Large stainless steel pipe rolling type external force polishing and derusting mechanism

A stainless steel tube and rolling technology, which is applied to the parts of the grinding machine tool, the grinding machine, and the grinding feed movement, etc., can solve the problems of steel tube maintenance without rust removal, steel pipes prone to rust, and difficulty in grinding and rust removal. Achieve the effect of improving rust removal efficiency, rapid rust removal and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

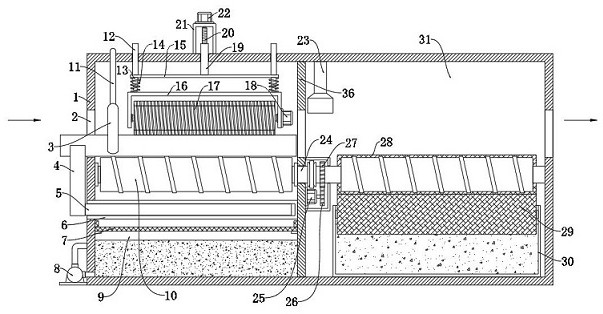

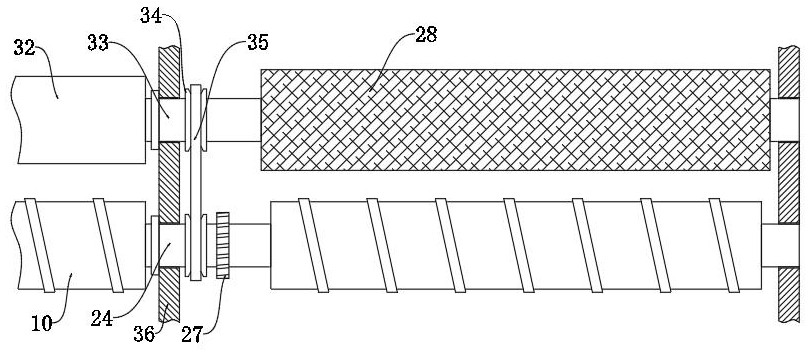

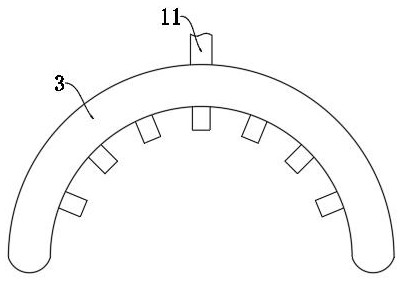

[0031] refer to Figure 1-4 , a large-scale stainless steel tube rolling type external force grinding and derusting mechanism, including a box body 1, the interior of the box body 1 is vertically provided with a partition 36, and the partition 36 divides the inside of the box body 1 into a rust removal chamber 9 arranged in a horizontal direction 1. Curing room 31, the rust remover is stored at the bottom of the rust removal room 9, the two side walls of the box body 1 and the partition plate 36 are provided with a feed port 2, and the partition plate 36 is penetrated with the first rotating shaft 24, the second Two rotating shafts 33, the first rotating shaft 24 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com