Pipeline inner wall derusting device

A pipeline and inner cavity technology, which is applied in the field of rust removal devices on the inner wall of pipelines, can solve the problems of affecting the working distance, slipping, and insufficient traction of the inner wall rust removal device, and achieve the effect of improving rust removal efficiency and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

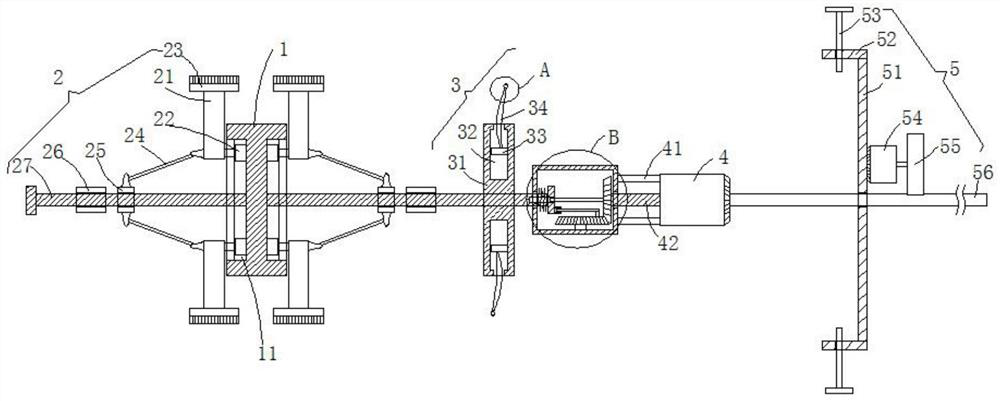

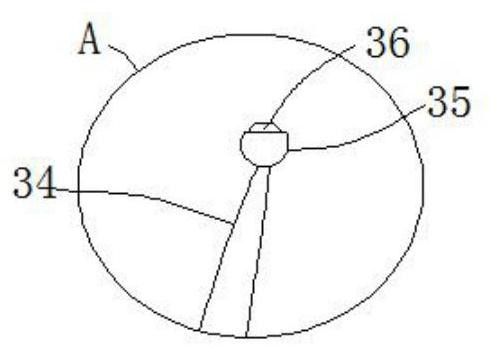

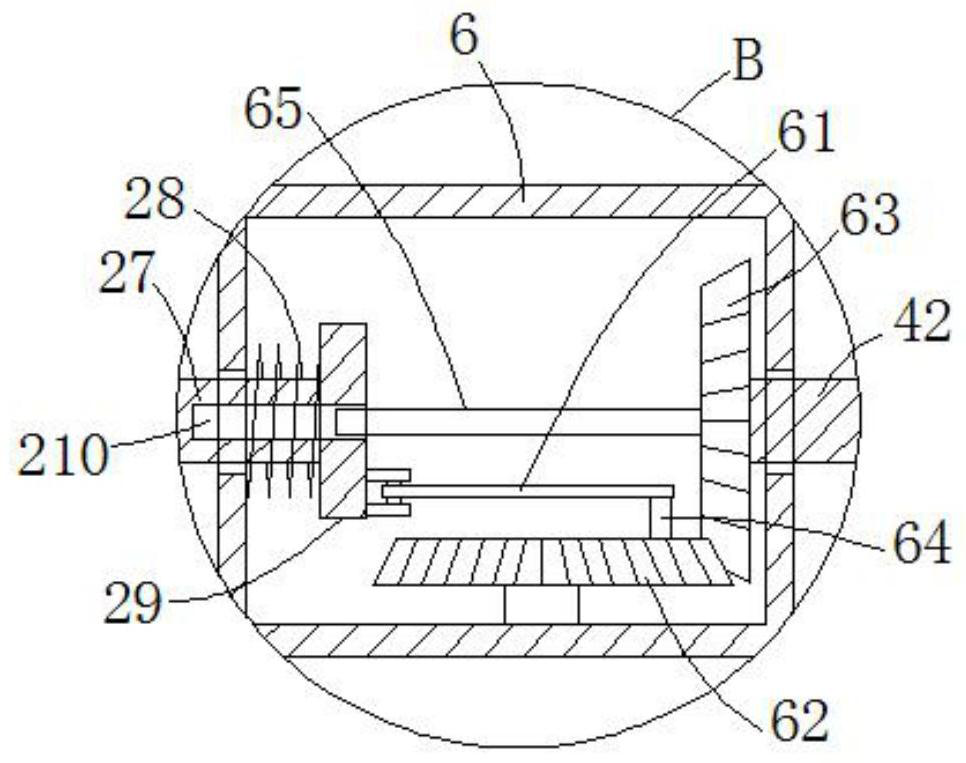

[0025] see Figure 1-3 , this embodiment provides a pipeline inner wall derusting device, including a fixing mechanism 5, a drive motor 4, a connecting seat 1, and two symmetrical derusting mechanisms 2 centered on the connecting seat 1, and the fixing mechanism 5 includes a fixing plate 51. Two positioning plates 52, a transmission motor 54 and a threaded transmission rod 56, the center position of the right end face of the driving motor 4 is rotationally connected with the left end of the threaded transmission rod 56, and the left end face of the driving motor 4 is connected with an inner cavity through two connecting rods 41 It is a hollow box 6 with a hollow structure. The drive motor 4 rotates through the right end surface of the hollow box 6 through the power shaft 42, and is connected with the first bevel gear 63 located in the inner cavity of the hollow box 6. The front side wall of the hollow box 6 The second bevel gear 62 is rotatably connected with the pin shaft. Th...

Embodiment 2

[0034] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0035] The rectangular rod outer wall of the threaded rod 27 of the right side derusting mechanism 2 slides and sleeves the spring 28 between the limit block 29 and the left end face of the hollow box 6 inner cavity, by setting the spring 28, the threaded rod of the right side derusting mechanism 2 When the rectangular rod 27 slides along the inner cavity of the hollow box 6, the impact force between the limit block 29 and the left end surface of the inner cavity of the hollow box 6 is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com