Surface rust removal device for petroleum drill rod

A technology of oil drill pipe and derusting machine, which is applied in the direction of grinding drive device, grinding machine, grinding machine tool parts, etc., which can solve the problems of derusting uniformity, drill pipe damage, difficult turning and feeding, etc., to achieve Good rust removal effect, improved convenience, and guaranteed thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

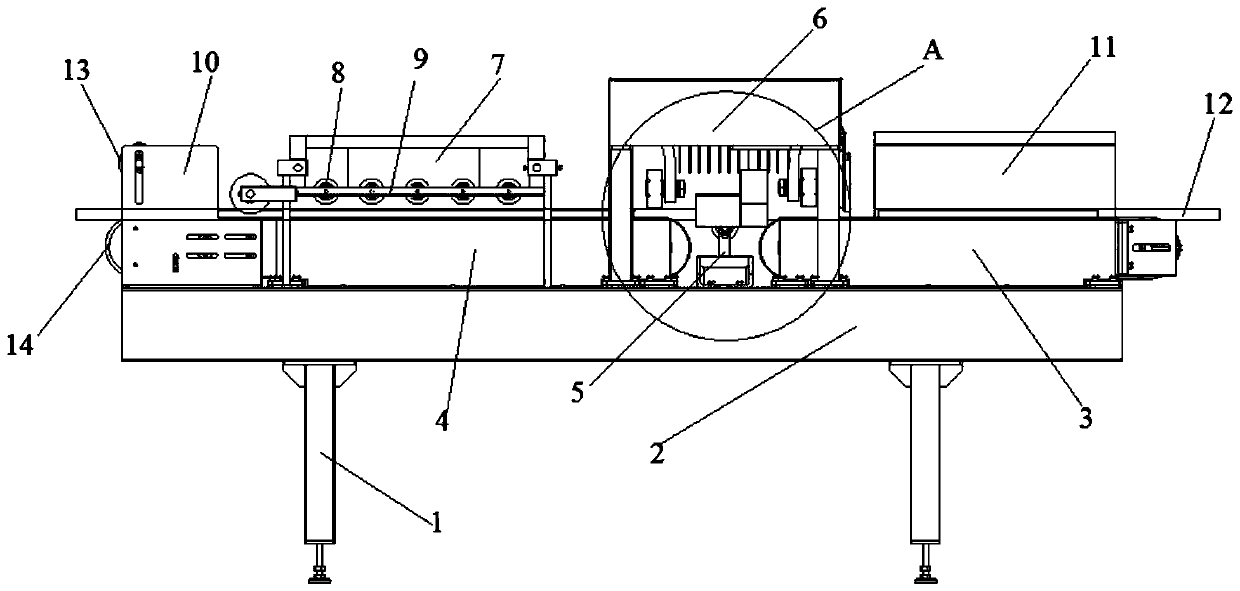

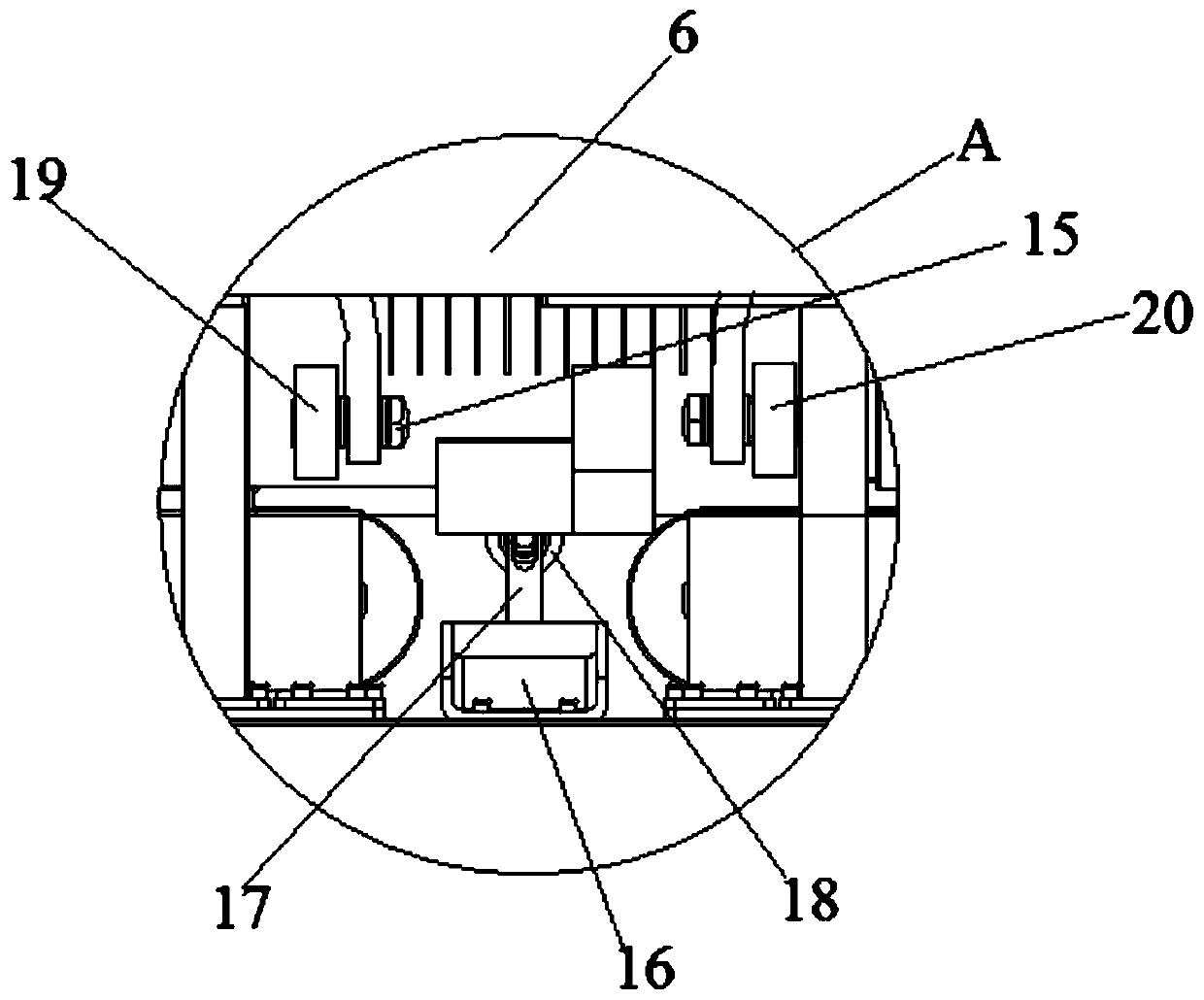

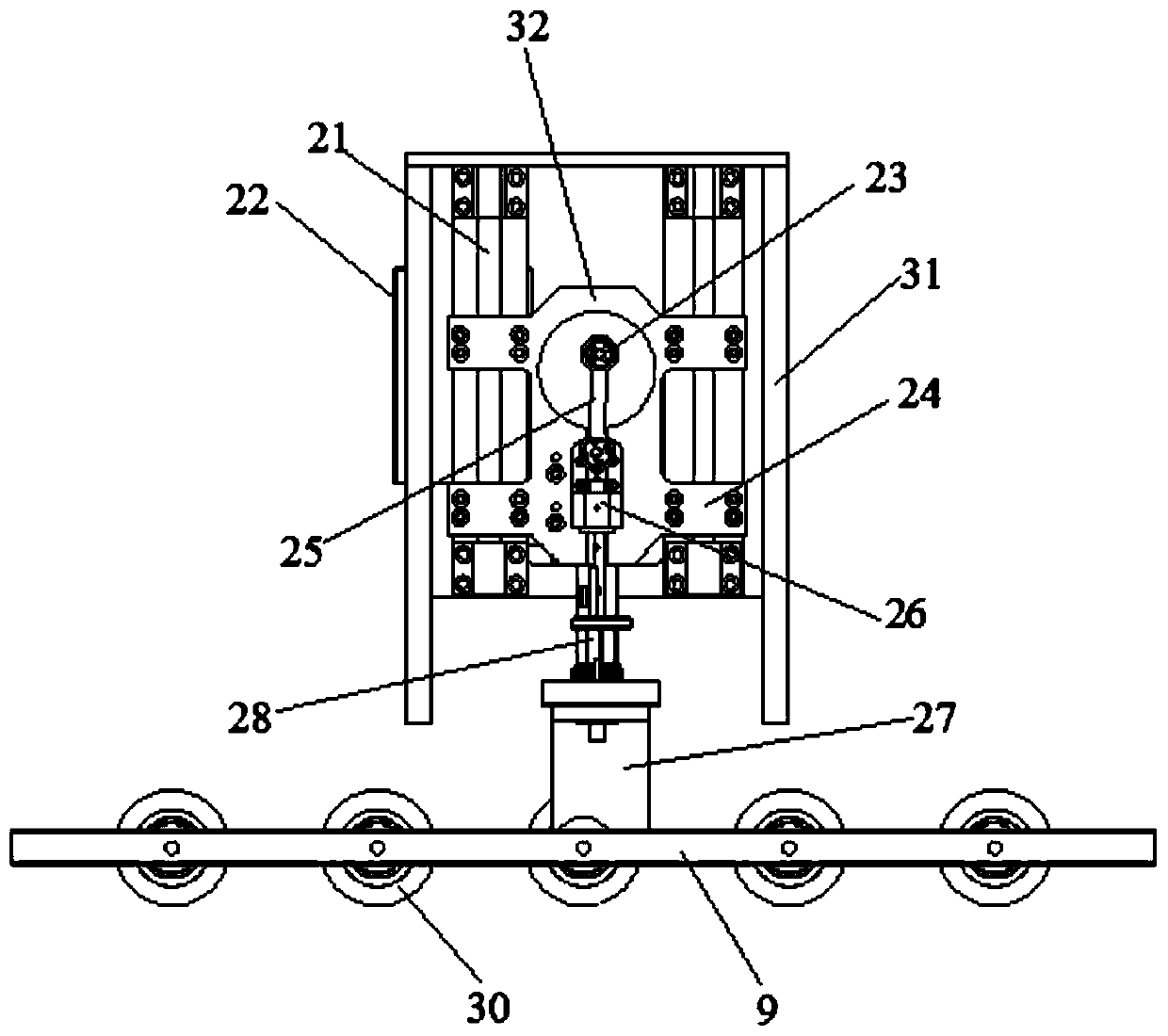

[0024] See Figure 1~7 In the embodiment of the present invention, a device for removing rust on the surface of oil drill pipes includes a support 1, a rust removing machine table 2, an input drive mechanism 3, an output drive mechanism 4, a rust removal support and jacking mechanism 5. The grinding and descaling mechanism 6, the pressing rod driving mechanism 7, the pressing beam 9, the pressing wheel set 8 and the guiding mechanism, wherein the bottom of the descaling machine table is supported by a plurality of supports, and the top of the descaling machine table The input drive mechanism 3 for inputting the drill rod 12 to be polished is provided on one side, and the output drive mechanism 4 for outputting the drill rod 12 to be polished is provided on the other side of the top of the derusting machine. It is characterized in that the rust removing support and lifting mechanism 5 is provided between the input driving mechanism and the output driving mechanism, and the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com