Industrial large-scale reaction vessel for preparing graphene

A graphene and reaction kettle technology, applied in graphene, chemical/physical/physical chemistry fixed reactors, nano-carbon and other directions, can solve the problems of poor corrosion, difficult to control stirring speed, small volume of the reaction kettle, etc. The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

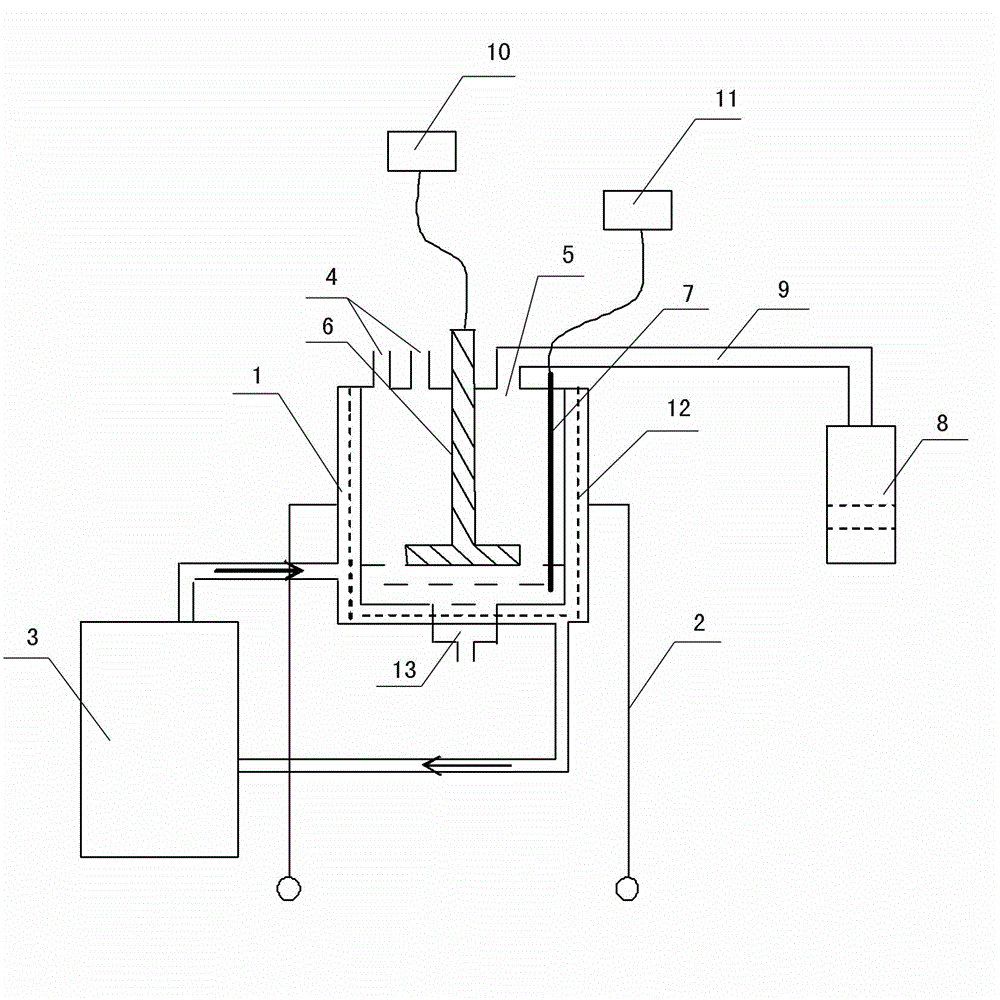

[0010] As shown in Figure 1, the present invention is a large-scale reaction kettle for preparing graphene for industrial use, including a shaft seal device, a transmission device, a protective support frame 2, and a gas collection bottle 8, and the reaction bottle 1 is mounted on the protective support frame 2. The interlayer of the reaction bottle 1 is externally connected with a constant temperature tank 3, and the constant temperature tank 3 is used for cooling or heating the cold and heat sources, and the cold and heat sources are passed into the interlayer through pipes to play a role of circulation and return, and control the temperature in the reaction bottle 1. The temperature range is -20 degrees Celsius to 100 degrees Celsius.

[0011] The upper part of the reaction bottle 1 of the present invention is provided with a feed port 4 and an exhaust gas discharge port 5. The feed port 4 is mainly used for adding reaction raw materials to the reaction bottle 1. The speed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com