Automatic rust removal cleaning device for cylinder outer wall

A cleaning equipment, automatic technology, applied in the direction of metal processing equipment, grinding/polishing equipment, grinding drive, etc., can solve the problems of low rust removal efficiency, lack of rust prevention treatment, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

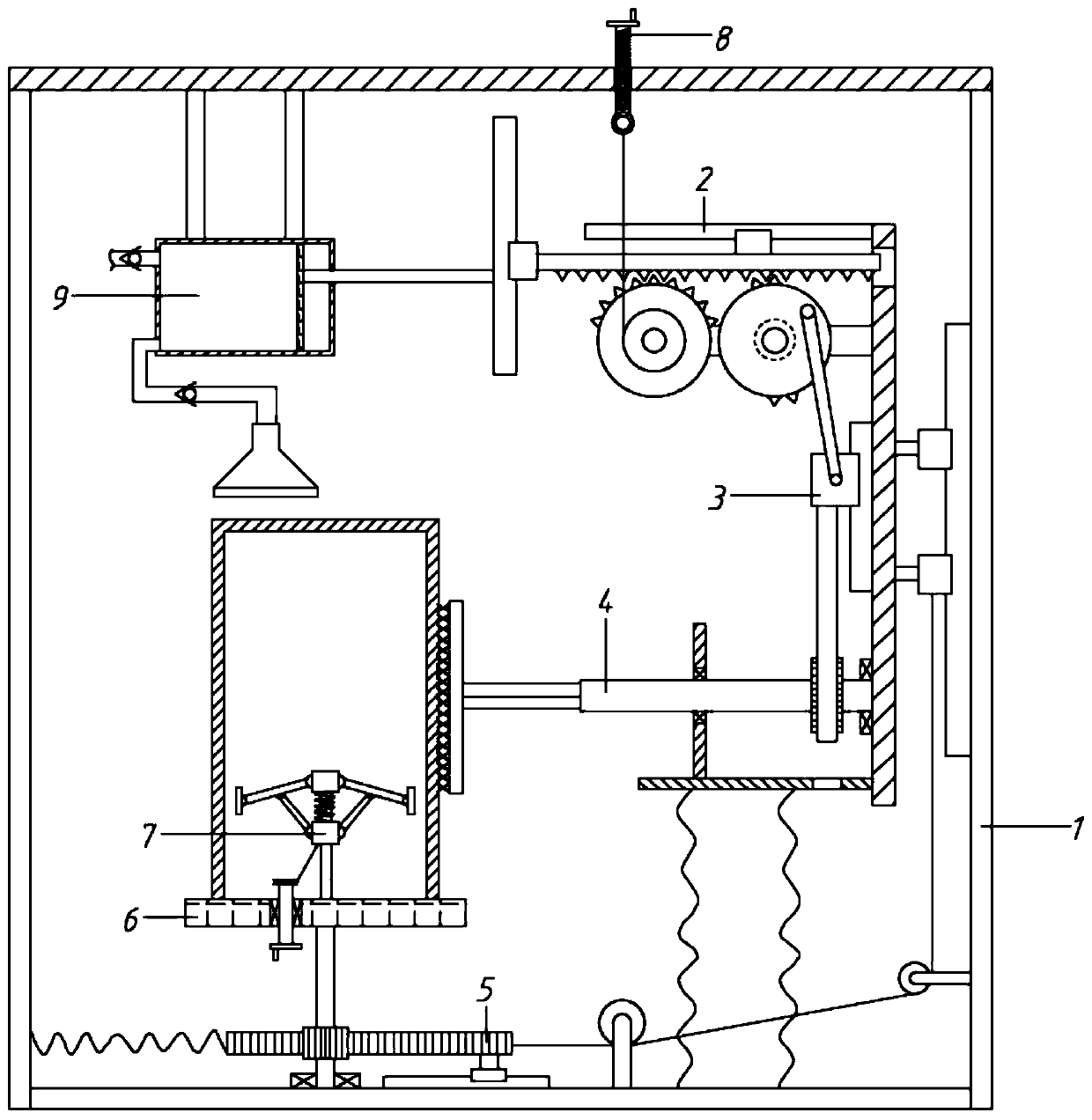

[0068] An automatic derusting and cleaning device for the outer wall of a cylinder, including a frame 1, a lifting component 2, a reciprocating component 3, a derusting component 4, a pulling component 5 and a supporting component 6;

[0069] The frame 1 includes a base 101, a left side plate 102, a right side plate 103 and a top plate 104. The left and right sides of the base 101 are fixedly connected to the left side plate 102 and the right side plate 103 respectively, and the tops of the left side plate 102 and the right side plate 103 pass through the top plate 104 connection; the lifting assembly 2 is set on the left side of the right side plate 103, the lifting assembly 2 is provided with a reciprocating assembly 3, and the rust removal assembly 4 is matched under the reciprocating assembly 2; the left part of the base 101 is provided with a support assembly 6, and the top of the support assembly 6 is used On the placement cylinder; the base 101 is provided with a pulling...

Embodiment 2

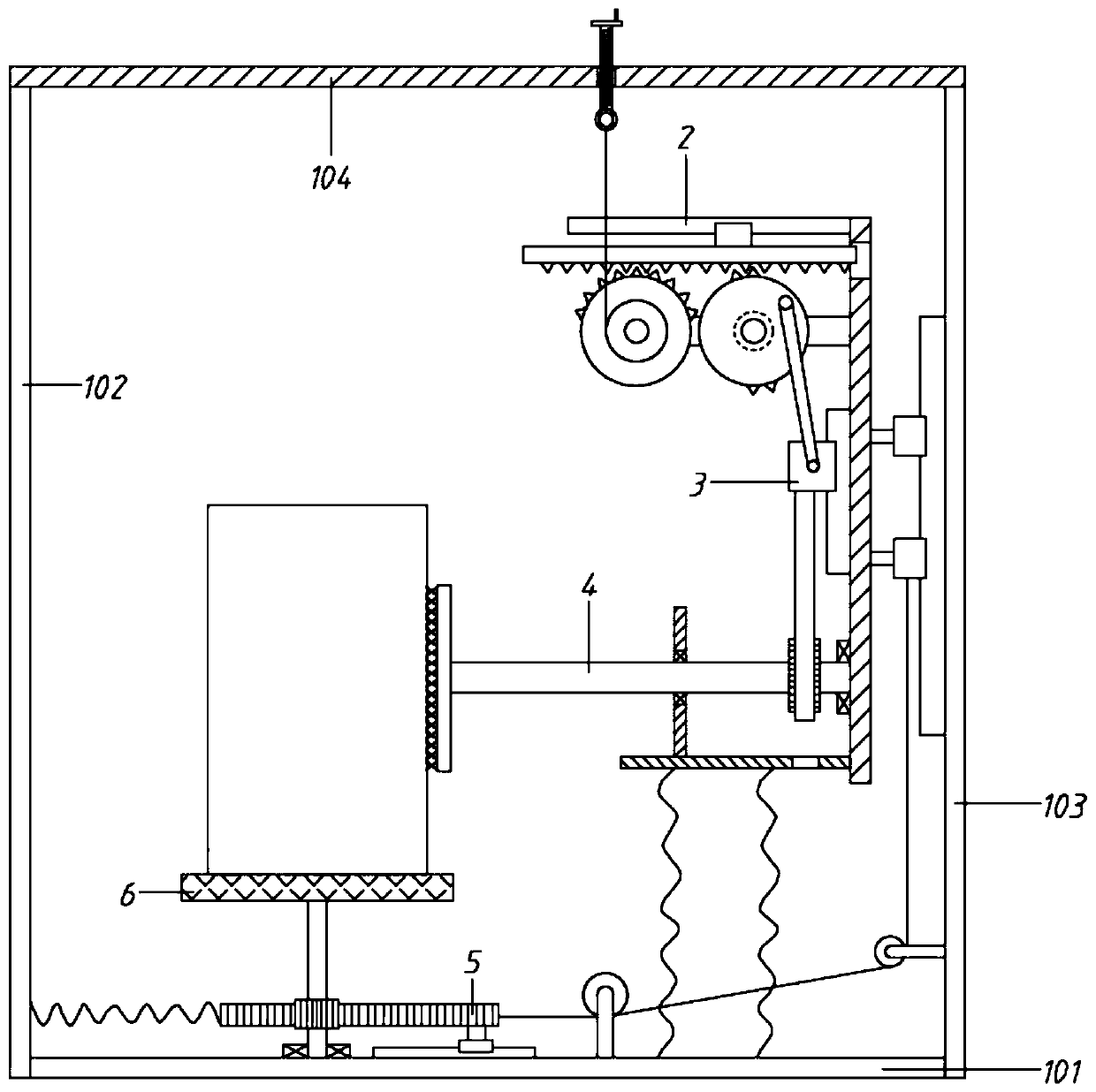

[0071] An automatic derusting and cleaning device for the outer wall of a cylinder, including a frame 1, a lifting component 2, a reciprocating component 3, a derusting component 4, a pulling component 5 and a supporting component 6;

[0072] The frame 1 includes a base 101, a left side plate 102, a right side plate 103 and a top plate 104. The left and right sides of the base 101 are fixedly connected to the left side plate 102 and the right side plate 103 respectively, and the tops of the left side plate 102 and the right side plate 103 pass through the top plate 104 connection; the lifting assembly 2 is set on the left side of the right side plate 103, the lifting assembly 2 is provided with a reciprocating assembly 3, and the rust removal assembly 4 is matched under the reciprocating assembly 2; the left part of the base 101 is provided with a support assembly 6, and the top of the support assembly 6 is used On the placement cylinder; the base 101 is provided with a pulling...

Embodiment 3

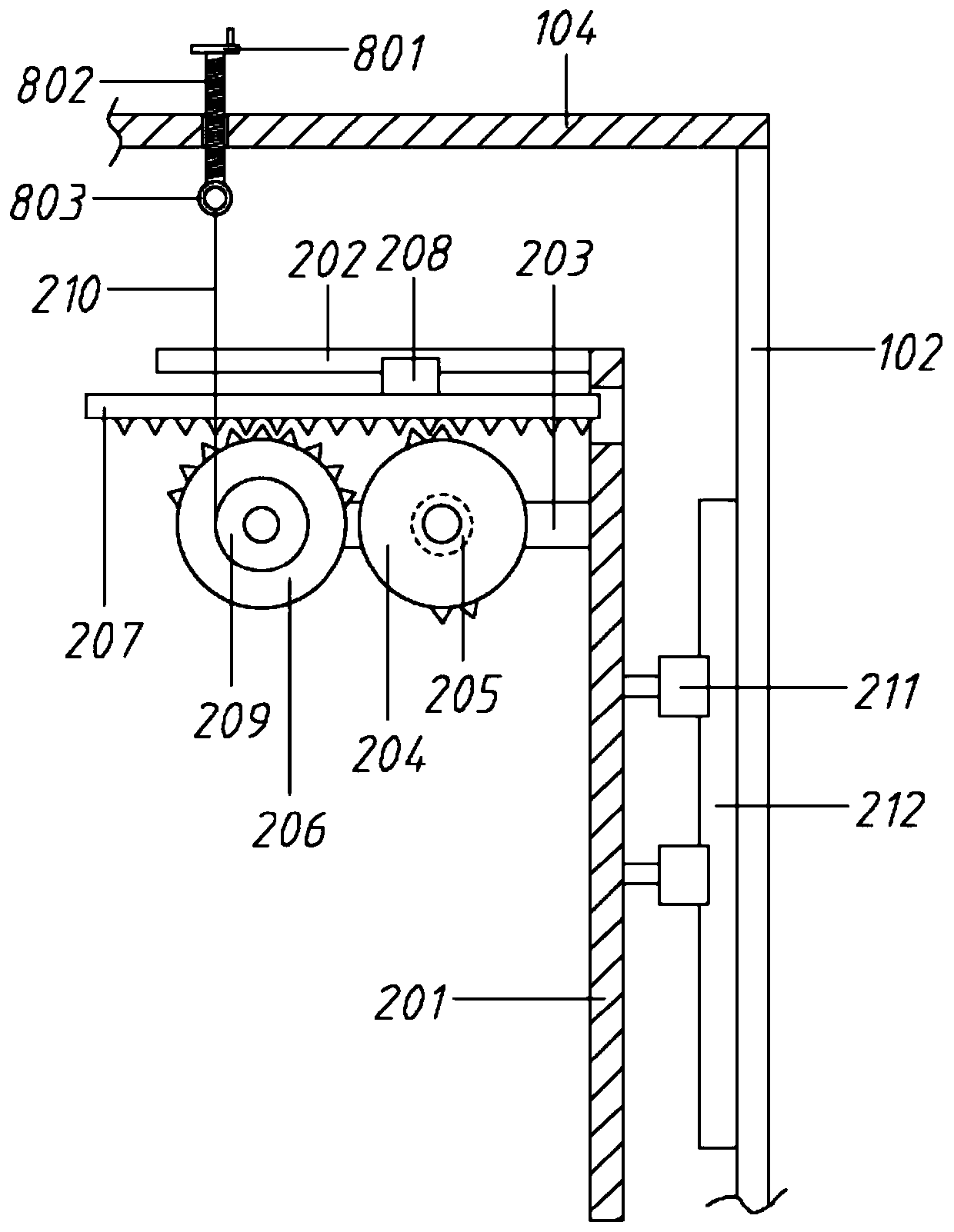

[0094] On the basis of embodiment 2,

[0095] Also includes the inner support assembly 7; the inner support assembly 7 includes the No. 1 handle 701, the rotating shaft 702, the No. 2 take-up wheel 703, the fixed rod 704, the sliding sleeve 705, the No. 2 spring 706, the top block 707, the No. 1 rod 708, No. 2 pole 709 and clamping plate 710;

[0096] The center of the support seat 602 is fixedly connected with a fixed rod 704, and the top of the fixed rod 704 is fixedly connected with a top block 707. The fixed rod 704 is equipped with a sliding sleeve 705, and a No. 2 spring 706 is connected between the sliding sleeve 705 and the top block 707; 708 and No. 2 rod 709 are evenly arranged in the circumferential direction; the inner end of No. 1 rod 708 is hinged with top block 707, and the outer end is hinged with clamp 710; the inner end of No. 2 rod 709 is hinged with sliding sleeve 705, and the outer end is connected with No. 1 rod 708 The middle section is hinged; the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com