System for railway steel rail laser rust removal

A technology of laser rust removal and rail, which is applied in laser welding equipment, cleaning methods and tools, manufacturing tools, etc., can solve the problems of low quality of rust removal, inability to remove rust in all directions, and single rust removal angle, so as to avoid human body Effects of inhalation and environmental pollution, saving rust removal time, and low learning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

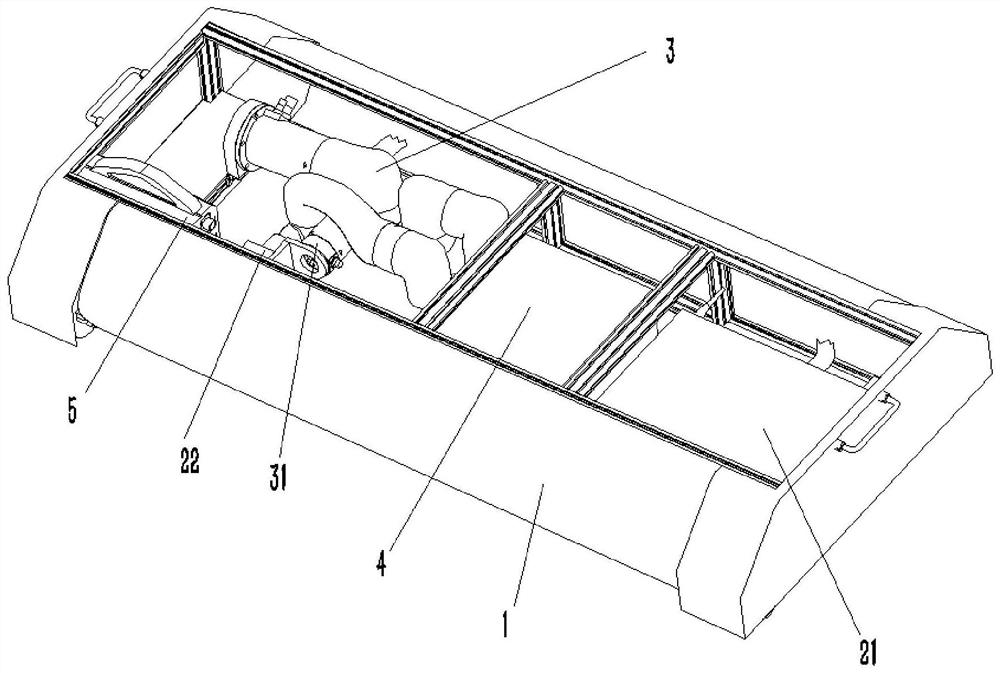

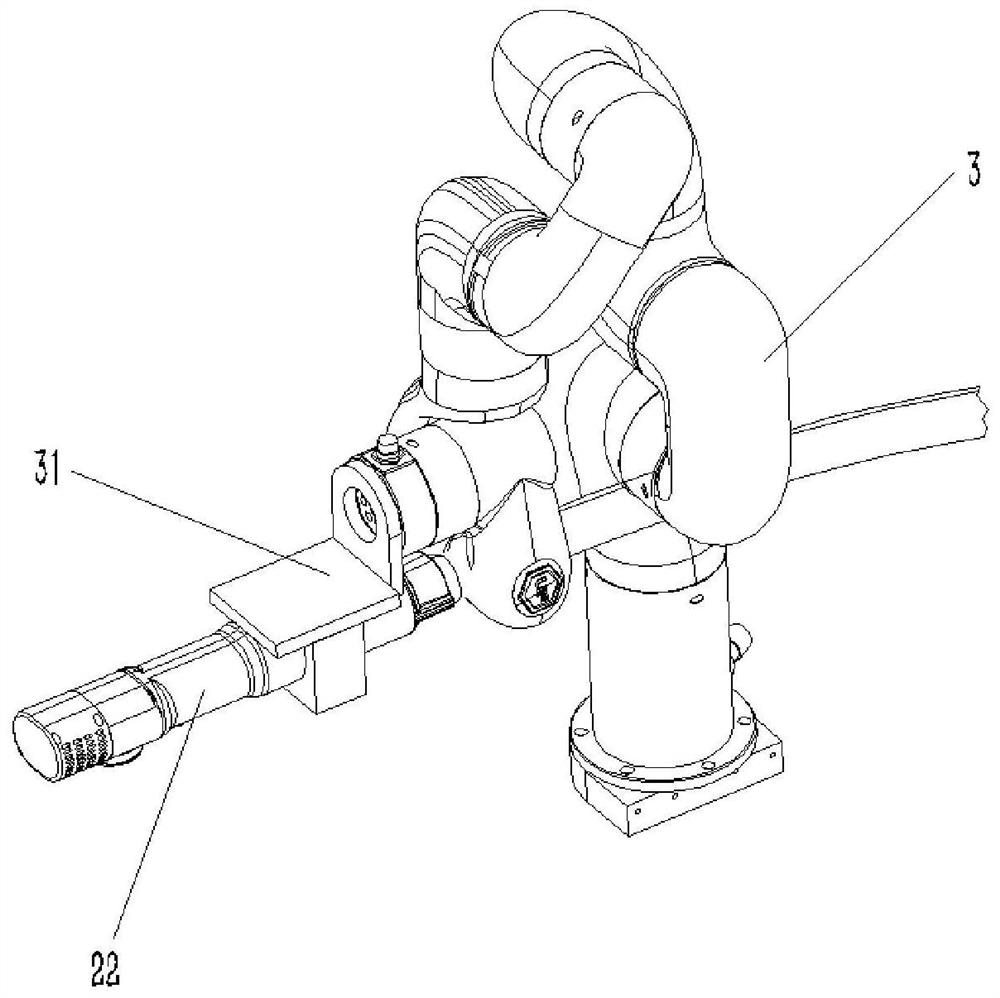

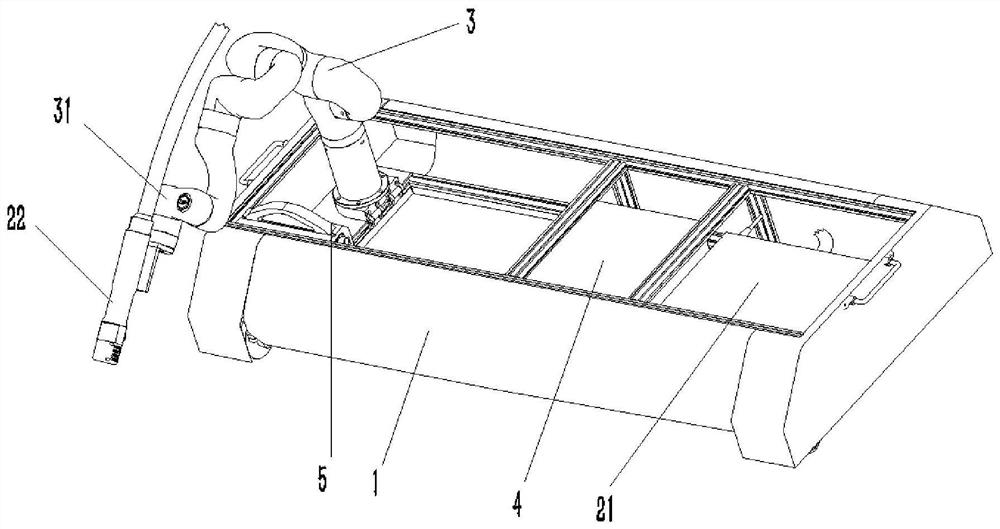

[0029] Such as Figure 1-5 As shown, a kind of laser rust removal system for railway rails involved in the present invention includes a rail car 1, a mechanical arm 3, a laser generator, a dust collector 4, a controller 5, a wireless remote control and a mobile power supply;

[0030] Rail car 1 bottom both sides are equipped with four rail wheels driven by drive motors, rail wheels can drive rail car to move on the track, rail car is a box structure, and rail car 1 is provided with an opening and is used to cover the opening. The car cover 11 at the entrance, the storage compartment, the power supply compartment and the laser generating compartment are arranged in sequence from left to right inside the rail car 1, and the cover 11 is divided into a storage compartment cover 111 covering the storage compartment and a power supply compartment covering the power supply compartment and the laser generating compartment Cover 112, while handles are installed on the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com