Surface defect inspection apparatus, surface defect inspection method, and surface defect inspection program

A technology of defect inspection and camera device, which is applied in the direction of measuring device, optical device, optical test defect/defect, etc., which can solve the problem of increasing maintenance man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

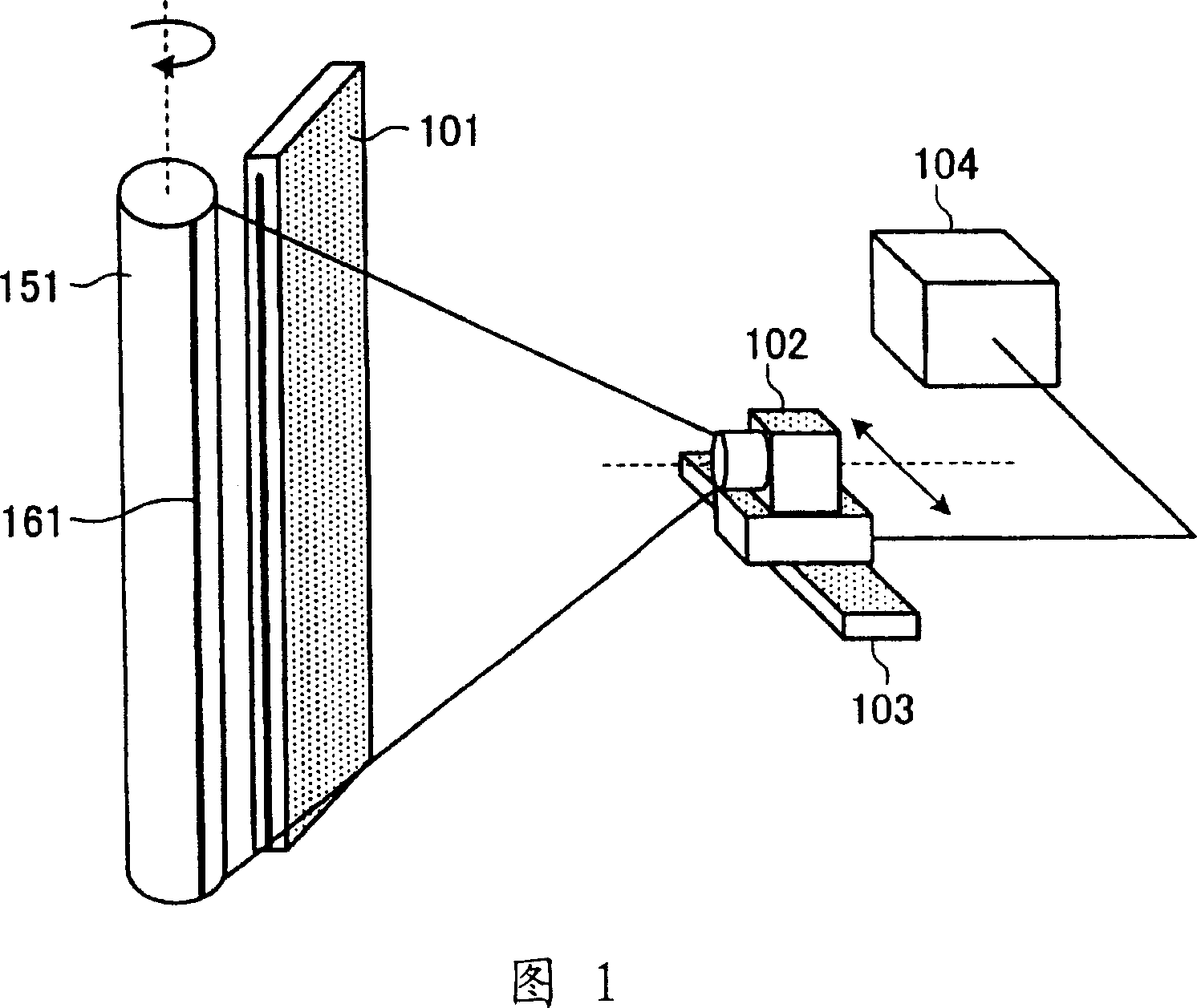

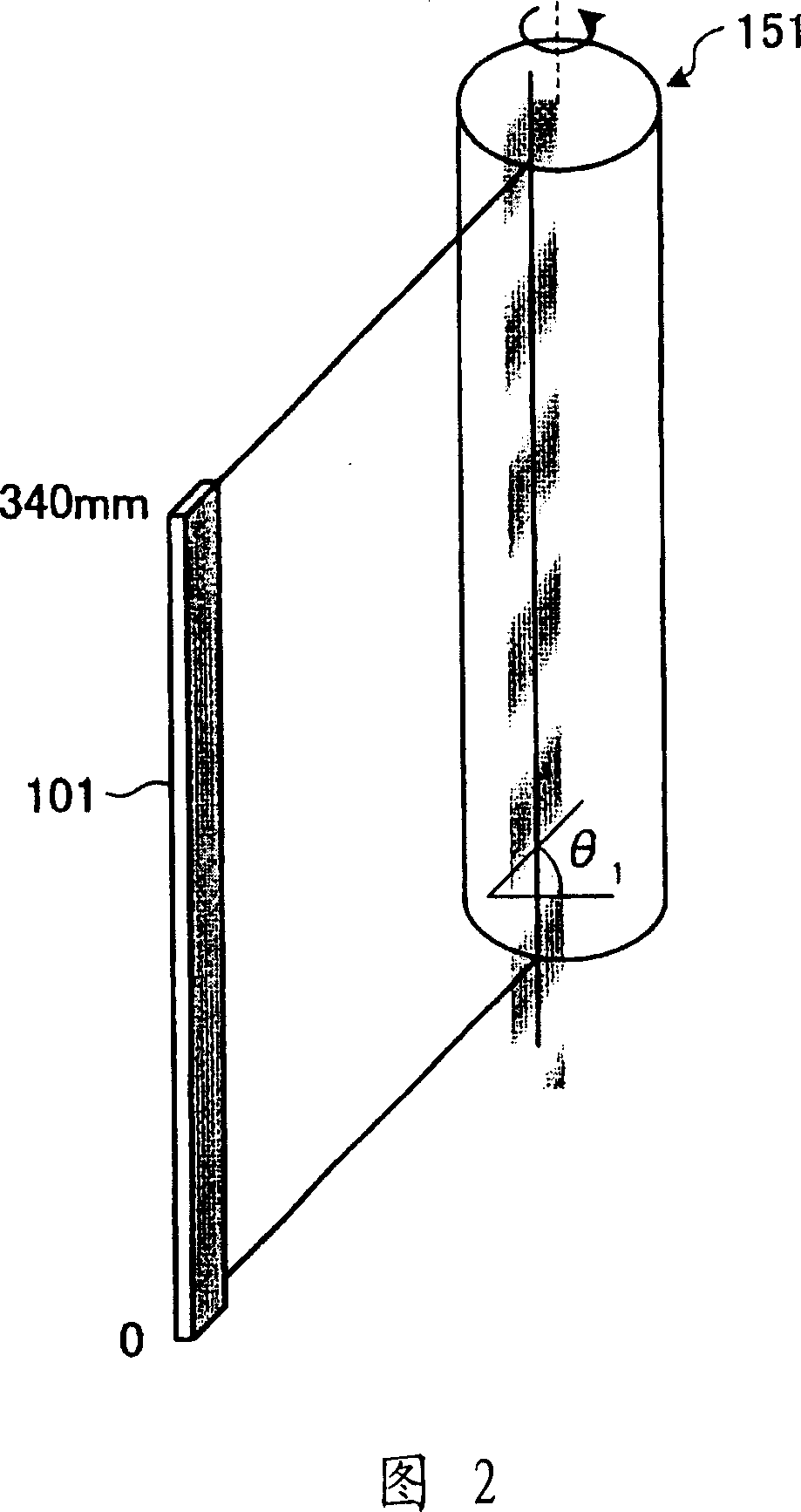

[0092] FIG. 1 is a perspective view showing the configuration of a surface defect inspection apparatus 100 according to the first embodiment. As shown in the figure, the surface defect inspection device 100 is composed of a line light source 101 , a line sensor 102 , a linear stand 103 , and a housing 104 , and inspects whether there is a defect on the surface of a rotating inspection object 151 .

[0093] The inspection object 151 may have any shape, and in this embodiment, a cylindrical photoreceptor drum will be described as an example. The inspection object 151 is rotated, and the inspection position of the inspection object irradiated with pattern light from the line light source 101 described later moves with time. In this way, the line sensor 102 can inspect the entire surface of the inspection target object 151 .

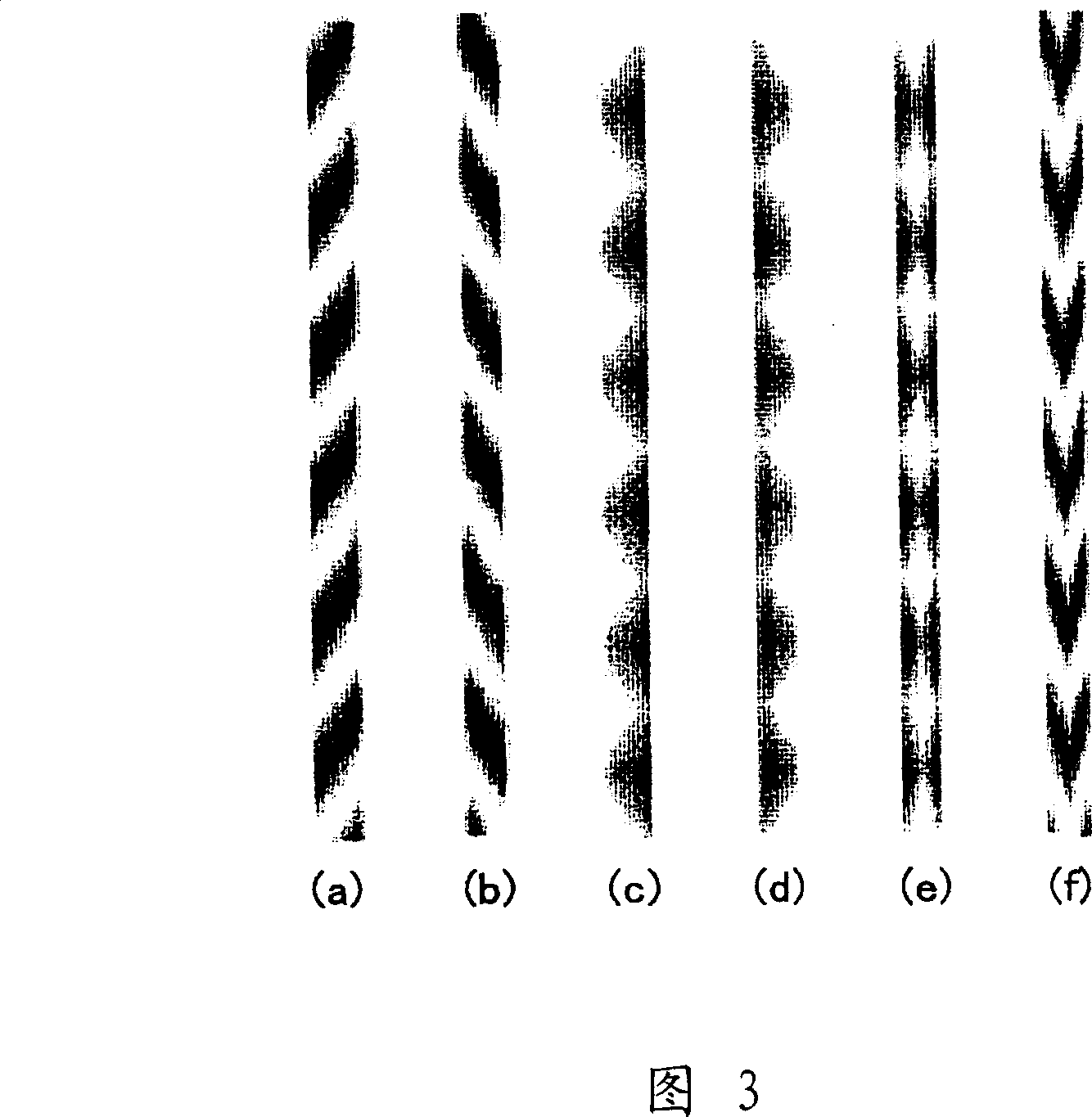

[0094] The line light source 101 irradiates the rotating inspection object with long pattern light having a predetermined pattern in the longitudinal direc...

no. 2 approach

[0162] In the above-mentioned embodiment, the period of the luminance of the pattern light is ten times or more of the size of the defect to suppress the decrease in the detection accuracy of the defect, but it is not limited to such an embodiment. Here, in the second embodiment, a case where the pattern light is irradiated outside the defect detection area object will be described. The surface defect inspection device in the second embodiment has substantially the same configuration as that shown in FIG. 1 in the first embodiment, and only the different points will be described below.

[0163] FIG. 15 is an explanatory view showing a state in which a line light source 1301 according to the present embodiment irradiates pattern light on an object 151 to be inspected. As shown in the figure, the patterned light irradiated by the line light source 1301 irradiates the light without pattern in the detection area, and irradiates the patterned light in the area outside the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com