by mass of mixed potassium chloride and potassium iodide are added to 100 parts of coal after crushing and screened Catalyst, the mass fraction ratio of potassium chloride and potassium iodide catalyst is 1:0.5, after the catalyst and coal are fully mixed evenly, the mixture is evenly spread in the reactor;

[0035]Step 2, feed the generating gas A of equimolar methane and carbon monoxide in the reactor of step 1, the space velocity of generating gas A is 10000h -1 , when the microwave heating power is 1-30KW and the microwave wavelength is 121.704mm, the coal is heated intermittently to 1050°C with a total heating cycle of 6 hours, the interval between two heatings is 30 minutes, and the intermittent single heating time is 10 minutes , a small amount of coal-based carbon nanotubes were obtained on the coal surface;

[0036] Step 3: When the temperature of...

Embodiment 3

[0040] Embodiment 3: step 1, a bituminous coal is crushed and screened to a particle size range of 0.01-0.5 mm, and 7.5 parts by mass of mixed potassium chloride and potassium iodide are added to 100 parts of coal after crushing and screened Catalyst, the mass fraction ratio of potassium chloride and potassium iodide catalyst is 1:0.25, after the catalyst and coal are fully mixed evenly, the mixture is evenly spread in the reactor;

[0041] Step 2, feed the generating gas A of equimolar methane and carbon monoxide into the reactor of step 1, and the space velocity of generating gas A is 5000 h -1 , when the microwave heating power is 1-30KW and the microwave wavelength is 121.704mm, the coal is heated intermittently to 1050°C with a total heating cycle of 0.5 h, the interval between two heatings is 10 minutes, and the intermittent single heating time is 10 minutes , a small amount of coal-based carbon nanotubes were obtained on the coal surface;

[0042] Step 3: When the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com