Steel pipe raw material surface rust removal equipment for intelligent manufacturing

A technology of intelligent manufacturing and raw materials, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low work efficiency, high labor intensity and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

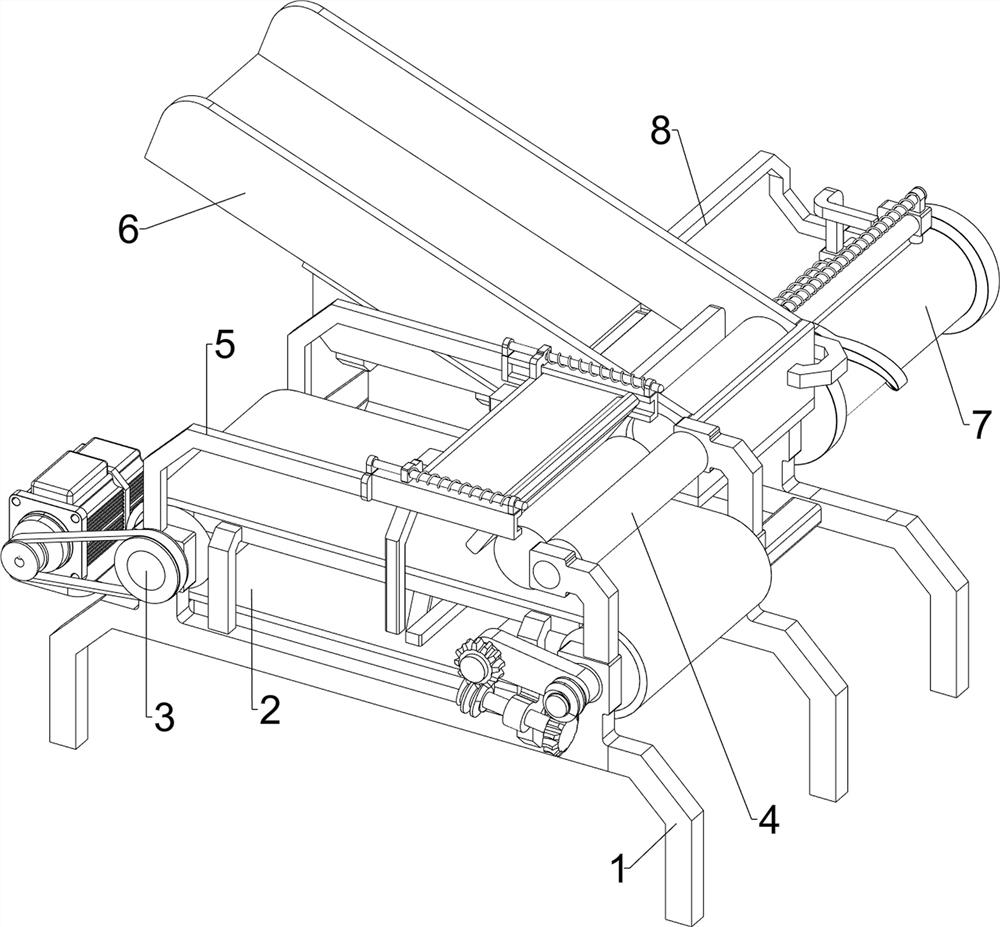

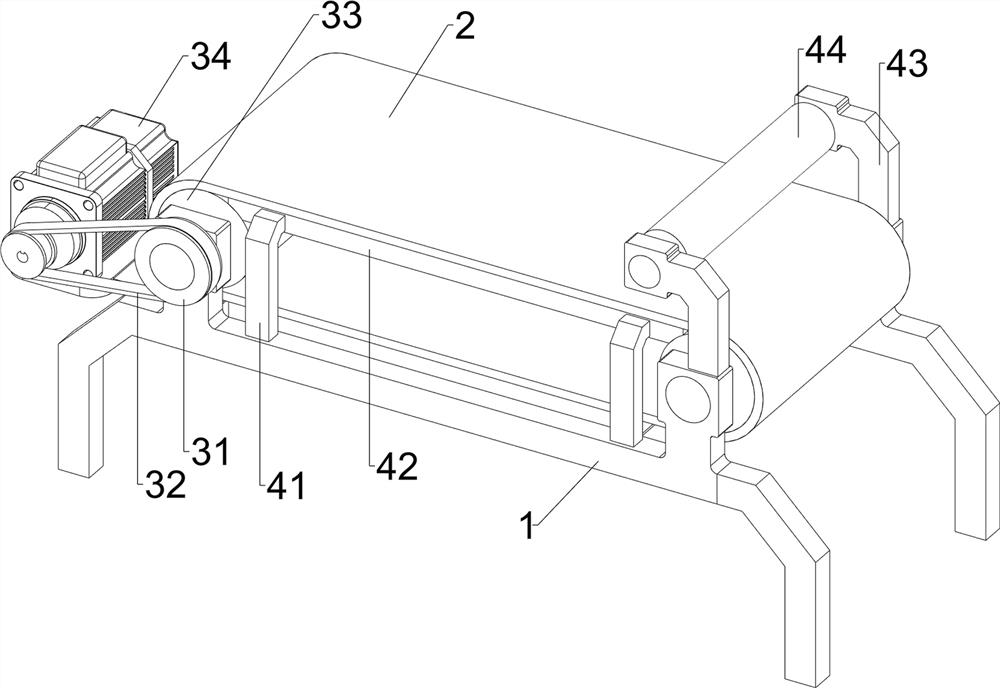

[0025] A kind of rust removal equipment on the surface of steel pipe raw materials for intelligent manufacturing, such as Figure 1-Figure 3 As shown, it includes a base 1, an abrasive belt 2, a grinding mechanism 3, a supporting mechanism 4 and a clamping mechanism 5. The top of the base 1 is provided with a grinding mechanism 3, the base 1 is provided with a supporting mechanism 4, and the grinding mechanism 3 is provided with a sanding mechanism. The belt 2 and the grinding mechanism 3 are provided with a clamping mechanism 5 .

[0026] First, people place the rusty steel pipe on the abrasive belt 2, the clamping mechanism 5 clamps and fixes the rusty steel pipe, and starts the grinding mechanism 3 to cooperate with the support mechanism 4, so that the abrasive belt 2 derusts the surface of the rusty steel pipe. After the steel pipe is derusted, the grinding mechanism 3 is closed to achieve an efficient derusting effect.

[0027] Grinding mechanism 3 comprises transmission...

Embodiment 2

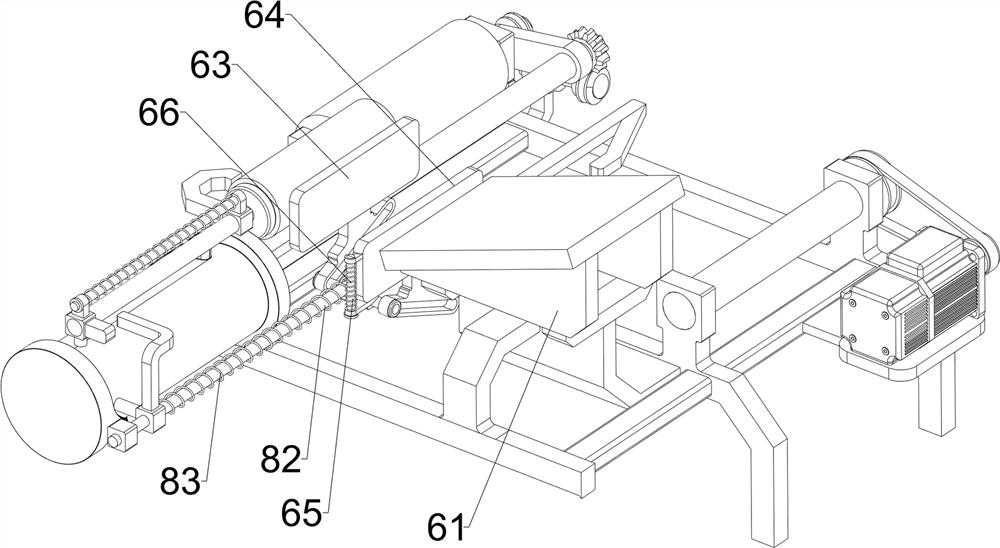

[0032] On the basis of Example 1, such as Figure 4-Figure 6 As shown, a material storage mechanism 6 is also included, and the material storage mechanism 6 includes a fourth mounting frame 61, a trough 62, a first baffle plate 63, a second baffle plate 64, a second guide rod 65 and a second spring 66, The base 1 is provided with a fourth mounting frame 61 on the right rear side, and the fourth mounting frame 61 is provided with a trough 62, the front side of the trough 62 is slidably provided with a first baffle plate 63, and the slidable type on the trough 62 is provided with a second stopper. plate 64, the second baffle plate 64 is positioned at the rear side of the first baffle plate 63, and the second baffle plate 64 right side is provided with a second guide rod 65, and the second guide rod 65 is slidably connected with the trough 62, and the second baffle plate 64 A second spring 66 is connected with the trough 62 , and the second spring 66 is sleeved on the second guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com