Inner surface polishing and derusting tool of hollow axle of CRH train

A hollow axle and inner surface technology is applied in the field of grinding devices for the inner surface of hollow axles used in EMU trains, which can solve the problems of lack of rust removal tools and the like, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

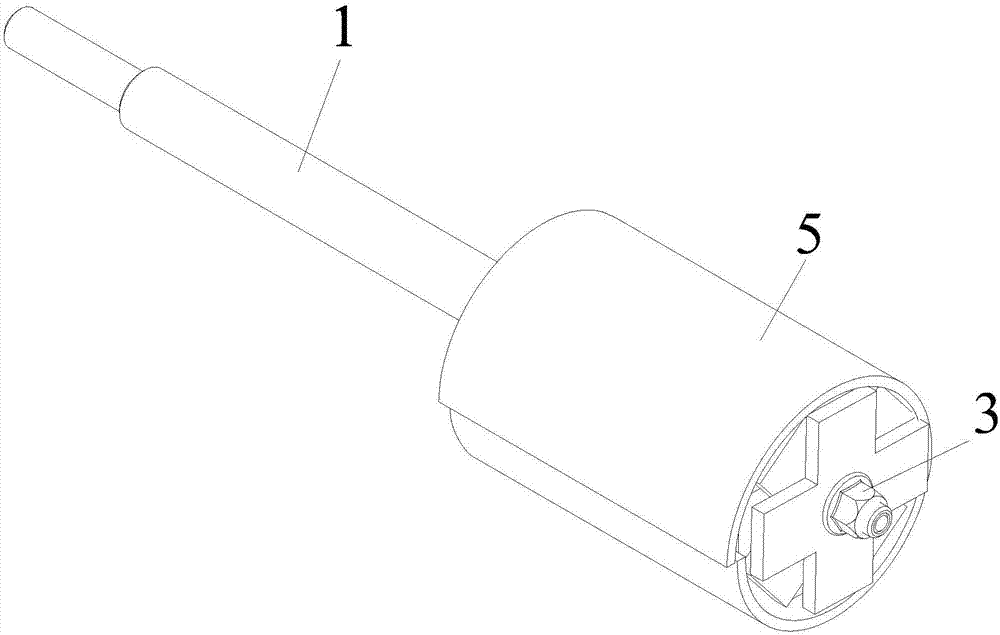

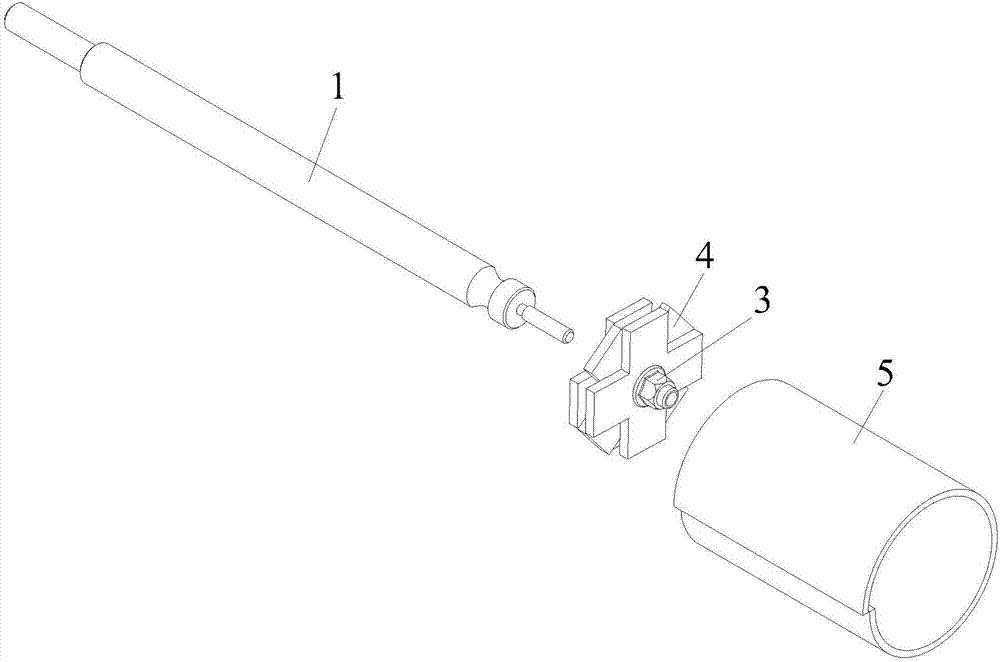

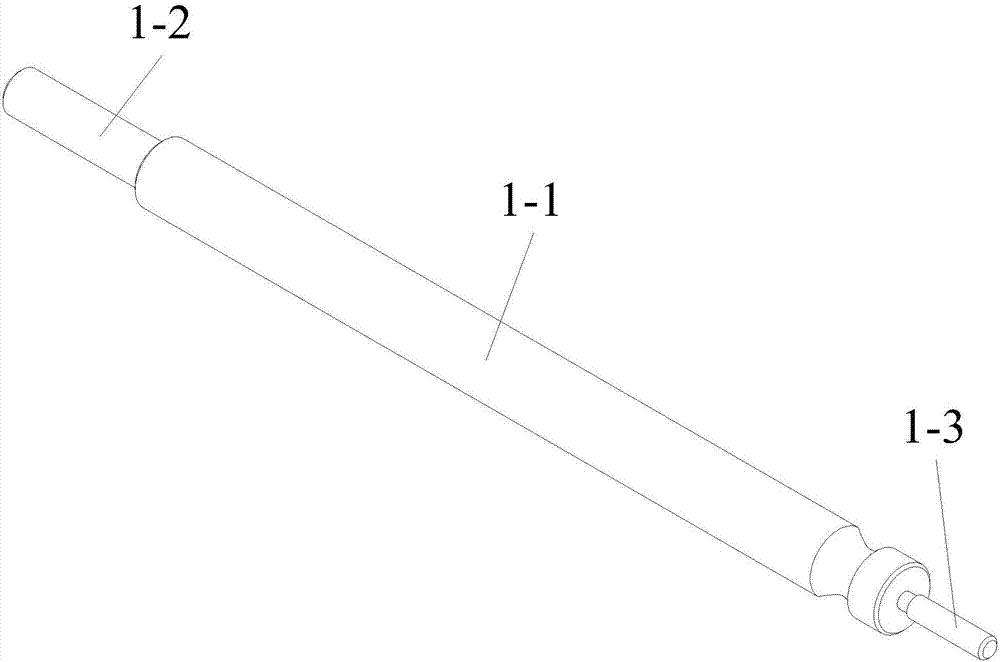

[0022] Such as Figure 1 to Figure 6 As shown, the grinding and derusting tool for the inner surface of the hollow axle of the EMU is characterized in that: the tool includes an extension rod 1, a grinding head base 2, an end nut 3, a grinding sheet composition 4 and an outer layer grinding sheet 5; The diameter of the extension rod 1 is 12 mm, and the total length is 1200 mm, the middle section is the rod body 1-1, the end of the extension rod 1 is provided with a docking seat 1-2, and the front end of the extension rod 1 is provided with a rod end stud 1-3 , the three are integrally formed; the length of the rod end stud 1-3 is 13 millimeters, the diameter is 4 millimeters, and its outer wall is a cone with a taper. The grinding head base 2 comprises a base disc 2-1 and a threaded cylinder 2-2, the end face of the base disc 2-1 is provided with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com