Efficient and convenient rust removal device for hardware machining

A convenient and efficient technology, used in heating devices, metal processing equipment, grinding drive devices, etc., can solve the problems of slow rust removal efficiency, inability to remove rust from metal plates, poor grinding effect, etc., and achieve scientific and reasonable structure, fast and effective. Rust removal, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

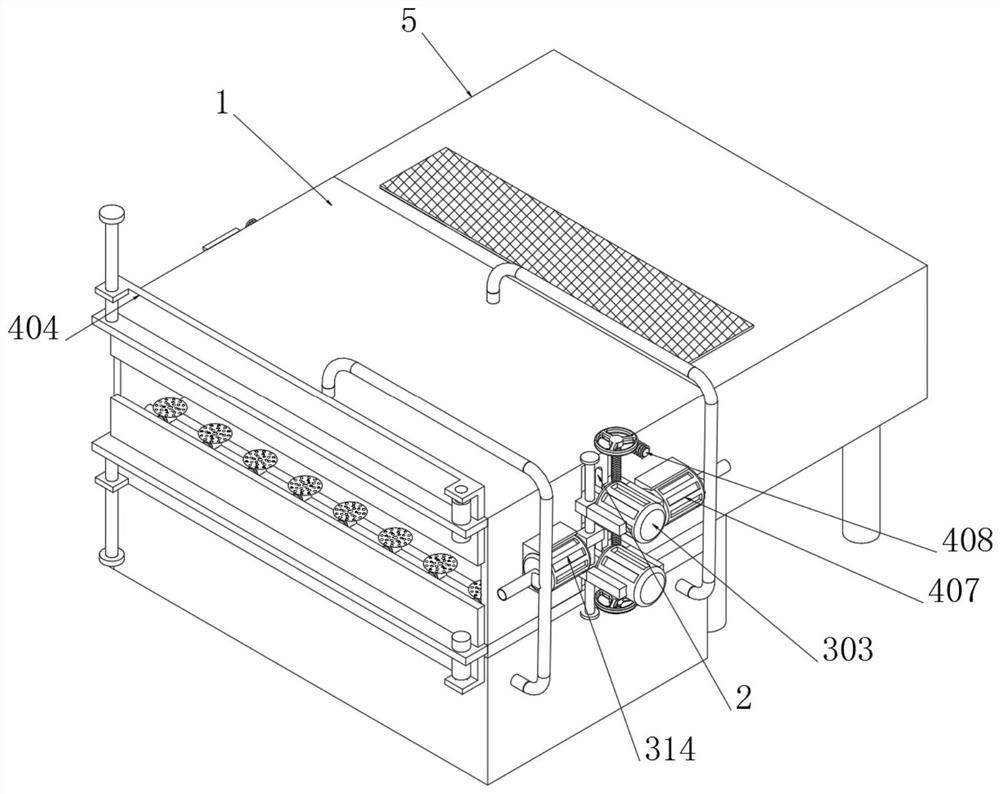

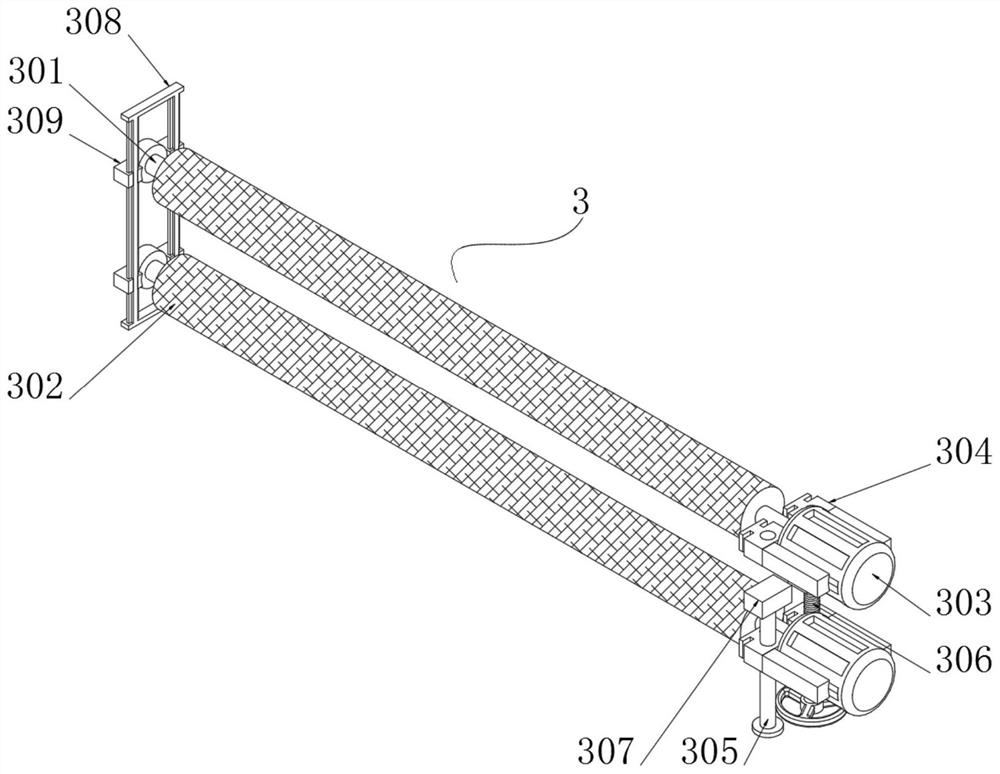

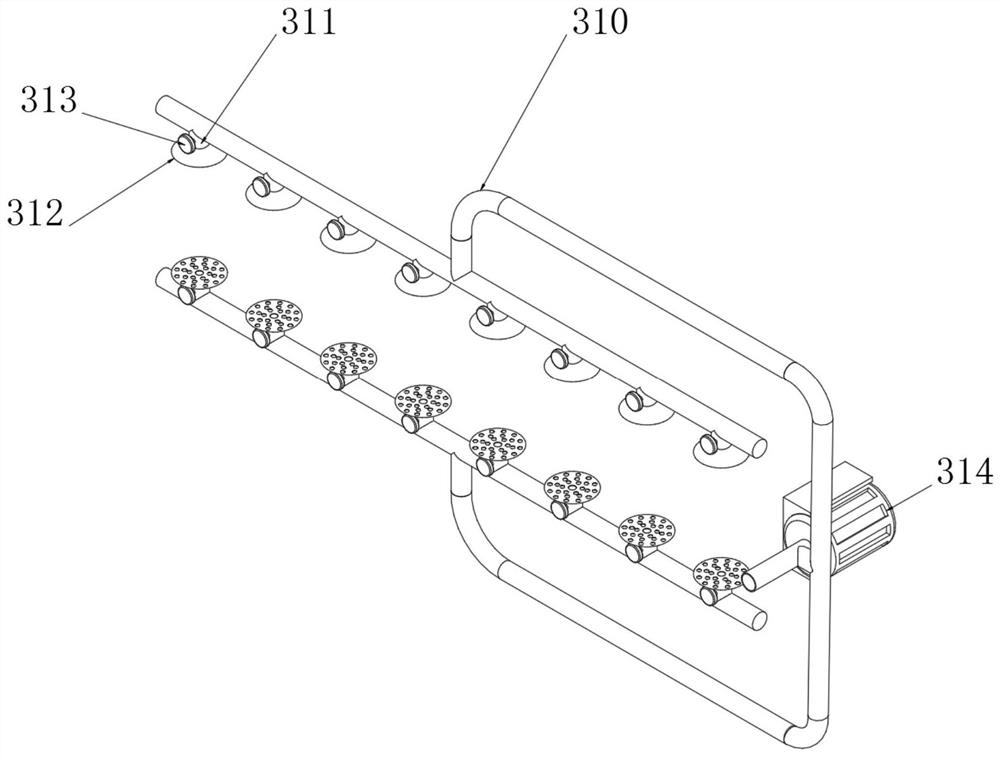

[0033] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, an efficient and convenient rust removal device for metal processing, including a housing 1, a moving hole 2 is provided on one side of the housing 1, and a rust removal assembly 3 is installed on one side of the moving hole 2, and Rust assembly 3 comprises rotating rod 301, derusting roller 302, drive motor 303, mobile mounting block 304, mobile guide rod 305, moving screw mandrel 306, fixed mounting block 307, fixed mobile frame 308, limit slip ring 309, removing Rust drain pipe 310, connecting pipe 311, rust removal nozzle 312, discharge limiting valve 313 and booster water pump 314;

[0034] The inner side of the moving hole 2 is symmetrically mounted with a rotating rod 301 , one end of the rotating rod 301 is sleeved with a rust removal roller 302 , one end of the rotating rod 301 is connected to the output end of the transmission motor 303 , and one end of the housing 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com