Fly ball wheel and hammering operation method

A technology of flyweight and flyweight assembly, which is applied in the laying of tracks, roads, tracks, etc. It can solve the problems of increasing the difficulty of work, inconvenient carrying and using fuel, and damaging the rails, so as to save the effect of motion transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

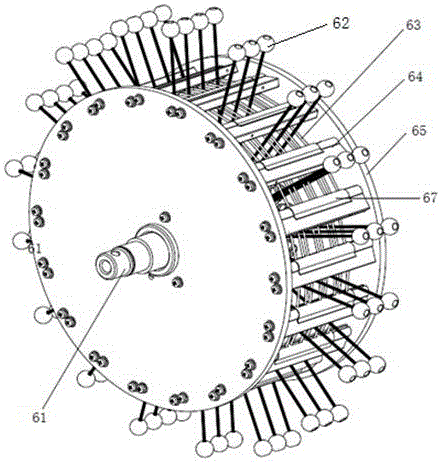

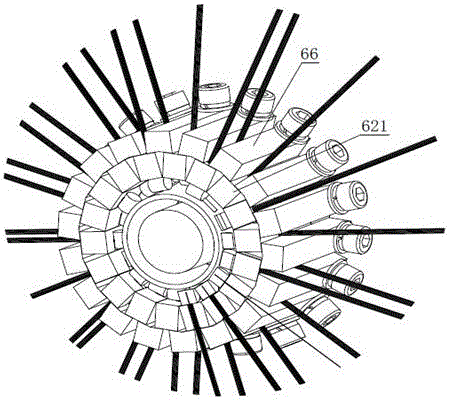

[0043] like figure 1 and figure 2 As shown, the flyweight wheel provided by the present invention includes a central drive shaft 61, a fixed limit

[0044] device, flyweight body group 62 and fixture 66. The central drive shaft 61 is connected with the driving device outside the flyweight wheel, and each group of flyweight bodies is mounted on the central drive shaft 61 through a fixing device 66 . The central positions of the two positioning plates are passed through by the central drive shaft, and driven to rotate by the central drive shaft.

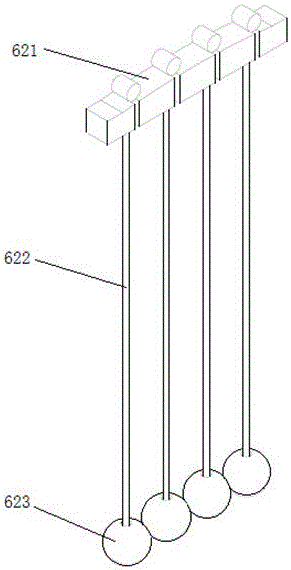

[0045] like image 3 As shown, the flyweight body group 62 is composed of an axial beam 621 , a flexible traction metal rope 622 for the flyweight body and a metal hammer body 623 . The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com