Bowl scaffold steel tube derusting machine

A scaffolding and derusting machine technology, applied in the field of scaffolding steel pipe derusting machine and bowl buckle type scaffolding steel pipe derusting machine, can solve the problems of cleaning machine damage, collision, inability to derust the whole steel pipe, etc. The effect of reducing vibration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

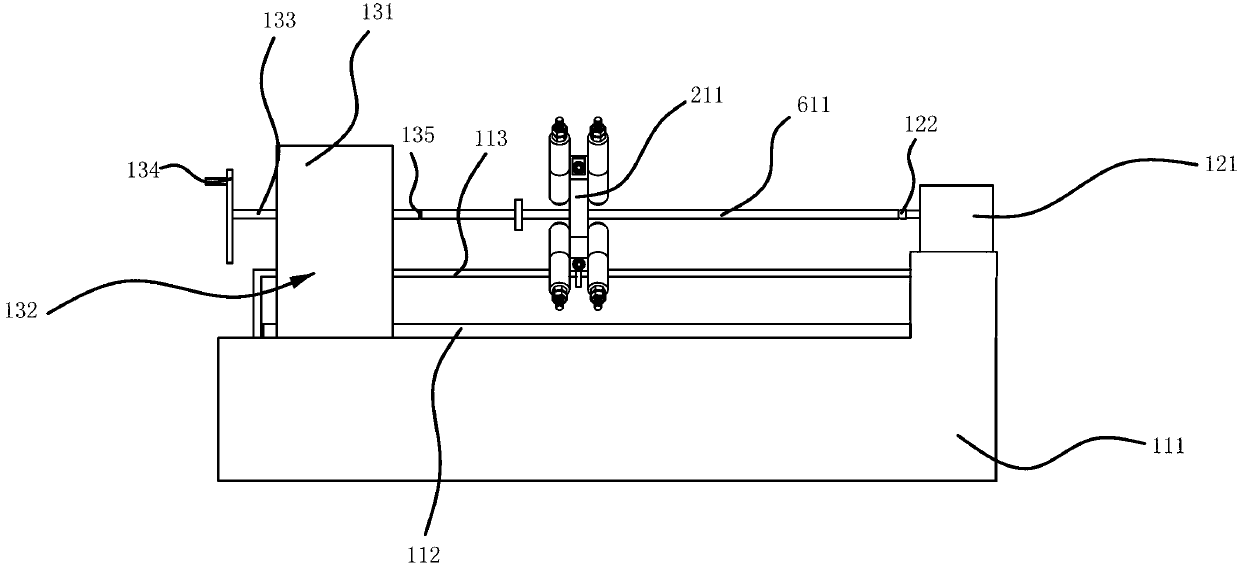

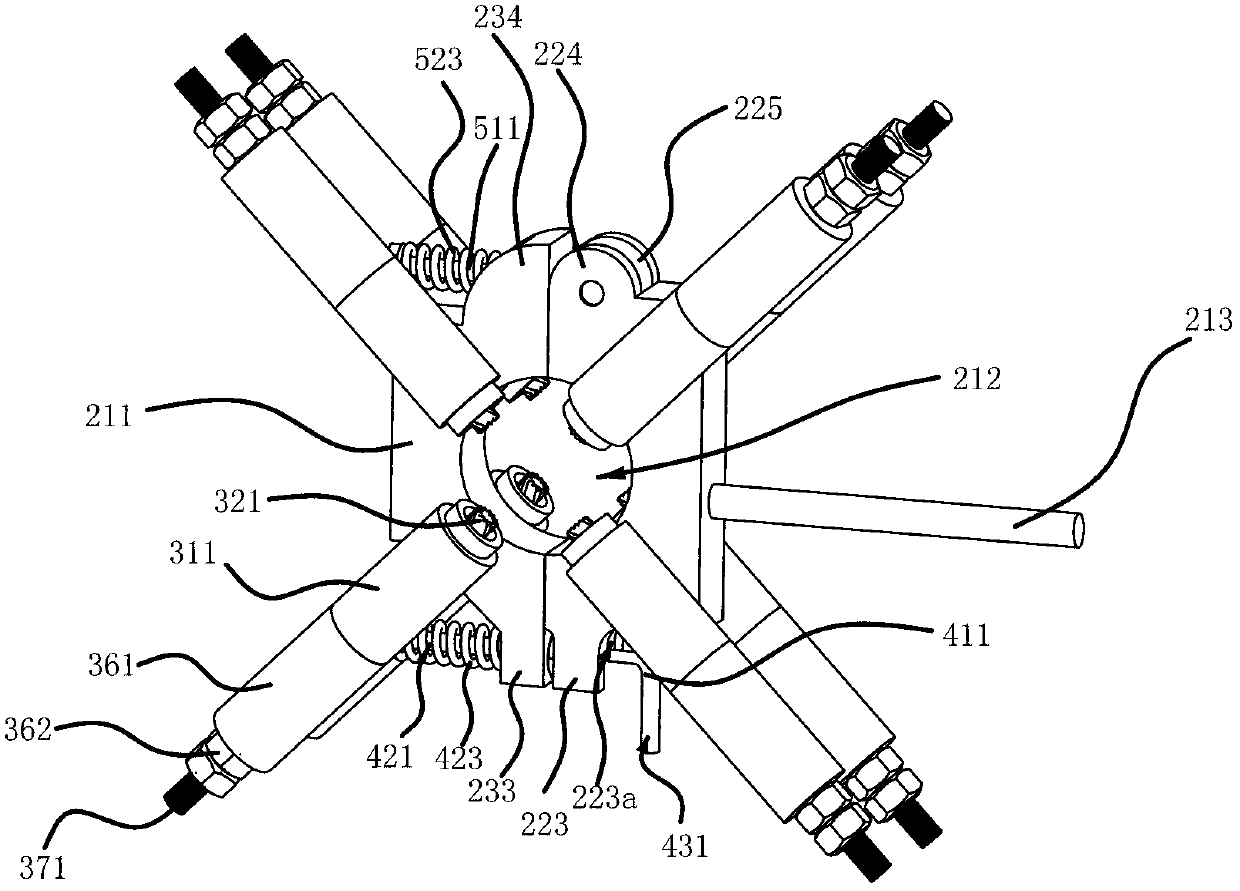

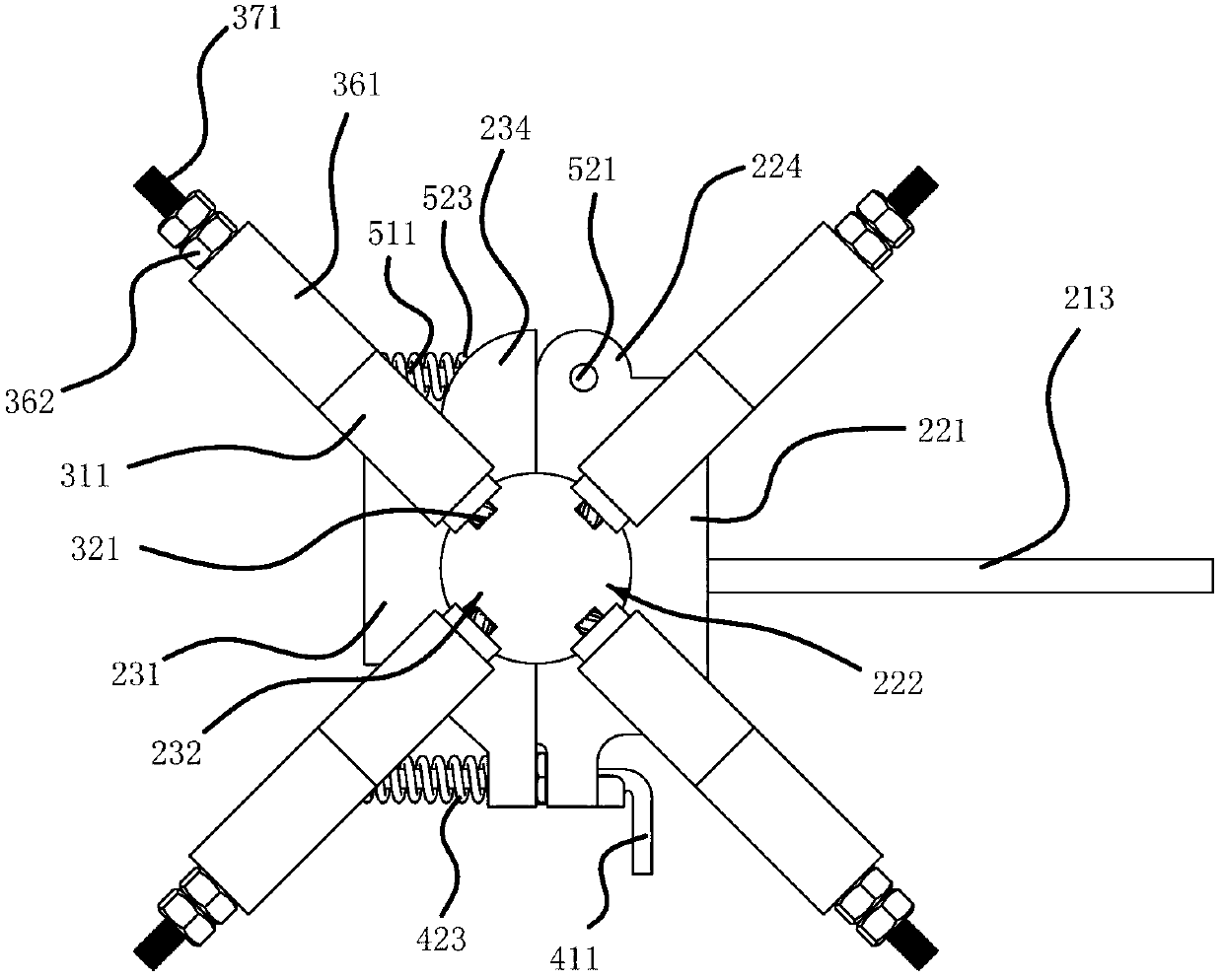

[0028] Such as Figure 1 to Figure 5 As shown, a bowl buckle type scaffolding steel pipe derusting machine includes a frame 111 and a derusting ring 211, and one end of the frame 111 is fixed with a deceleration motor 121, and the deceleration motor 121 in the present embodiment one is available on the market For example, the YCJ series gear reducer produced by Zibo Fumate Transmission Equipment Co., Ltd., the other end of the frame 111 is provided with a fixed seat 131, and the fixed seat 131 can move along the frame 111 to position the steel pipe 611 on the geared motor 121 and fix it Between the seats 131, the side of the frame 111 is axially fixed with a retaining rod 113, such as figure 2 As shown, the rust removal ring 211 has a through hole 212 for the steel pipe 611 to pass through. Fixed sleeve 311, the central axis of fixed sleeve 311 is parallel to the side of derusting ring 211 and intersects with the central axis of through hole 212, the inner end of fixed sleev...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the adjustment assembly includes gasket 1 fixed on one end of the brush head, a buffer spring and a cover plate, and the buffer spring is sleeved on the brush head to buffer One end of the spring abuts against the gasket one, one end of the cover plate is provided with a groove, the groove wall of the groove is provided with an internal thread, the cover plate is threadedly connected with the fixing sleeve, and the gasket one abuts against the groove bottom surface of the groove. By adjusting the length of the threaded connection between the cover plate and the fixed sleeve, the length of the brush head protruding from the fixed sleeve is adjusted.

Embodiment 3

[0037] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the locking structure includes a locking part 1 protruding from the other end of the rotating plate, a locking part 2 protruding from the other end of the fixed plate and screws , locking part 1 and locking part 2 can lean against each other, screw hole 1 is set on locking part 1, screw hole 2 is set on locking part 2, internal thread is set on the hole wall of screw hole 2, screw hole 1 and screw hole The two phases are connected, and the screw passes through the first screw hole and is threadedly connected with the second screw hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com