Cleaning and derusting device and method for water cavity system

A technology of water chamber and cleaning liquid, which is applied in the field of cleaning and derusting, cleaning and derusting devices for water chamber systems, can solve the problems of easy rusting in the cooling water system of maintenance equipment, etc., so as to adapt to cleaning and derusting, ensure normal operation, The effect of convenient mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

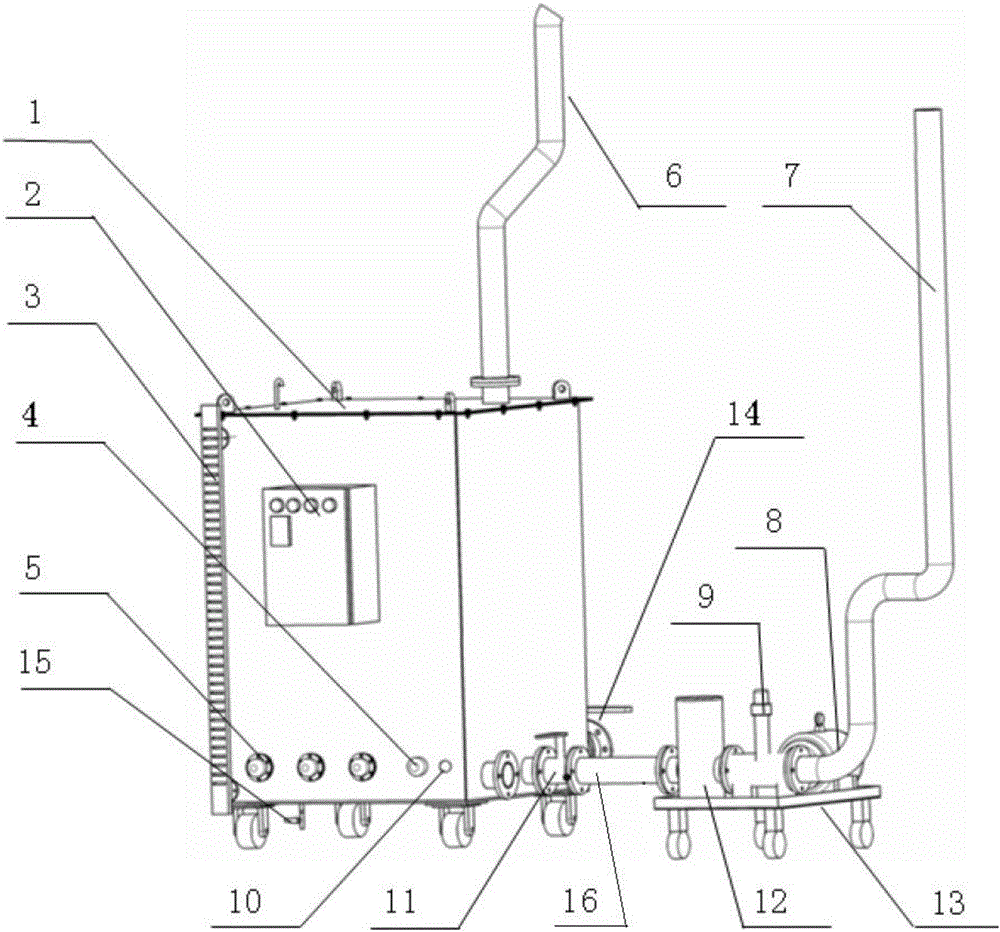

[0038] Please refer to figure 1 , figure 2 and image 3 , which shows that the cleaning and derusting device for the water chamber system is connected with the cooling water system of the maintenance equipment to form an integral circuit, which includes a flushing water tank 1, a filter 12, a centrifugal pump 9 and an electrical unit 2.

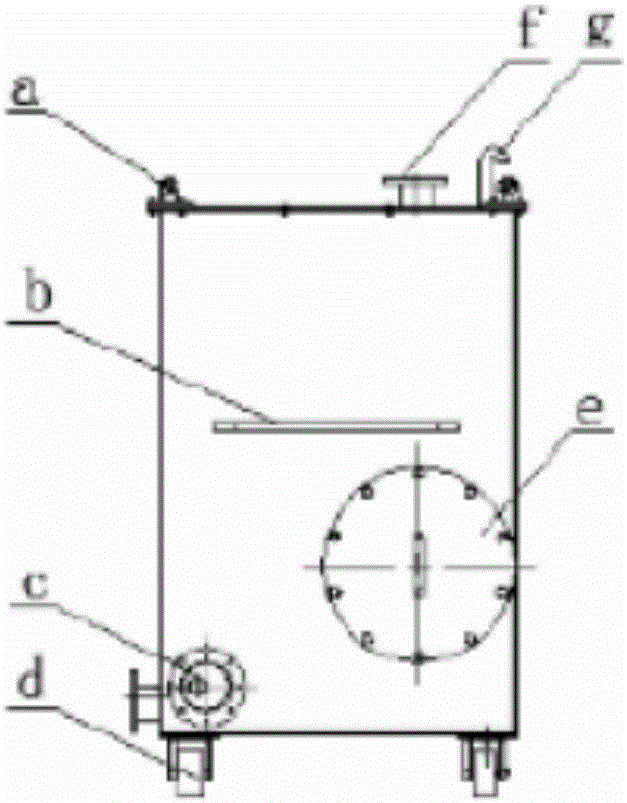

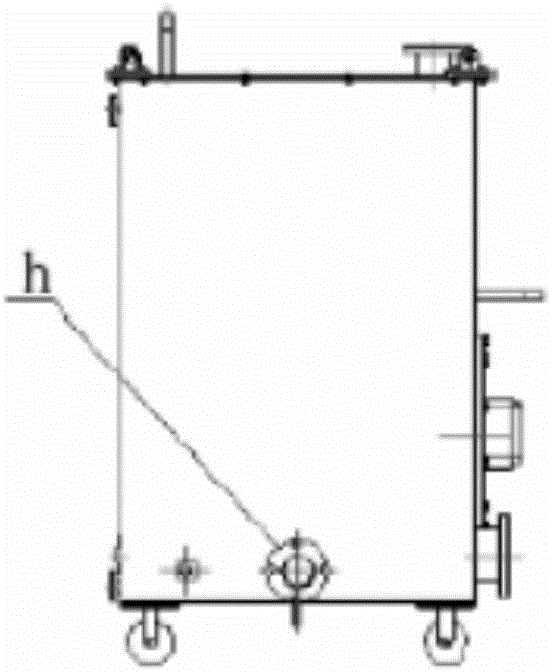

[0039]The inside of the flushing water tank 1 contains a cleaning solution containing a rust remover, which is the basis for derusting the cooling water system, and is composed of fresh water and rust remover added to the flushing water tank 1 . The side of the lower part of the flushing water tank 1 is provided with a water outlet h, and the top is provided with a water return port f, and the water return port f is flange-connected to the return water end of the cooling water system of the maintenance equipment through the return water pipe 6 . The top of the flushing water tank 1 is provided with a ventilation pipe g for hydraulic ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com